Special roof-spraying waterproof material

A technology of waterproof materials and raw materials, applied in the direction of anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problems of poor UV resistance and aging resistance, unsuitable for roof spraying and waterproofing, etc., and achieve good fatigue resistance and follow-up performance. Strong adaptability to interface deformation and cracking, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

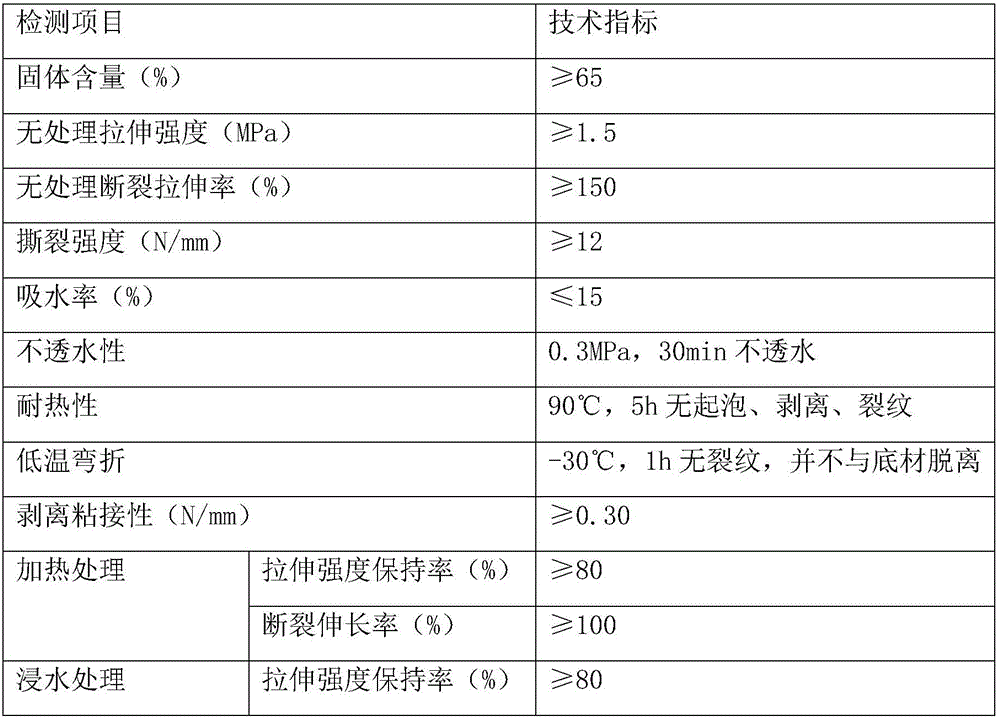

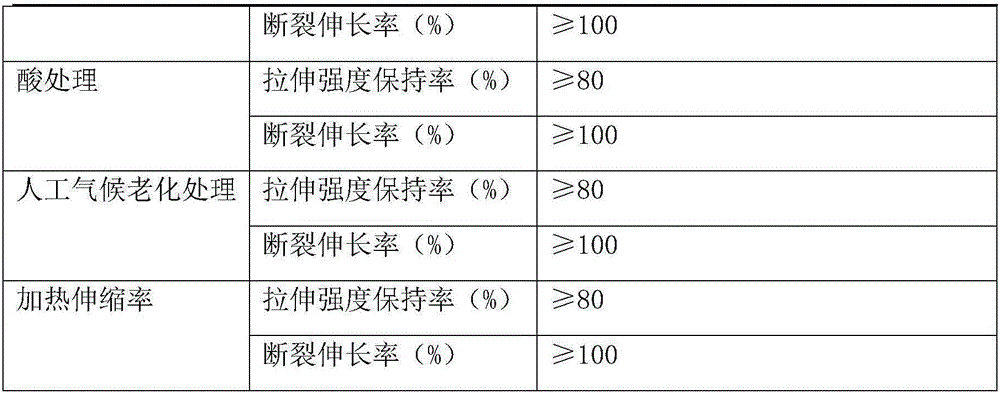

Image

Examples

Embodiment 1

[0013] 450 parts of acrylic emulsion, 100 parts of silica powder, 350 parts of calcite powder, 50 parts of rutile titanium dioxide, 40 parts of deionized water, 3 parts of dispersant, 3 parts of defoamer, 2 parts of preservative, 1 part of UV absorber, anti-aging 1 part; mix silicon powder, calcite powder, rutile titanium dioxide, deionized water, dispersant, defoamer, preservative, ultraviolet absorber, and anti-aging agent at high speed and mix well, then add acrylic emulsion at low speed and mix well Get it by filtering.

Embodiment 2

[0015] 400 parts of acrylic emulsion, 50 parts of aliphatic waterborne polyurethane emulsion, 100 parts of silica powder, 350 parts of calcite powder, 50 parts of rutile titanium dioxide, 40 parts of deionized water, 3 parts of dispersant, 3 parts of defoamer, 2 parts of preservative , 1 part of ultraviolet absorber, 1 part of anti-aging agent; mix silicon powder, calcite powder, rutile titanium dioxide, deionized water, dispersant, defoamer, preservative, ultraviolet absorber, and anti-aging agent at high speed and mix well, then Add acrylic emulsion and aliphatic waterborne polyurethane emulsion at low speed, mix well and filter.

Embodiment 3

[0017] 400 parts of acrylic emulsion, 50 parts of water-based epoxy resin emulsion, 100 parts of microsilica powder, 350 parts of calcite powder, 50 parts of rutile titanium dioxide, 40 parts of deionized water, 3 parts of dispersant, 3 parts of defoamer, 2 parts of preservative , 1 part of ultraviolet absorber, 1 part of anti-aging agent; mix silicon powder, calcite powder, rutile titanium dioxide, deionized water, dispersant, defoamer, preservative, ultraviolet absorber, and anti-aging agent at high speed and mix well, then Add acrylic emulsion and water-based epoxy resin emulsion at low speed, stir well and filter to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com