Control system for integrated synchronous jacking of cut pier and control method

A technology of integral jacking and synchronous jacking, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of difficult continuous monitoring, discontinuous lifting of cutting piers, unbalanced height difference exceeding the limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

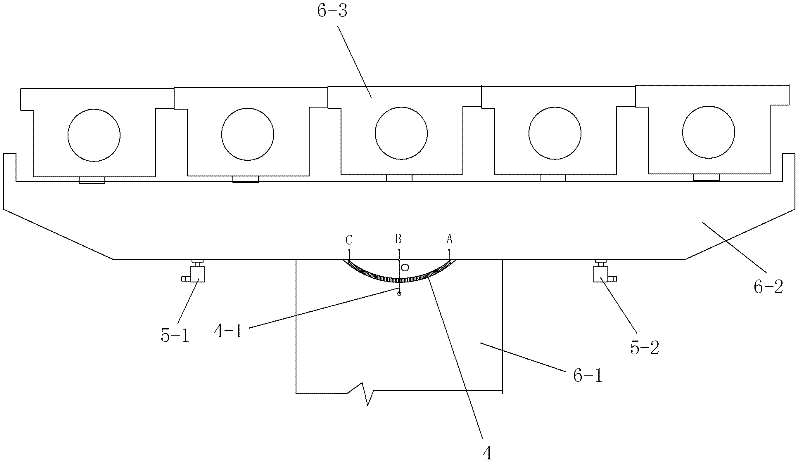

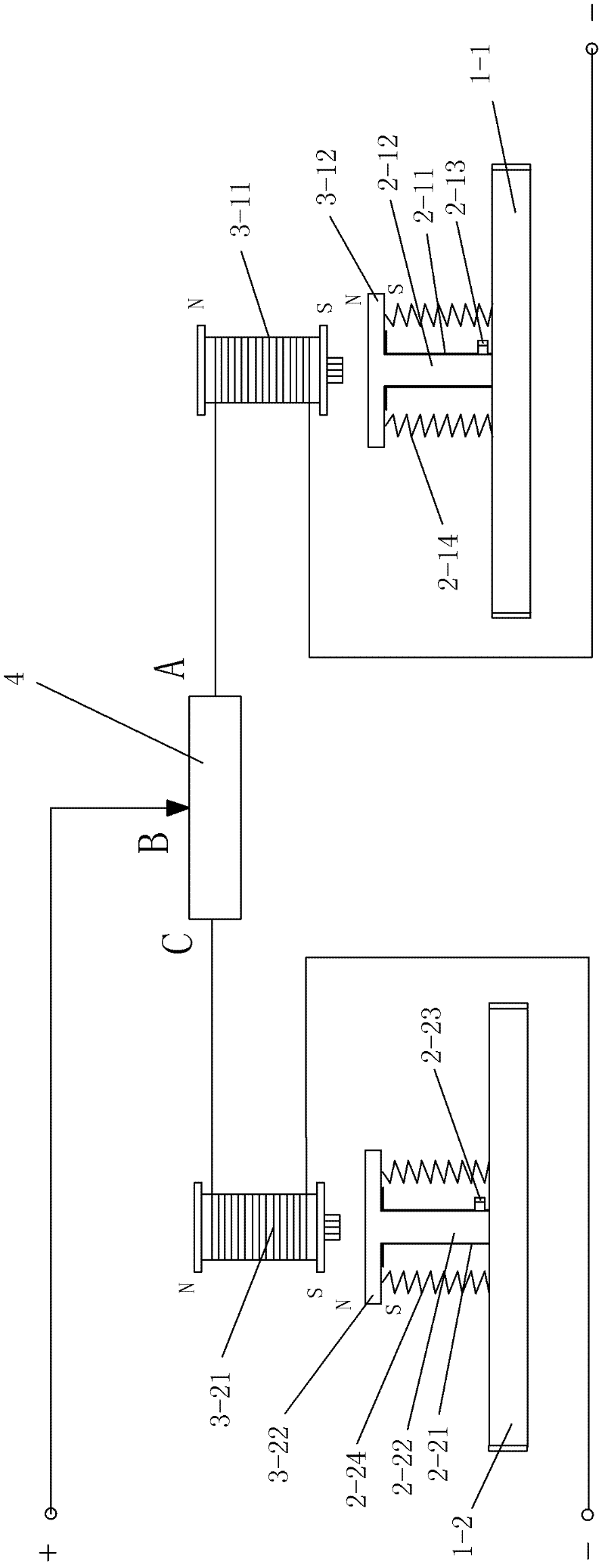

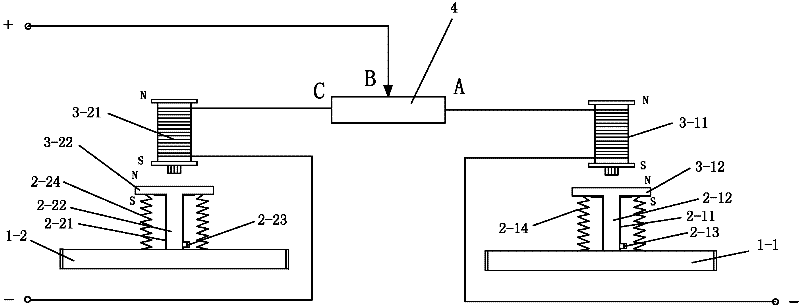

[0052] like figure 1 , figure 2 As shown, the overall synchronous jacking control system for cutting bridge piers according to the present invention includes two hydraulic jacking devices for providing jacking power and for jacking up the entire bridge structure that needs to be jacked up horizontally as a whole. The two hydraulic circuits connected to the hydraulic jacking device, the two oil intake adjustment devices installed on the two hydraulic circuits respectively, and the balance state of the bridge structure that needs to be lifted as a whole during the jacking process are carried out in real time. A jacking balance state monitoring device for monitoring and correspondingly controlling the two oil intake adjustment devices according to the monitoring results.

[0053] The two hydraulic jacking devices are respectively a hydraulic jacking device 1 and a hydraulic jacking device 2 which are symmetrically supported under the left and right sides of the bridge structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com