Patents

Literature

68results about How to "Continuous construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

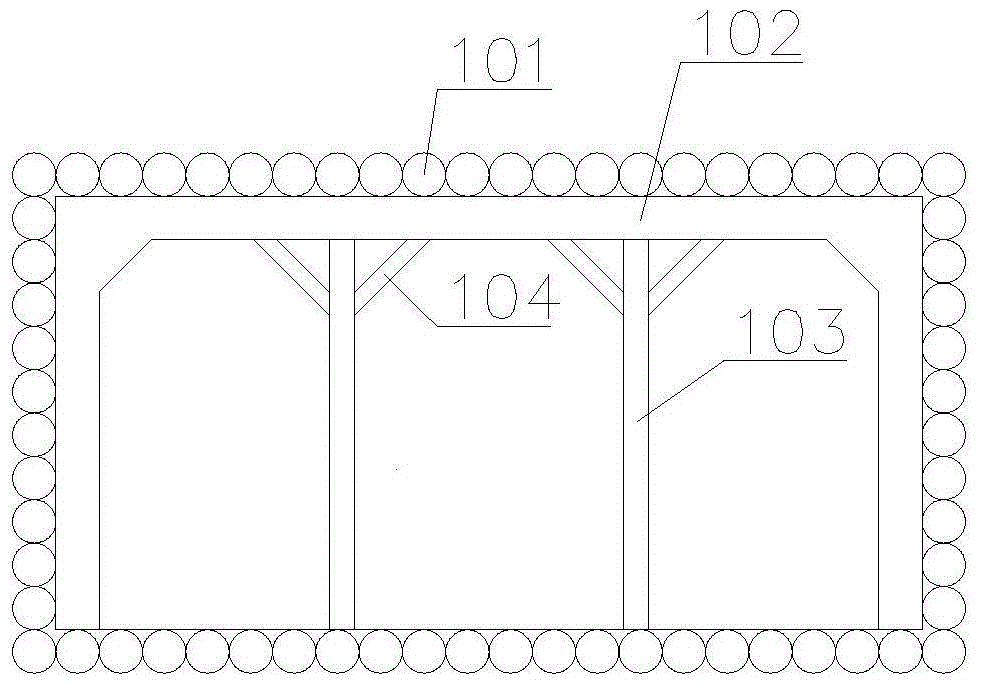

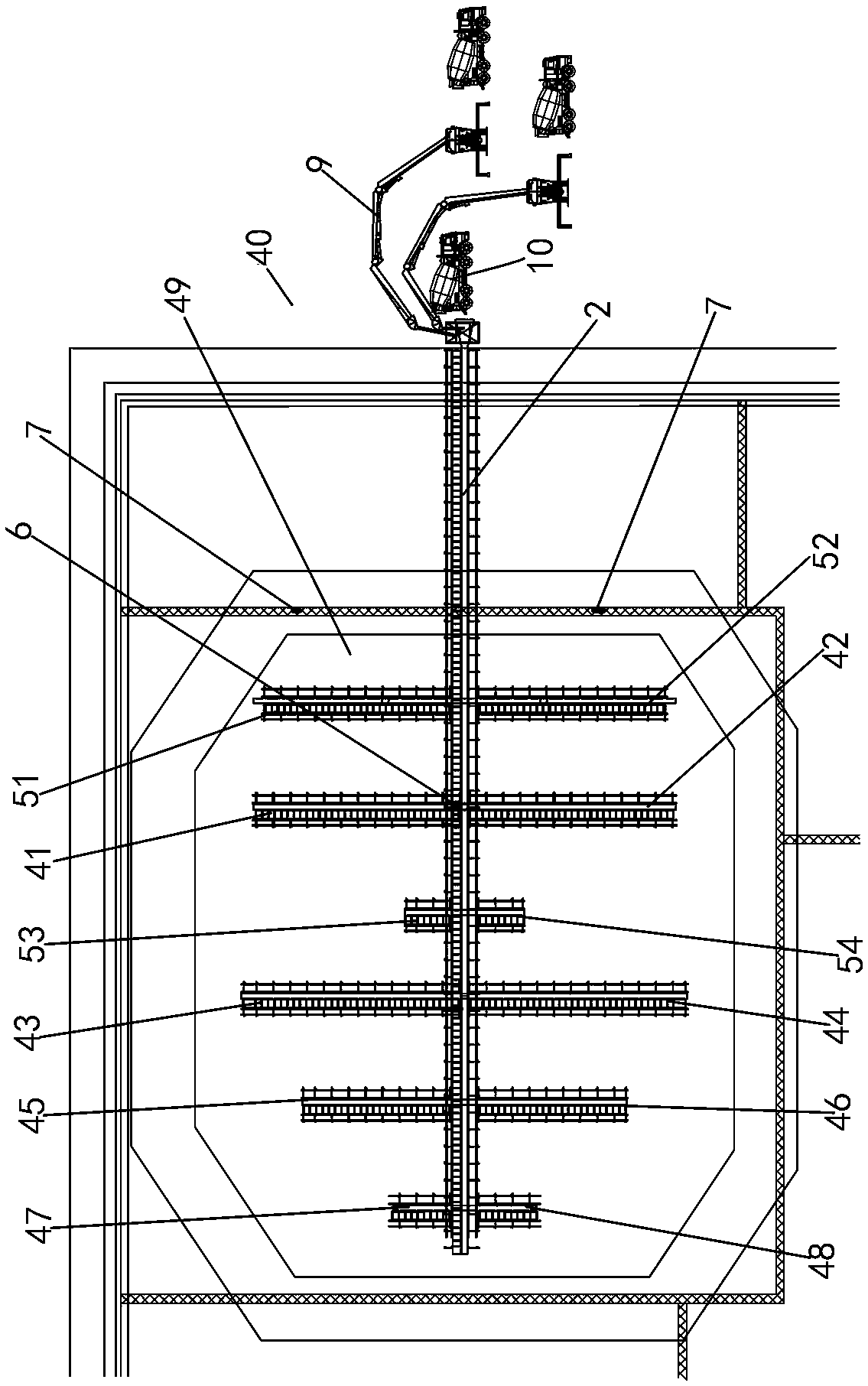

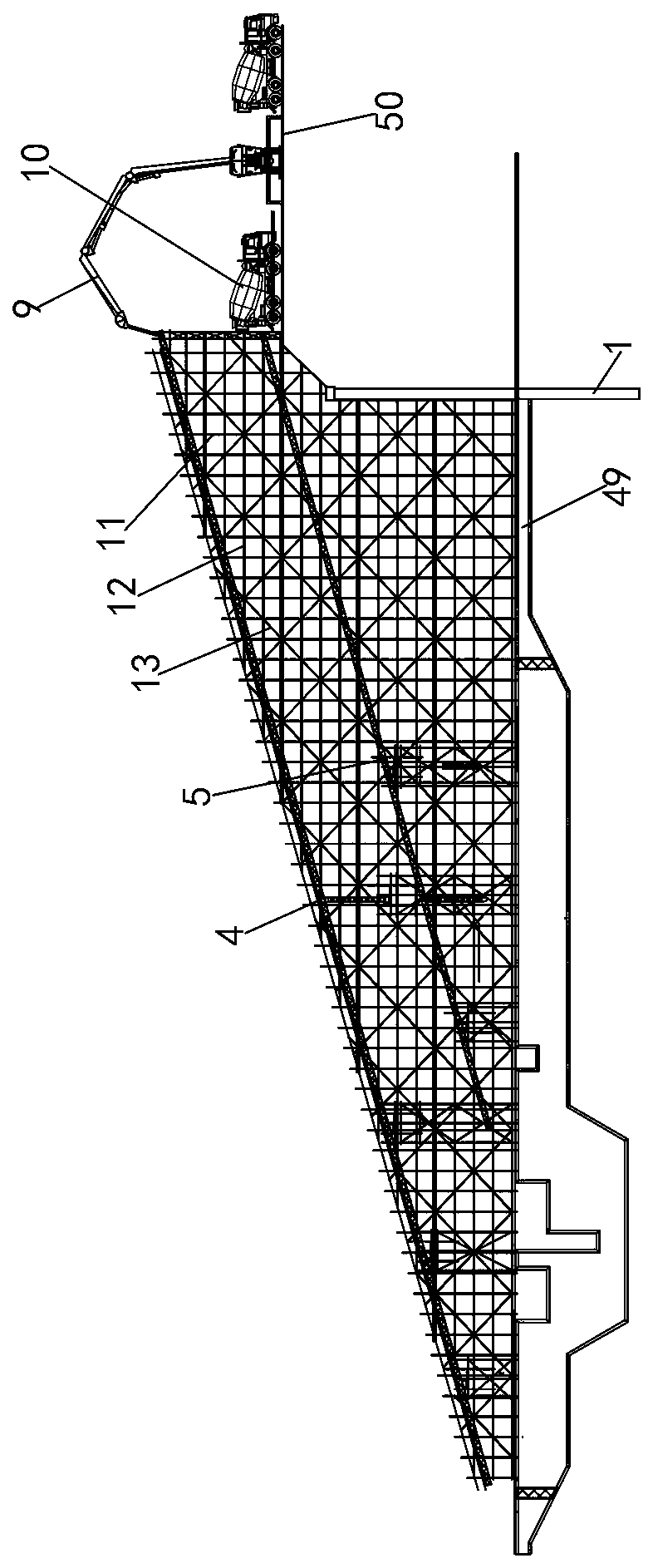

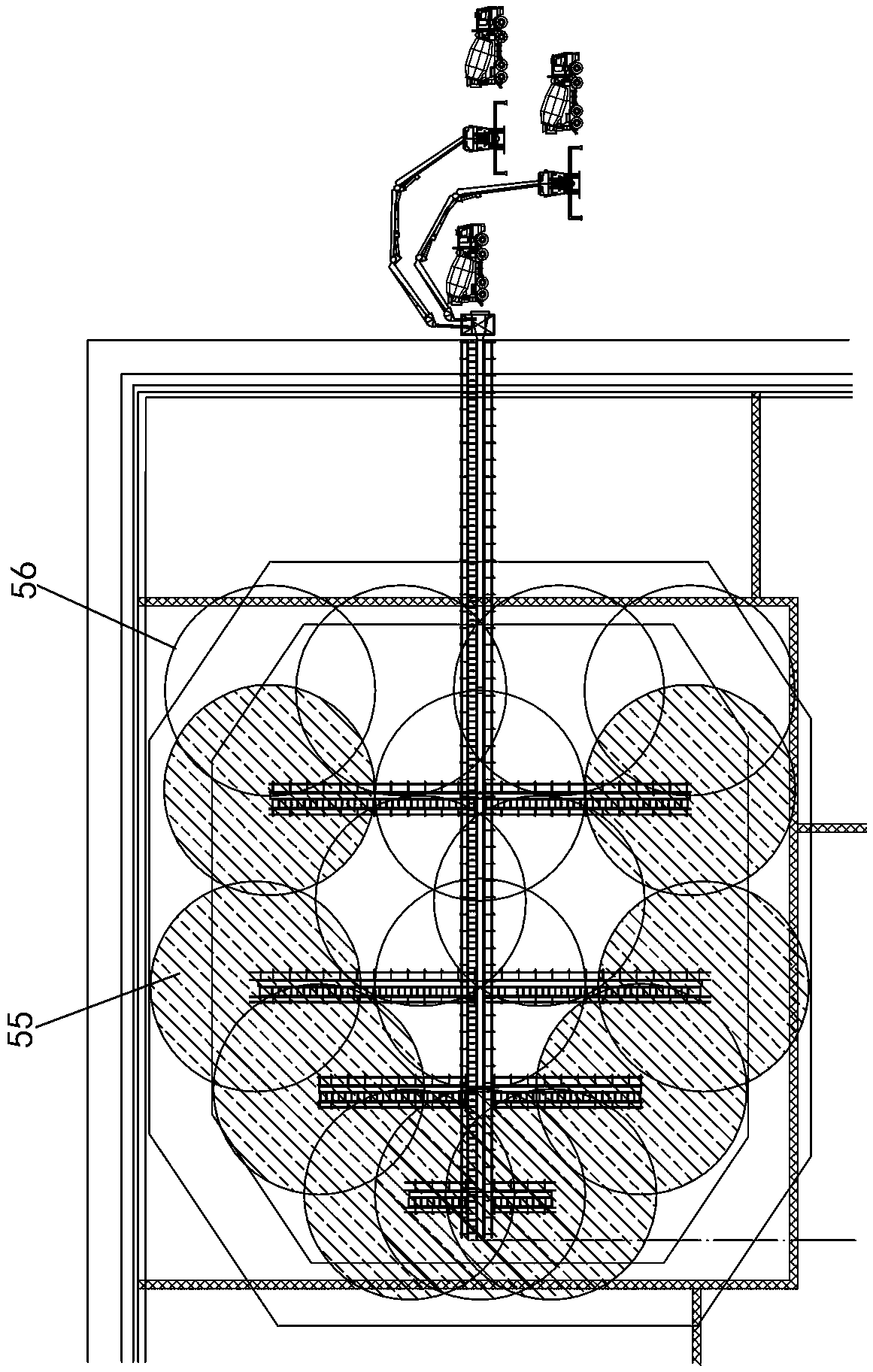

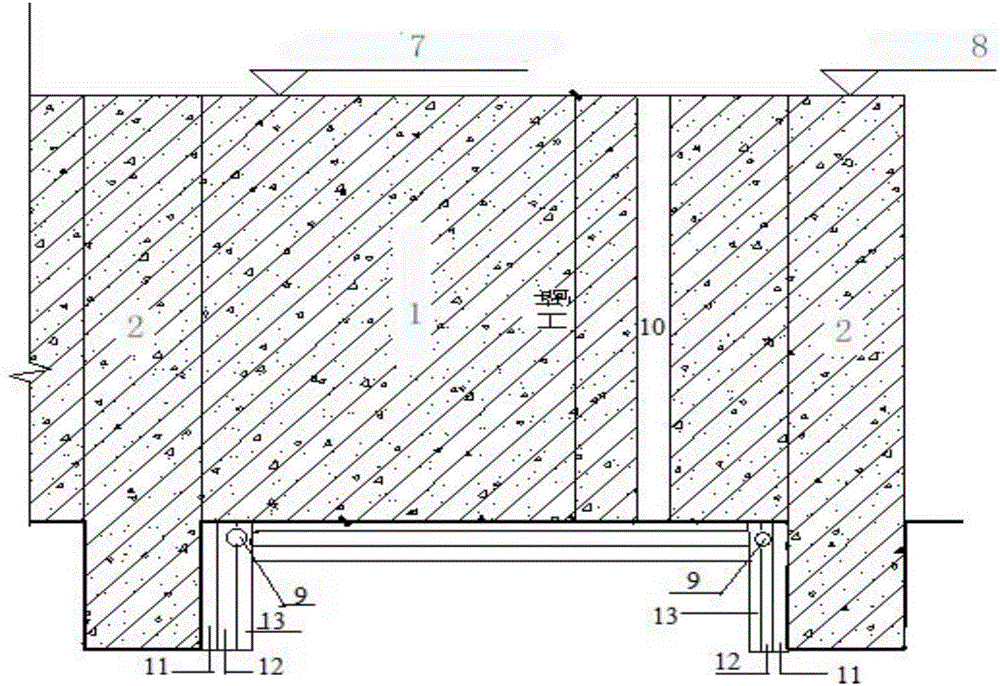

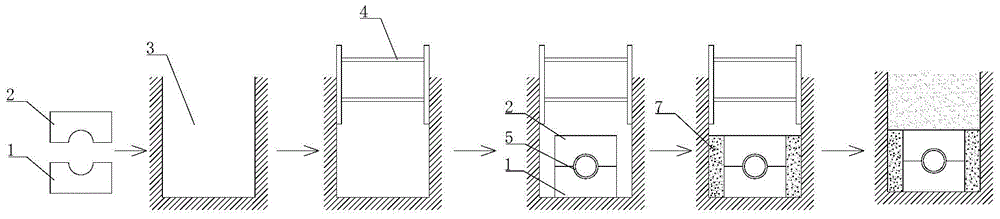

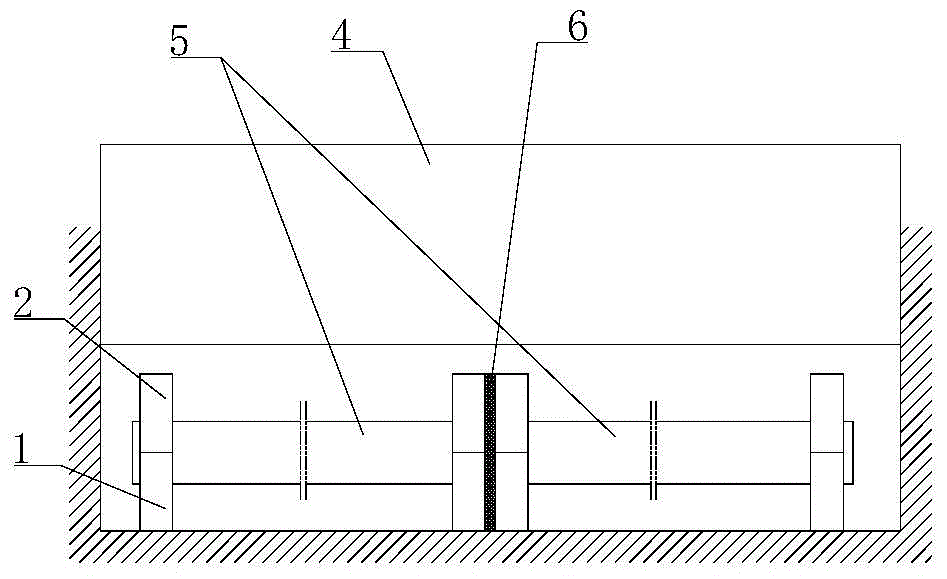

Underground space construction method and supporting structure

ActiveCN104675403ASatisfy continuous constructionSave engineering time and costArtificial islandsUnderground chambersUnderground spaceStructure of the Earth

