Patents

Literature

31results about How to "Eliminate subjective errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

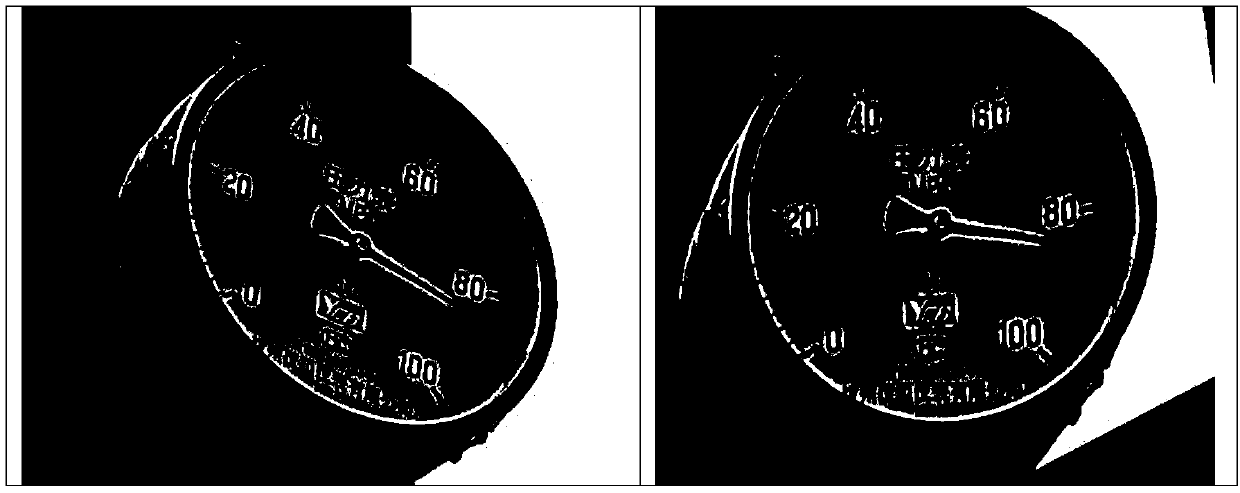

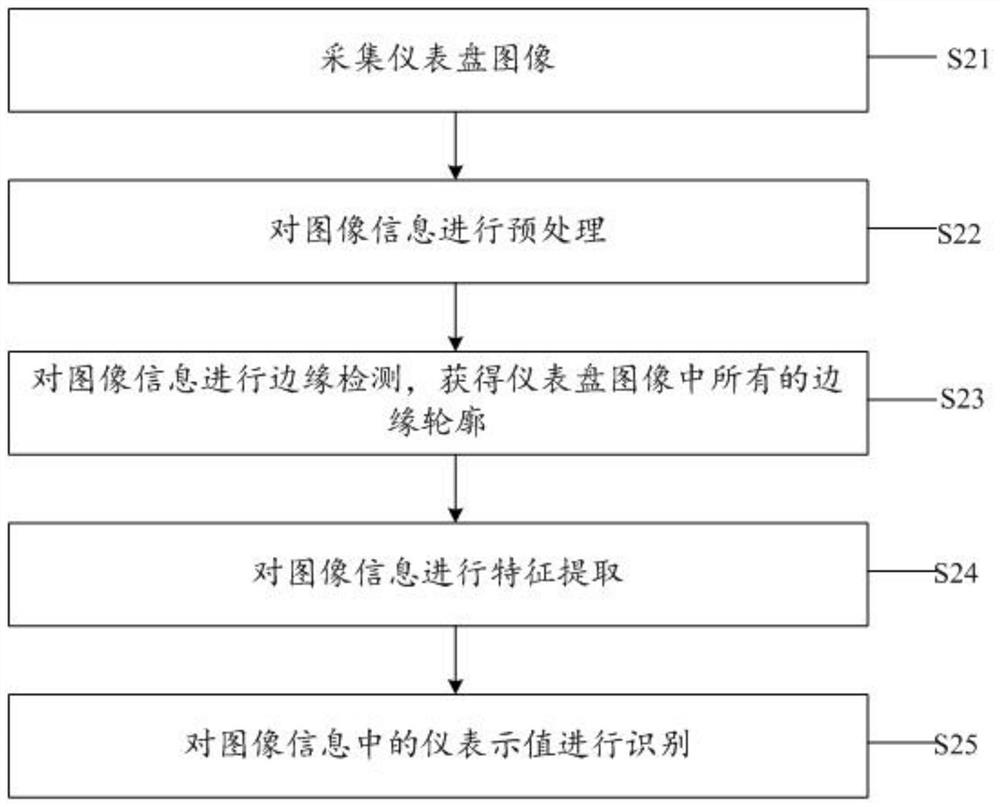

Image processing method for automatic pointer-type instrument reading recognition

ActiveCN104392206ASmall amount of calculationHigh positioning accuracyCharacter and pattern recognitionTemplate matchingImaging processing

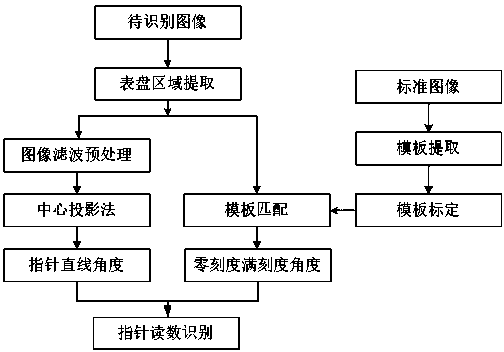

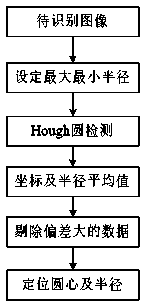

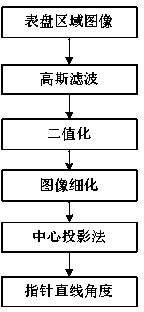

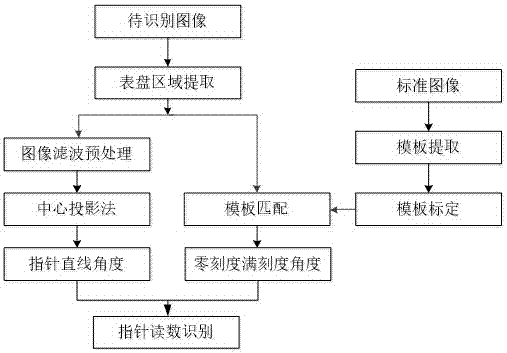

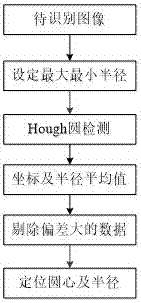

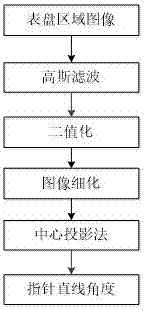

The invention discloses an image processing method for automatic pointer-type instrument reading recognition. The method comprises the following steps: (1) Hough circle detection is carried out on the image, a weighted average method is used for positioning the circle center and the radius of a dial, and a dial region square image is extracted; (2) the image is pre-treated, and a binary thinning image of the instrument pointer is extracted; (3) a central projection method is used for determining a pointer angle; (4) a zero graduation line and full graduation line position templates are extracted, and a range starting point and ending point positions are calibrated; (5) by using template matching, zero graduation line and full graduation line angles are obtained; and (6) according to the pointer angle, the zero graduation line angle and the full graduation line angle, the pointer reading is obtained through calculation. Thus, the problem that the instrument dial position on the acquired image is not fixed as the relative position between a camera and the pointer-type instrument is not fixed can be solved, subjective errors as the reading of the instrument is read manually can be eliminated, the efficiency and the precision can be improved, safety of people is ensured, the application range is wide, and robustness is strong.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pointer instrument reading identification method

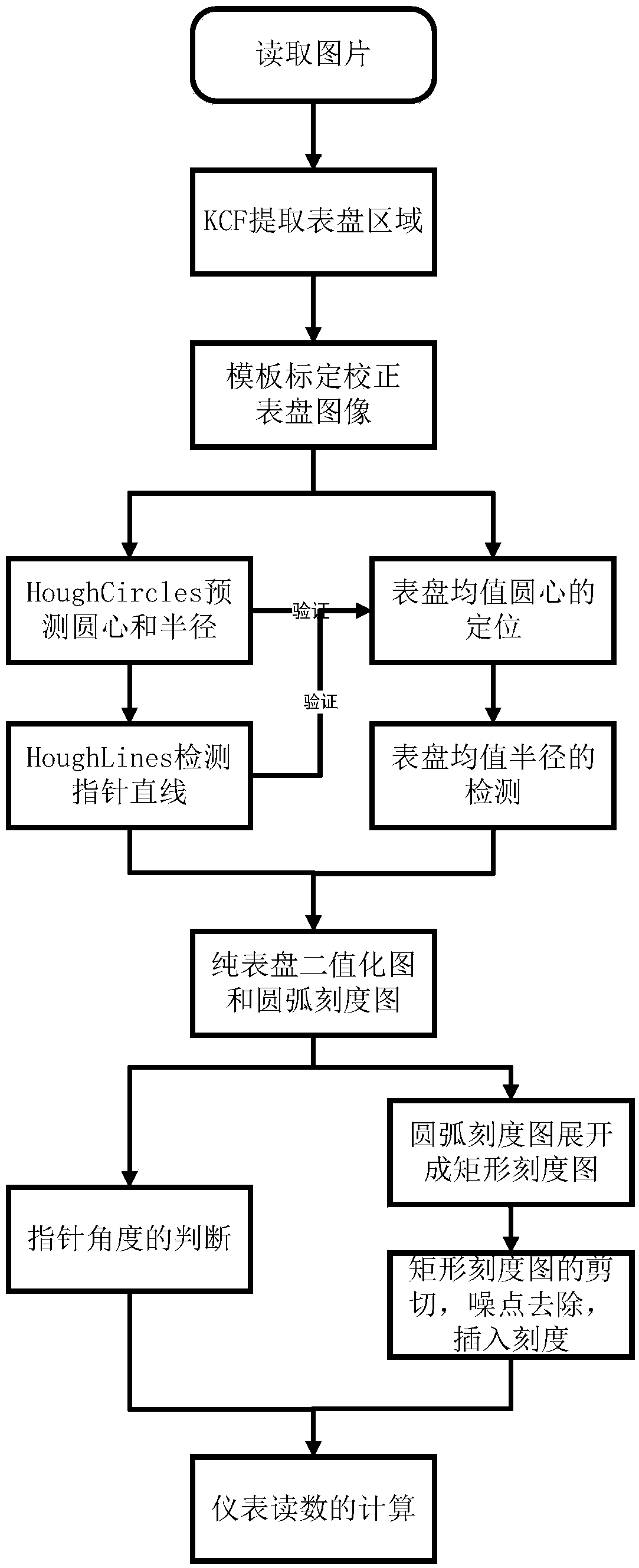

InactiveCN107609557AImprove anti-interference abilityPrevent inversionImage analysisCharacter and pattern recognitionCentroidLinear fitting

