Concrete pouring system with double-layer chute and construction method thereof

A technology of concrete and chute, which is applied in the direction of construction, building structure, and building material processing. It can solve the problems of easy blockage of ground pumps, interruption of construction, slow pouring speed of single-layer chute, and inability to ensure construction quality. The effect of reduced investment, rapid construction, and avoiding the effect of easy pipe blockage and interruption of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

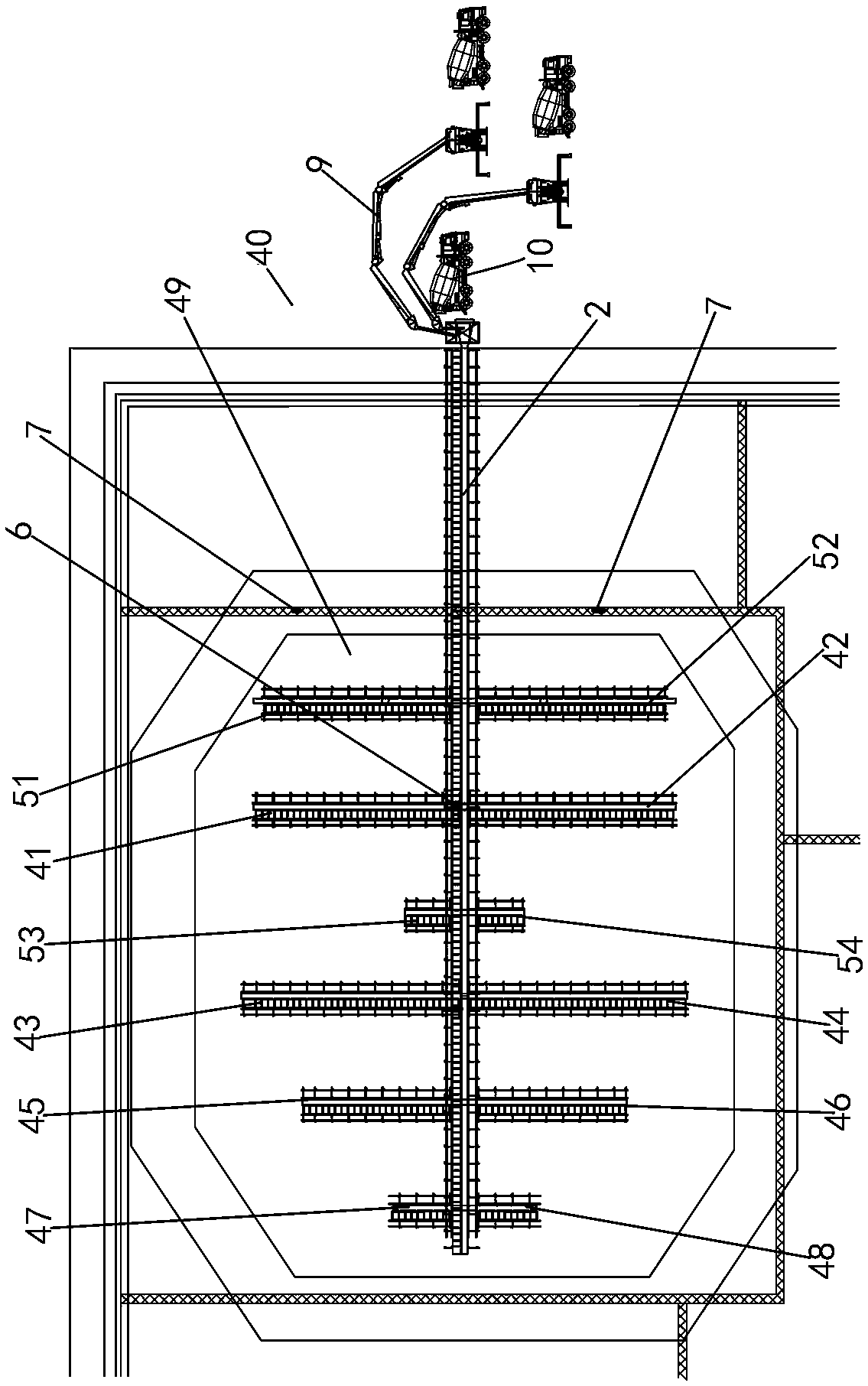

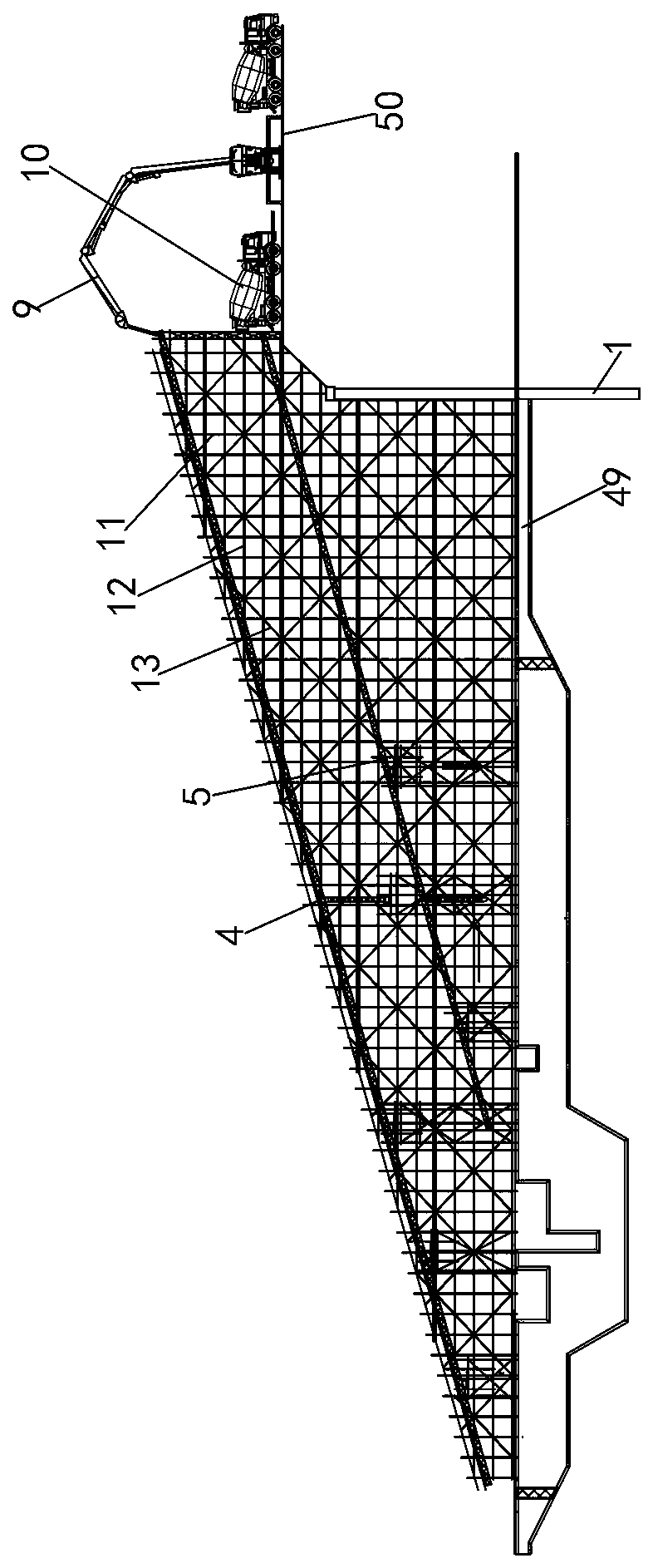

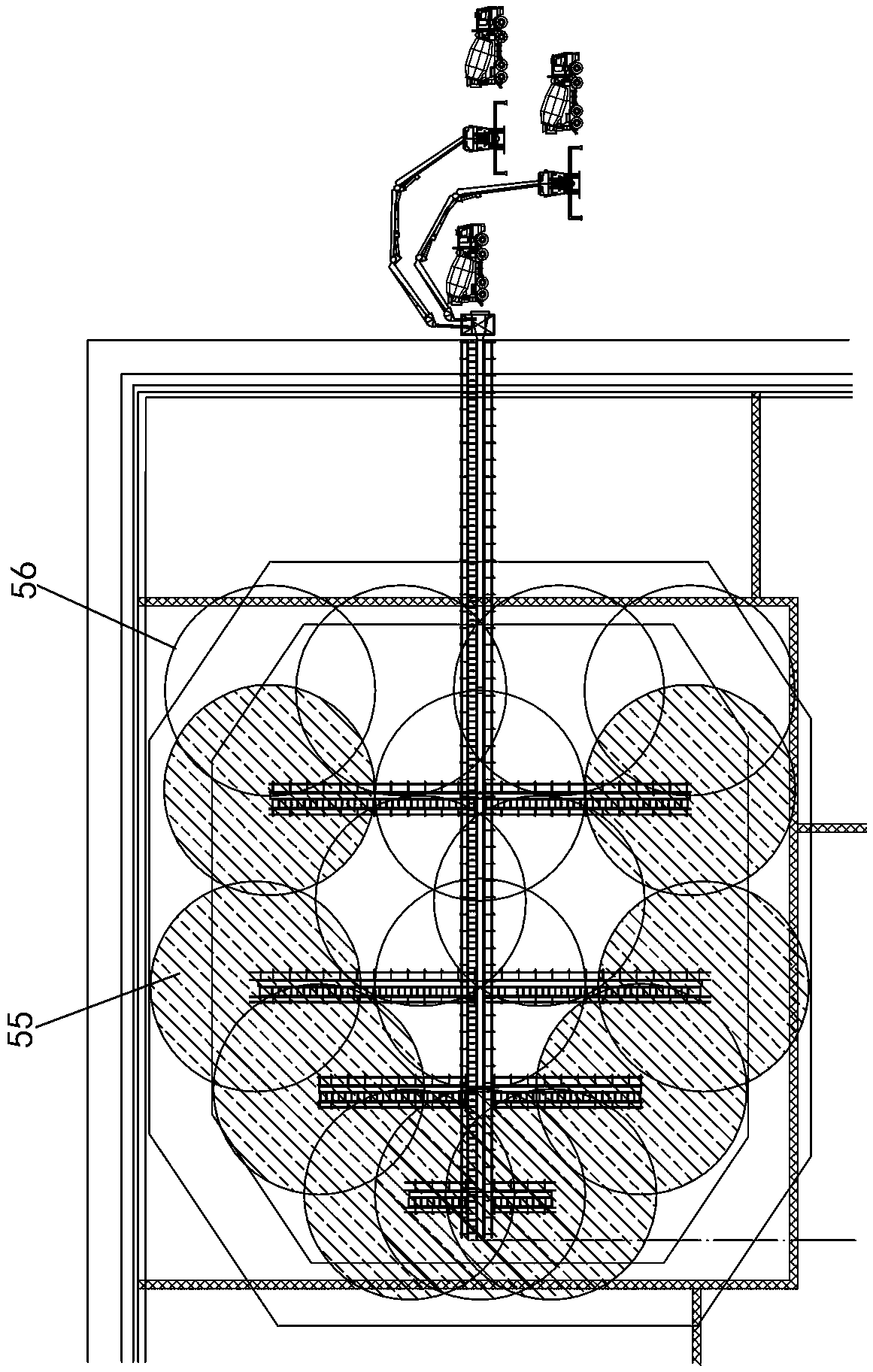

[0056] Examples see Figure 1-4 As shown, a double-layer chute concrete pouring system includes a pouring device, a chute scaffold, a chute main body, a string tube and a movable chute frame.

[0057] The chute scaffold stands on the upper side of the inner bottom plate 49 of the foundation pit, is supported on the bottom of the chute main body for a long time, and the inner side is close to the slope protection pile 1 . The main body of the chute is a double-layer chute, including a main chute along the longitudinal direction of the foundation pit and a branch chute along the transverse direction of the foundation pit. The main chute includes an upper main chute 2 and a lower main chute 3, and the branch chute includes an upper branch chute 4 And the lower branch chute 5, the upper branch chute 4 is the axis of the upper floor main chute 2, symmetrically arranged on both sides of the upper floor main chute 2, the lower floor branch chute 5 is the axis of the lower floor main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com