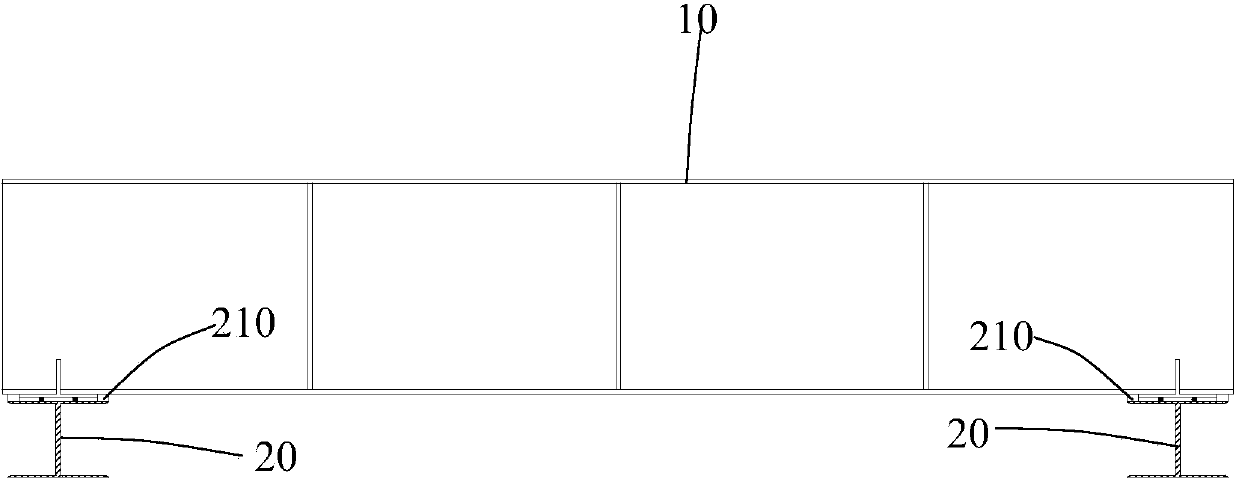

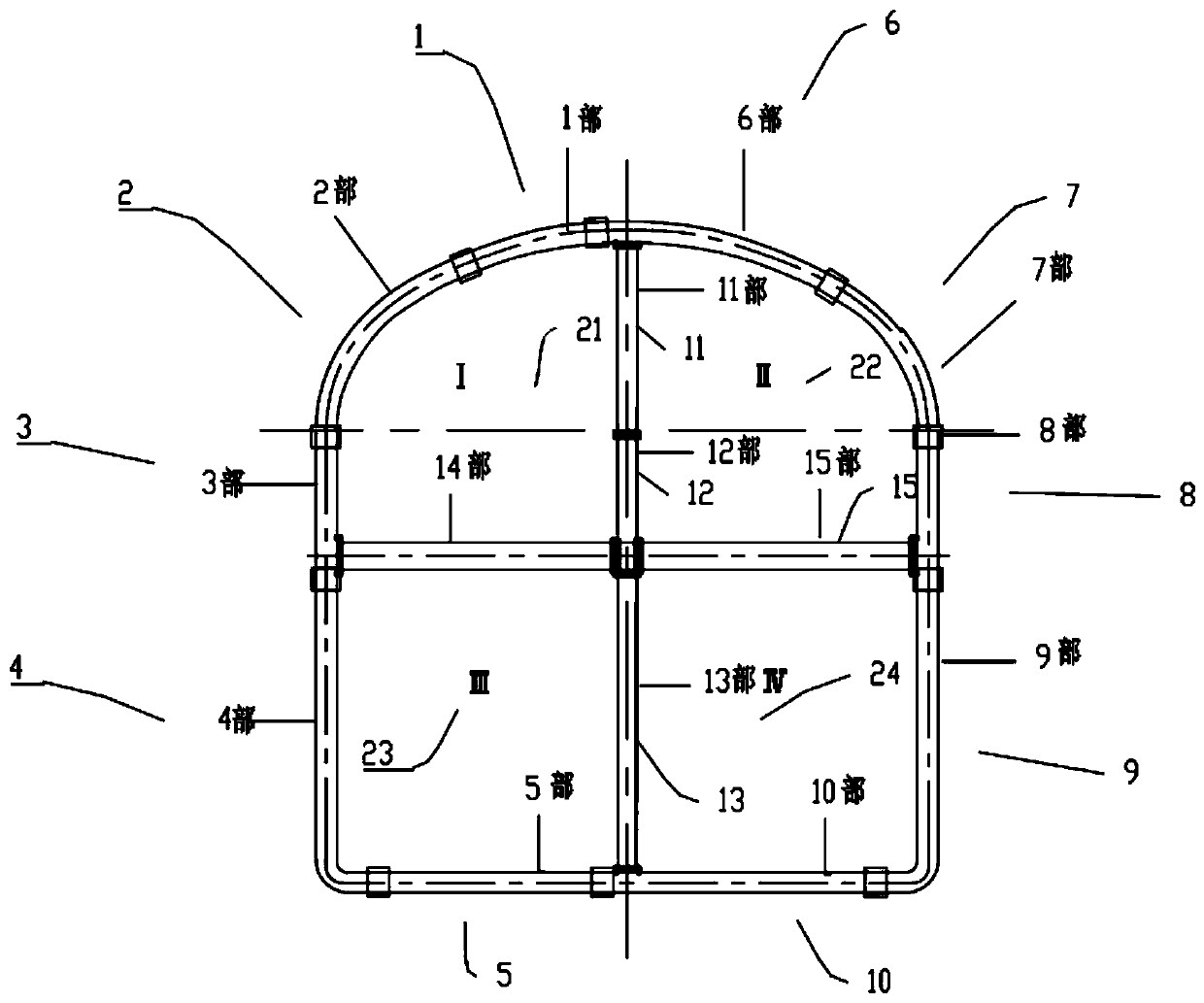

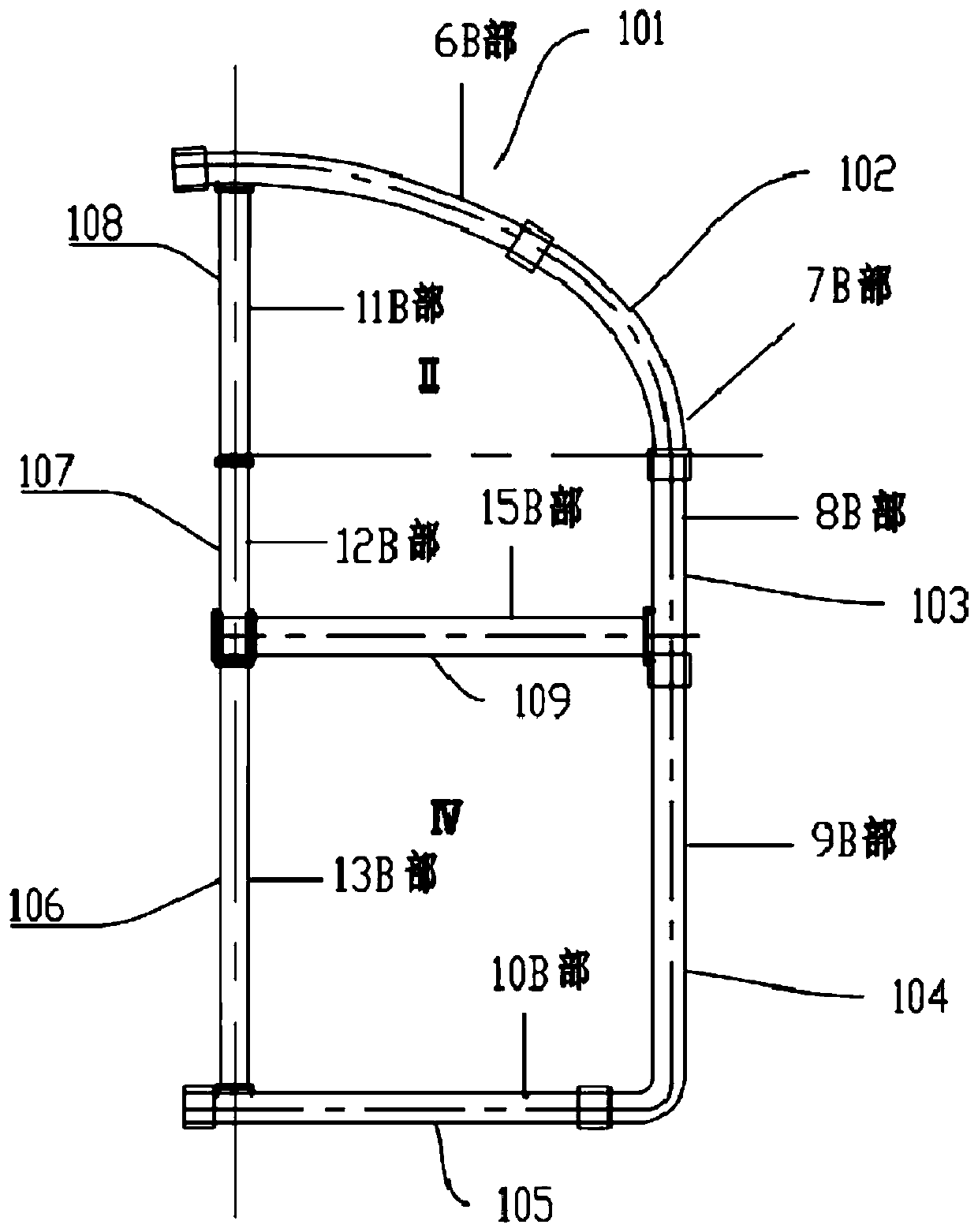

The invention discloses an underground space construction method and a supporting structure and belongs to the technical field of civil building engineering construction. According to the underground space construction method and the supporting structure, a launching shaft and a receiving shaft are firstly constructed, then an enclosing structure and waterproof curtain construction of a whole planned whole underground space are completed, a pipe curtain is constructed to enable a first underground layer to form a waterproof space, a soil body in the pipe curtain is reinforced till the supporting structure is formed, excavation and supporting are carried out till a pipe curtain section is excavated to be through, meanwhile a structural body of the first underground layer is casted, and soil taking openings are reserved when base plate structure slabs of the first underground layer are cast; excavation of a soil body and casting construction of a structure body of a second underground layer are performed through the soil taking openings formed in the base plate structure slabs of the first underground layer after maintenance of the next underground layer of base plate structure slabs is completed, and soil taking openings are reserved when the base plate structure slabs of the second underground layer are cast; the cycle is repeated to perform following construction layer by layer till casting of the base plates of the whole underground space is completed, and accordingly construction of the underground space is completed.

Owner:SHANGHAI CONSTRUCTION GROUP +1

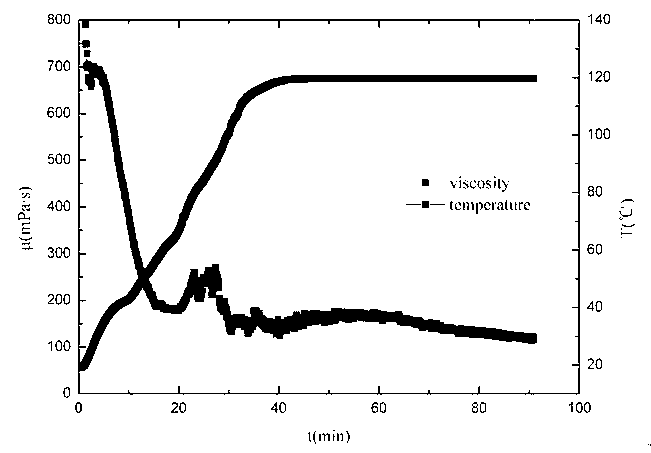

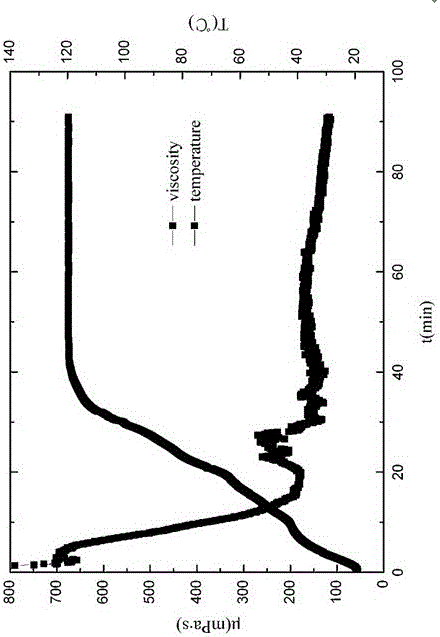

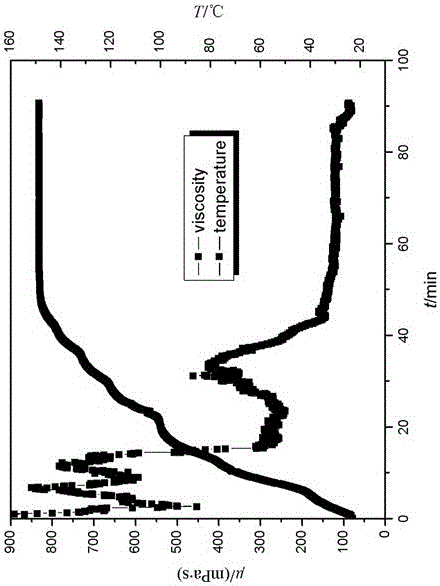

Seawater-based fracturing fluid for fracturing sea high-temperature oil-gas reservoir

ActiveCN103215024AFulfil requirementsControllable delay timeDrilling compositionCross-linkFracturing fluid

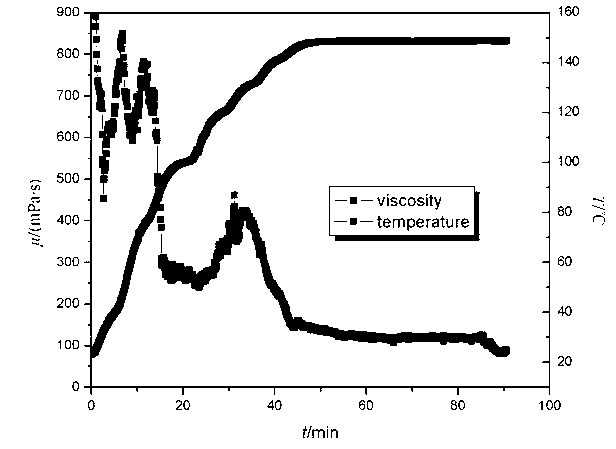

The invention discloses a seawater-based fracturing fluid for fracturing a sea high-temperature oil-gas reservoir and relates to the technical field of cross-linked gel fracturing fluid. The seawater-based fracturing fluid comprises a base solution, a cross-linking agent and a thickening agent, wherein the base solution comprises the components (in percentage by weight) in terms of the weight of the prepared seawater-based fracturing fluid total solution as follows: 0.3%-0.8% of thickening agent, 0.1%-0.3% of pH regulating agent, 0.1%-0.5% of discharge aiding agent and the balance being seawater; relative to the mass fraction of the base solution, the cross-linking agent is 0.4%-0.6%; and the thickening agent refers to guar gum, carboxy-methyl hydroxypropyl guar gum, hydroxypropyl guar gum, fenugreek gum or sesbania gum. The seawater-based fracturing fluid is adopted, so that the dissolving speed of the thickening agent is quick, and therefore, direct mixing and continuous constructing can be realized, and therefore, the seawater-based fracturing fluid is in particular suitable for the fracturing construction of the sea high-temperature oil-gas reservoir. Meanwhile, the fracturing fluid can be continuously sheared for 90 minutes under the conditions of 150 DEG C and 170s<-1>, so that the viscosity is kept to be 70mPa.s or more.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

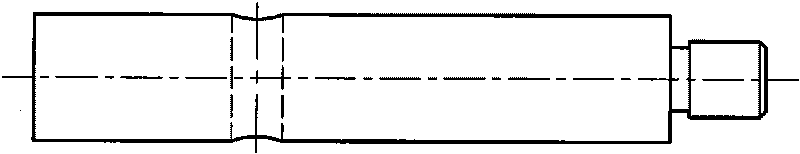

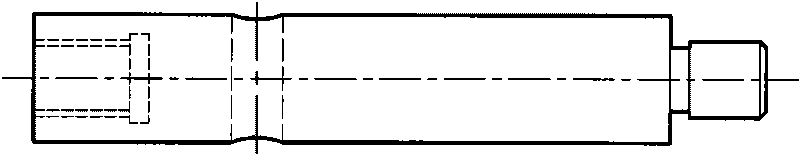

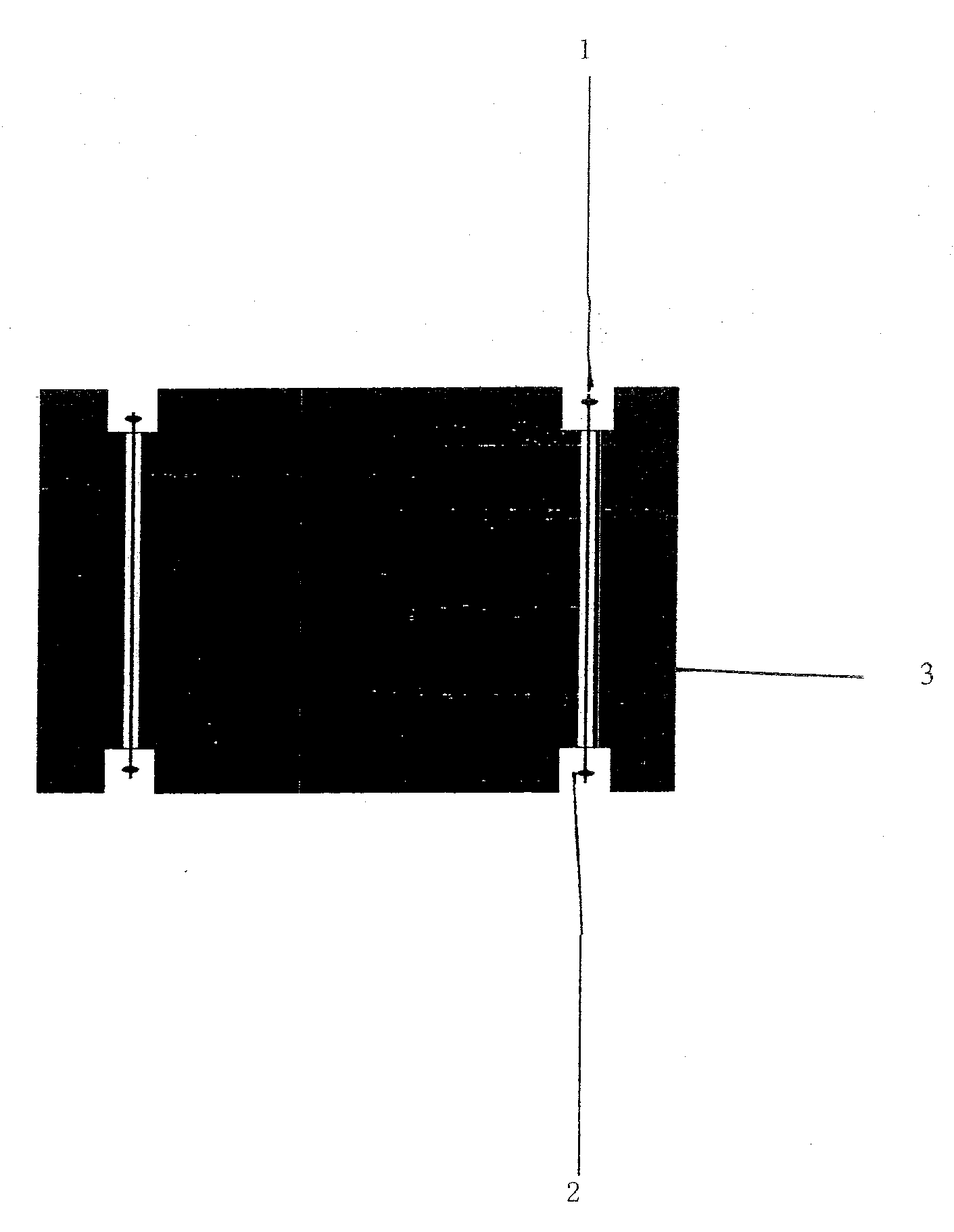

Insulation of stator windings with shrink-on sleeves

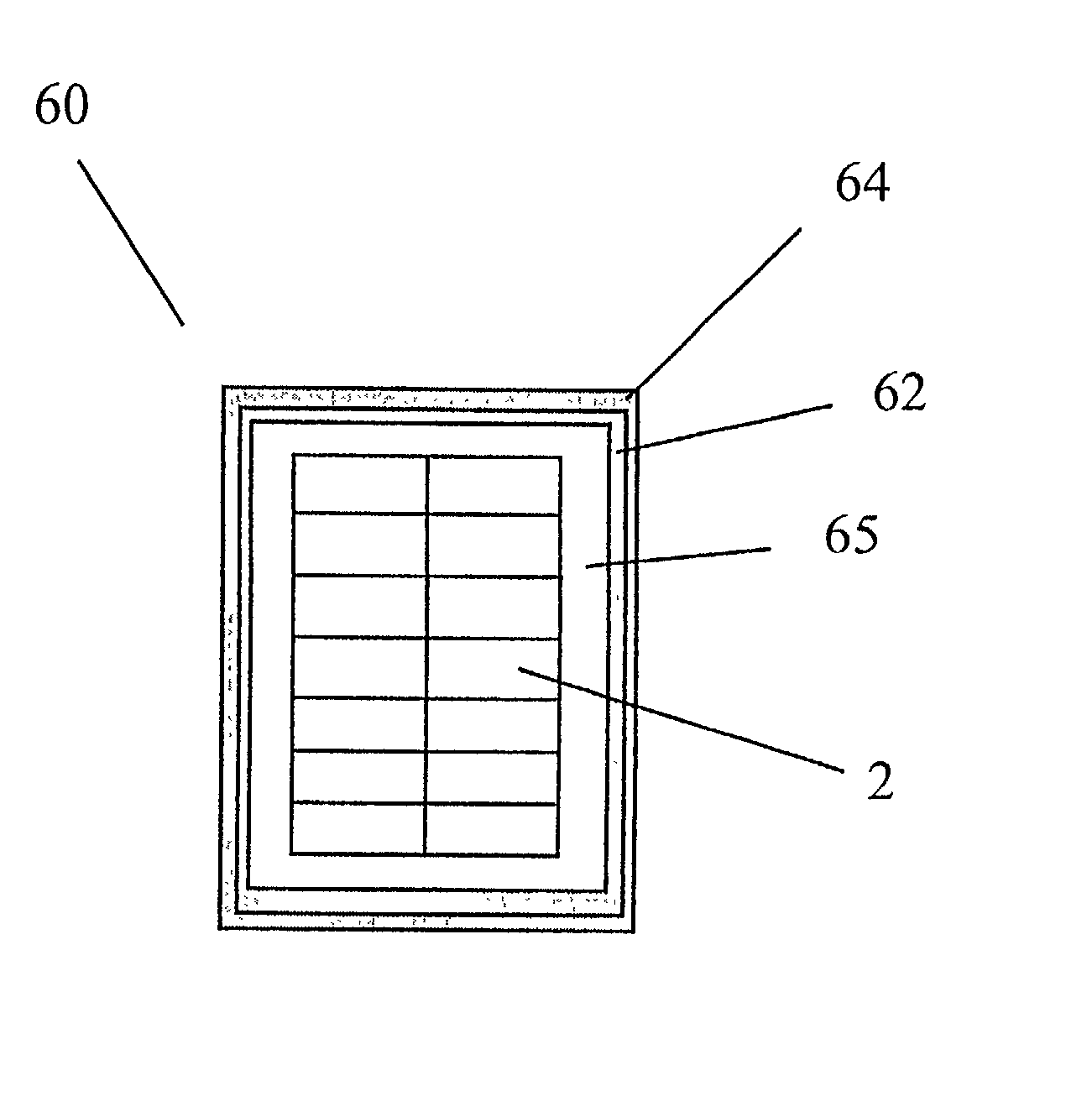

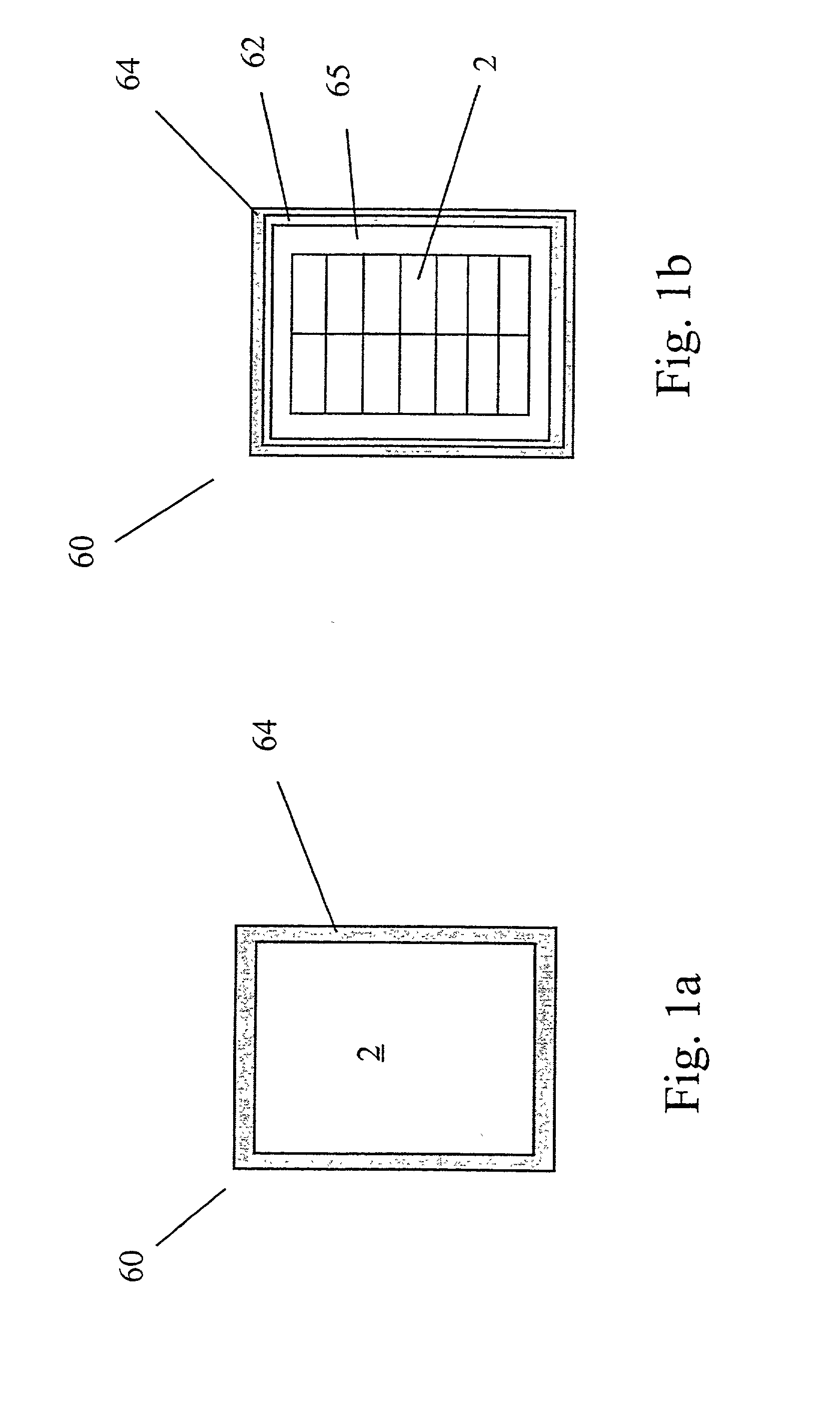

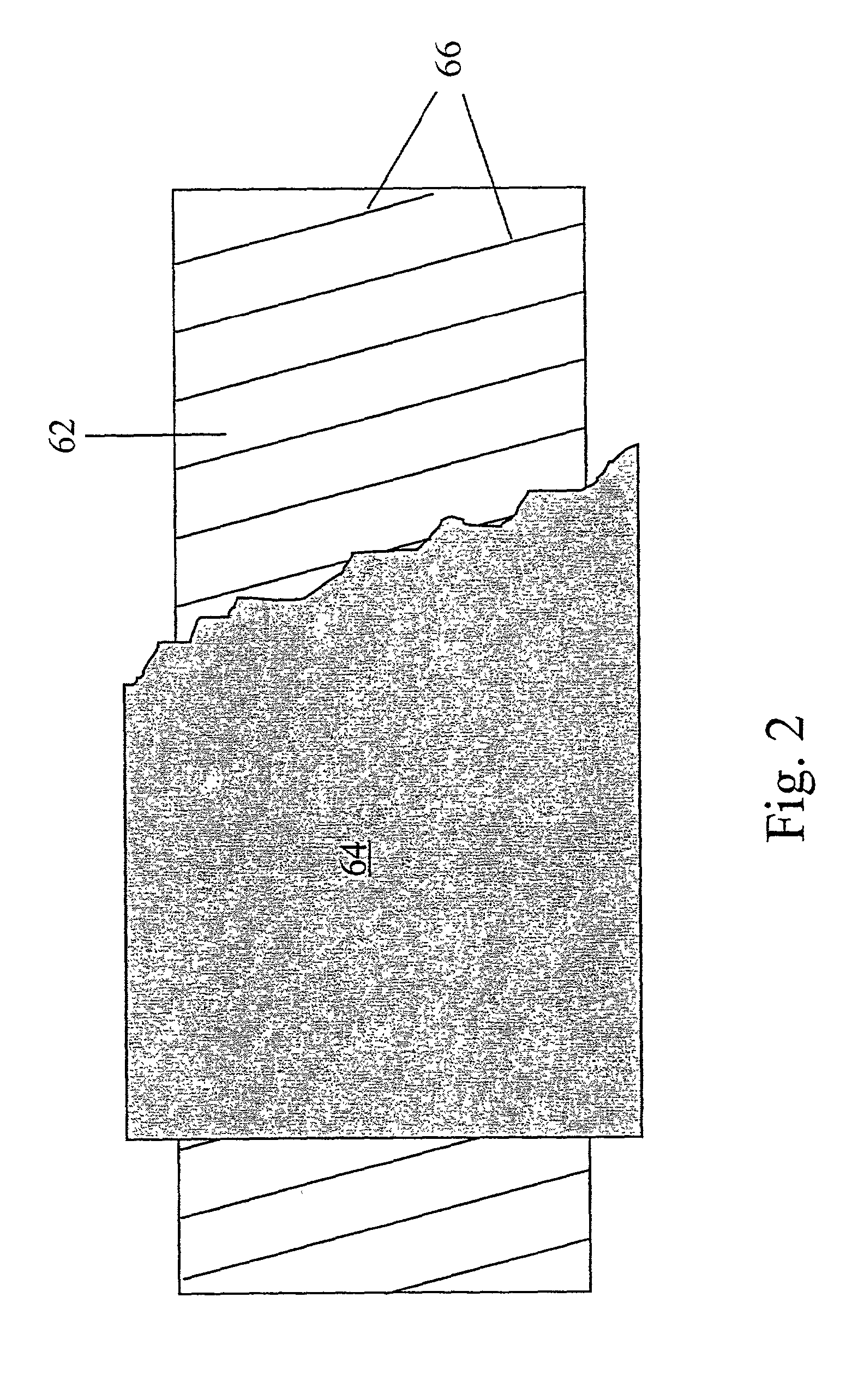

InactiveUS20020046875A1Improve thermal conductivityContinuous constructionWindings insulation shape/form/constructionInsulated cablesElectrically conductiveStator

Described is a method for the production of an insulated stator winding for rotating electrical machines, in particular, direct current machines and alternating current machines, whereby an insulated stator winding is produced that ensures adequate insulation over the intended life span of the electrical machine. The insulated stator winding is constructed of at least one electrically conductive conductor bar (2) with an essentially rectangular cross-section, whereby at least one electrically insulating shrink-on sleeve (64) with an essentially rectangular cross-section is applied to the periphery of the conductor bar (2) and then shrunk onto it.