The invention discloses a pointer instrument reading identification method. The method comprises the steps of extracting a dial plate, removing interference, and correcting the dial plate by using affine transformation; performing circle detection and straight line detection on the dial plate to obtain predicted circle center and pointer angle; based on features of a scale connected domain on thedial plate, screening out the scale connected domain, performing linear fitting on the scale connected domain, calculating an intersection point of every two fitting straight lines, and performing screening verification on a to-be-selected circle center by utilizing the predicted circle center and pointer angle to obtain the circle center of the dial plate, wherein a distance from the centroid ofthe scale connected domain to the circle center on the dial plate is the radius of the dial plate; and according to information such as the circle center of the dial plate, the radius of the dial plate, the straight lines of a pointer, extracting an arc scale bar of the dial plate, expanding the arc scale bar in a rectangular shape, then according to horizontal coordinate distribution of scale onthe rectangular scale bar, performing minimum and maximum scale detection, noisy point removal and scale insertion, and finally in combination with the pointer angle, calculating reading of the dial plate. The method is high in universality and high in timeliness; and the reading has relatively high accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

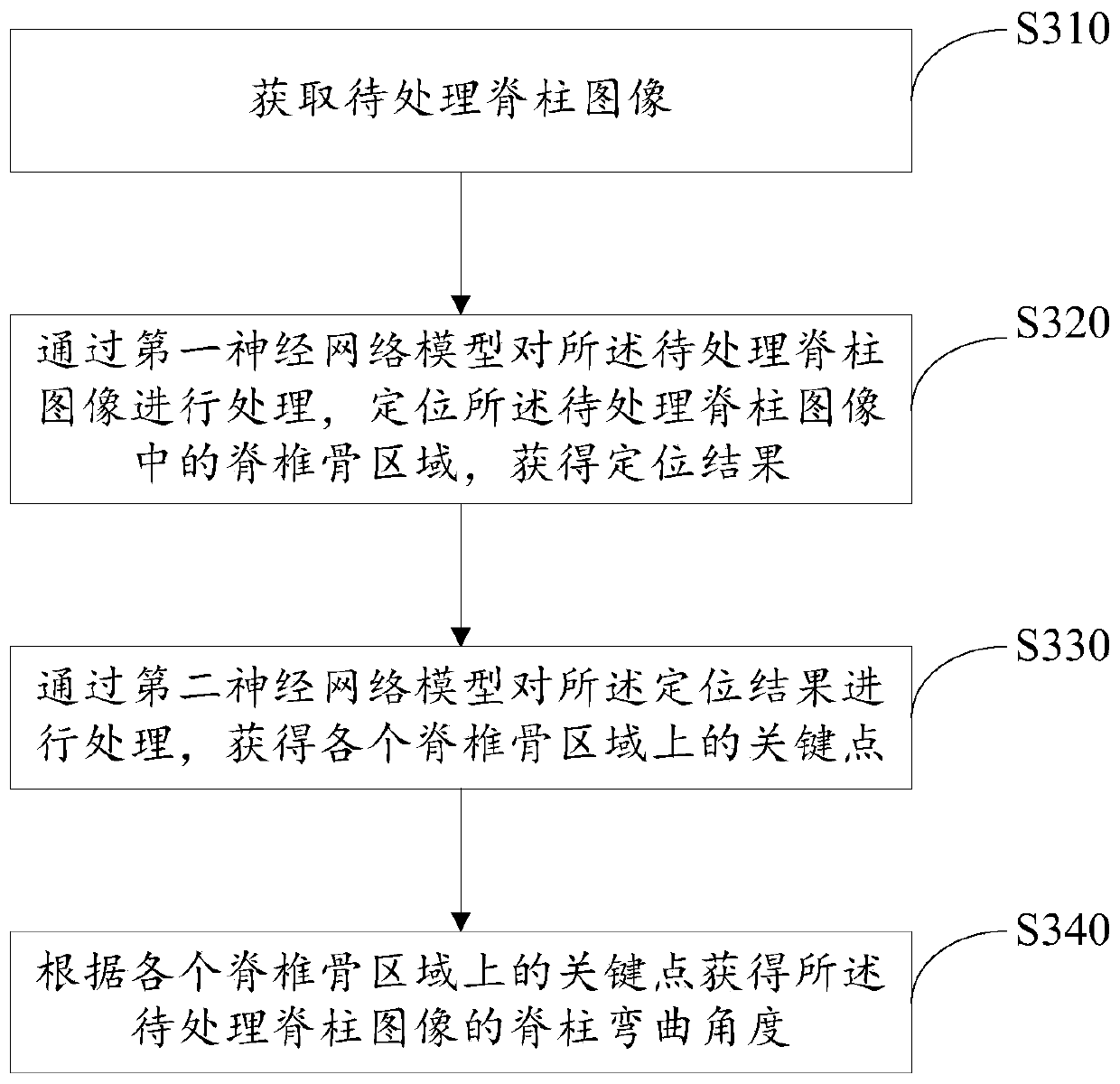

Image processing method and related equipment

InactiveCN110415291AReduce noiseImprove accuracyImage enhancementImage analysisNerve networkCrucial point

The embodiment of the invention provides an image processing method and related equipment, and belongs to the technical field of computers. The method comprises the following steps: acquiring a spineimage to be processed; processing the spine image to be processed through a first neural network model, positioning a vertebra region in the spine image to be processed, and obtaining a positioning result; processing the positioning result through a second neural network model to obtain key points on each vertebra region; and obtaining a spinal curvature angle of the spinal image to be processed according to the key points on each vertebral region. The technical scheme of the embodiment of the invention provides an image processing method, which can improve the measurement accuracy of spinal curvature angle measurement.

Owner:TSINGHUA UNIV +1

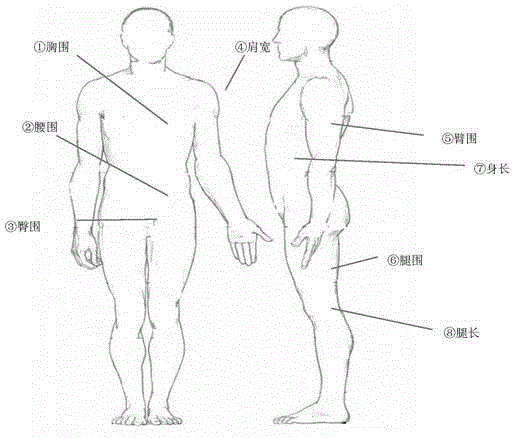

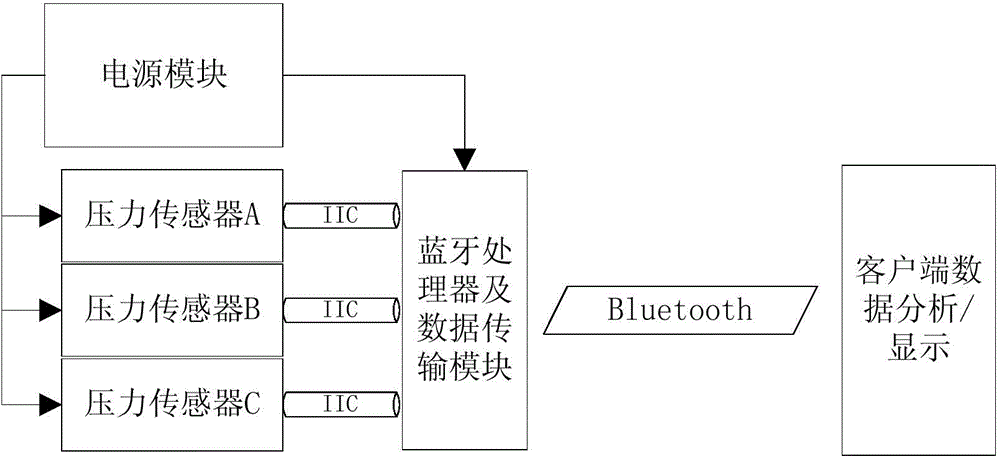

Intelligent garment achieving body data measurement through tension sensors

InactiveCN105982380AImprove science and accuracyEliminate subjective errorsClothes making applicancesTrademarkPull force

The invention relates to an intelligent garment achieving body data measurement through tension sensors. A tight garment is made by taking a macromolecular elastic material as a basic material, some macromolecular elastic material threads are fixed to the portions such as the chest portion and the waist portion of which the sizes are to be measured of the garment, one tension sensor is arranged at the joint of each macromolecular elastic material thread for measurement, and a low-consumption Bluetooth communication chip and a matched circuit thereof are additionally arranged at a garment trademark or corner. When each macromolecular elastic material thread deforms, the corresponding tension sensor connected with the macromolecular elastic material thread can detect the corresponding tension and transmit data to the Bluetooth processor chip for calculation processing. According to the intelligent garment, the electronic equipment bodies responding data measurement are achieved through elastic material deformation characteristic collection; elastic material deformation characteristics can be converted into the corresponding tension data through the tension sensors, the tension data is subjected to calculation processing through the processor and then transmitted to terminal equipment through a Bluetooth transmission technique, and the intelligent garment is achieved through an integrated innovative technique.

