Integrated construction process of ecological dredging and synchronous sludge dehydrating

A construction technology and sludge technology, which is applied in the field of integrated construction technology of ecological dredging and synchronous sludge dewatering, can solve the problems of low construction efficiency, non-processed operation mode, and surrounding environmental pollution, and achieves a high degree of mechanization and automation. Destruction of river ecology and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

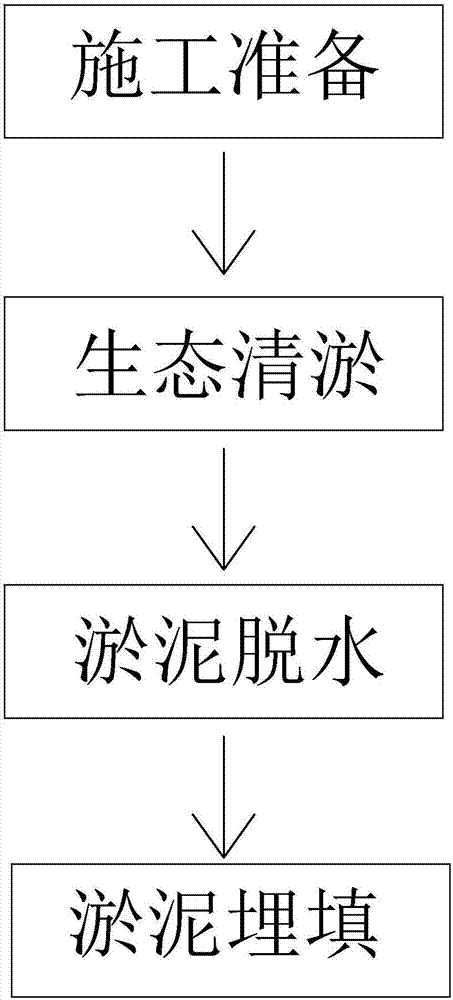

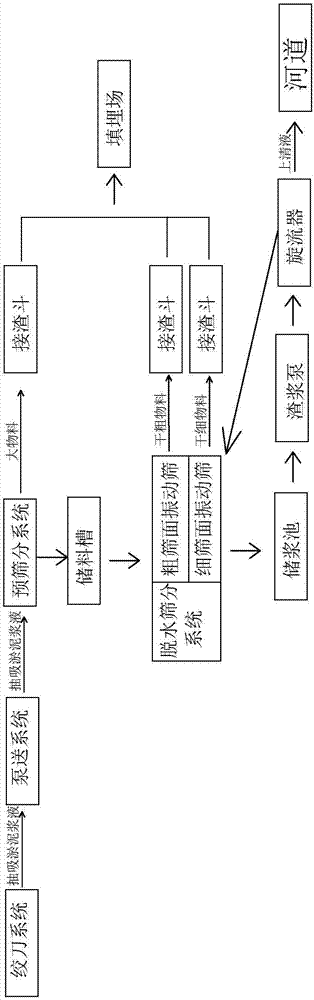

[0038] like Figure 1-2 As shown, the present invention is an integrated construction process of ecological dredging and synchronous sludge dehydration, wherein the dredger is equipped with a reamer system, a pumping system and a trolley propulsion system, and the reamer system is used to stir the river bottom silt , forming high-concentration sludge slurry, the pumping system is used for suction and discharge of sludge slurry, it can handle high-concentration slurry (maximum volume concentration can reach 30%), and pass through large-diameter particles (maximum particle diameter can reach 82mm), trolley The propulsion system is used to drive the dredger to move the dredger on the river;

[0039] The screening device includes a pre-screening system and a dehydration screening system. The pre-screening system and the dehydration screening system are respectively connected with a slag receiving hopper. The pre-screening system is used for screening materials larger than 15mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com