Owner:ALSTOM TECH LTD

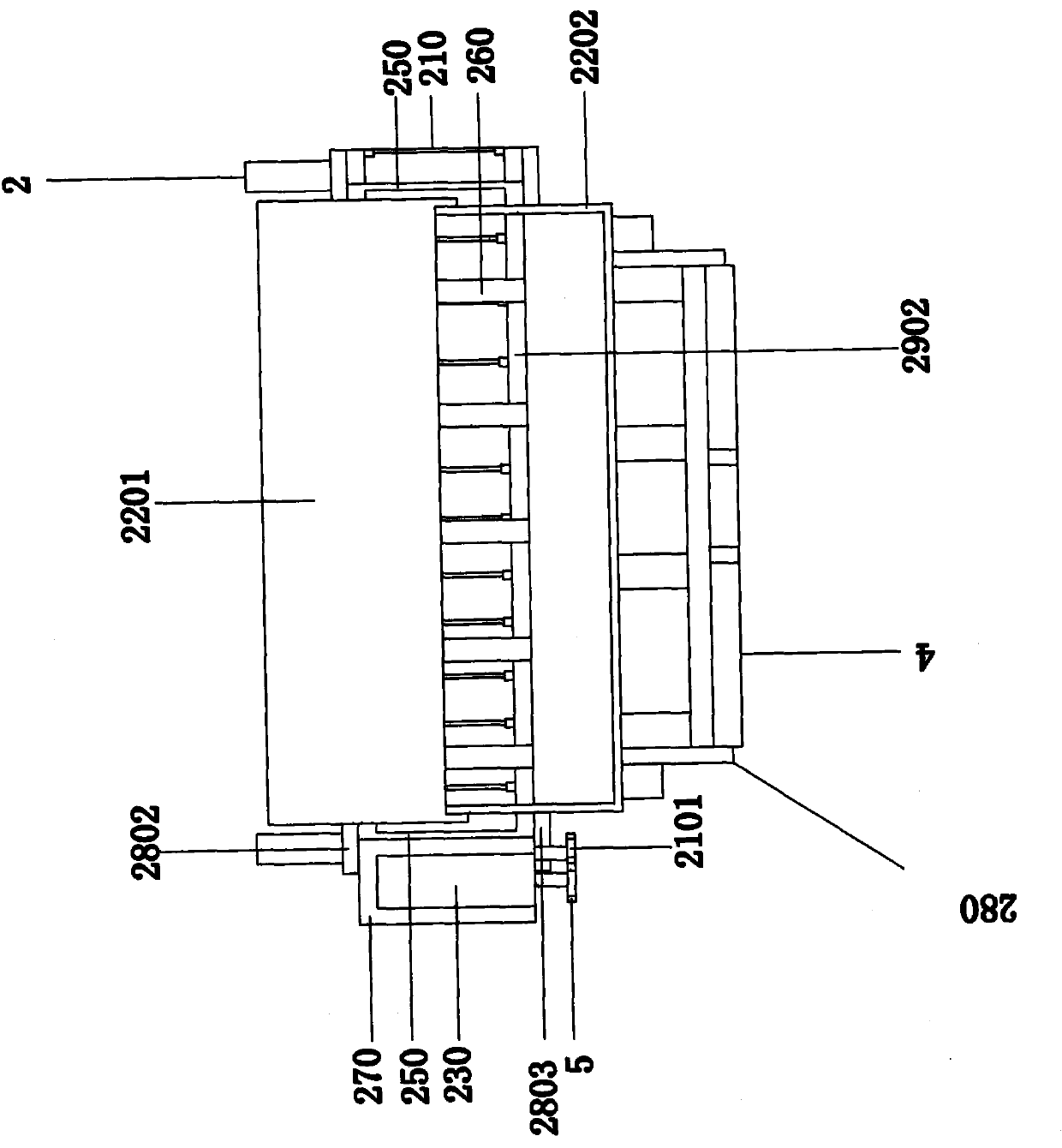

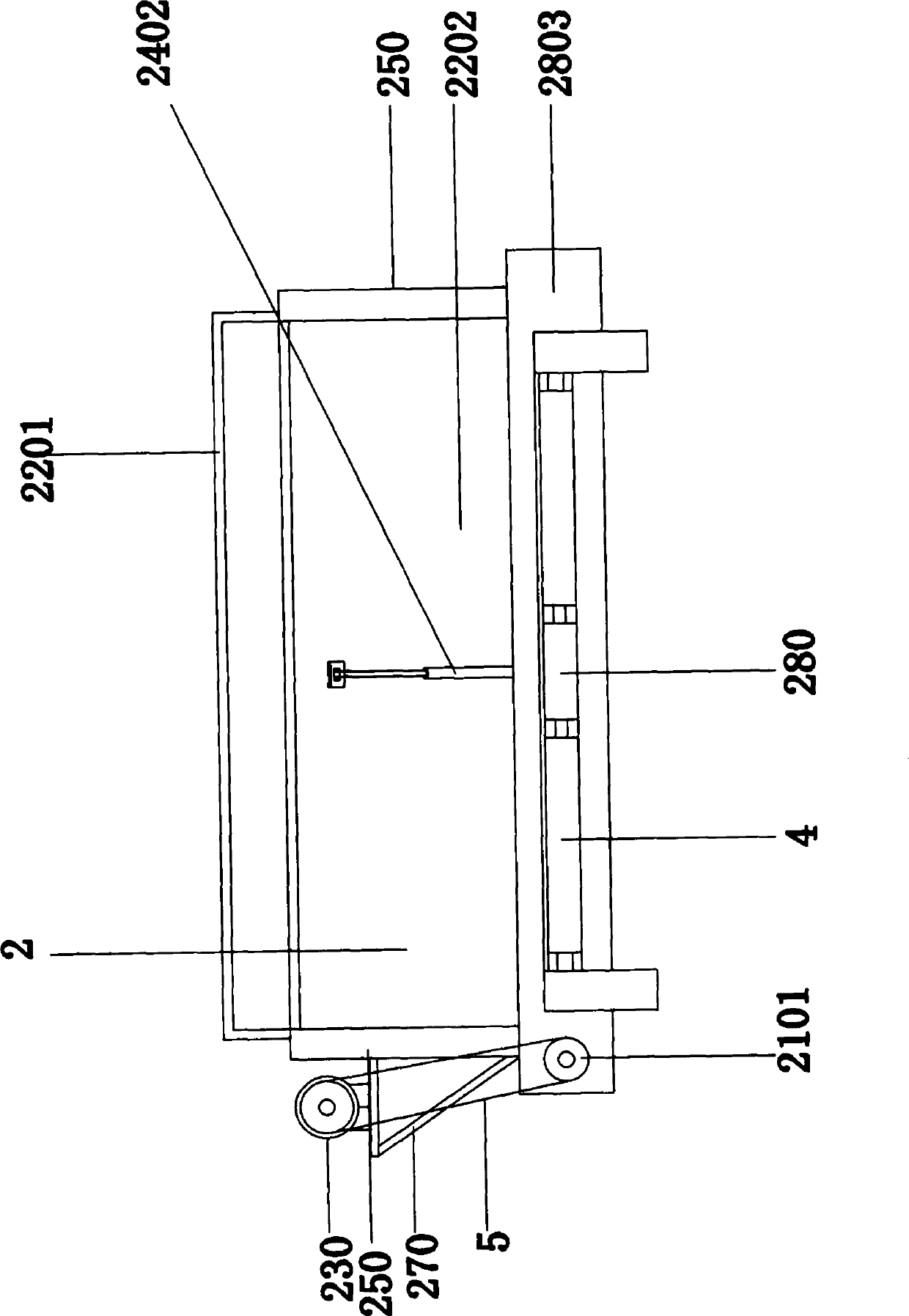

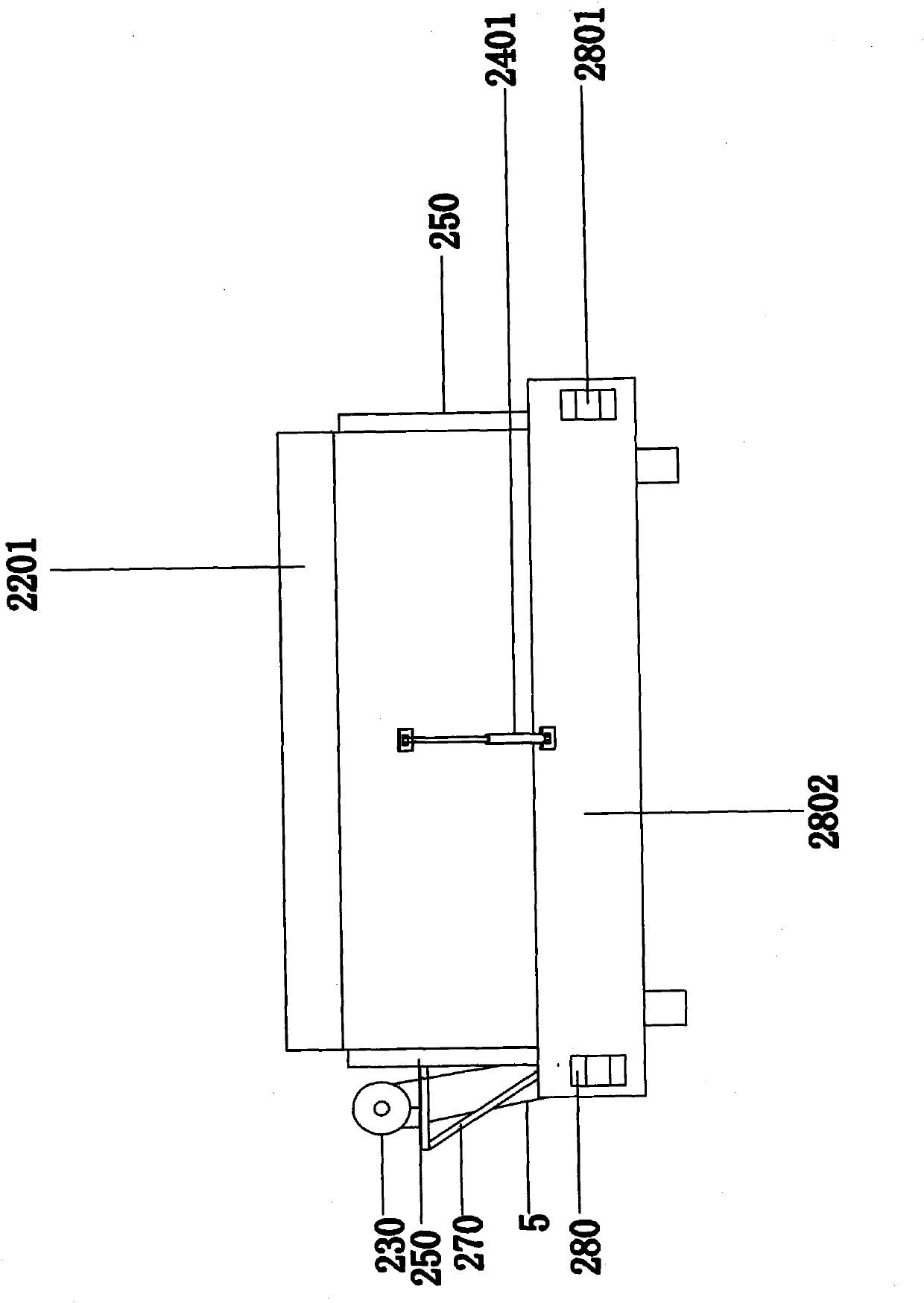

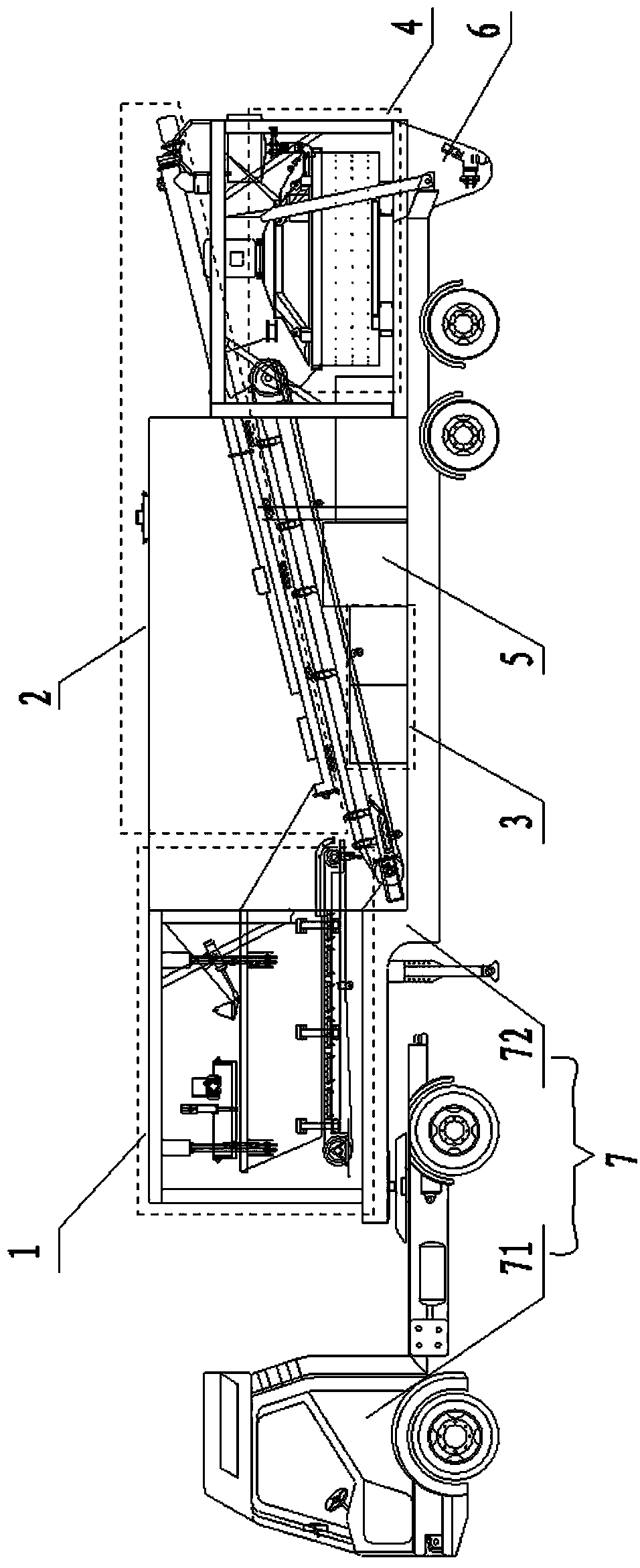

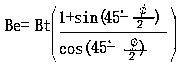

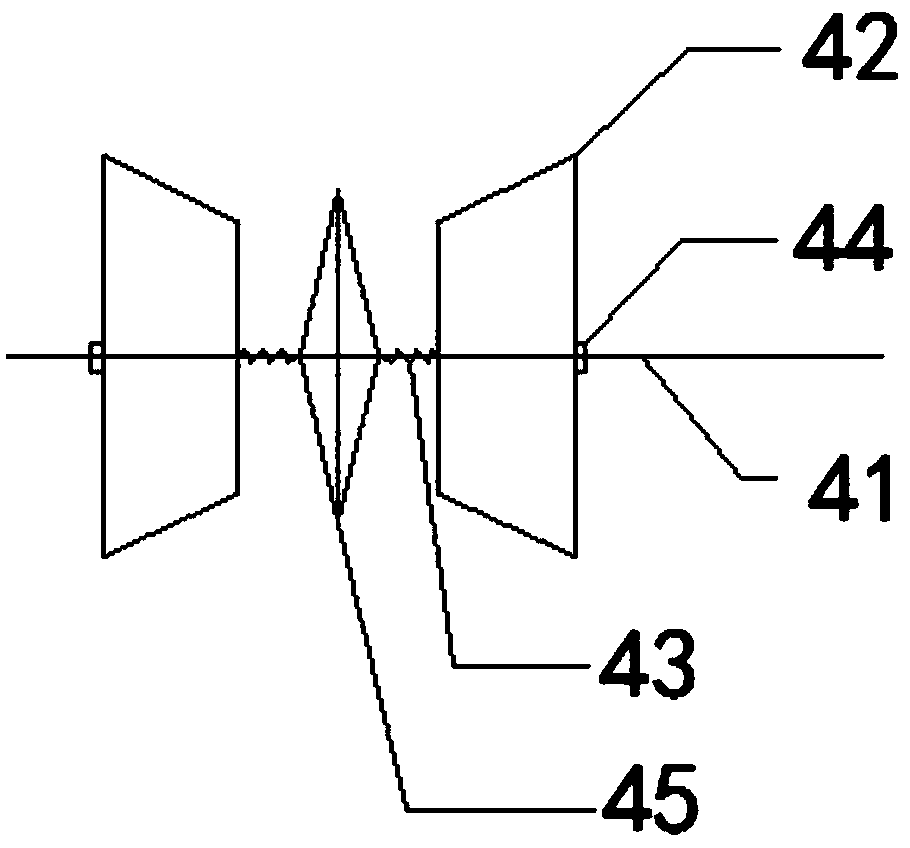

Paver

InactiveCN104179114ASimple and fast operationContinuous constructionRoads maintainenceScreedPavement engineering

The invention provides a paver and relates to the field of pavement engineering machinery. The paver comprises a main frame, a buffer cylinder mounted on the front end of the main frame, a swing beam mounted behind the buffer cylinder at the front end of the main frame, an electric appliance control system, a screed plate on the rear end of a draft arm, main frame connecting columns, a road shoulder distributor and a road shoulder forming machine, wherein the main frame connecting columns are correspondingly arranged on the left and right sides of the main frame and behind the swing beam; the road shoulder distributor is arranged between the swing beam of the main frame and the buffer cylinder mounted on the front end of the main frame; the road shoulder forming machine is mounted on the side surface of the screed plate. The paver is capable of completing paving, leveling and punning in one step during road shoulder filling, is simple and convenient to operate and is capable of carrying out continuous construction, the construction quality is improved and the cost is saved.