Owner:上海卜珑智能科技有限公司

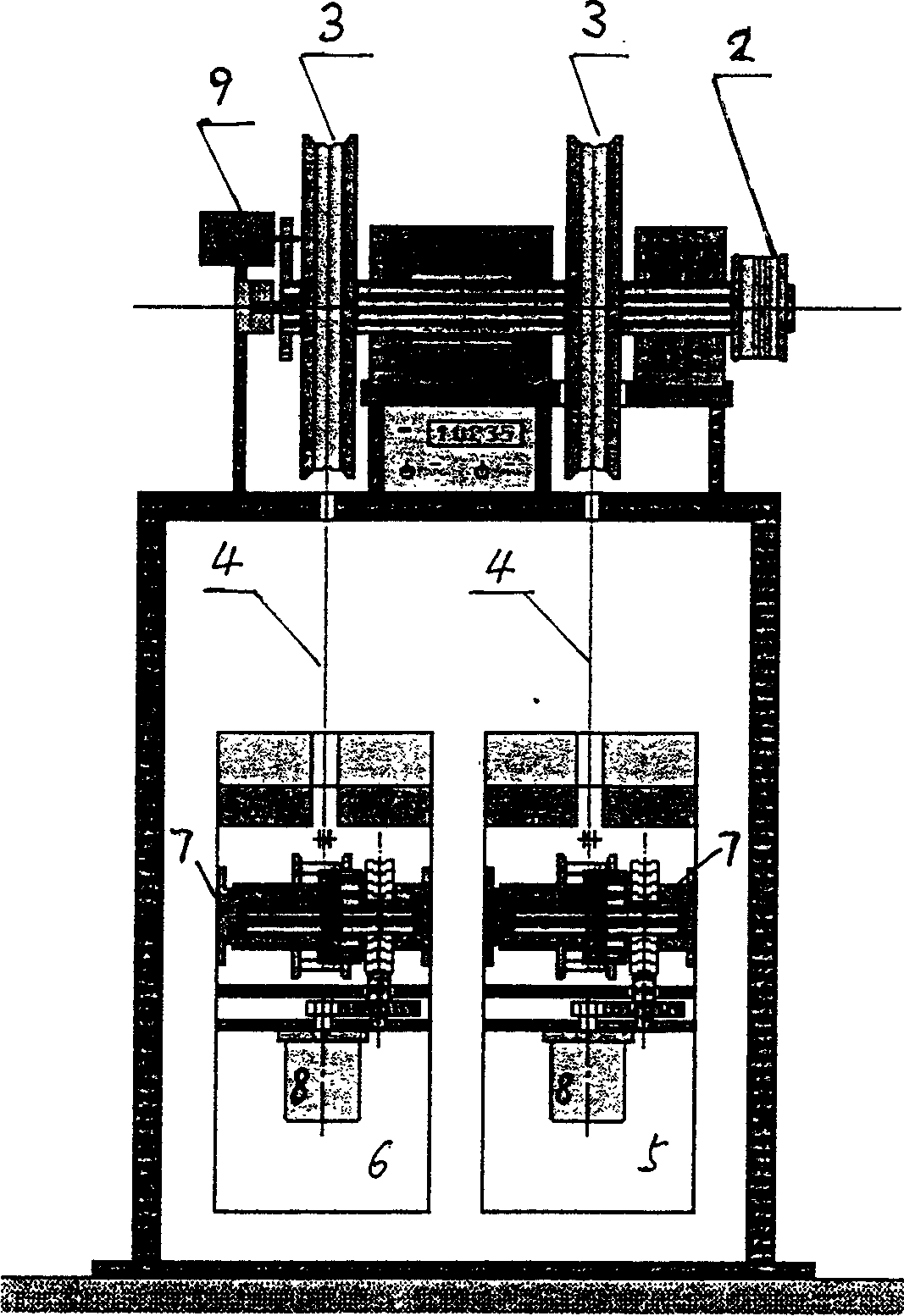

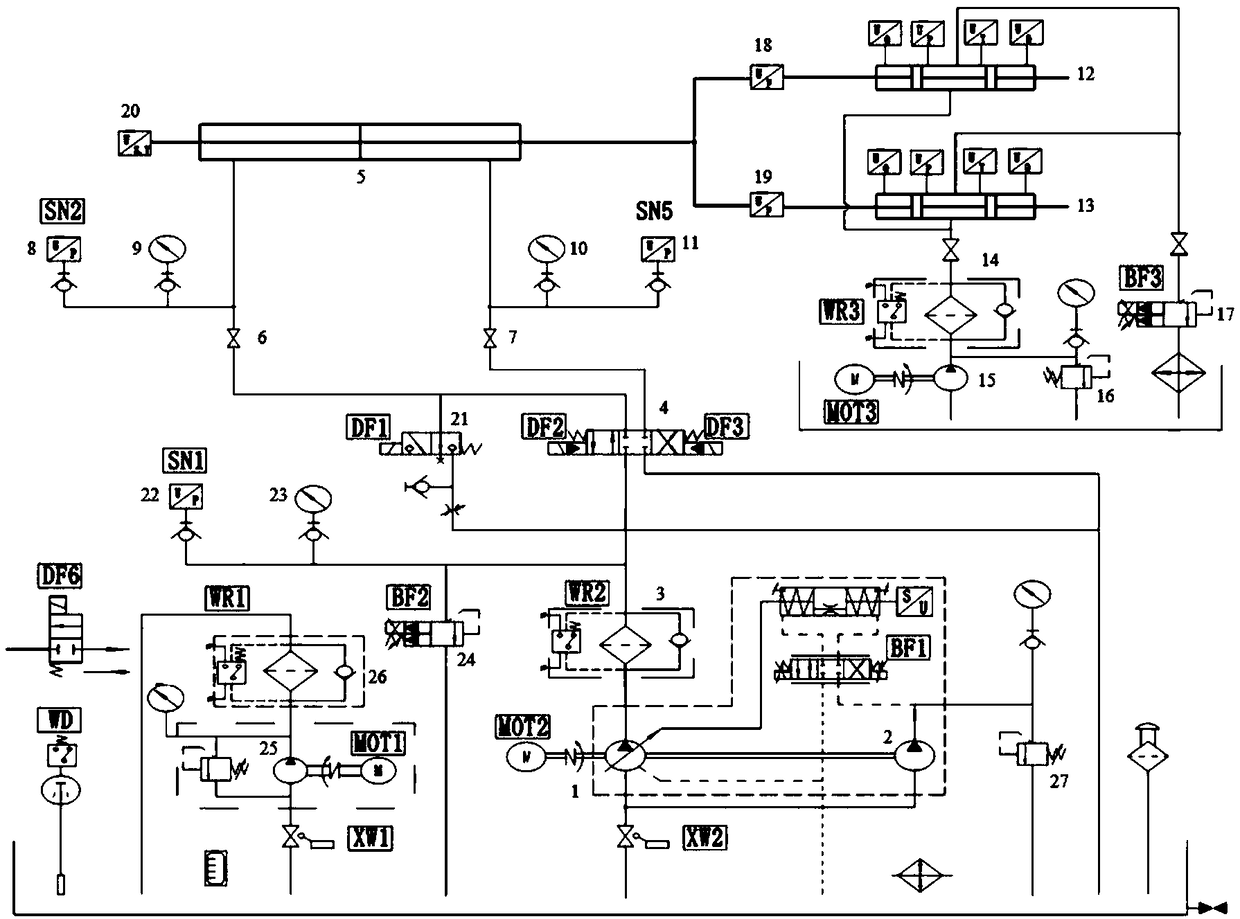

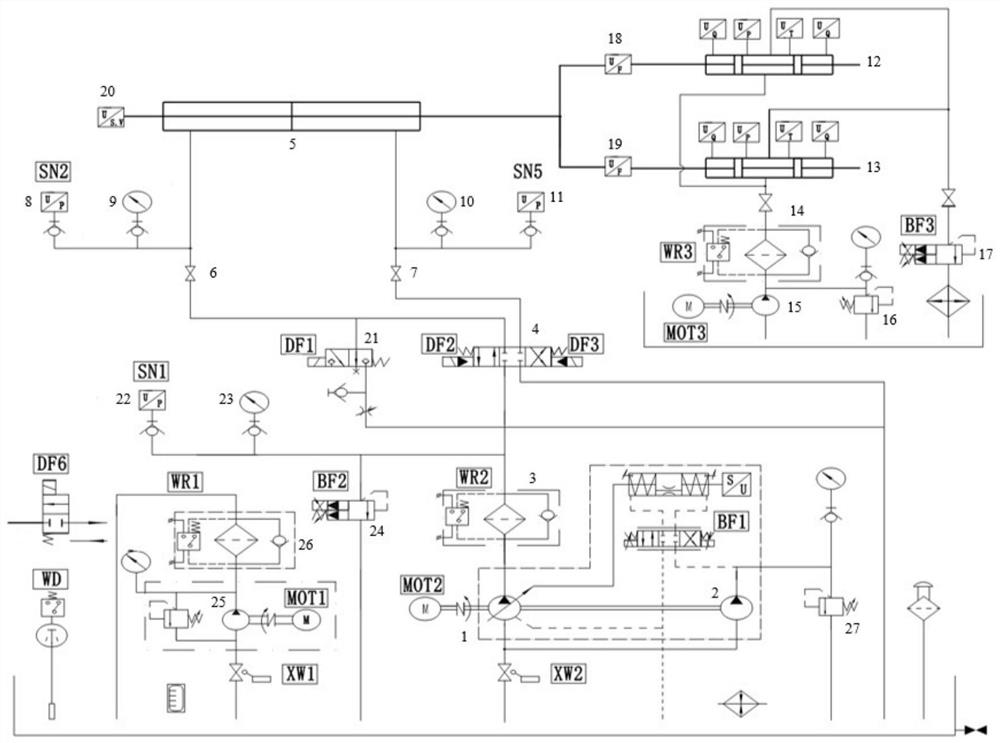

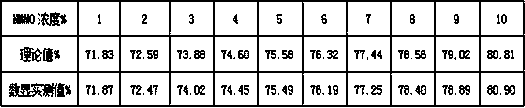

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642AReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