Owner:刘全

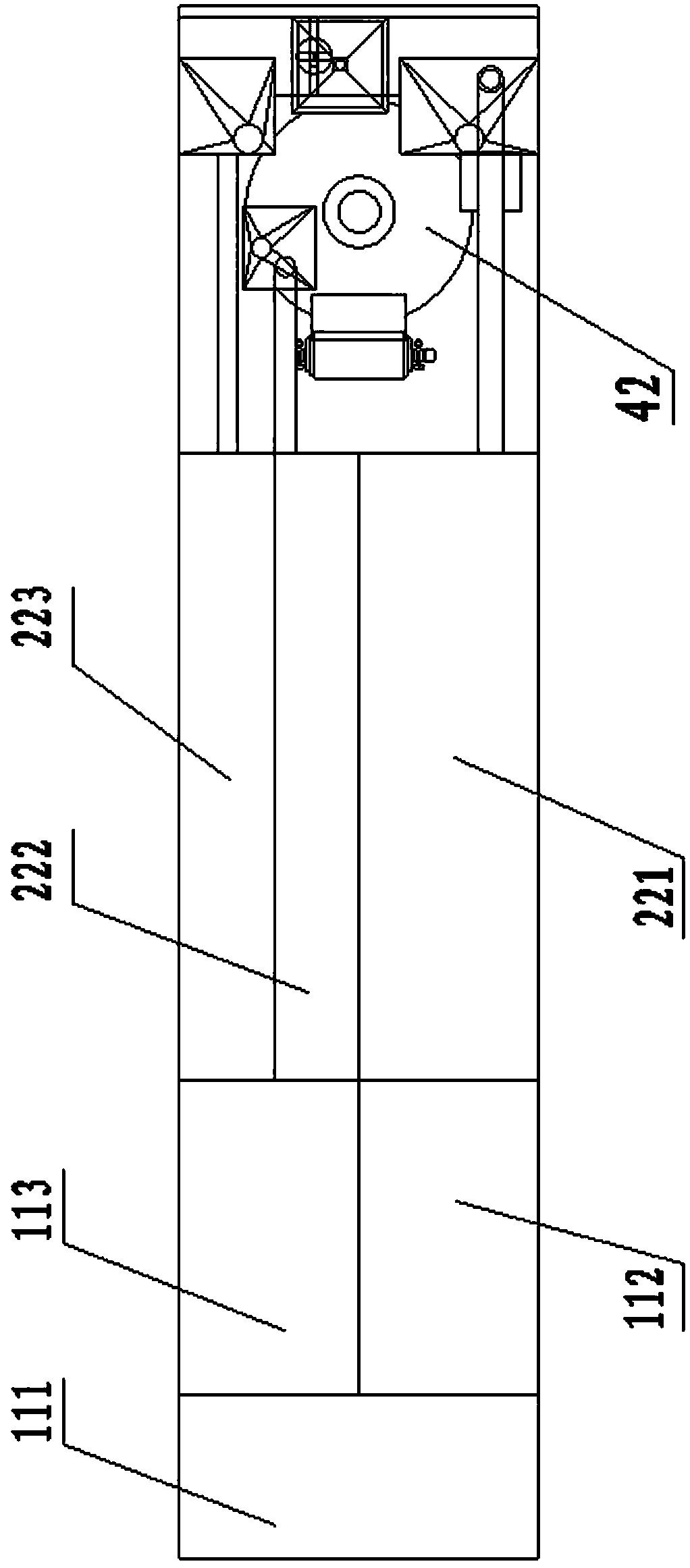

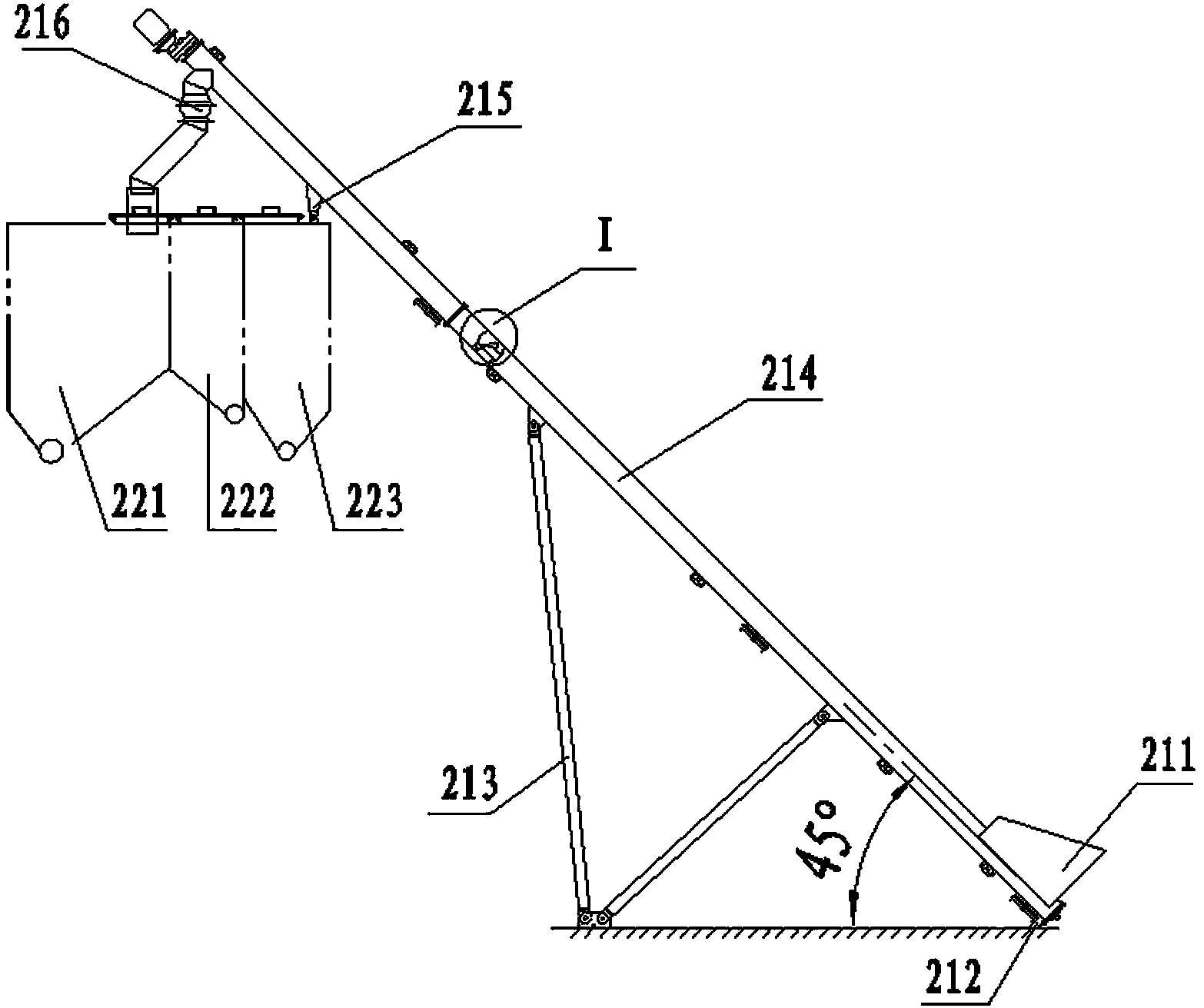

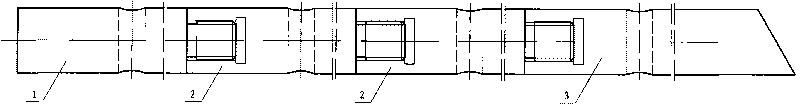

Quickly-moving type concrete mixing station

ActiveCN103660040AShorten the production periodIncrease productivityDischarging apparatusIngredients weighing apparatusMaterial supplyDelivery system

The invention discloses a quickly-moving type concrete mixing station, and relates to the technical field of concrete production equipment. The station comprises an aggregate supplying system, a powdered auxiliary material supplying system, a liquid auxiliary material supplying system, a stirring system, a control panel, a pump delivery system, and a transportation system; wherein the transportation system comprises traction equipment and a trailer plate, the aggregate supplying system, the powdered auxiliary material supplying system, the liquid auxiliary material supply system, the stirring system, the control panel, and the pump delivery system are all arranged on the trailer plate; the aggregate supplying system, the powdered auxiliary material supplying system, and the liquid auxiliary material supplying system all communicate with the stirring system, the stirring system comprises a frame and a stirrer, the stirrer is arranged on the frame; and the pump delivery system is arranged below the material unloading door of the stirrer. The quickly-moving type concrete station has the advantages of compact structure, user-friendliness, and rapid movement, can shorten the construction time and guarantee the concrete quality, satisfies the using requirement of small-batch concrete, improves the construction efficiency, and saves the construction cost.

Owner:SHIJIAZHUANG TIEDAO UNIV +2

Special construction method by utilizing electricity jacking pipe

InactiveCN103855650AGuaranteed unobstructedContinuous constructionTunnelsApparatus for laying cablesElectricityEnvironment effect

The invention discloses a special construction method by utilizing an electricity jacking pipe. The method comprises the following steps of working pit construction, hoisting equipment installation, rail installation, jacking, cave opening reinforcement and grouting and backfill. According to the construction method, the construction process by utilizing the jacking pipe is adopted, the influence on a road can be reduced as much as possible, and it can be guaranteed that the road is unobstructed. As the influence on an ambient environment is small, construction can be carried out day and night. Besides, continuous construction can be carried out, and construction quality is stable.

Owner:STATE GRID CORP OF CHINA +1

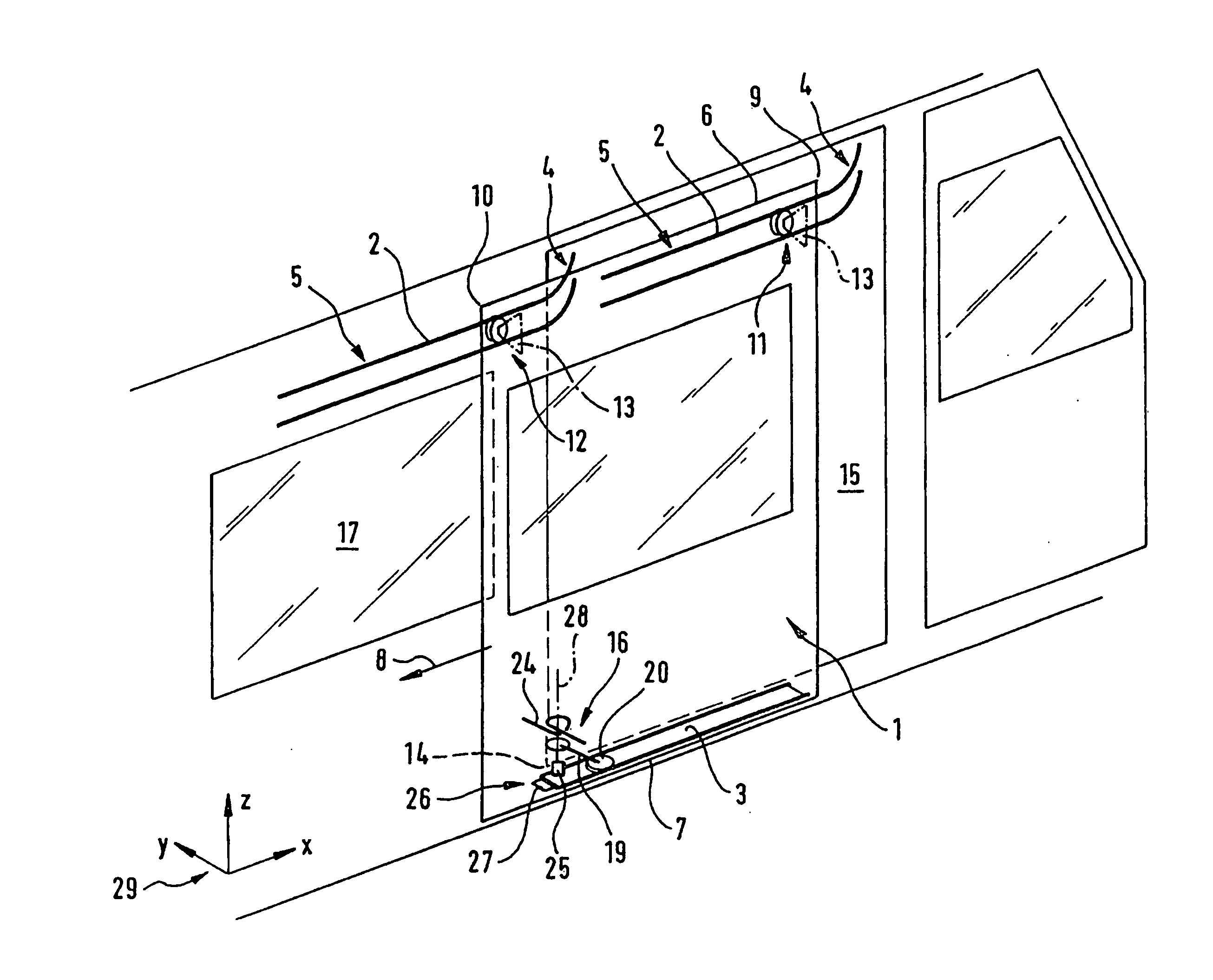

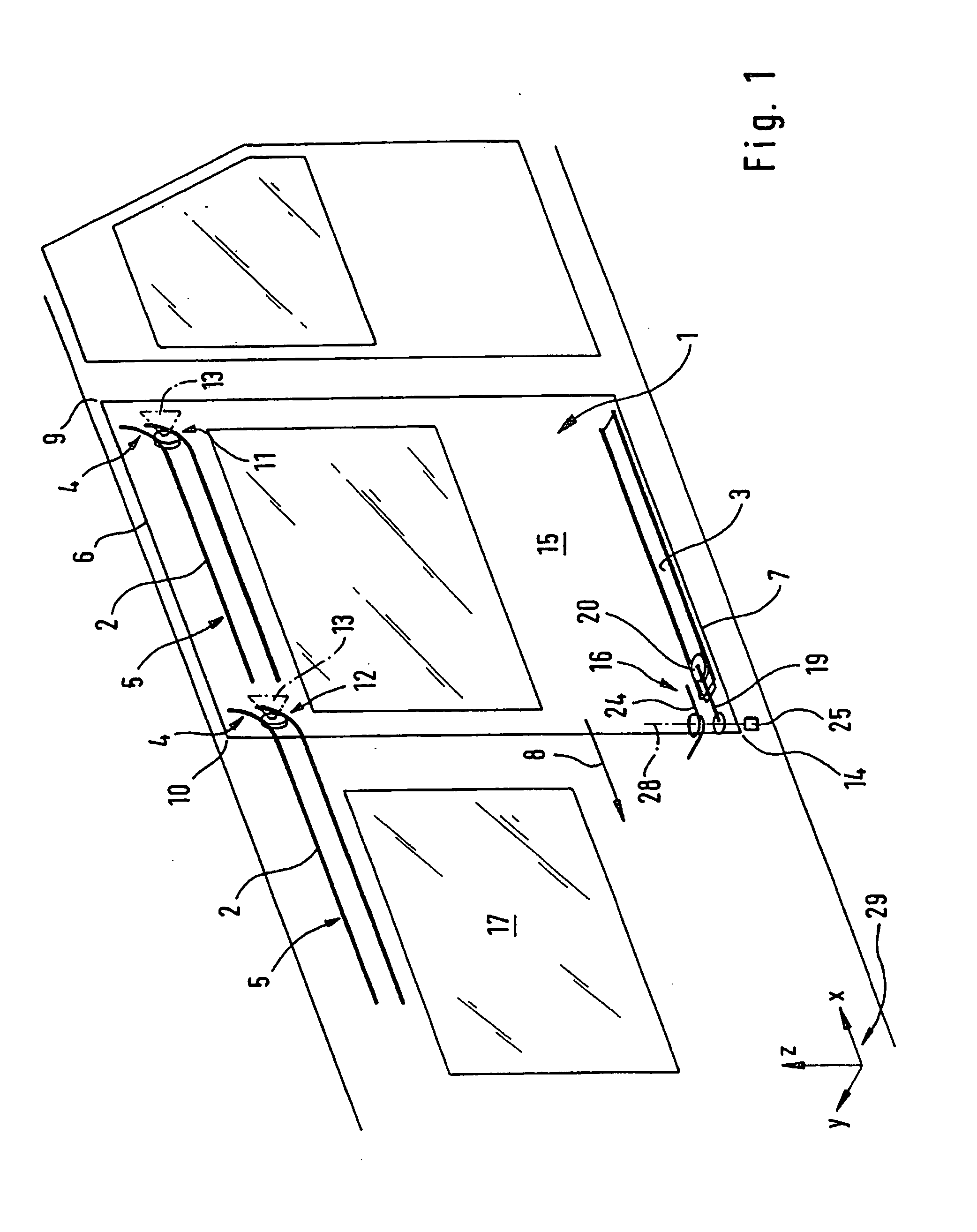

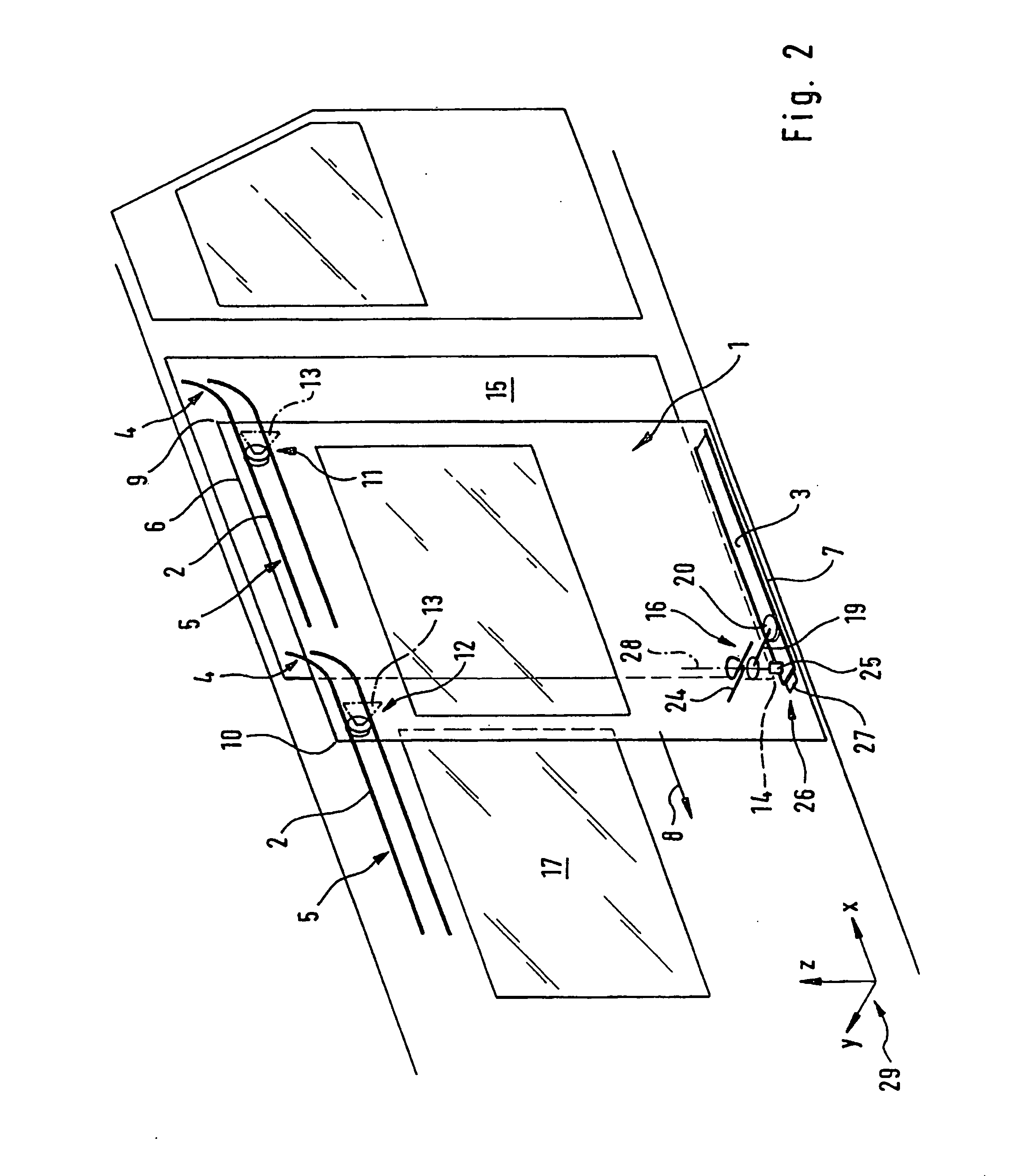

Exterior Sliding Door for a Vehicle

Owner:DAIMLER AG

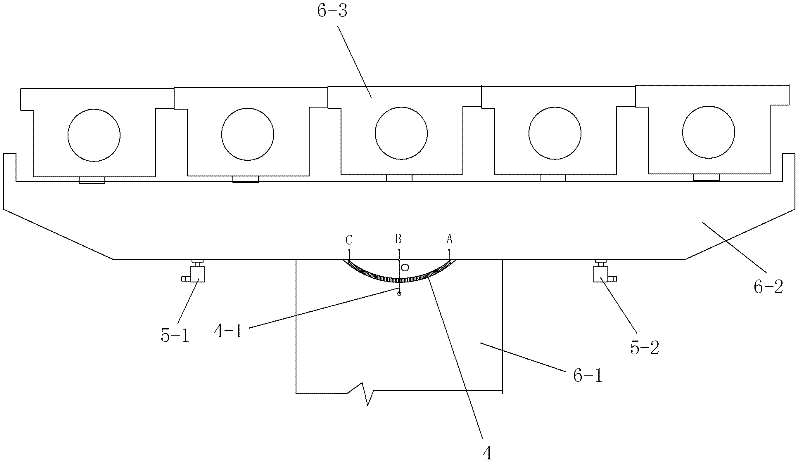

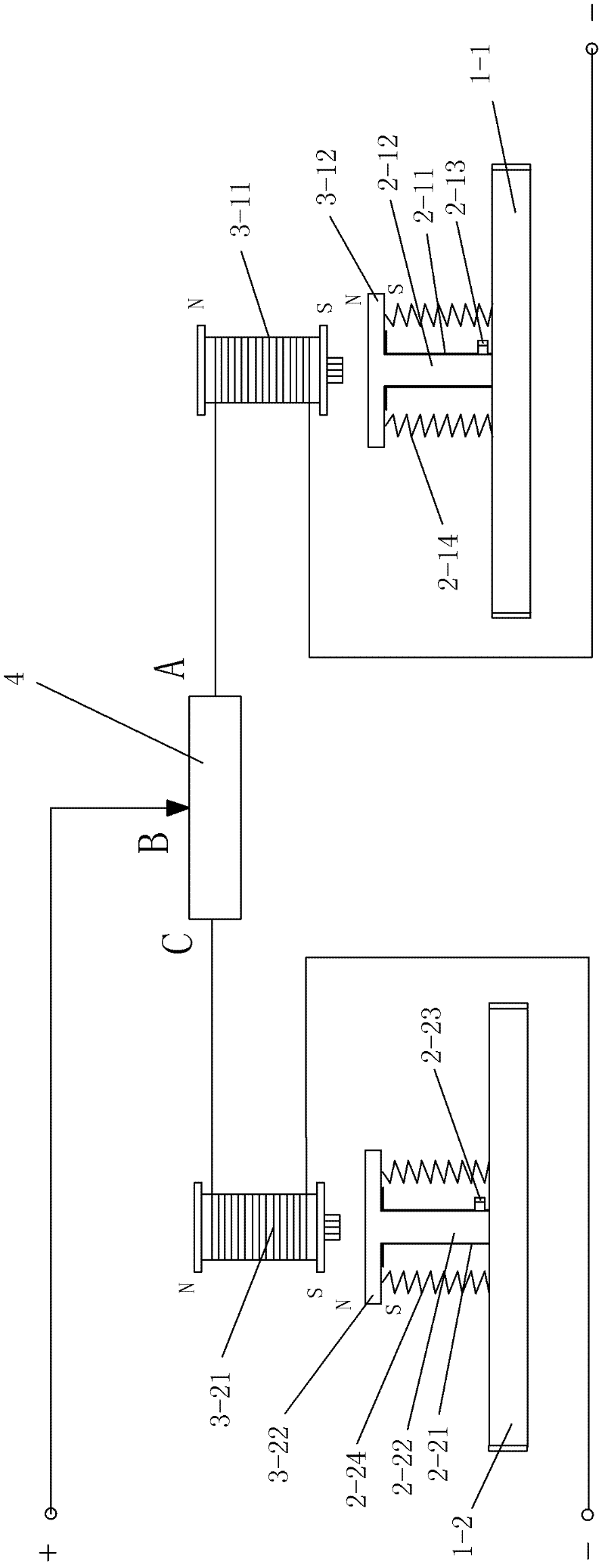

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642AReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

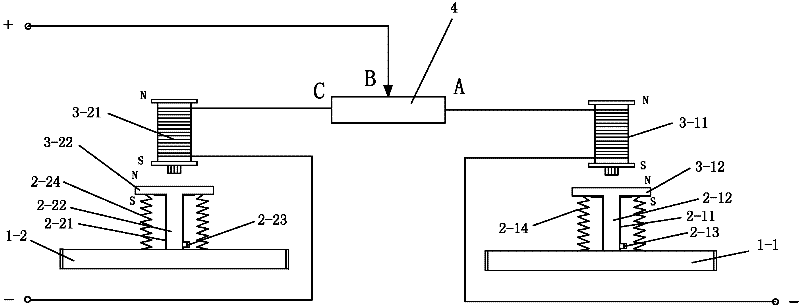

Municipal blowdown pipeline laying construction method

ActiveCN105605308AShort construction periodSave the initial setting timePipe laying and repairBriquetteCushion

The invention relates to a municipal blowdown pipeline laying construction method. The municipal blowdown pipeline laying construction method adopts a sectional continuous construction mode to carry out laying, and adopts bottom concrete cushion blocks and top concrete briquettes, which are prefabricated in advance, in the laying process of each section. The laying process of each section comprises: pouring and prefabricating a plurality of bottom concrete cushion blocks and a plurality of top concrete briquettes on the ground of a construction site; digging a groove to form a foundation trench; installing a foundation trench supporting structure; sequentially placing a plurality of prefabricated bottom concrete cushion blocks, one or a plurality of pipes and a plurality of top concrete briquettes in the foundation trench, enabling both ends of each pipe to be respectively supported in a semicircular groove of one bottom concrete cushion block and be respectively compressed in a semicircular groove of one top concrete briquette, and placing a polyethylene telescopic seam plate between each two sets of bottom concrete cushion block and top concrete briquette combination structures; pouring pipe encased concrete in the foundation trench; and refilling the groove. According to the construction method, the process is simplified, the construction period is shortened, and construction efficiency is improved.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Portable manual automatic control cable stripper

PendingCN109510120AReduce the risk of scratchesFast constructionApparatus for removing/armouring cablesAutomatic controlEngineering

The invention discloses a portable manual automatic control cable stripper, which comprises a C-type frame, a hob cutter holder arranged above the inside of the C-type frame and a cable conveyor arranged below the inside of the C-type frame. A hob assembly is supported in the hob cutter holder, and the hob assembly and the cable conveyor are opposed up and down to form a cable conveyor channel. The two ends of the hob cutter holder are supported in two side wall rails above the inner side of the C-shaped frame through a support shaft. The upper middle part of the hob cutter holder is connectedwith a screw adjusting member which penetrates the upper wall of the C-shaped frame perpendicularly, and the screw adjusting member is provided with a lock nut. The outer side of the C-shaped frame in the middle-lower direction protrudes to form an L-shaped box body, and a driving control mechanism for driving the cable conveyor to operate is arranged in the L-shaped box body. The portable manualautomatic control cable stripper can realize rapid, efficient, continuous and safe construction in a place where cable head manufacturing is centralized, and greatly reduces the labor cost consumed in stripping cable sheaths.

Owner:SINOPEC TENTH CONSTR

Anchor rod for measuring tunnel floor heave large deformation and method therefor

InactiveCN101737070AAdaptableHigh precisionUsing mechanical meansAnchoring boltsContinuous measurementEngineering

The invention relates to an anchor rod for measuring tunnel floor heave large deformation, which is composed of a tail rod piece, a multi-section middle rod piece and a head rod piece which are connected; wherein the tail rod piece is connected with the tail of the multi-section middle rod piece, the head rod piece is connected with the head of the multi-section middle rod piece. The tail rod piece, the multi-section middle rod piece and the head rod piece of the anchor rod are sheathed and then anchored into drilled holes; the height from the tail rod piece to the tunnel top is measured, tunnel height changes such as excessive tunnel floor heave are measured in real time; after bottom canch cleaning is finished, the rod pieces completely exposed out of the ground are taken down, the remaining rod pieces still have certain length exposed. Length of rod pieces taken down is accumulated and height to the tunnel top is initially measured, thus obtaining tunnel floor heave deflection. The multi-section measuring anchor rod is convenient to follow-up observation and does not affect pedestrians and construction inside the tunnel. The anchor rod can be repeatedly used and the measuring anchor rod dispenses with mounting trays, screw nuts and the like. The anchor rod and the method of the invention feature simple structure, convenient construction, easy maintenance, continuous measurement and high accuracy.

Owner:CHINA UNIV OF MINING & TECH +1

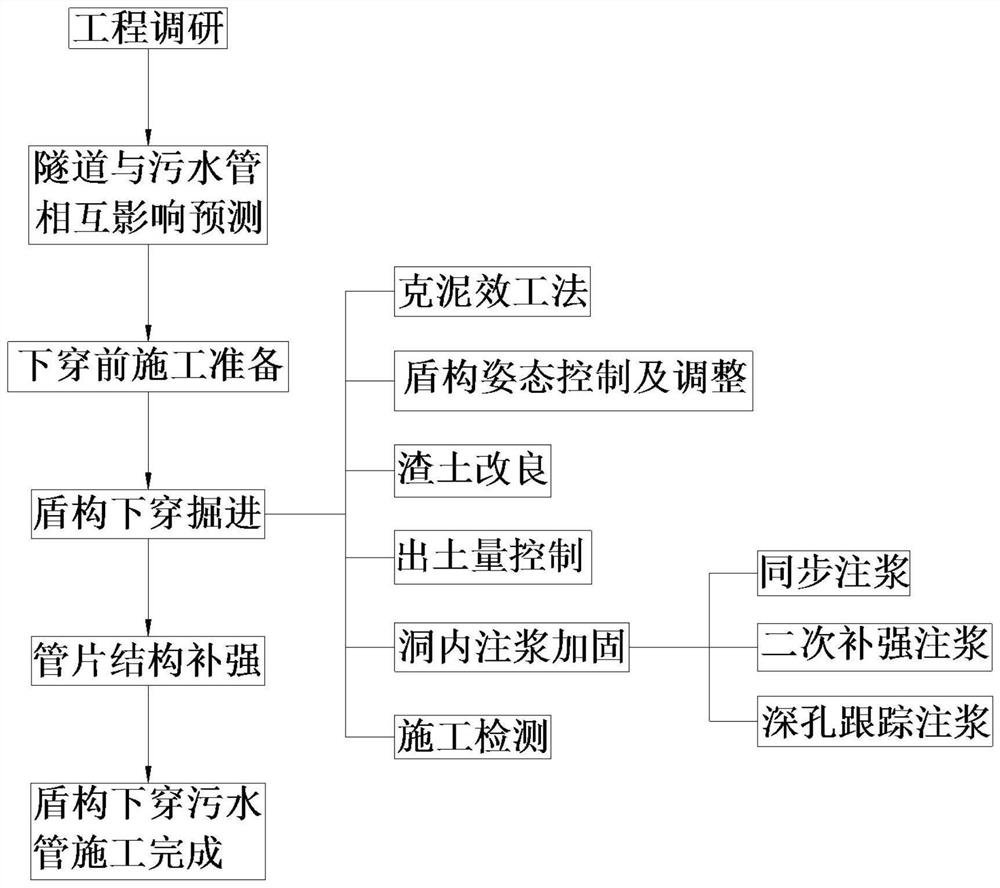

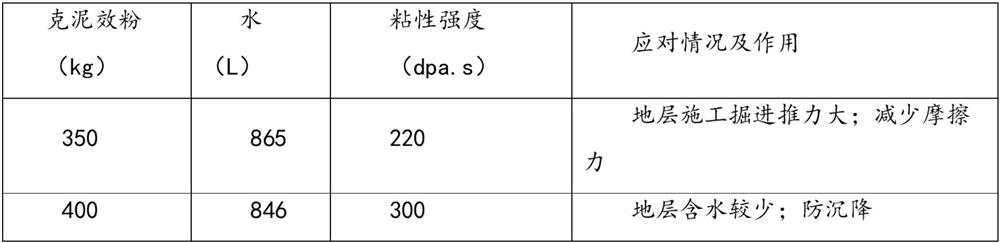

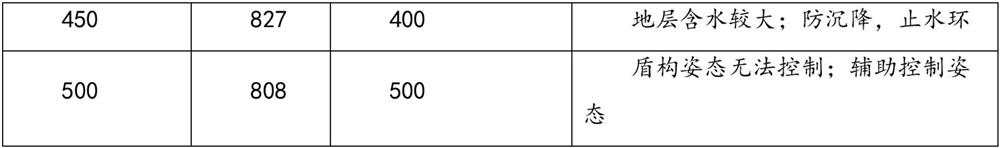

Construction method for earth pressure balance shield to pass through large-diameter sewage main pipe underground

InactiveCN111706341AReduce casualtiesReduce economic lossMining devicesUnderground chambersStatistical analysisSewage

The invention relates to the technical field of shield construction, in particular to a construction method for an earth pressure balance shield to pass through a large-diameter sewage main pipe underground, and is used for solving the problems of high construction difficulty, high risk and great casualties and economic loss easily caused by improper control when the shield passes through the large-diameter sewage main pipe underground in the prior art. The construction method comprises the following steps that 1, engineering investigation is carried out, an underwater color television and a geological radar are adopted; 2, the mutual influence of a tunnel and a sewage pipe is predicted, deformation analysis is carried out by adopting a stratum I structure model; 3, construction preparation before underneath pass is carried out, comprehensive statistical analysis is carried out by adopting a 60m experimental section; and 4, shield underneath pass tunneling is carried out, and stratum settlement is controlled through a clay shock method. According to the construction method for the earth pressure balance shield to pass through the large-diameter sewage main pipe underground, the construction difficulty and the corresponding risk can be effectively reduced through engineering investigation, prediction of the mutual influence of the tunnel and the sewage pipe, construction preparation before underneath pass and shield underneath pass tunneling, and therefore casualties and economic losses can be reduced.

Owner:郑州地铁集团有限公司

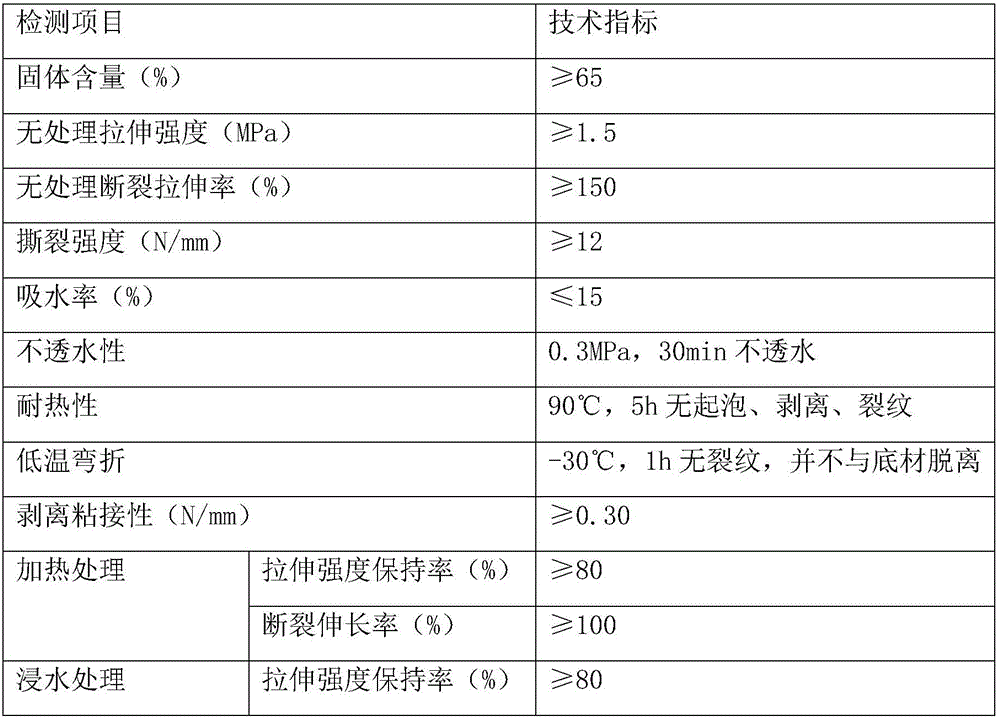

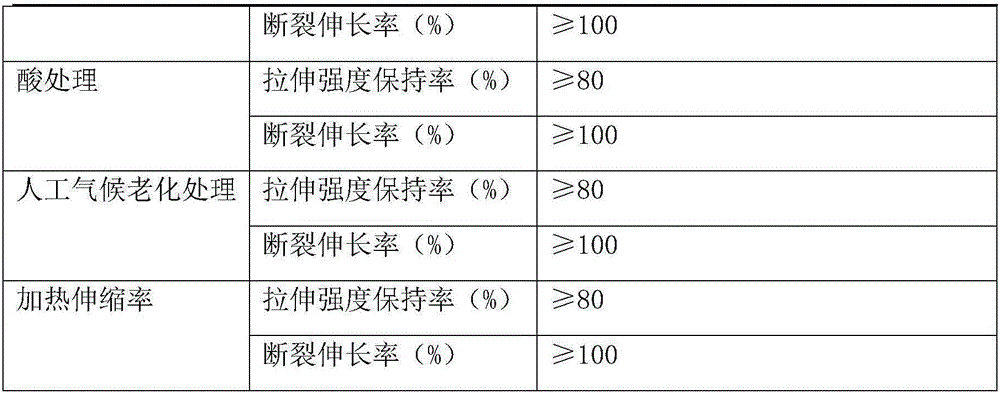

Special roof-spraying waterproof material

ActiveCN106221450AImprove adhesionImprove sealingFireproof paintsAntifouling/underwater paintsEpoxyLow speed

The invention discloses a special roof-spraying waterproof material. The special roof-spraying waterproof material is prepared from, by weight, 400-550 parts of emulsion, 80-120 parts of silica powder, 300-400 parts of calcite powder, 40-60 parts of rutile titanium dioxide, 30-50 parts of deionized water, 2-4 parts of dispersing agent, 2-4 parts of defoaming agent, 1.5-2.5 parts of preservative, 0.8-1.2 parts of ultraviolet light absorber and 0.8-1.2 parts of anti-aging agent. A preparing method of the special roof-spraying waterproof material includes the steps that the silica powder, the calcite powder, the rutile titanium dioxide, the deionized water, the dispersing agent, the defoaming agent, the preservative, the ultraviolet light absorber and the anti-aging agent are stirred to be even at a high speed, the emulsion is added at a low speed, the mixture is stirred to be even, and the special roof-spraying waterproof material is obtained through filtering. The emulsion is acrylic emulsion or a mixture of acrylic emulsion and aliphatic-series waterborne polyurethane emulsion or a mixture of acrylic emulsion and waterborne epoxy resin emulsion. The special roof-spraying waterproof material is mainly used for water resisting of roofs.

Owner:成都市嘉洲新型防水材料有限公司

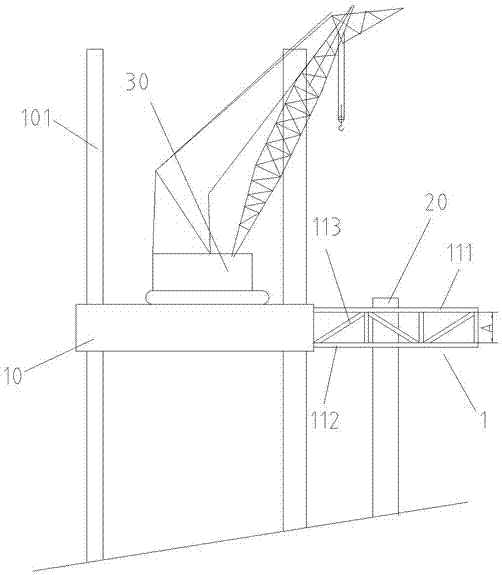

Drainage tunnel stand pipe planting construction device and method

ActiveCN107190776AShorten the efficiency of pipe planting constructionImprove the efficiency of pipe planting constructionArtificial islandsUnderwater structuresVertical tubePunching

The invention discloses a drainage tunnel stand pipe planting construction device. The drainage tunnel stand pipe planting construction device comprises a ship platform with one side being provided with a plurality of punching pile positioning and guiding frames horizontally at intervals. Each punching pile positioning and guiding frame is composed of two steel pipe trusses which are arranged in parallel and provided with rectangular cross sections, and the upper ends of a plurality of steel casings are supported and locked on every two corresponding steel pipe trusses. A method comprises the steps of (1) drainage port punching construction, (2) percussion drilling or rotary-drill drilling, (3) drainage port stand pipe construction and (4) connection of a stand pipe and a tunnel. According to the drainage tunnel stand pipe planting construction device, the ship platform is adopted for construction, construction is not influenced by winter monsoons and can be continuously conducted, and the construction period is shortened. A plurality of punching piles can be simultaneously conducted, and the common problems that during pipe-jacking construction, the pipe jacking resistance is overlarge, a cave outlet close cover is clamped, and the bearing capacity of a tunnel base is insufficient are solved. The construction efficiency of steel casing pile sinking and stand pipe planting is improved, and construction safety is ensured.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

Rigid polyurethane foam culture stone and production method thereof

InactiveCN101649674ASmall adjustment rangeHigh closed cell rateCovering/liningsThermal insulationEngineering

The invention aims at the shortcomings that the current culture stones are heavy in weight, high in cost or poor in thermal insulation properties and have poor bondability with the building blocks, masonries and the like, are easily spalled, have short service lives and the like, and provides a rigid polyurethane foam (RPUF) culture stone and a production method thereof. The RPUF product with goodbondability, good thermal insulation property, light materials and long service life is obtained by improving the culture stone raw materials, production steps and technological conditions, which issuitable for the indoor and outdoor decoration in various environments.

Owner:宿迁特力新材料有限公司

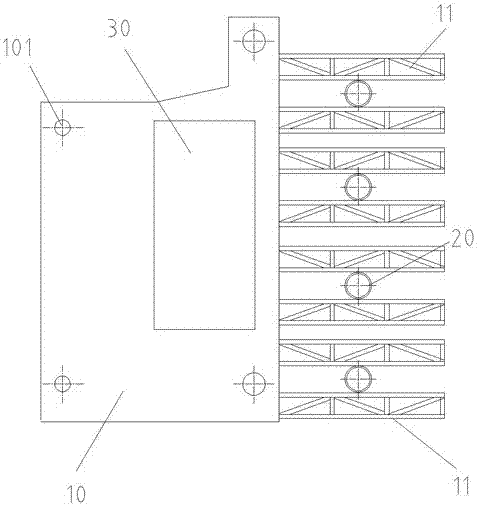

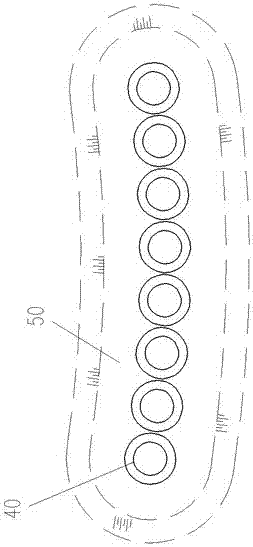

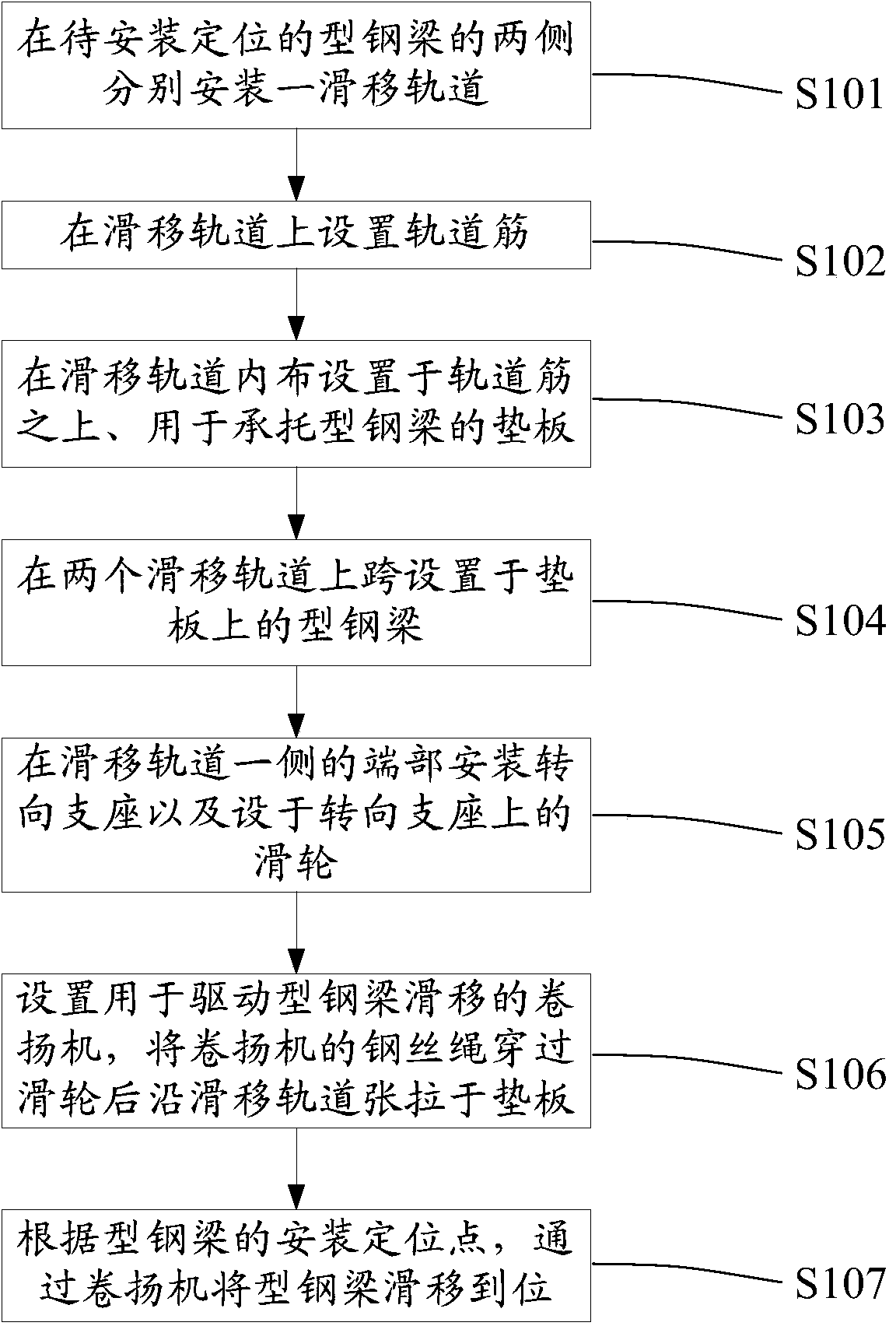

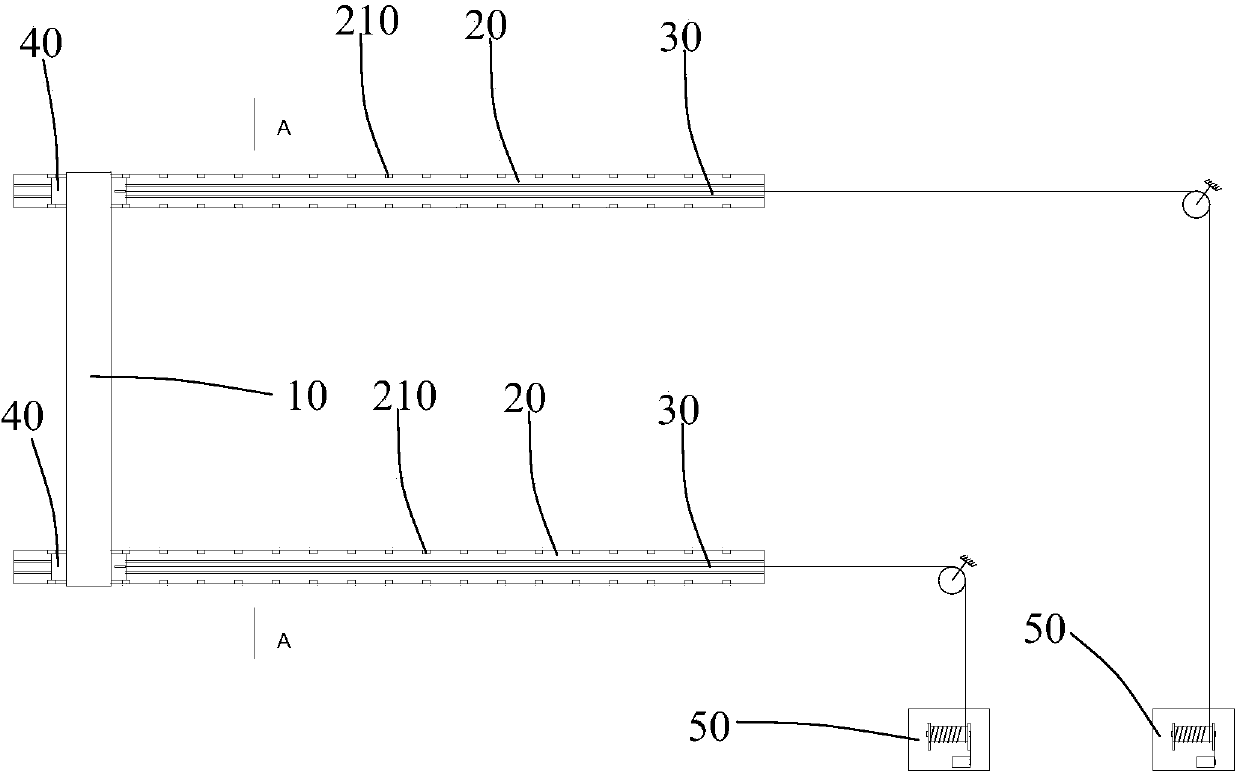

Sliding installation method for large span section steel beam

ActiveCN104727563ASolve lengthSolve the difficulties that cannot be constructedBuilding material handlingWinchPulley