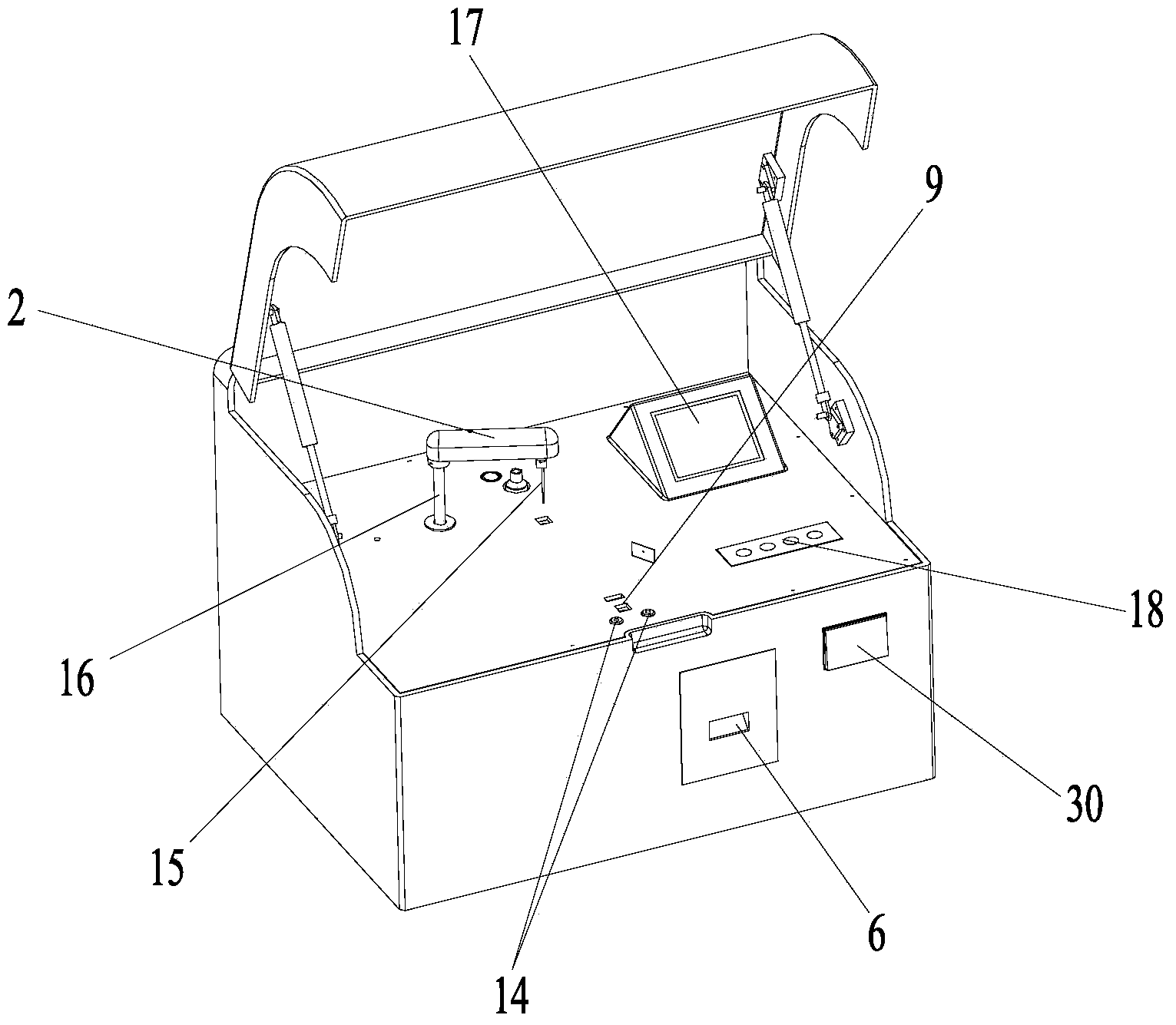

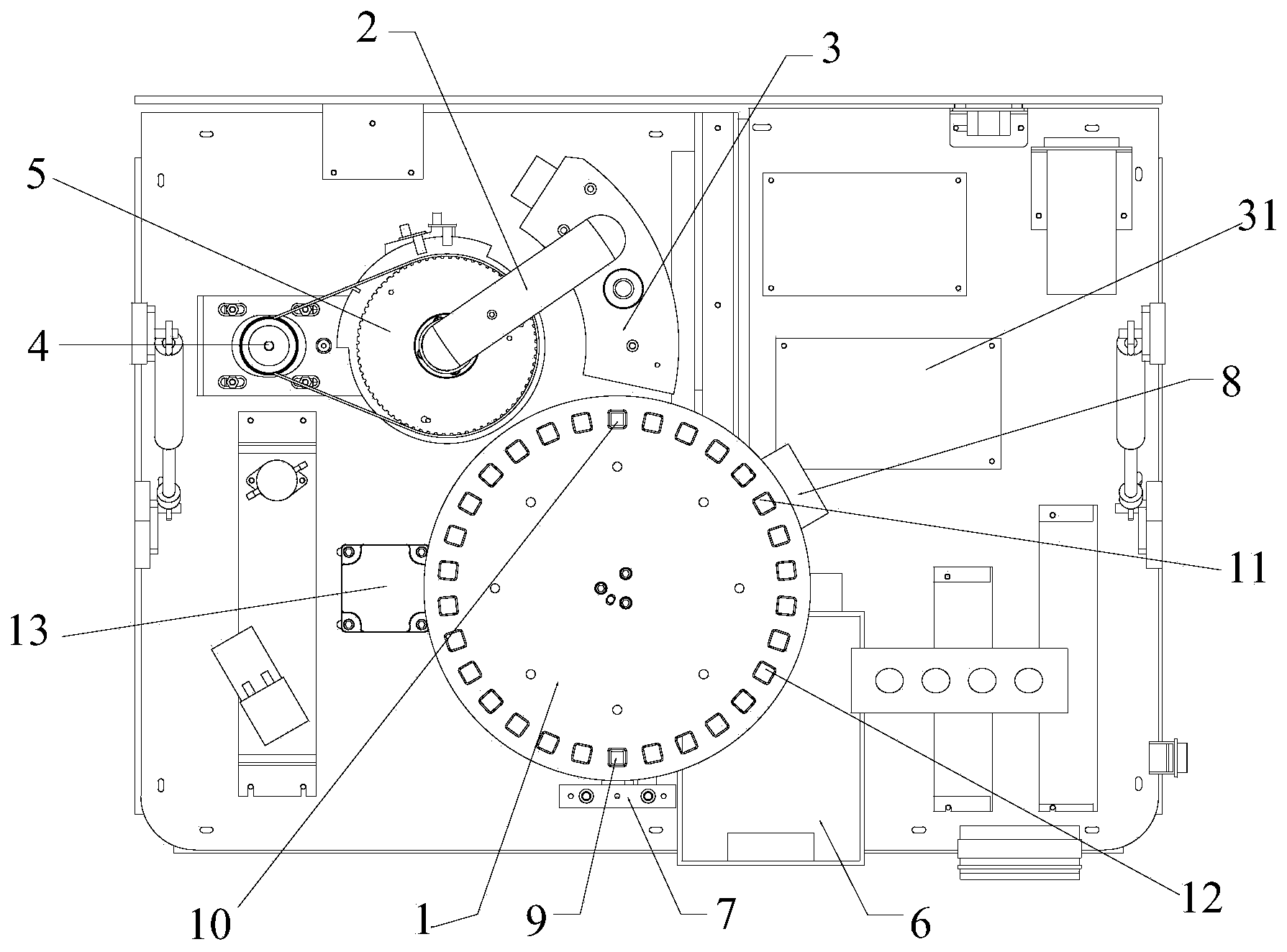

Automatic bacterial vaginosis detector

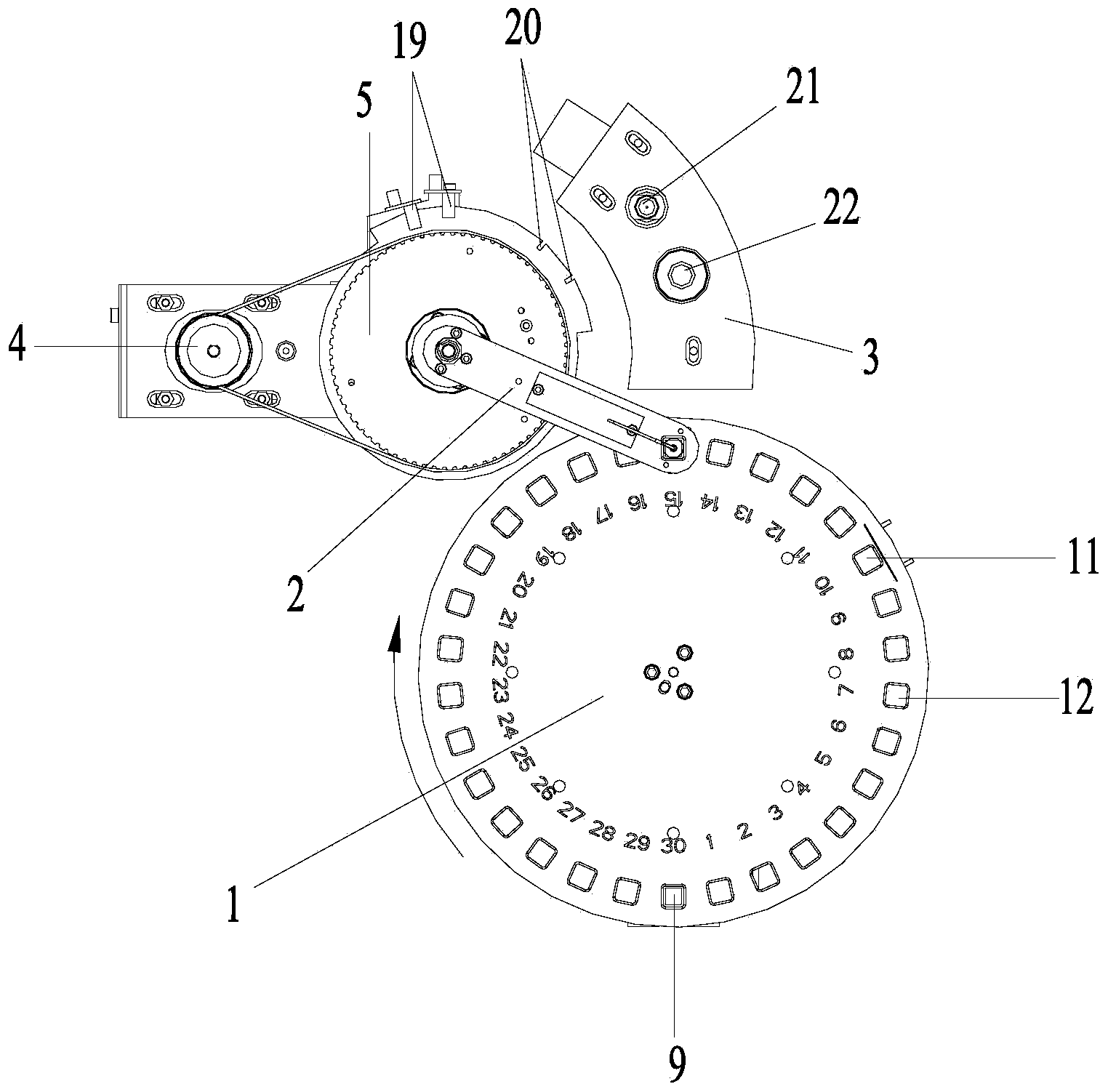

ActiveCN103728460AFully automated detection is easy to operateHigh activityMaterial analysisFailure rateBacterial vaginosis

The invention discloses an automatic bacterial vaginosis detector, comprising a loading device, an incubation device, a sampling needle device and a detection device, wherein the loading device is used for placing a sample cup; the incubation device is used for incubating a sample; the sampling needle device is used for adding a color developing agent to the sample; the detection device is used for carrying out color developing detection on the sample. Compared with the prior art, by adopting the automatic bacterial vaginosis detector provided by the invention, the automatic degree and the detection efficiency of the bacterial vaginosis (BV) detector can be improved, the stability of enzymatic activity is ensured, cross infection is eliminated, and the failure rate and energy consumption of the detector in operation are reduced.