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Support form for realizing mining method tunnel small radius turning and construction method

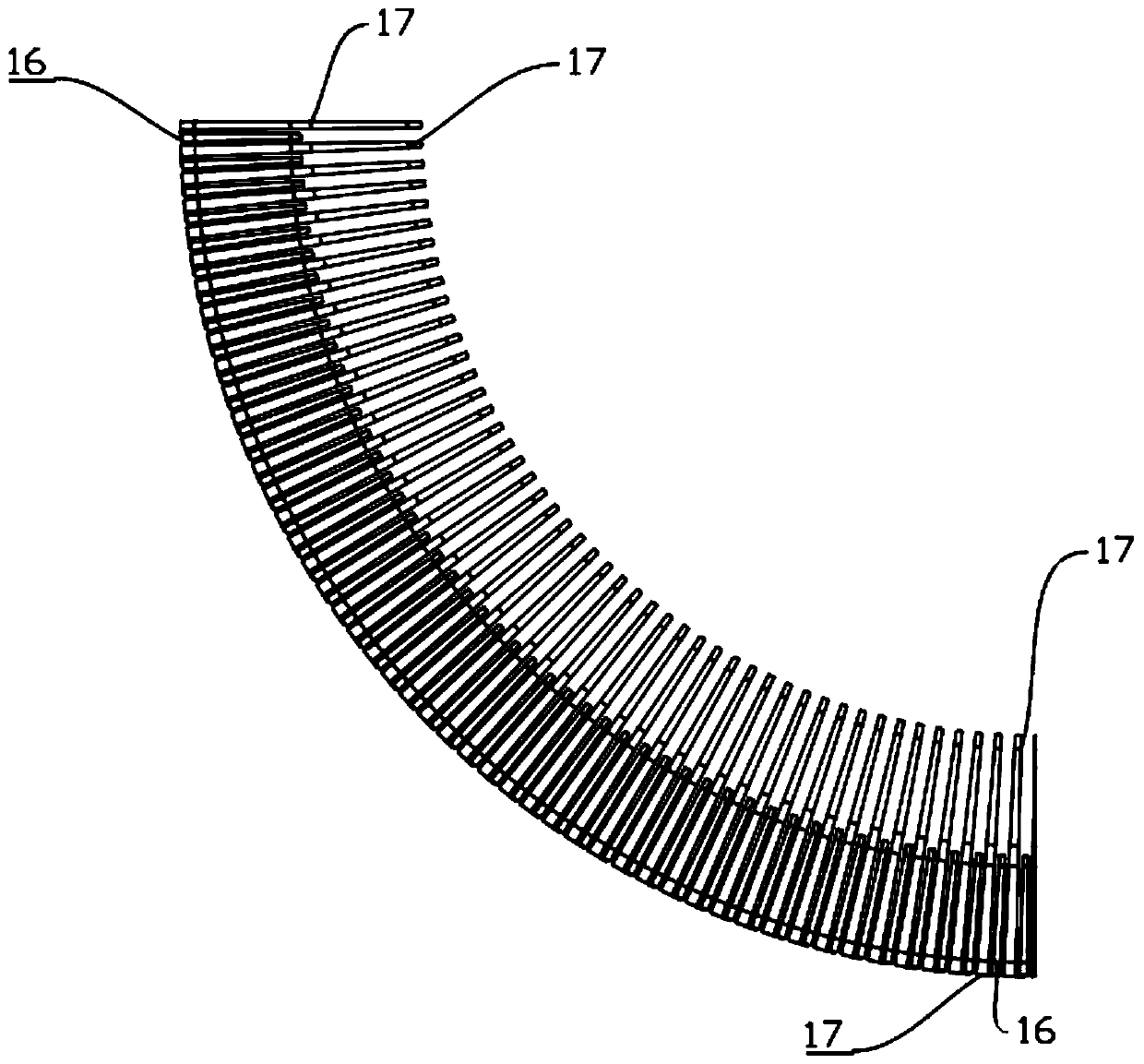

PendingCN109973100AContinuous constructionEfficient constructionUnderground chambersTunnel liningEconomic benefitsSteel frame

The invention relates to the technical field of underground structure engineering, in particular to a support form for realizing mining method tunnel small radius turning and a construction method. The construction method comprises the steps that a plurality of standard-range grating steel frame supports are used, after inner side steel frames are densely distributed, semi-range off-standard grating steel frames are crisscross arranged between outer side standard-range grating steel frames under the condition of the interval of the outer side steel frames being larger than the design requirement, and soon, internal chambers with different partitions are excavated in order. According to the support form for realizing mining method tunnel small radius turning and the construction method, theconstruction form of high section surface can be avoided during tunnel construction, the smallest tunnel turning radius is brought, the safety is high, the economic benefits are good and the construction period is saved in the process of city tunnel construction, and the influence of other underground facilities such as water pipe lines on the construction is reduced to the minimum.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

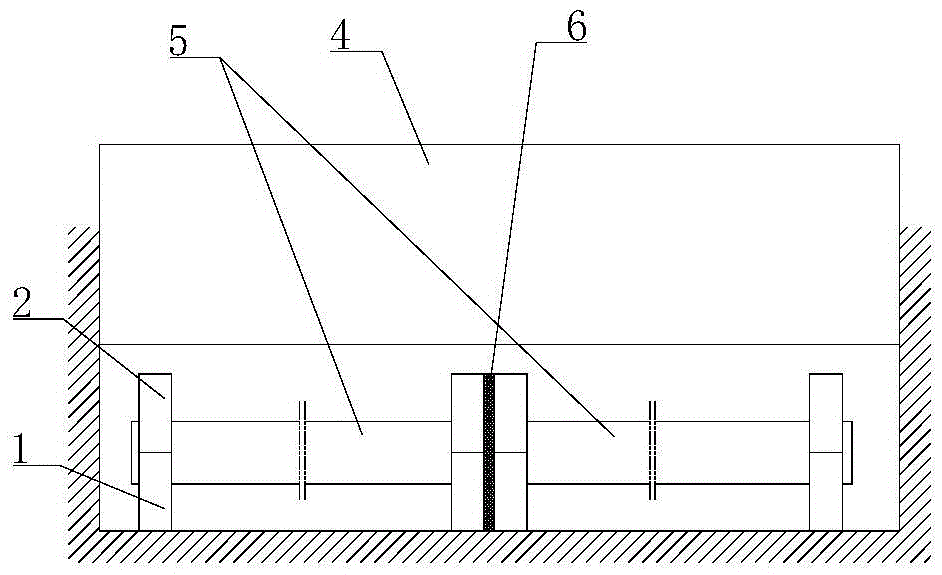

Concrete pouring system with double-layer chute and construction method thereof

PendingCN111119487AQuick pourReduce demandBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a concrete pouring system with a double-layer chute and a construction method thereof. The concrete pouring system with the double-layer chute comprises a pouring device, a chute scaffold, a chute main body, a tumbling barrel and a movable chute frame, wherein the chute main body is a double-layer chute and comprises main chutes and branch chutes; and the horizontal projections of the upper main chute and the lower main chute are overlapped. The concrete pouring system with the double-layer chute is innovative on the principle of the traditional chute; the upper chute and branching facilities thereof are added above the traditional chute; and an automobile pump is adopted in the upper chute so as to coordinate the discharging, and thus, a double-layer three-dimensional long-distance concrete pouring construction method is formed. Due to the increase in the height of the chute, the entire system can cover the pouring area of a baseplate in a relatively large area,and realizes the rapid pouring of the baseplate. In addition, when the concrete is poured on the baseplate, the demand for roads is also greatly reduced.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

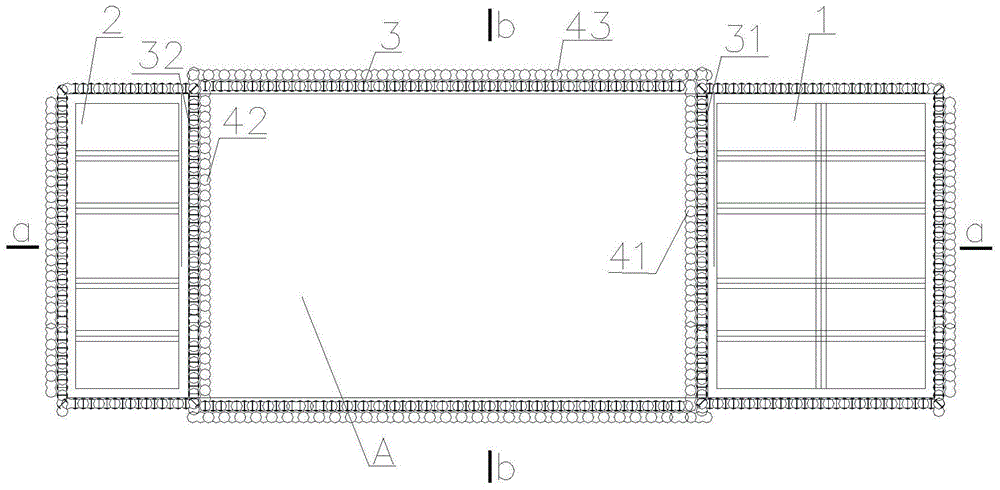

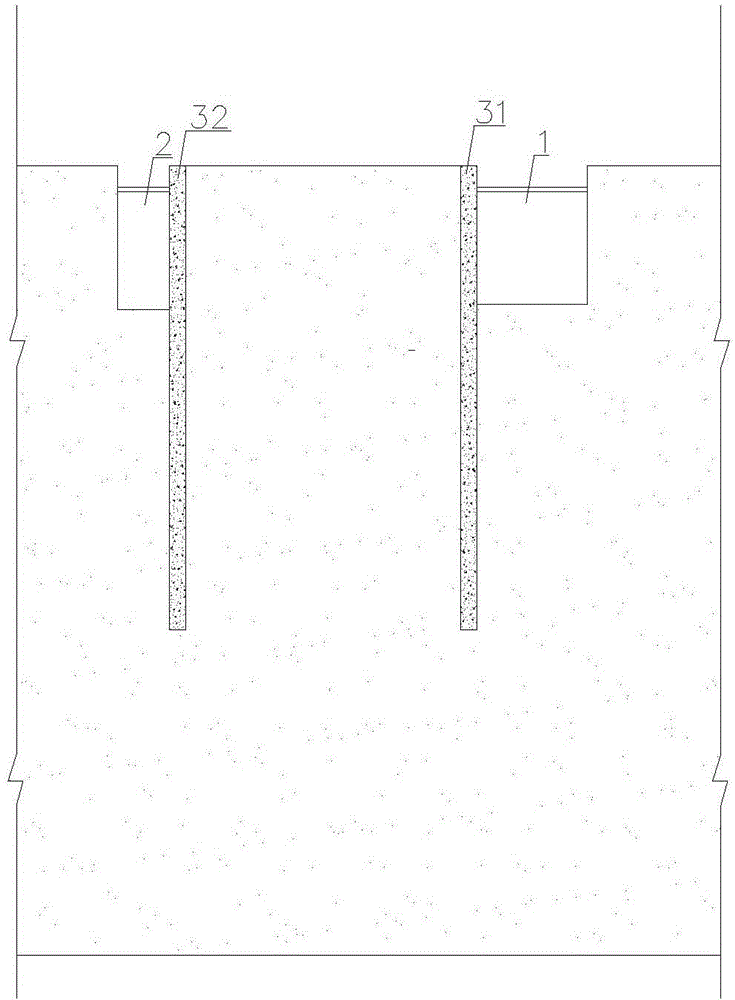

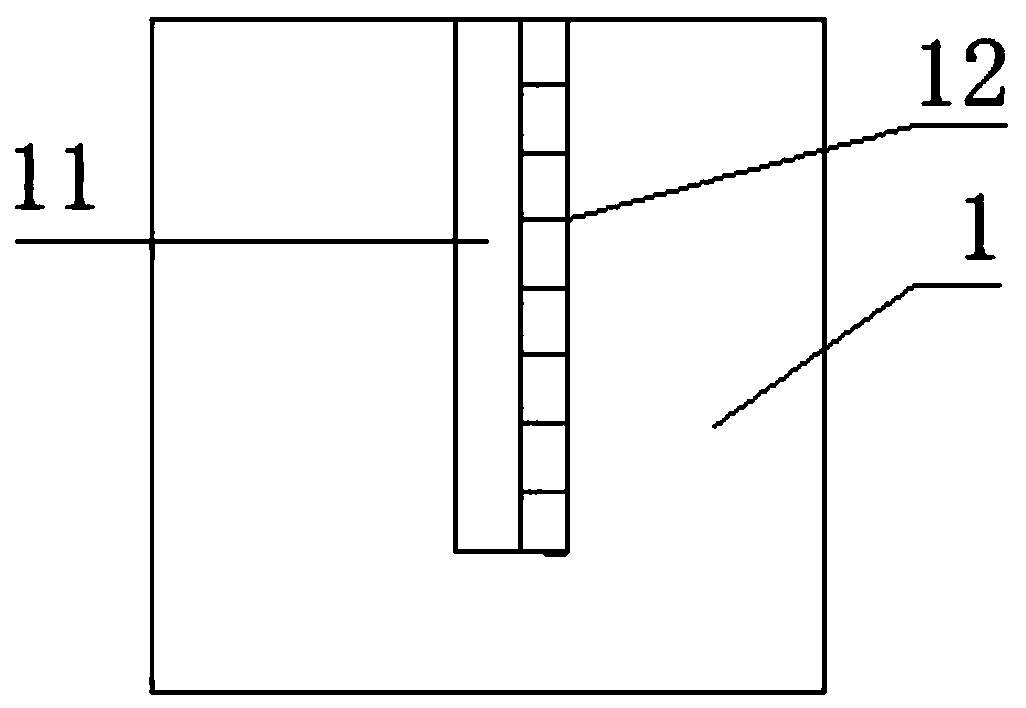

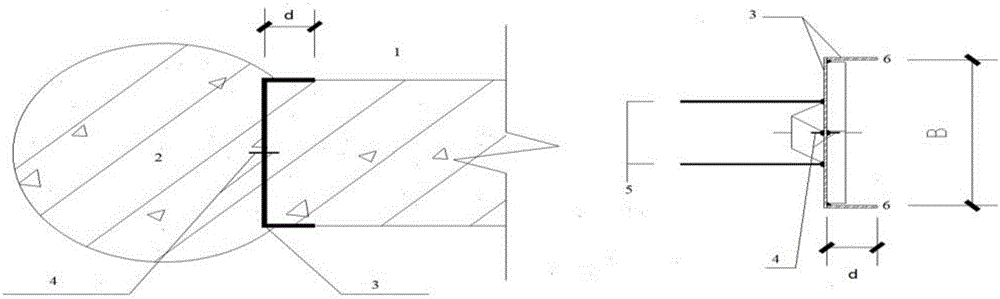

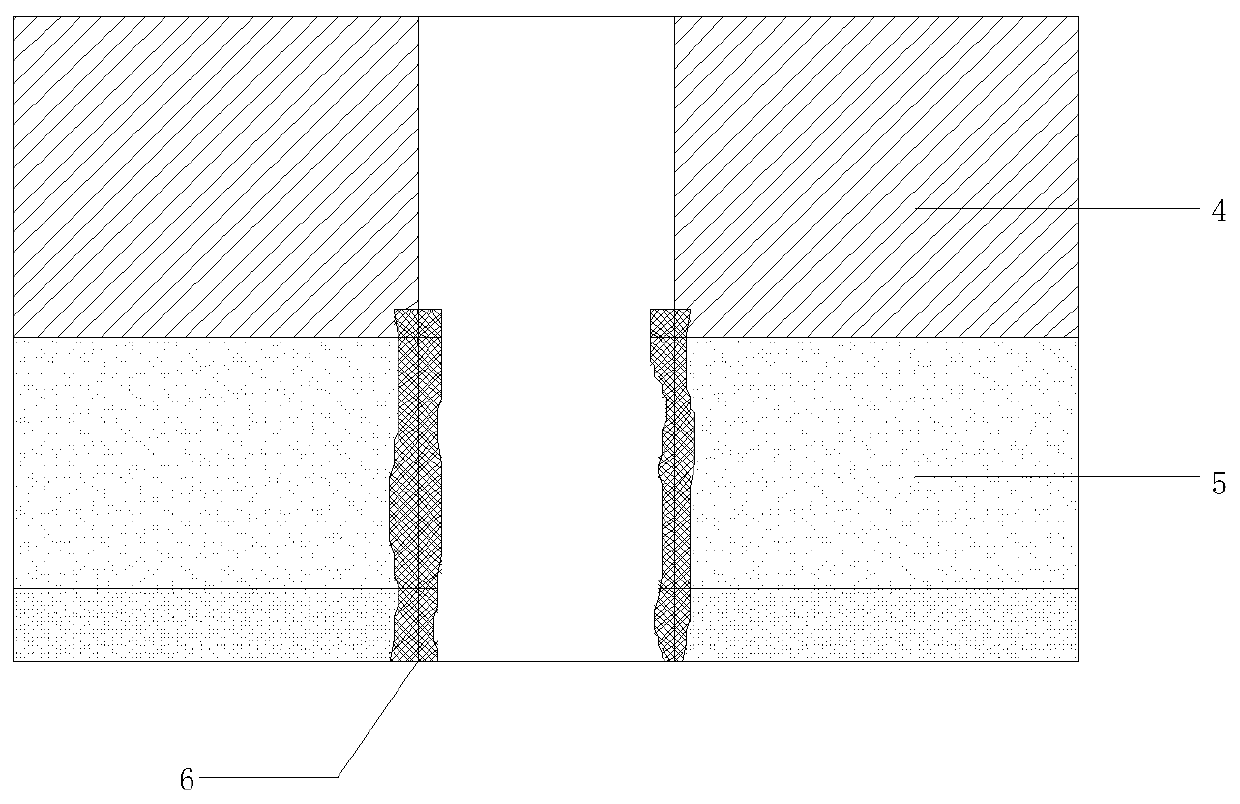

Indoor piling wall support structure and construction method therefor

ActiveCN105804090AQuality assuranceEliminate common quality problemsArtificial islandsExcavationsEngineeringCement mortar

The invention discloses an indoor piling wall support structure. The indoor piling wall support structure comprises underground diaphragm walls and cast-in-place piles, wherein the cast-in-place piles are arranged on two sides of each underground diaphragm wall respectively, and the underground diaphragm wall and each corresponding cast-in-place pile are in lap joint meshing through an embedded part embedded at edges of the underground diaphragm wall and the corresponding cast-in-place pile; two ends of each embedded part extend horizontally along the outer surface of the corresponding underground diaphragm wall and folded to form embedded part flanges which are perpendicular to a main body of the embedded part and are parallel to each other; a water stop component is arranged on each embedded part; the underground diaphragm walls, the cast-in-place piles and the water stop components constitute water stop piling walls; a cement mortar layer is arranged on the side, connected with the corresponding underground diaphragm wall, of each cast-in-place pile, and a pipe component pre-equipped with a wire and made of a waterproof insulating material is arranged in the cement mortar layer; a cement mortar layer, prefabricated thermal mortar soft boards and prefabricated waterproof soft boards are arranged sequentially on the outer wall surface of underground space formed between the bottoms of the underground diaphragm walls and the cast-in-place piles; a displacement sensor is arranged between the prefabricated thermal mortar soft boards at a junction of each underground diaphragm wall and each corresponding cast-in-place pile, and a wire of the displacement sensor extends to the wall top from the corresponding pipe component.

Owner:JIANGXI THE SECOND CONSTR +1

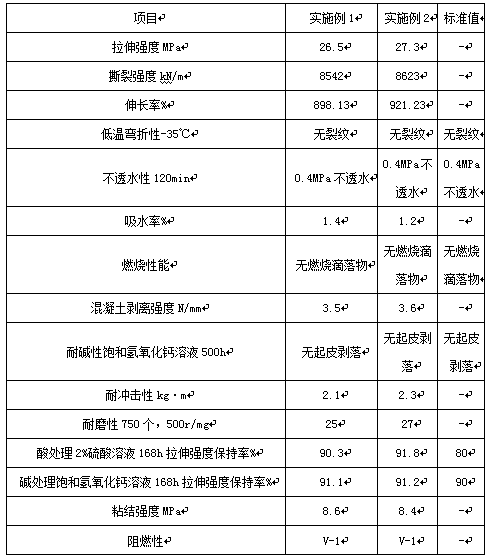

Preparation method of high-temperature-resistant polyurea elastic flame-retardant waterproof coating

InactiveCN110862741AOvercome the fatal shortcoming of sharp drop in performanceHigh reactivityFireproof paintsAnti-corrosive paintsElastomerPolymer science

The invention belongs to the technical field of waterproof coatings, and in particular, relates to a preparation method of a high-temperature-resistant polyurea elastic flame-retardant waterproof coating. The polyurea elastomer coating prepared by the preparation method disclosed by the invention has the advantages of high solid content, greenness, environmental friendliness, thick, compact and flexible coating film, strong adhesive force with a substrate, excellent ultraviolet resistance, impact resistance and the like, and simplicity and convenience in construction, adopts vinyl ester resinto modify a polyurea coating, and does not contain any hydroxyl component or catalyst. The reaction activity of an amino-terminated compound and an isocyanate component is extremely high, no catalystis needed, the high temperature resistance of the coating is further improved, and the coating has a good application prospect.

Owner:萧县金虹新型防水建材有限公司

Cast-in-place pile leaking stoppage hole reinforcing method and structure

PendingCN110965550AContinuous constructionGuarantee smooth constructionBulkheads/pilesSoil preservationArchitectural engineeringStructural engineering

The invention discloses a cast-in-place pile leaking stoppage hole reinforcing method and structure. Before a cast-in-place pile is constructed, a grouting influence radius test is carried out, a slurry influence radius is detected, a leaking stoppage hole and a wall reinforcing hole are formed around a cast-in-place pile hole, slurry is injected into the leaking stoppage hole and the wall reinforcing hole, after the slurry is solidified, construction of the cast-in-place pile is carried out, and an easily-leaking easily-collapsing layer around the cast-in-place pile can be reinforced. The method and structure are suitable for construction of the cast-in-place pile of the easily-leaking easily-collapsing layer such as gravel, cobble and limestone, the construction steps are reasonable in design, operation is easy, quality problems of slurry leaking, hole collapsing and the like in the construction process of the cast-in-place pile can be effectively solved, continuity and smoothness ofthe construction of the cast-in-place pile can be ensured, the construction efficiency of the cast-in-place pile can be improved, rework due to quality problems in the hole forming construction process of the cast-in-place pile can be reduced, and the construction quality of the cast-in-place pile can be effectively ensured.

Owner:CCCC FOURTH HARBOR ENG CO LTD

Screw-connected concrete wall block

The invention discloses a screw-connected concrete wall block. According to the invention, a screw-connection mold is manufactured by using a steel mold; reinforcement steel bars are braided into the screw-connection shape, and are flatly paved in the mold. Well mixed concrete is then poured into the mold, and is flattened and compacted by using a vibrating machine. Or, concrete and reinforcement steel bars are placed into the screw-connection mold, and the screw-connected construction wall block can be manufactured by punching by using a high-pressure punching machine. With the above methods, the screw-connected construction concrete wall block can be manufactured.

Owner:李义厚

Municipal sewage pipeline laying construction method

ActiveCN105605308BShort construction periodSave the initial setting timePipe laying and repairMunicipal sewageBriquette

The invention relates to a municipal blowdown pipeline laying construction method. The municipal blowdown pipeline laying construction method adopts a sectional continuous construction mode to carry out laying, and adopts bottom concrete cushion blocks and top concrete briquettes, which are prefabricated in advance, in the laying process of each section. The laying process of each section comprises: pouring and prefabricating a plurality of bottom concrete cushion blocks and a plurality of top concrete briquettes on the ground of a construction site; digging a groove to form a foundation trench; installing a foundation trench supporting structure; sequentially placing a plurality of prefabricated bottom concrete cushion blocks, one or a plurality of pipes and a plurality of top concrete briquettes in the foundation trench, enabling both ends of each pipe to be respectively supported in a semicircular groove of one bottom concrete cushion block and be respectively compressed in a semicircular groove of one top concrete briquette, and placing a polyethylene telescopic seam plate between each two sets of bottom concrete cushion block and top concrete briquette combination structures; pouring pipe encased concrete in the foundation trench; and refilling the groove. According to the construction method, the process is simplified, the construction period is shortened, and construction efficiency is improved.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Seawater-based fracturing fluid for offshore high-temperature oil and gas reservoir fracturing

ActiveCN103215024BGood temperature and shear resistanceInhibit swellingDrilling compositionCross-linkFracturing fluid

The invention discloses a seawater-based fracturing fluid for fracturing a sea high-temperature oil-gas reservoir and relates to the technical field of cross-linked gel fracturing fluid. The seawater-based fracturing fluid comprises a base solution, a cross-linking agent and a thickening agent, wherein the base solution comprises the components (in percentage by weight) in terms of the weight of the prepared seawater-based fracturing fluid total solution as follows: 0.3%-0.8% of thickening agent, 0.1%-0.3% of pH regulating agent, 0.1%-0.5% of discharge aiding agent and the balance being seawater; relative to the mass fraction of the base solution, the cross-linking agent is 0.4%-0.6%; and the thickening agent refers to guar gum, carboxy-methyl hydroxypropyl guar gum, hydroxypropyl guar gum, fenugreek gum or sesbania gum. The seawater-based fracturing fluid is adopted, so that the dissolving speed of the thickening agent is quick, and therefore, direct mixing and continuous constructing can be realized, and therefore, the seawater-based fracturing fluid is in particular suitable for the fracturing construction of the sea high-temperature oil-gas reservoir. Meanwhile, the fracturing fluid can be continuously sheared for 90 minutes under the conditions of 150 DEG C and 170s<-1>, so that the viscosity is kept to be 70mPa.s or more.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