Owner:GUANGZHOU HONGQI OPTICAL INSTR TECH

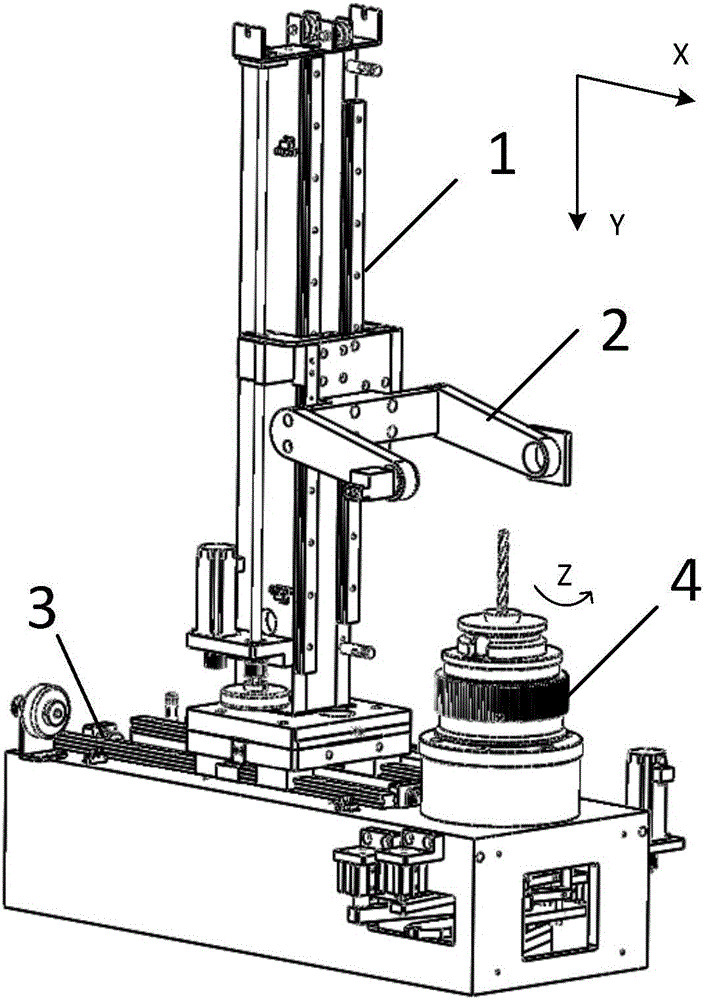

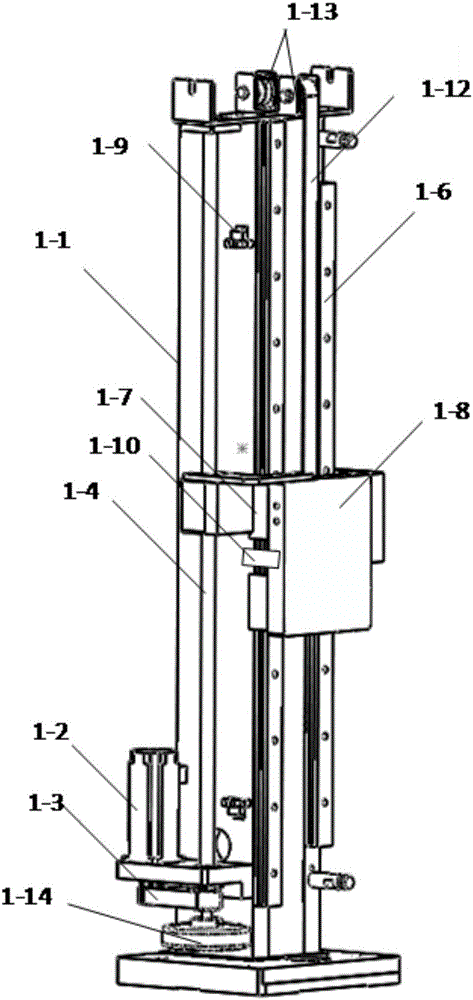

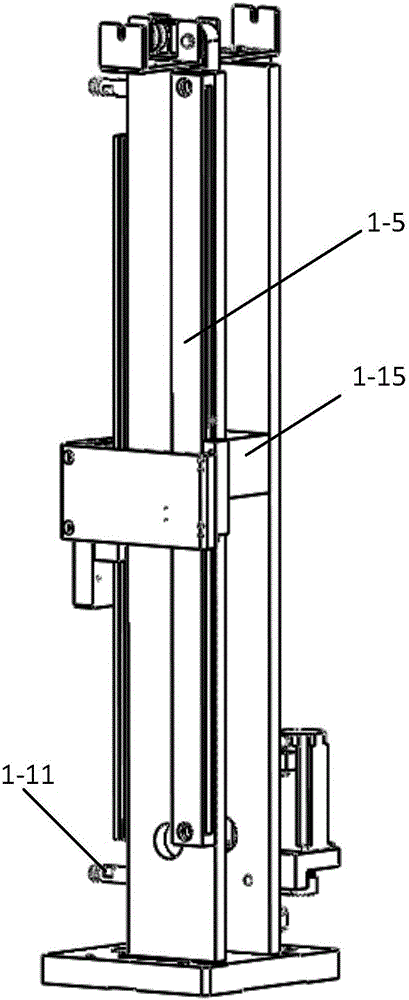

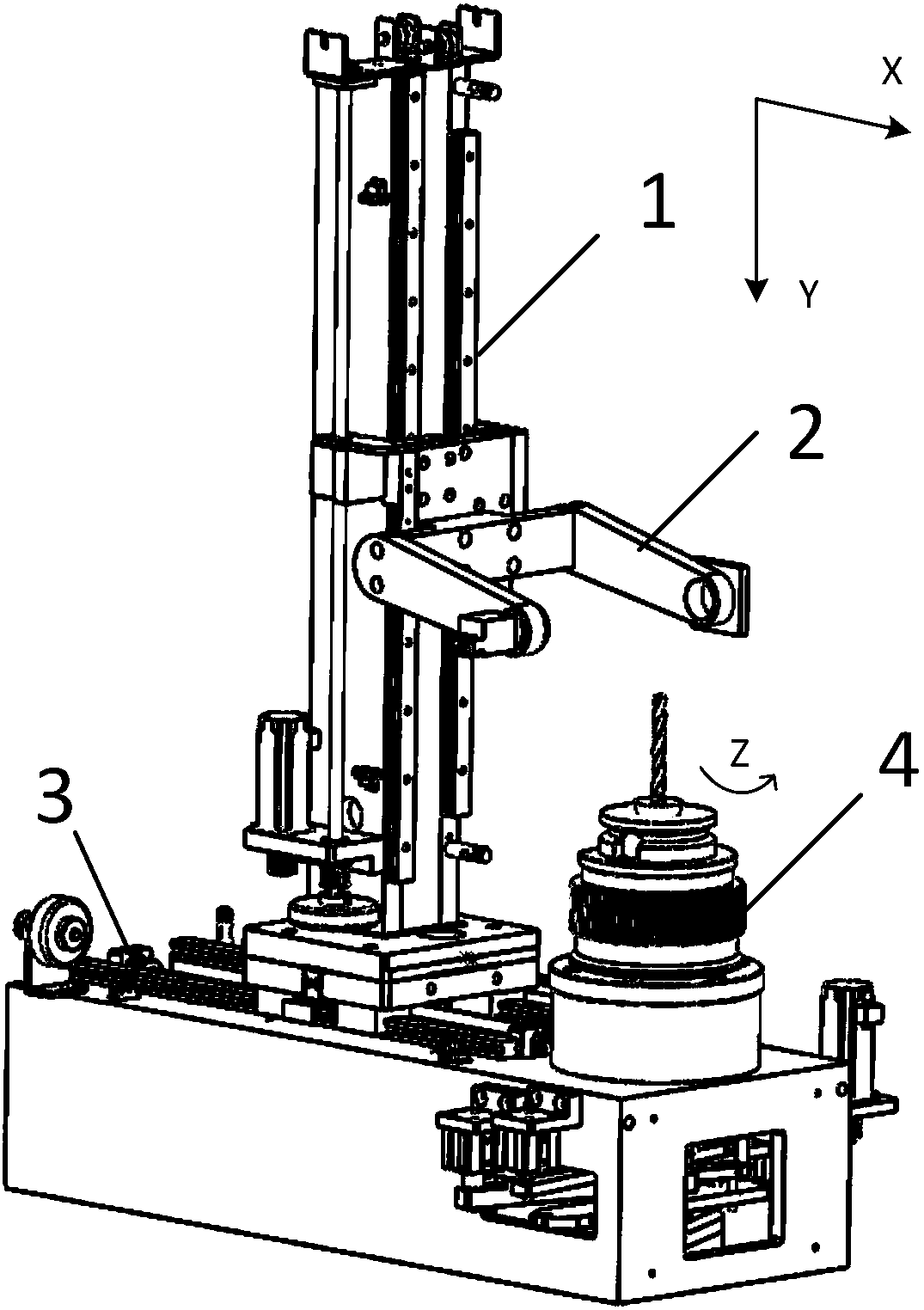

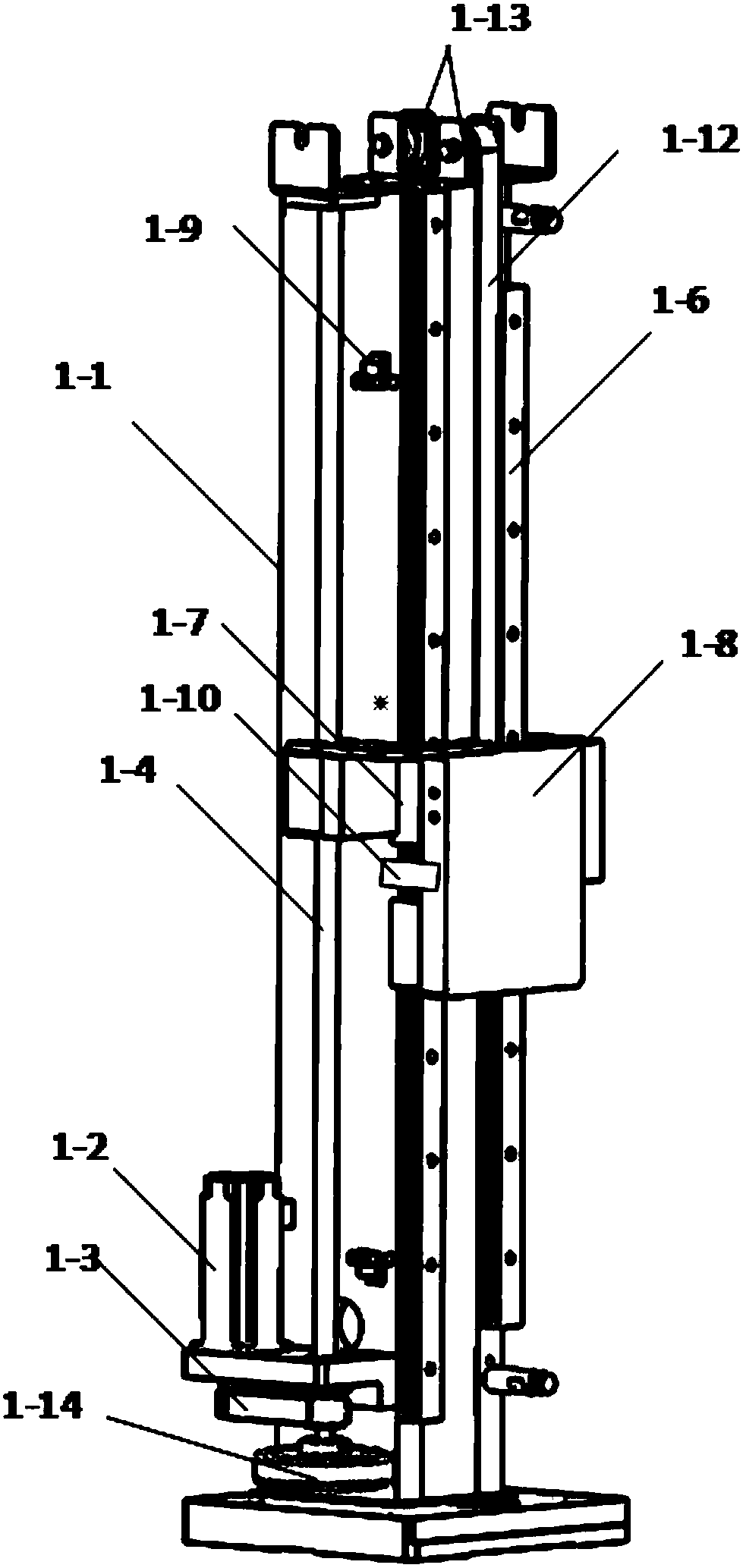

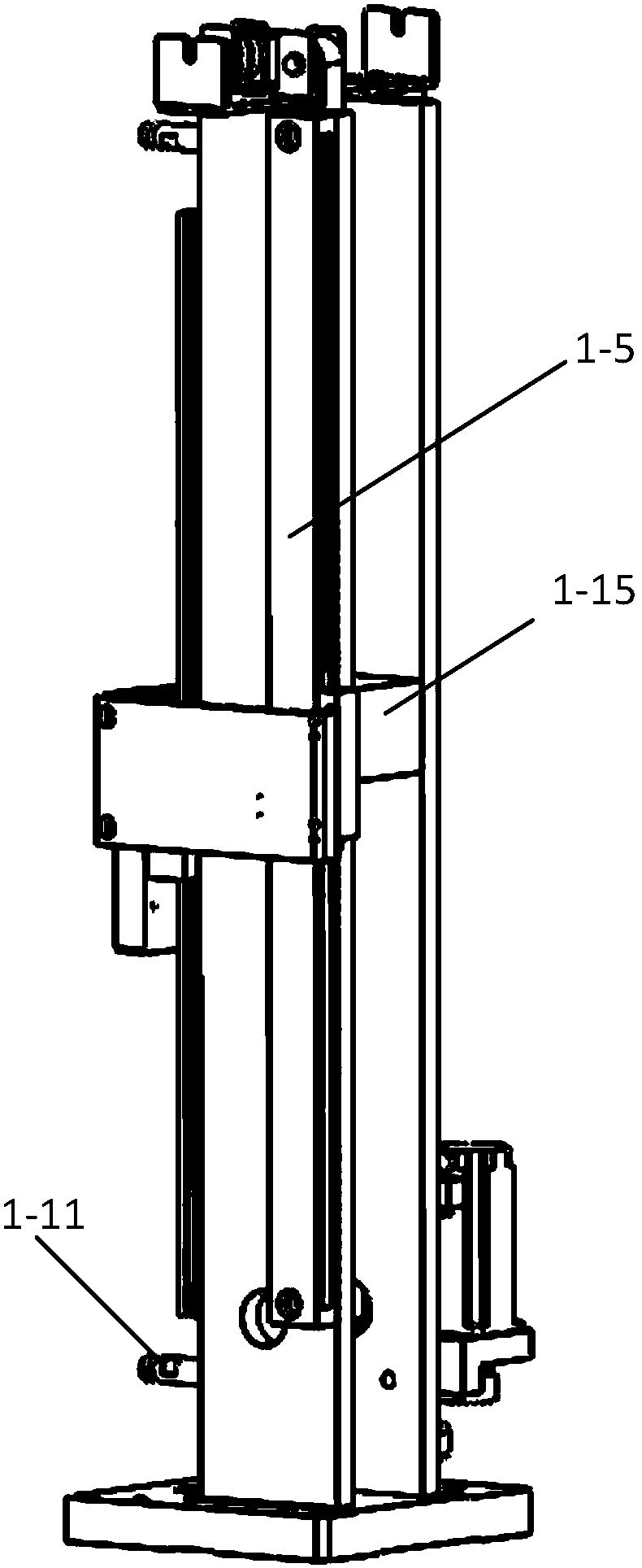

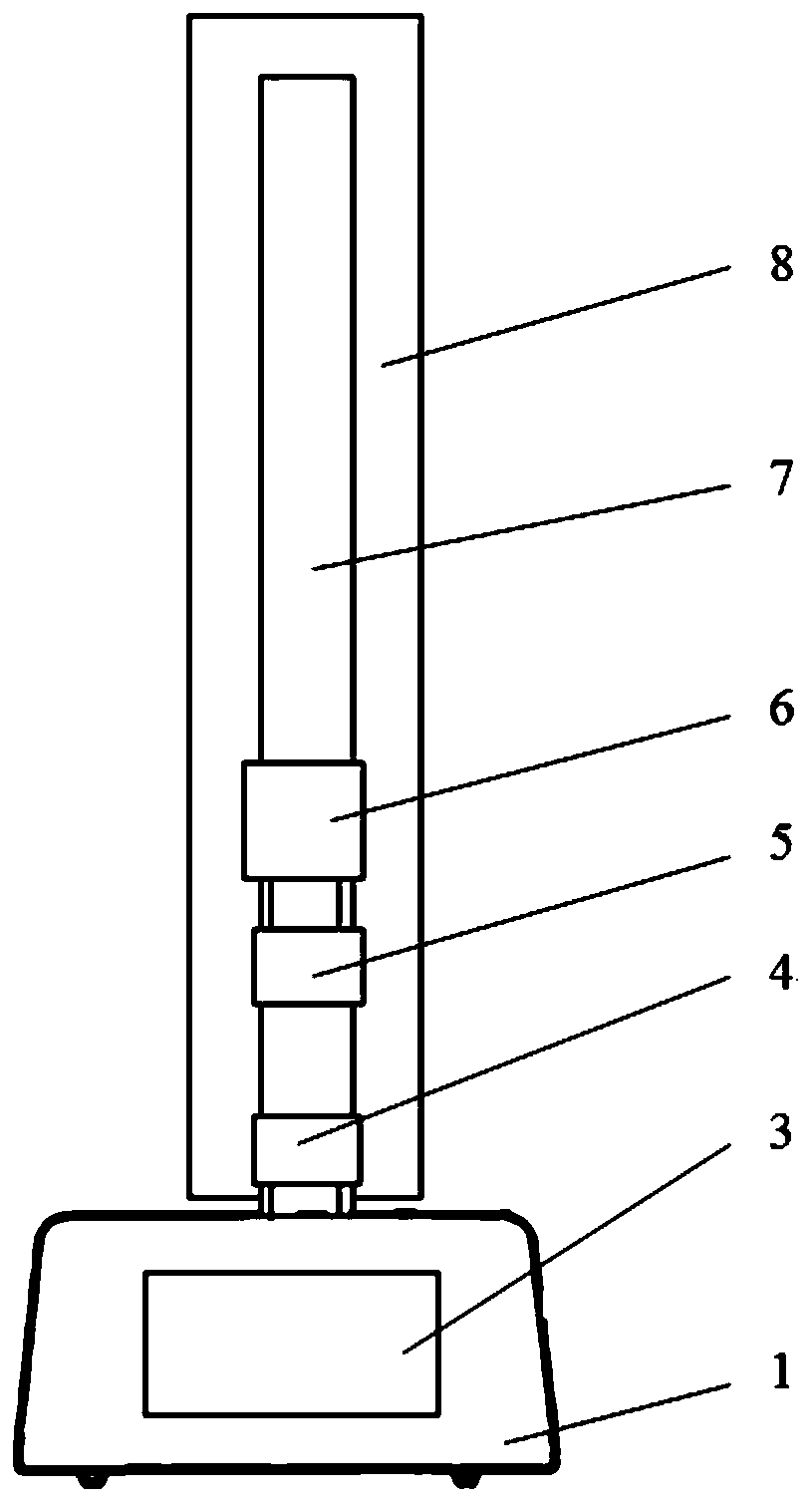

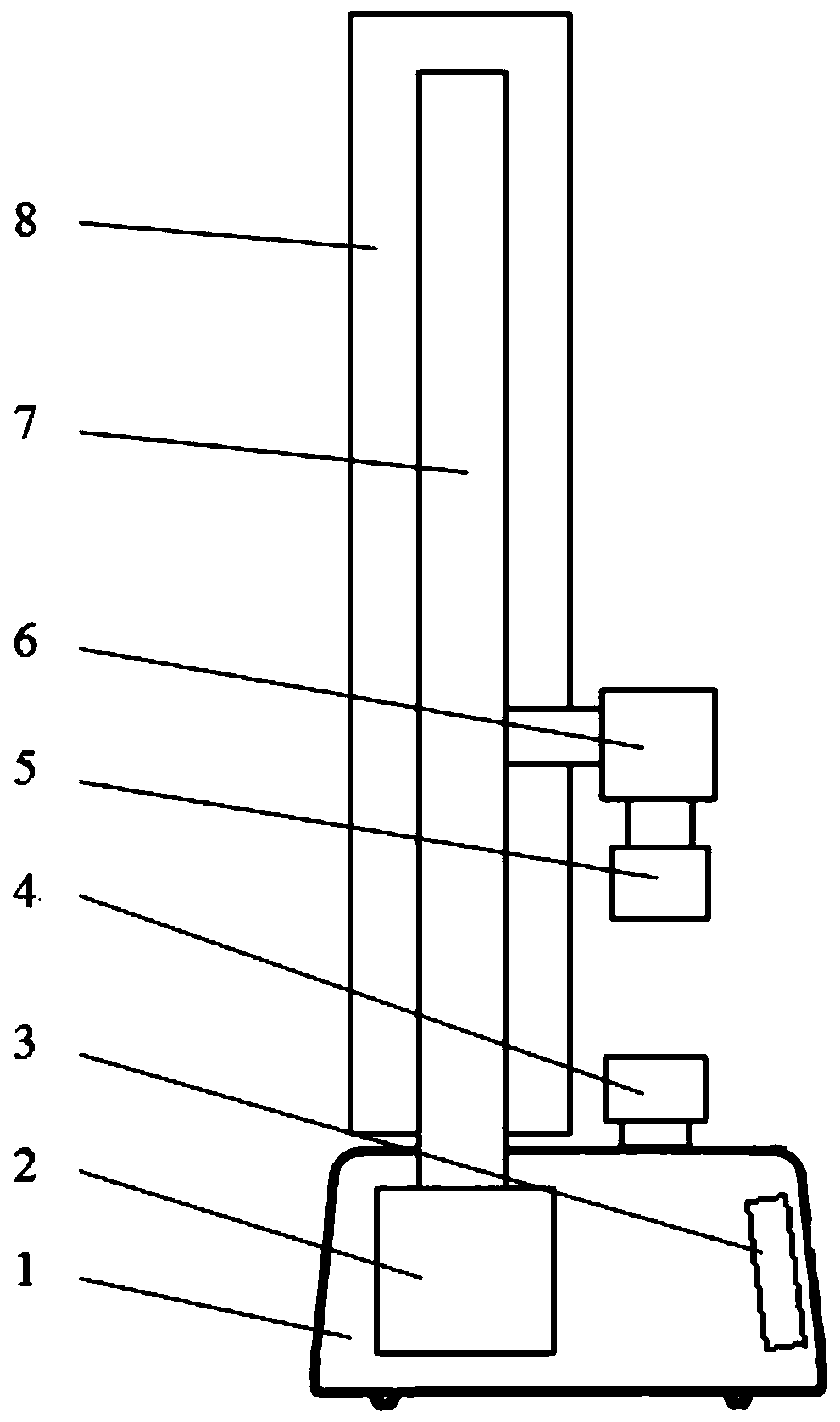

Electronic camera shooting type tool presetting device and measurement method

ActiveCN105922080AThe test result is accurateDetection speedAutomatic control devicesMeasurement/indication equipmentsGratingEngineering

The invention relates to an electronic camera shooting type tool presetting device and measurement method. The electronic camera shooting type tool presetting device is characterized in that the device comprises a Y-direction horizontally-moving mechanism, a detection mechanism, an X-direction horizontally-moving mechanism, a Z-direction main shaft mechanism and a drive module; the upper portion of the X-direction horizontally-moving mechanism is fixedly connected with the lower portion of the Y-direction horizontally-moving mechanism; the detection mechanism is connected with the Y-direction horizontally-moving mechanism; the Z-direction main shaft mechanism is arranged below the detection mechanism; the Y-direction horizontally-moving mechanism, the detection mechanism, the X-direction horizontally-moving mechanism and the Z-direction main shaft mechanism are controlled by the drive module to act; the Y-direction horizontally-moving mechanism comprises a stand column, a Y-direction servo motor, a Y-direction synchronous belt, a Y-direction toothless threaded rod, a Y-direction grating ruler, a Y-direction guide rail, a Y-direction slide block, a Y-direction slide table, a Y-direction limiting switch, a Y-direction limiting baffle, a connection belt, bearings, a Y-direction fine adjustment wheel and a detection mechanism balancing weight; the stand column is a rectangular frame, wherein the back face of the stand column is in a U shape; the Y-direction guide rail is installed on the front face of the stand column; and the Y-direction slide table is fixed to the Y-direction guide rail through the Y-direction slide block.