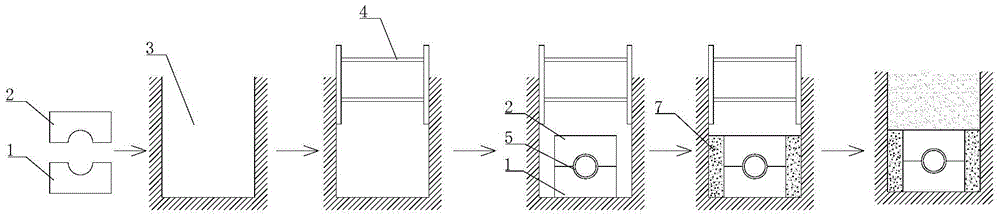

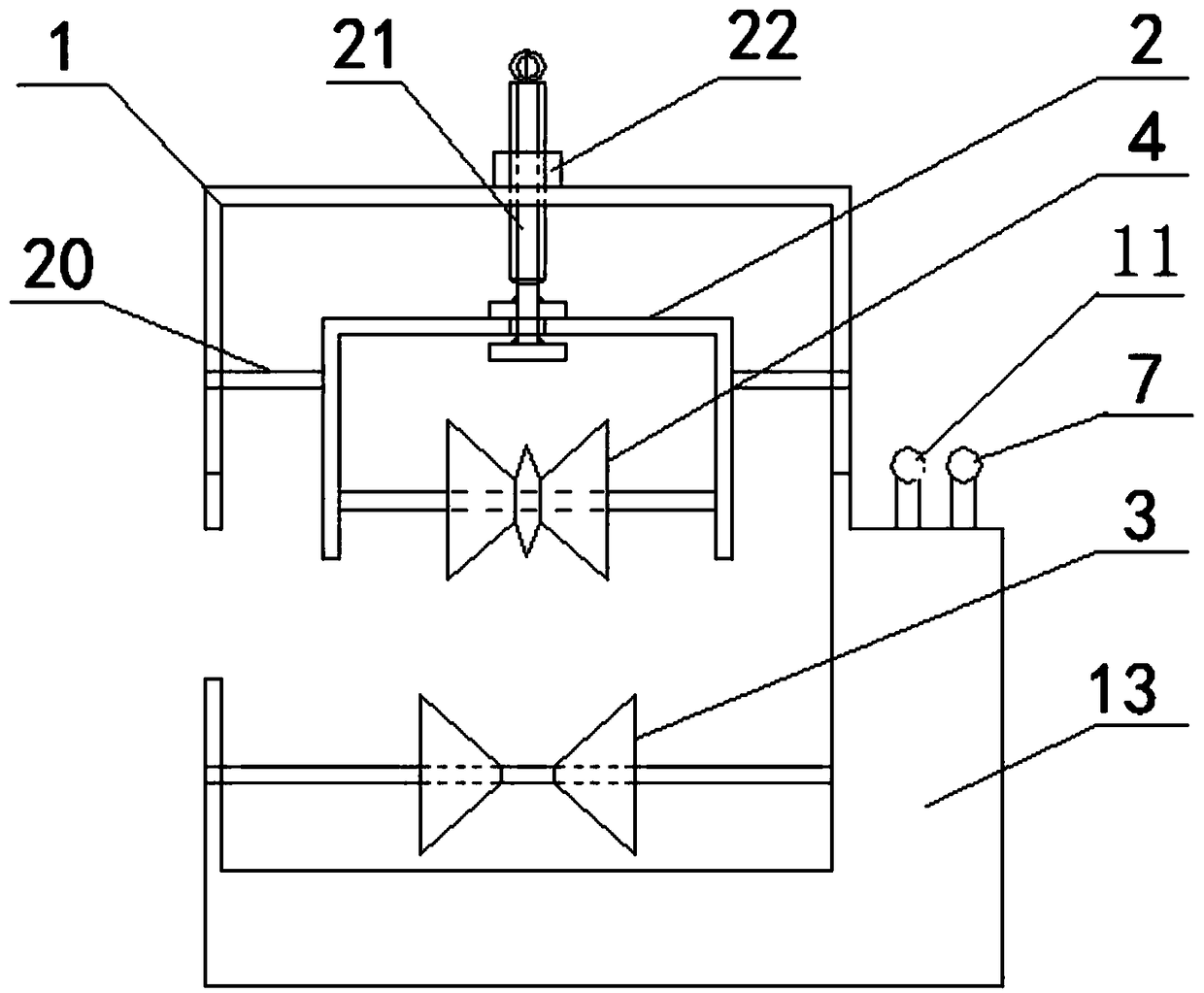

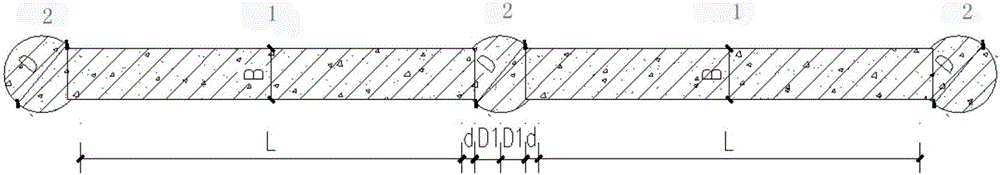

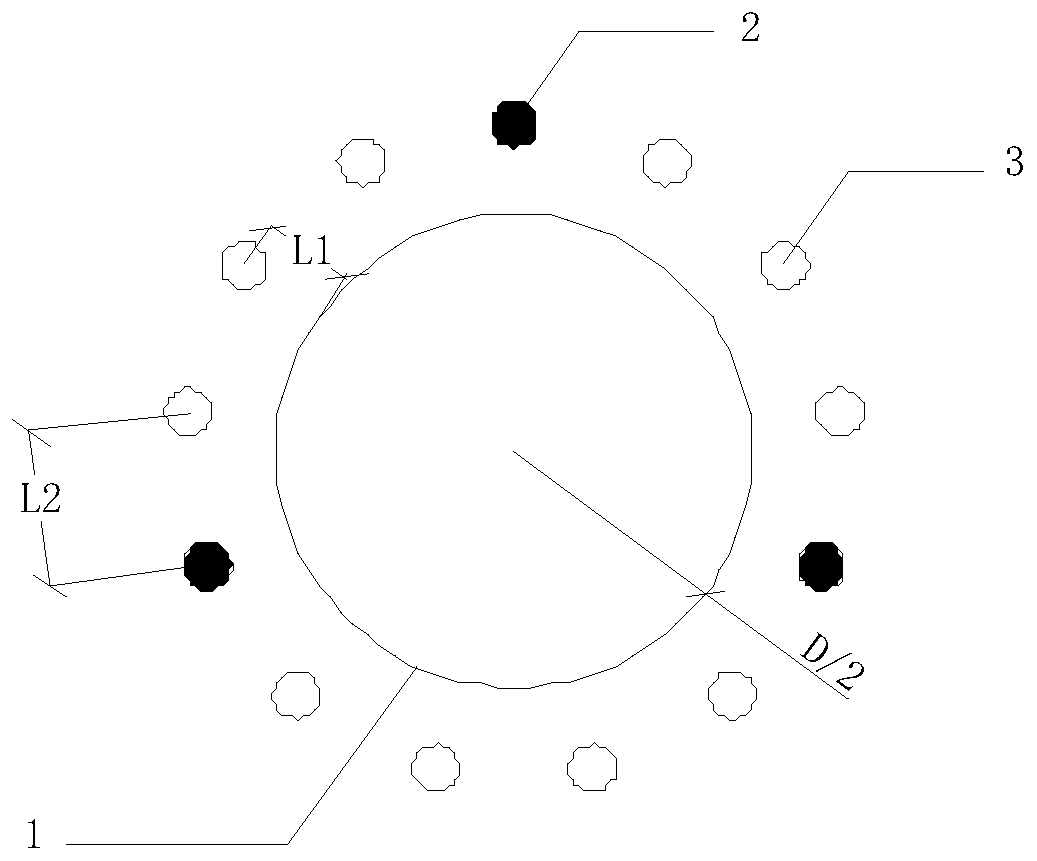

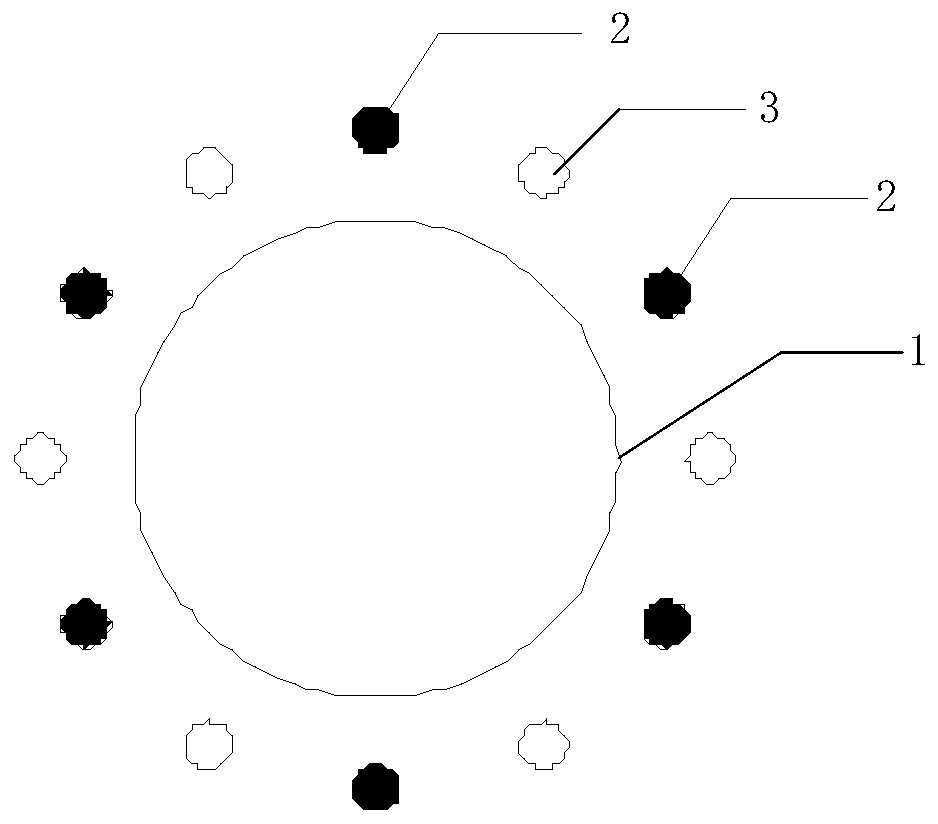

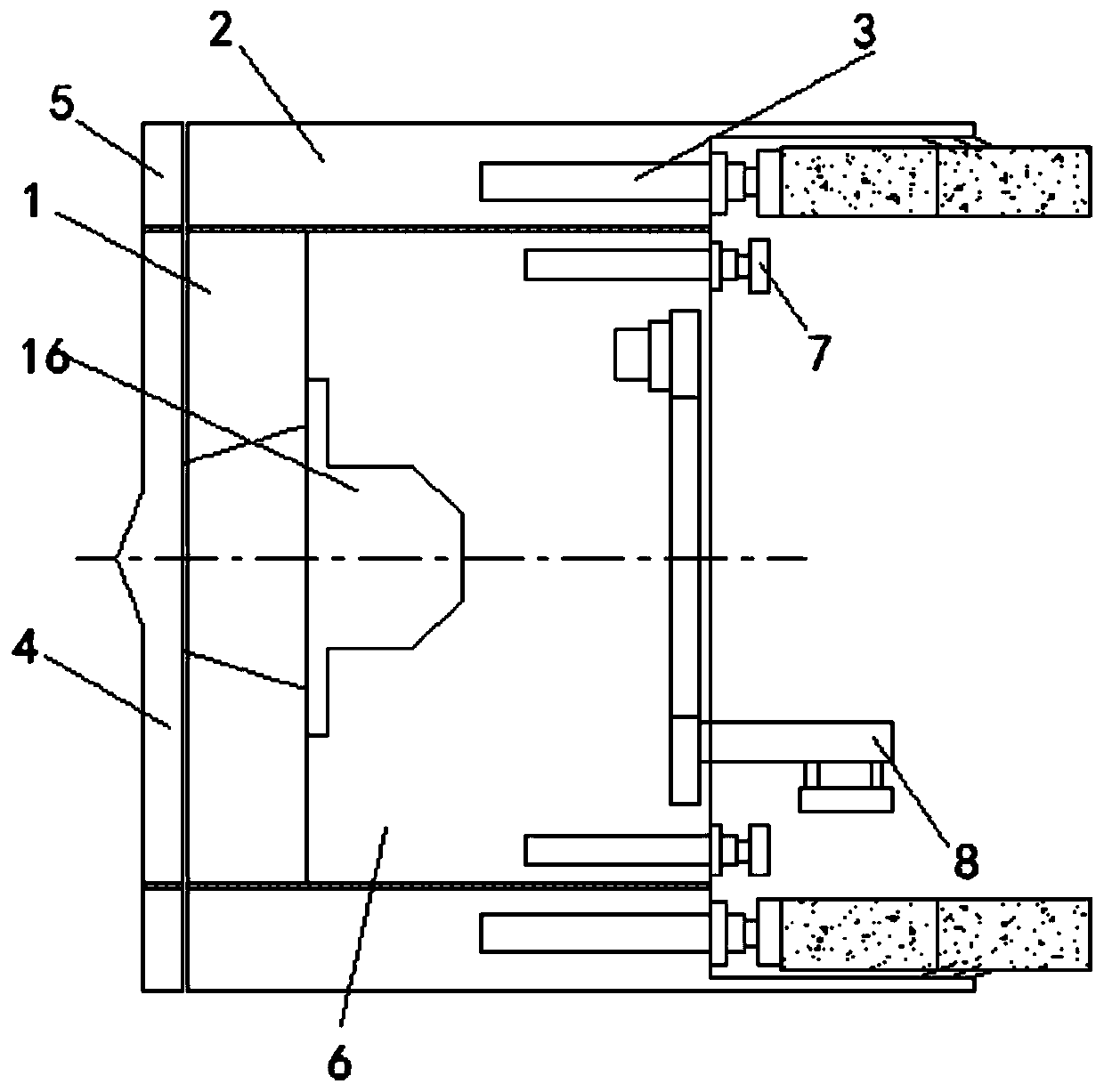

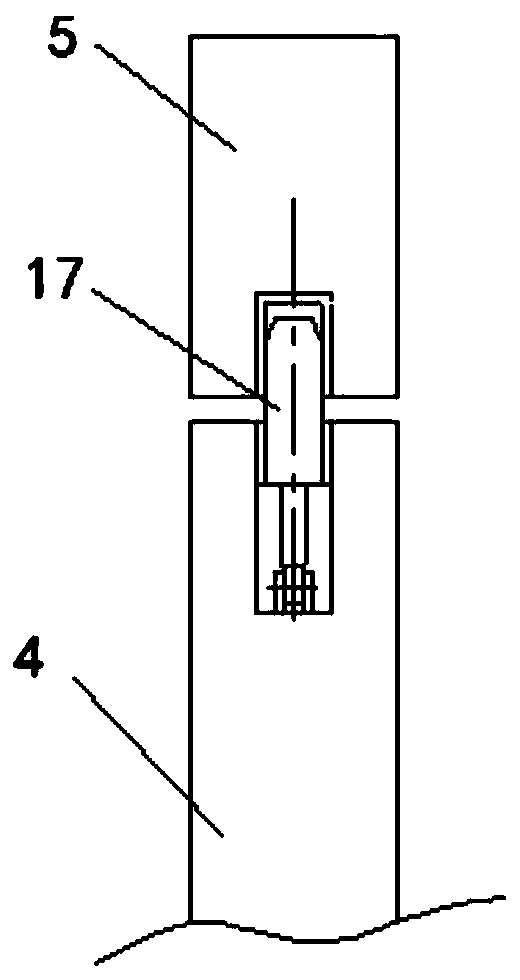

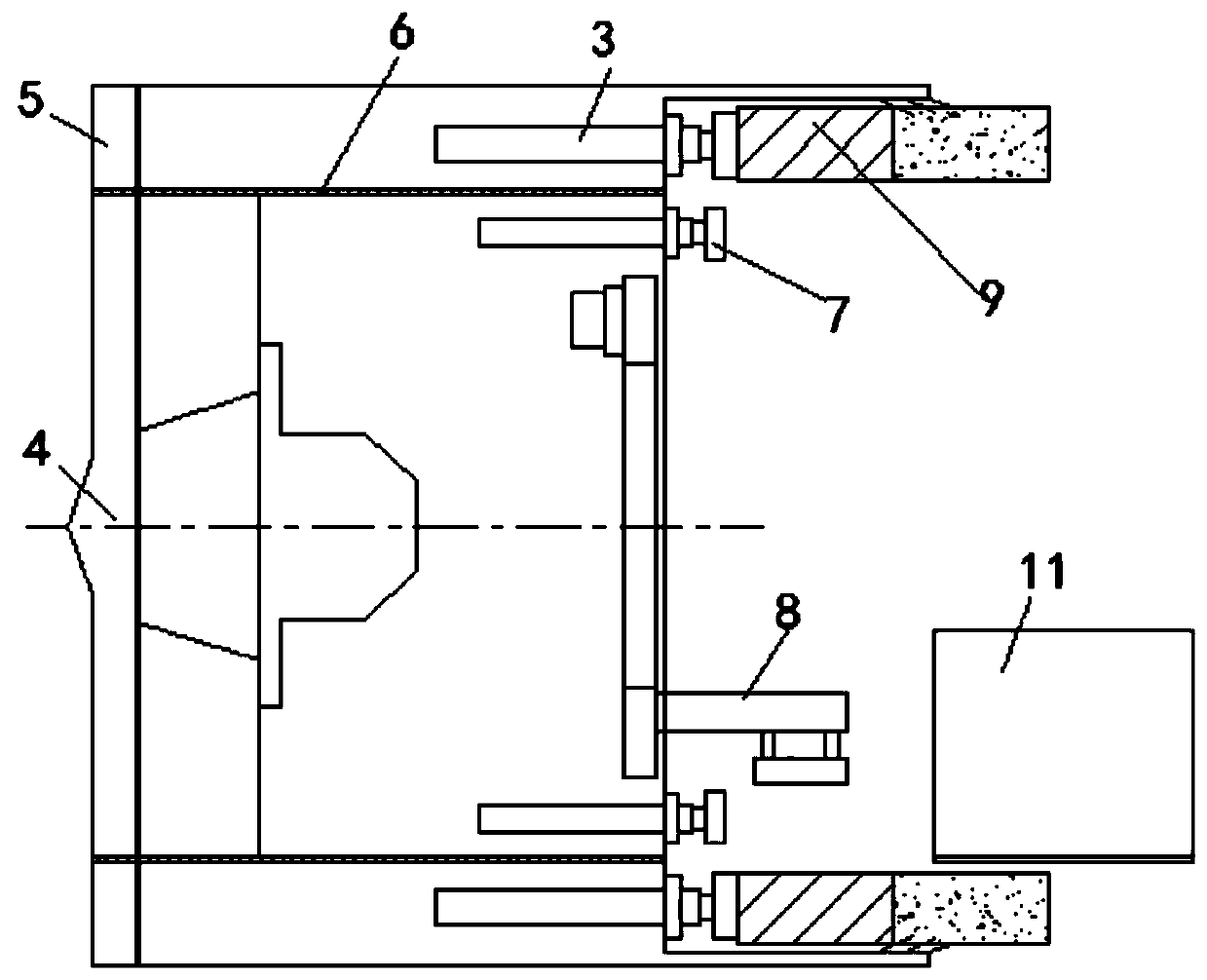

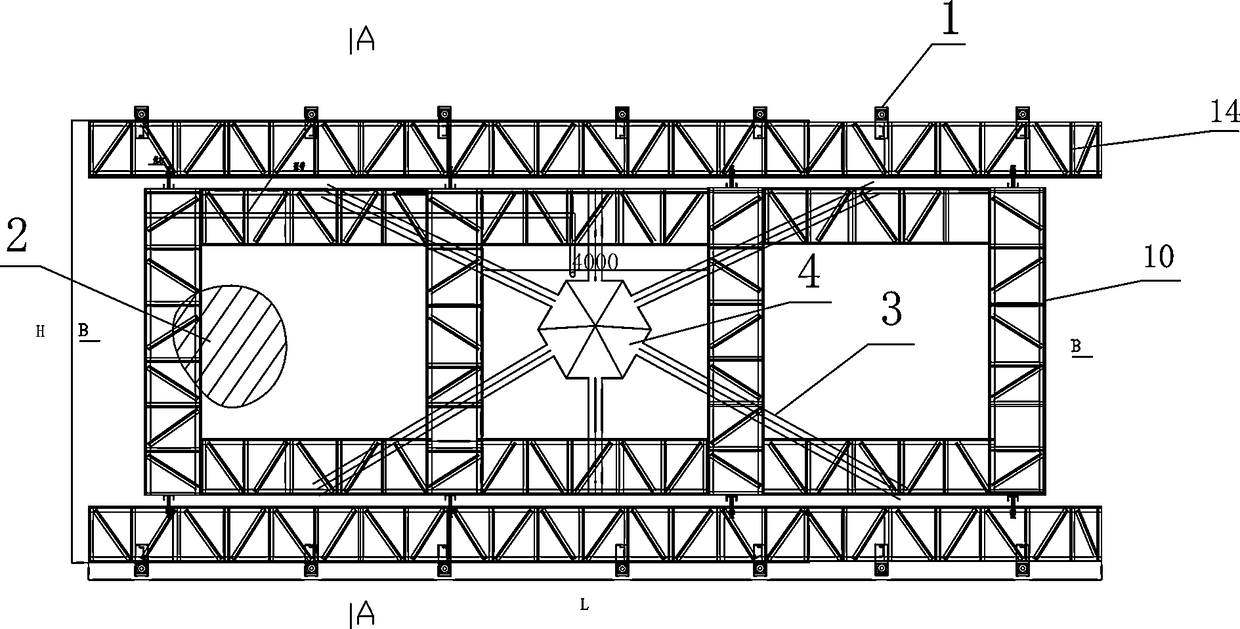

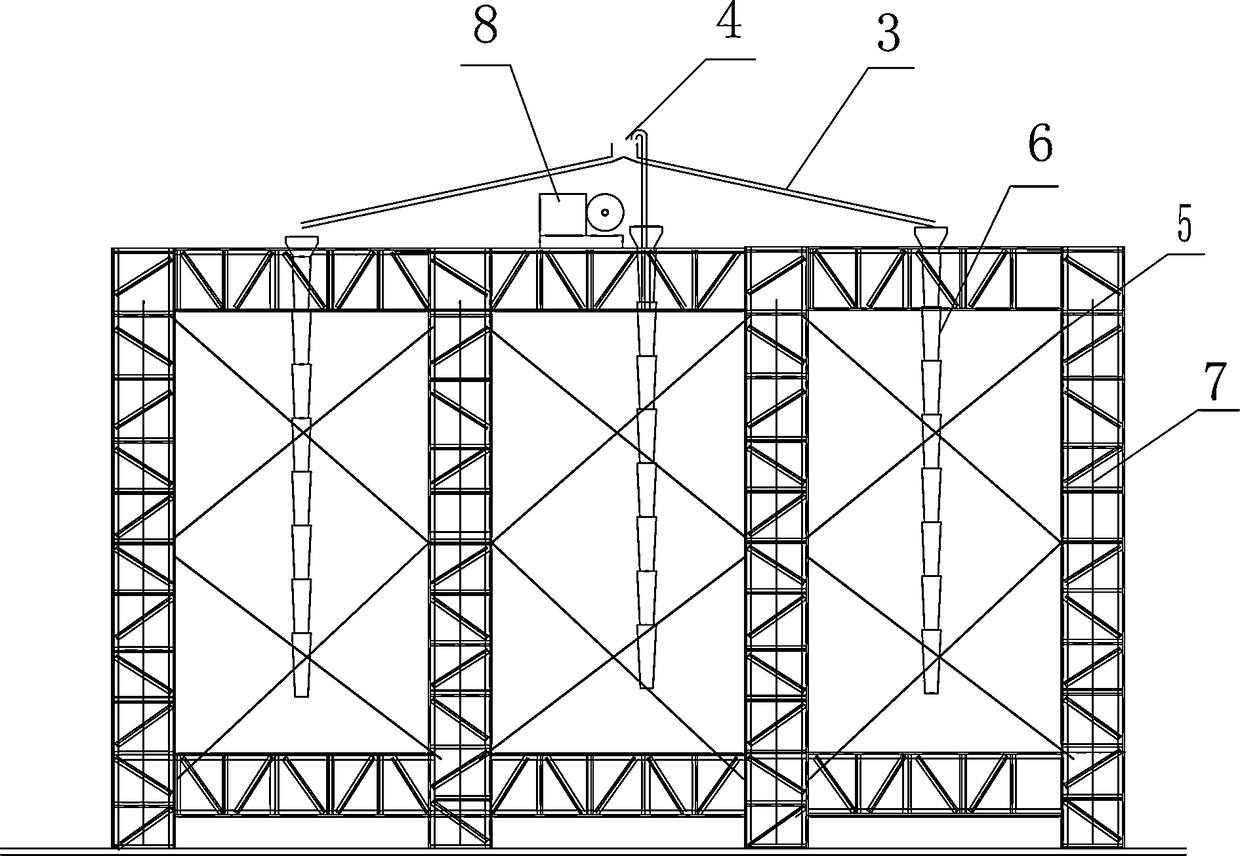

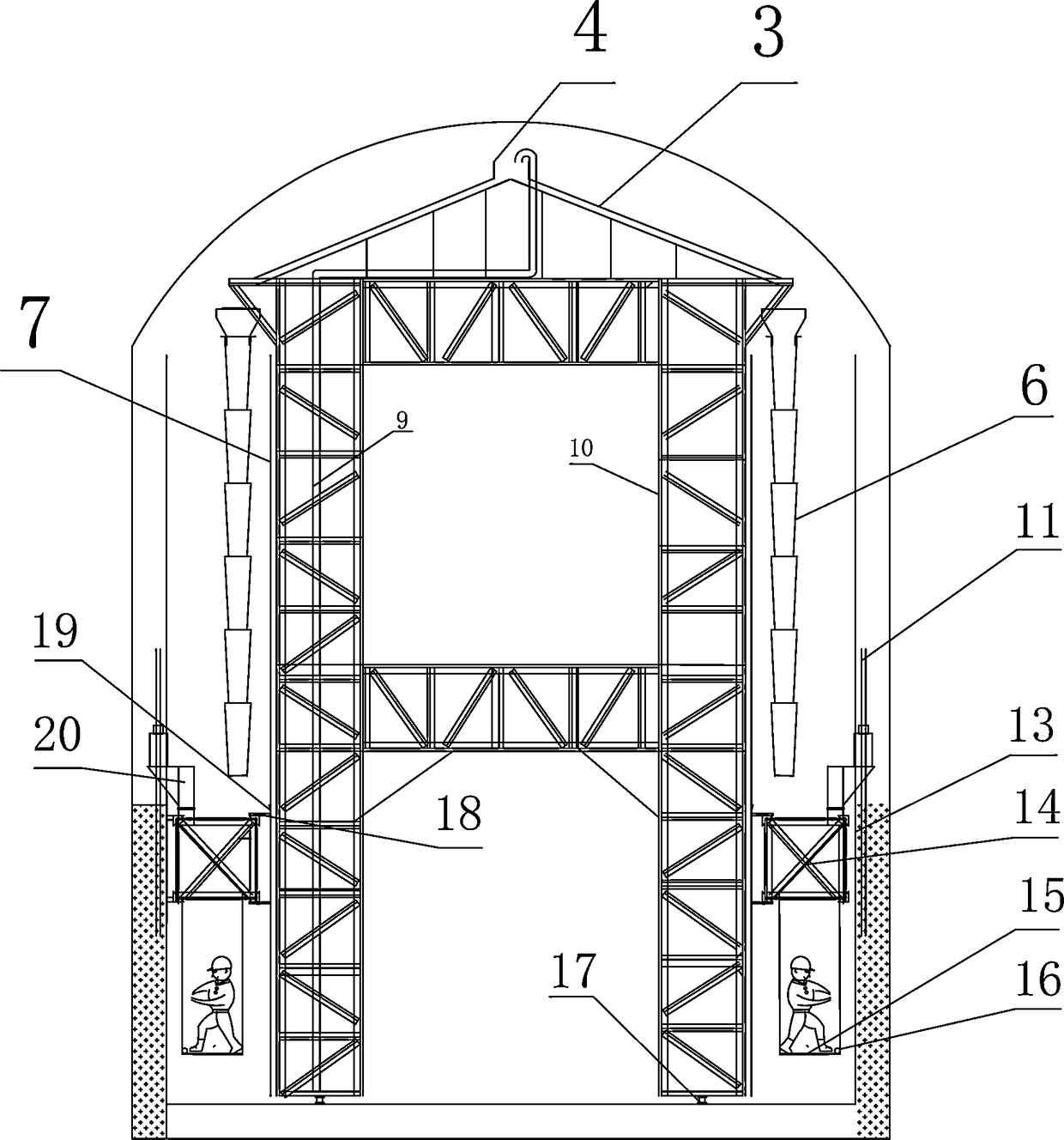

Variable diameter shield construction device and construction method thereof

PendingCN110185460AContinuous constructionSave timeUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention discloses a variable diameter shield construction device. The variable diameter shield construction device includes a shield tunneling machine main machine (1), the external circumference of the shield tunneling machine main machine (1) is provided with a ring-shaped sleeve (2), the ring-shaped sleeve (2) is provided with a large diameter shield push jack (3), the front end of the shield tunneling machine main machine (1) is provided with an inner circle cutter (4), the front end of the ring-shaped sleeve (2) is provided with an external circle cutter (5), and the inner circle cutter (4) and the external circle cutter (5) are concentrically arranged on the same horizontal plane and movably connected. The invention further discloses a construction method of the variable diameter shield construction device, the variable diameter shield construction device is a shield tunneling machine which can change diameters in the process of construction, working wells do not need to bearranged, the construction cost can be greatly saved, and working periods can be greatly shortened.

Owner:江苏格睿特管网工程有限公司

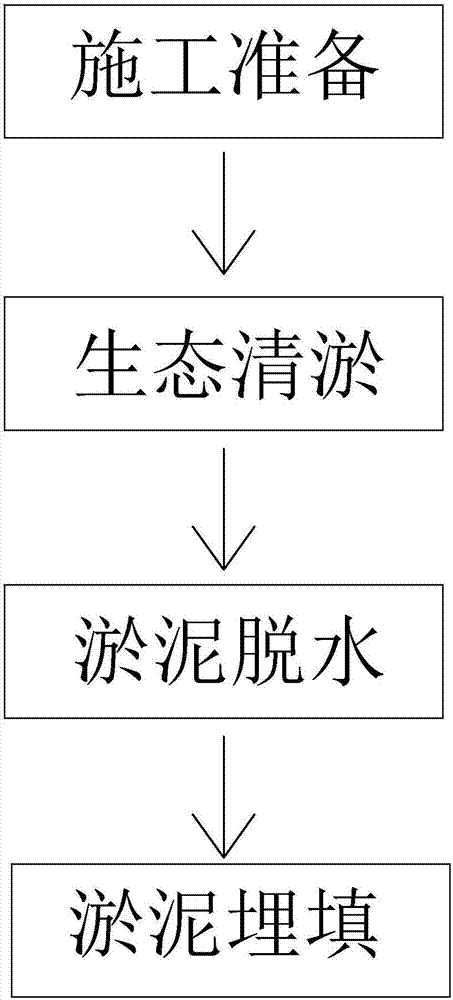

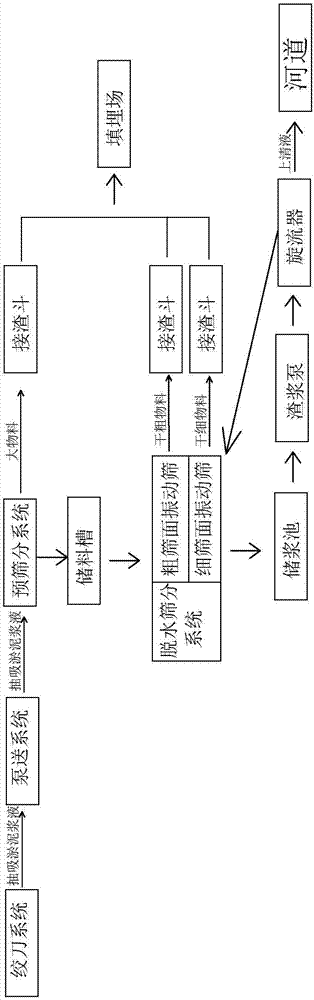

Integrated construction process of ecological dredging and synchronous sludge dehydrating

InactiveCN106884451AAvoid damageTo achieve the purpose of dredgingSoil-shifting machines/dredgersSludgeWater source

The invention discloses an integrated construction process of ecological dredging and synchronous sludge dehydrating. The construction process comprises the following steps of construction preparation, ecological dredging and sludge dehydrating. The river bottom is stirred through a reamer system in a dredger to form sludge slurry, a pumping system in the dredger conveys the sludge slurry to a screening device through a conveying pipeline to conduct sludge dehydrating treatment, and the purpose of dredging is achieved. In the construction process, the construction mode of dredging with water is adopted, so that water changing or water source adding is not needed in the dredging process; by means of the sludge dehydrating treatment through the screening device, the solid content of supernatant liquor is low, so that when the supernatant liquor returns back to a river, secondary pollution is avoided; the water content of dehydrated sludge is about 75%, and the dehydrated sludge can be subjected to landfill directly, so that the secondary pollution of the sludge containing a large quantity of sewage on the environment in the outward transporting process and follow-up treating process is avoided and reduced effectively; and compared with a traditional water-drained dredging method, by dredging with the water, damage to river ecology is reduced while the sludge is treated effectively.

Owner:王兵

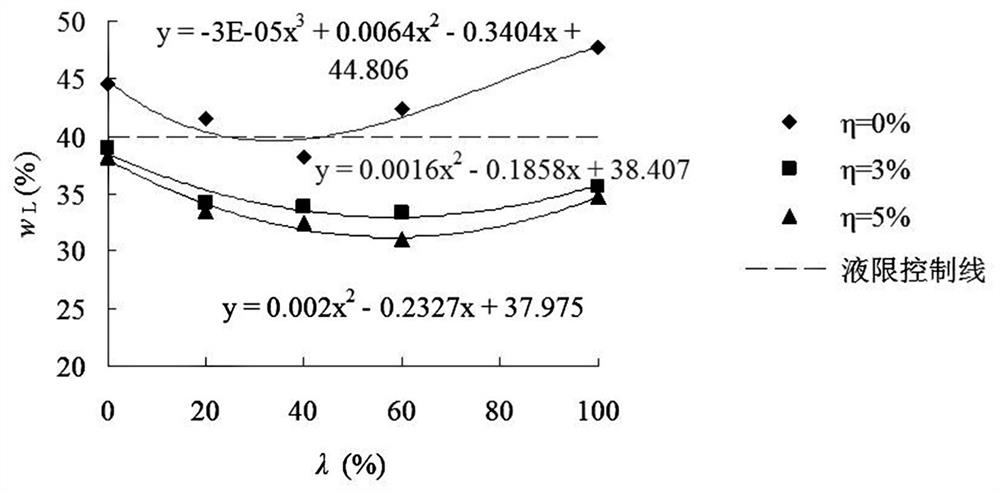

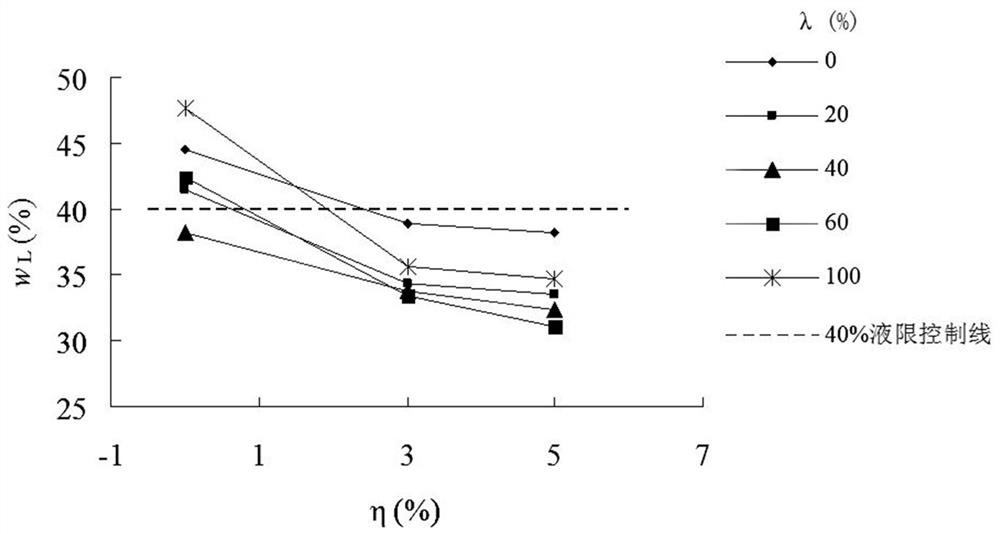

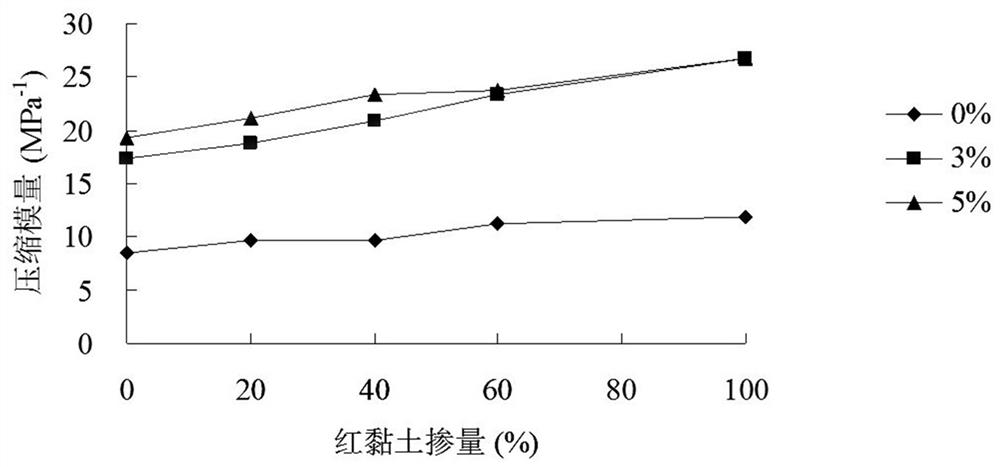

Method for improving fully-weathered phyllite by compounding red clay and cement

ActiveCN113526913ASatisfy fillingLower liquid limitRoadwaysSolid waste managementSoil scienceChemistry

The invention relates to a method for improving fully-weathered phyllite by compounding red clay and cement. The method specifically comprises the following steps: adding dry red clay with the mass of m1 and cement with the mass of m2 into fully-weathered phyllite with the mass of m0 for compounding and improving; and forming a C-group filler mixed filler with liquid limit less than 40%, safety factor of real-time ultimate bearing capacity of subgrade surface after rolling compaction beingnot less than 2, settlement less than 15mm and foundation coefficient K30 not less than 130MPa / m, wherein the blending ratio of red clay in the mixed filler ranges from 25.7% to 60%, and the blending ratio of cement in the mixed filler ranges from 3% to 5%. According to the present invention, the optimal blending ratio scheme is provided according to the requirements of common railways and high-speed railways, and the two special soils such as the red clay and the completely-weathered phyllite can be completely utilized, so that the liquid limit and the settlement amount of the completely-weathered phyllite can be reduced, and the safety coefficient of the ultimate bearing capacity and the foundation coefficient K30 can be improved; and the D-group filler is changed into the C-group filler, and the requirements of various indexes of the roadbed can be met.

Owner:EAST CHINA JIAOTONG UNIVERSITY

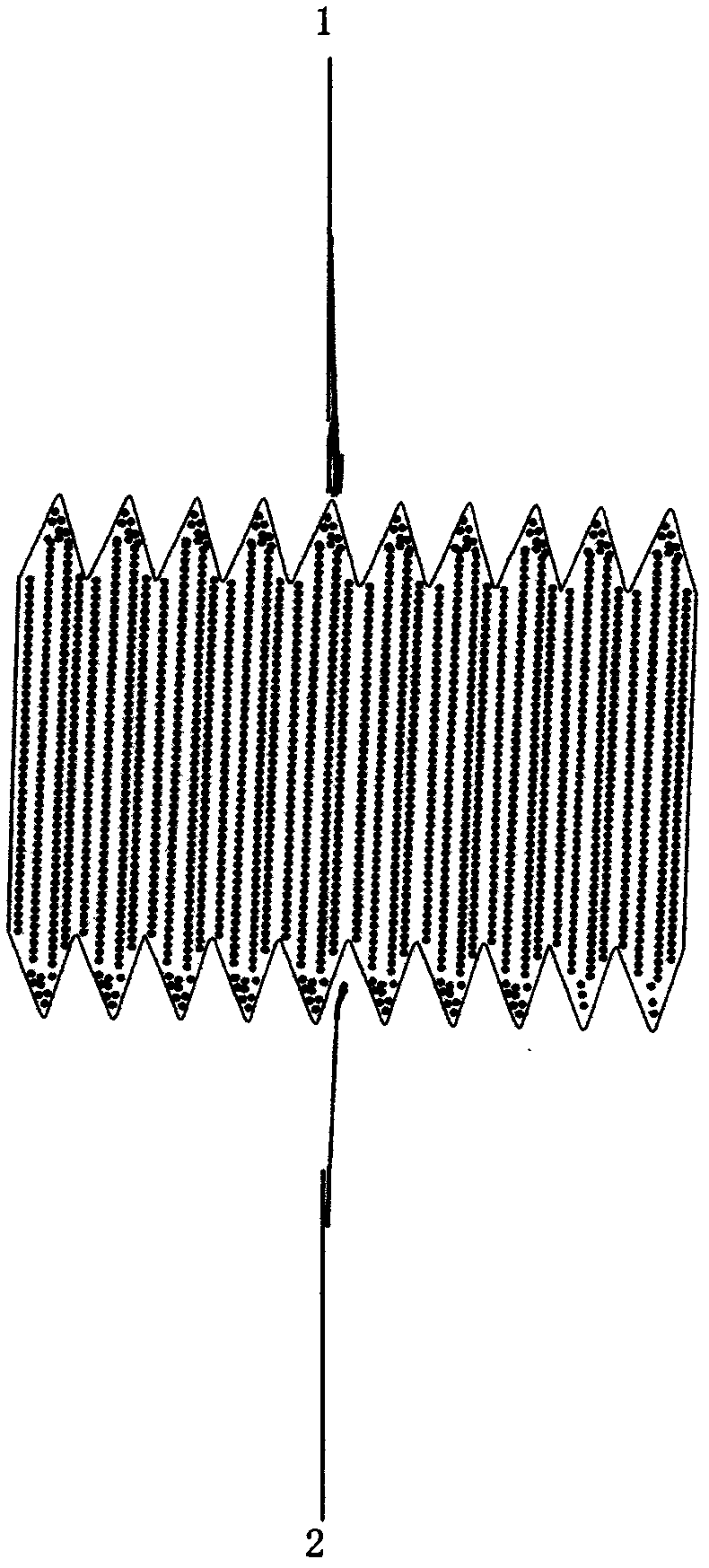

Right-sawtooth-type concrete wall block

InactiveCN103015607AHigh strengthLow costCeramic shaping apparatusBuilding componentsPunchingHigh pressure

The invention discloses a right-sawtooth-type concrete wall block. According to the invention, a right-sawtooth-type mold is manufactured by using a steel mold; reinforcement steel bars are braided into the right-sawtooth-type shape, and are flatly paved in the mold. Well mixed concrete is then poured into the mold, and is flattened and compacted by using a vibrating machine. Or, concrete and reinforcement steel bars are placed into the right-sawtooth-type mold, and the right-sawtooth-type construction wall block can be manufactured by punching by using a high-pressure punching machine. With the above methods, the concrete wall block with the right-sawtooth-type shape can be manufactured.

Owner:李义厚

Steel mold trolley for tunnel side wall concrete lining

PendingCN109139056ASolve the disadvantage that the height change part cannot be usedSolve the disadvantages that cannot be usedUnderground chambersTunnel liningDefect repairEngineering

Owner:CHINA INTERNATIONAL WATER & ELECTRIC CORPORATION +2

Hooked-type concrete wall block

The invention discloses a hooked-type concrete wall block. According to the invention, a hooked-type mold is manufactured by using a steel mold; reinforcement steel bars are braided into the hooked-type shape, and are flatly paved in the mold. Well mixed concrete is then poured into the mold, and is flattened and compacted by using a vibrating machine. Or, concrete and reinforcement steel bars are placed into the hooked-type mold, and the hooked-type construction wall block can be manufactured by punching by using a high-pressure punching machine. With the above methods, the concrete wall block with the hooked-type shape can be manufactured.

Owner:李义厚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com