Owner:TIANJIN TIANMEN JINBAO TECH CO LTD

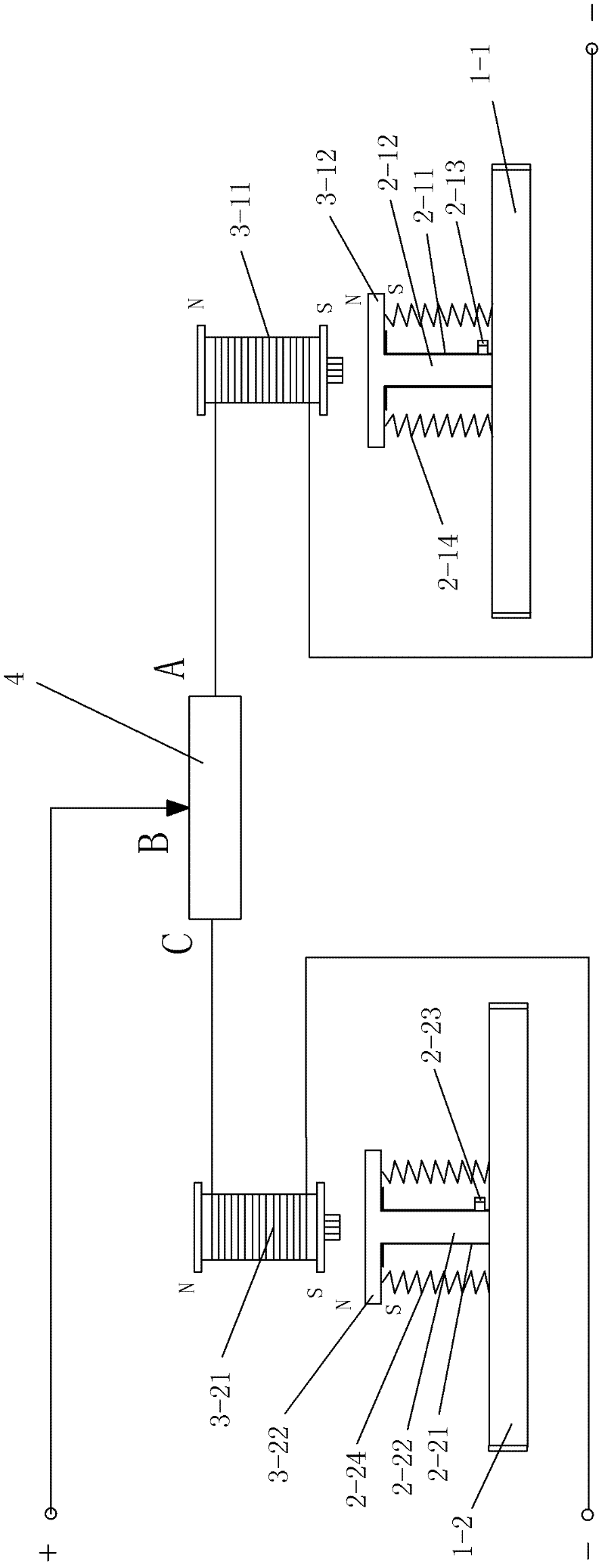

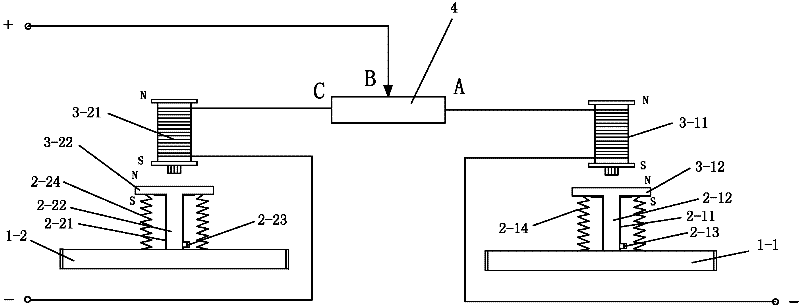

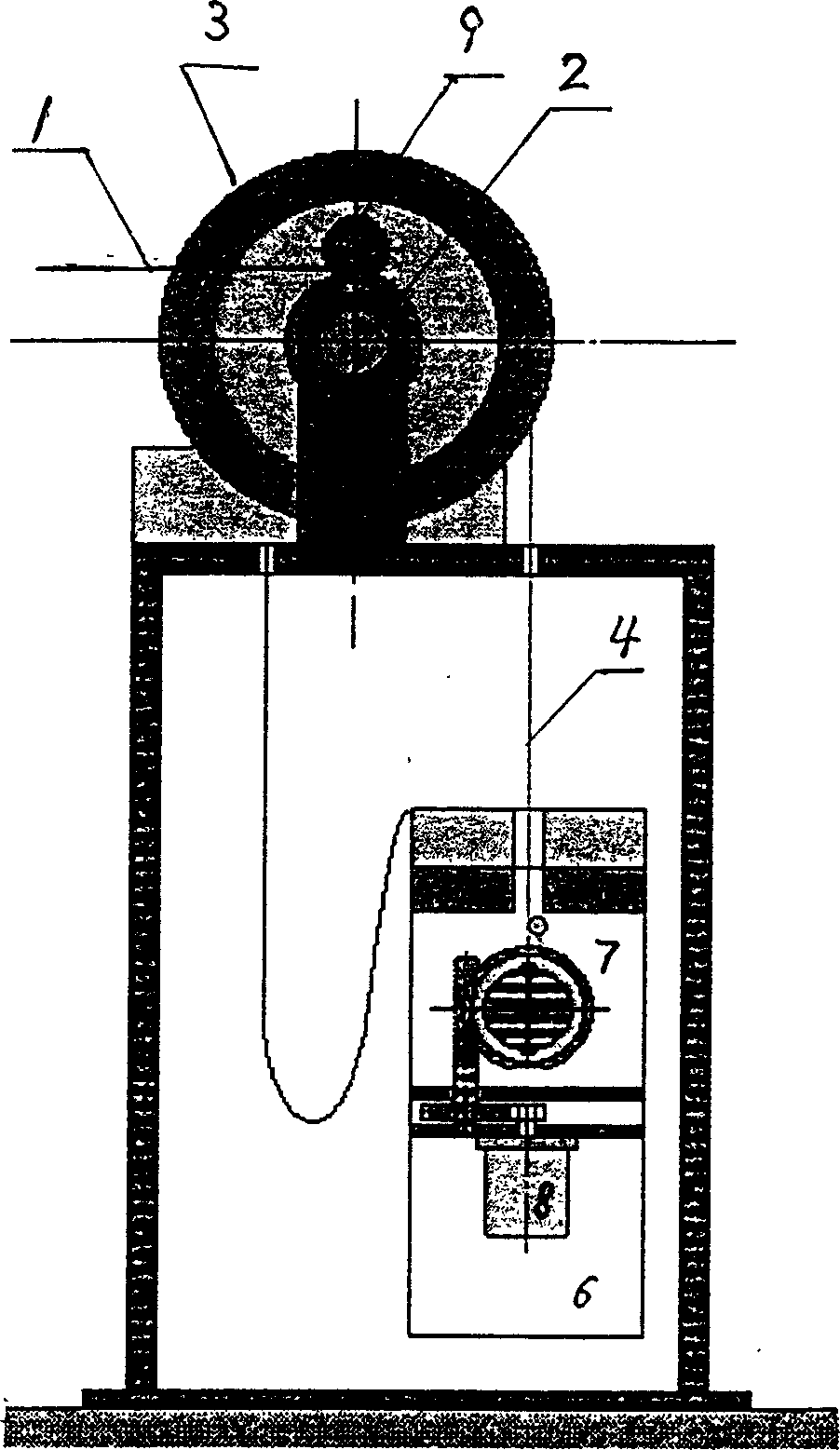

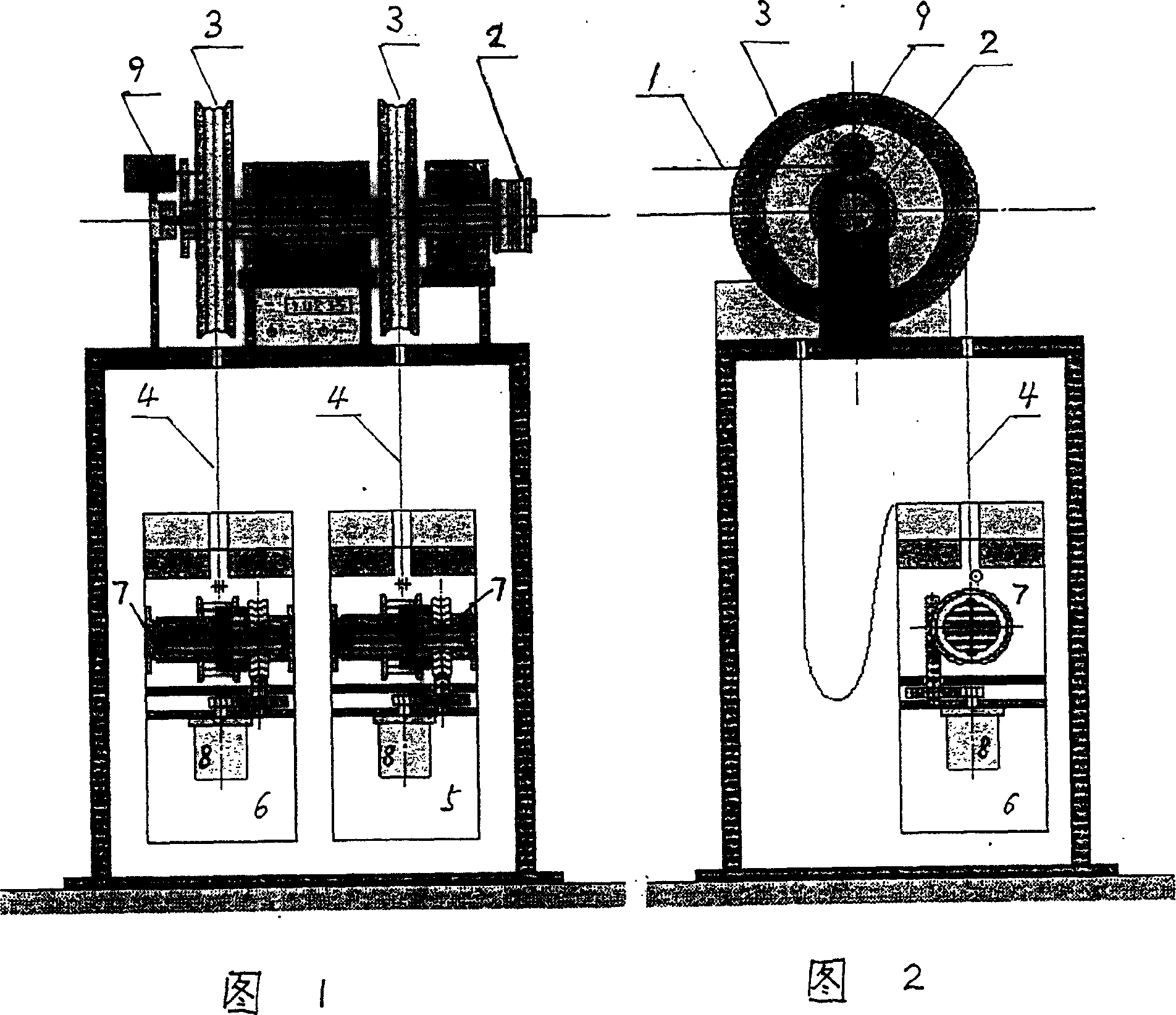

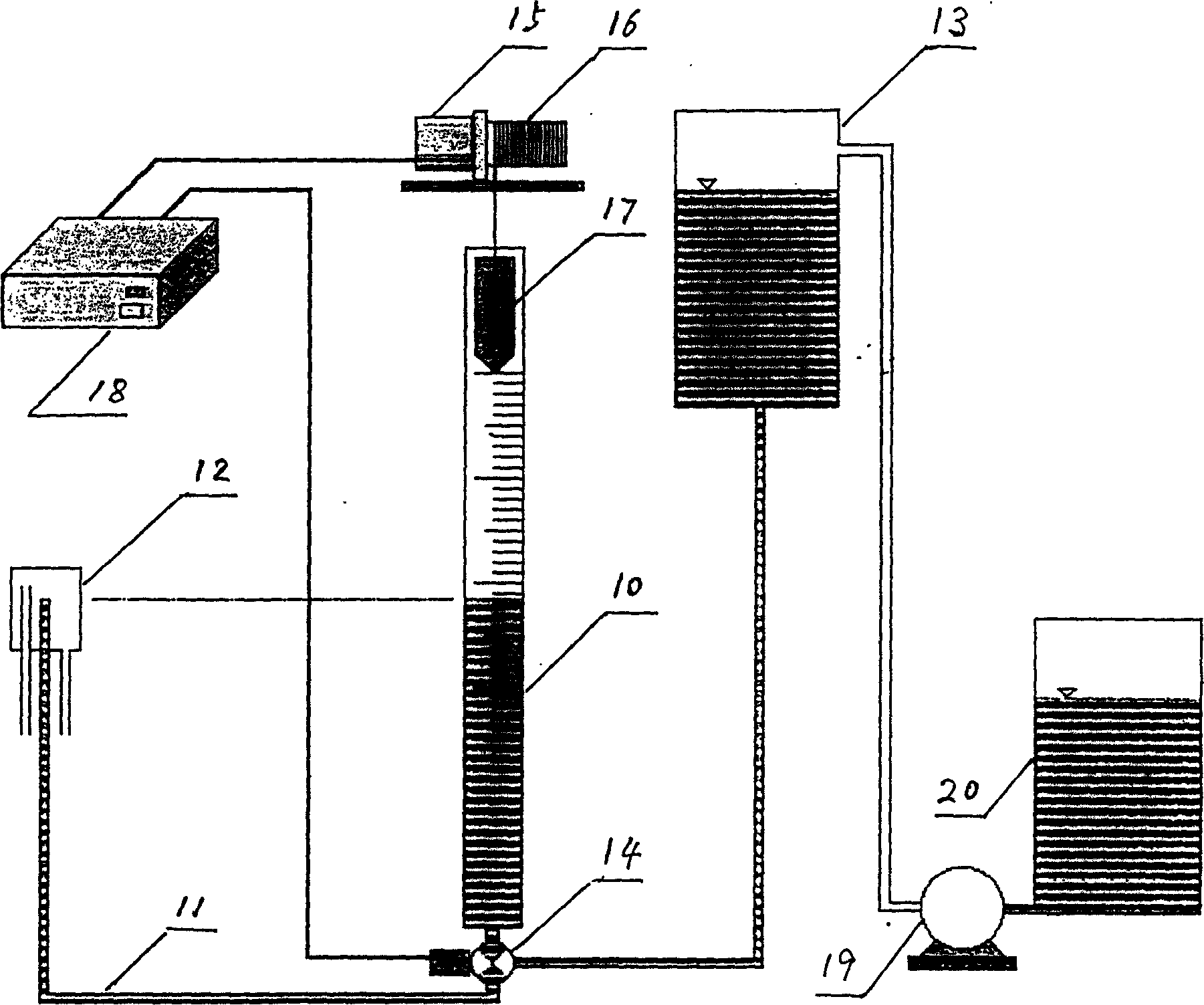

Remotely-measuring remotelly-controlled rertical displacement meter

InactiveCN1495405AReduce laborEliminate subjective errorsBarrages/weirsElectrical/magnetic solid deformation measurementRemote controlElectromagnetic valve

Two portions of large dam horizontal-vrtical displacement meter are respectively improved, the horizontal portion, the counterpoise for measuring steel wire is changed into electric measurement, the internally-mounted small type hoist can be used for controlling suspension and put-down of the counterpoise, and the displacement can be read out by coder, and the horizontal measurement portion, a liquid-supplying box is added, an electromagnetic valve is set and is connected with level meter, and a controller is used for controlling electromagnetic valve to supply liquid. It also includes the components of stepper motor and plumb, and can make two displacement measurements so as to implement automation, remote measurement and remote control, and can raise the measurement accuracy.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

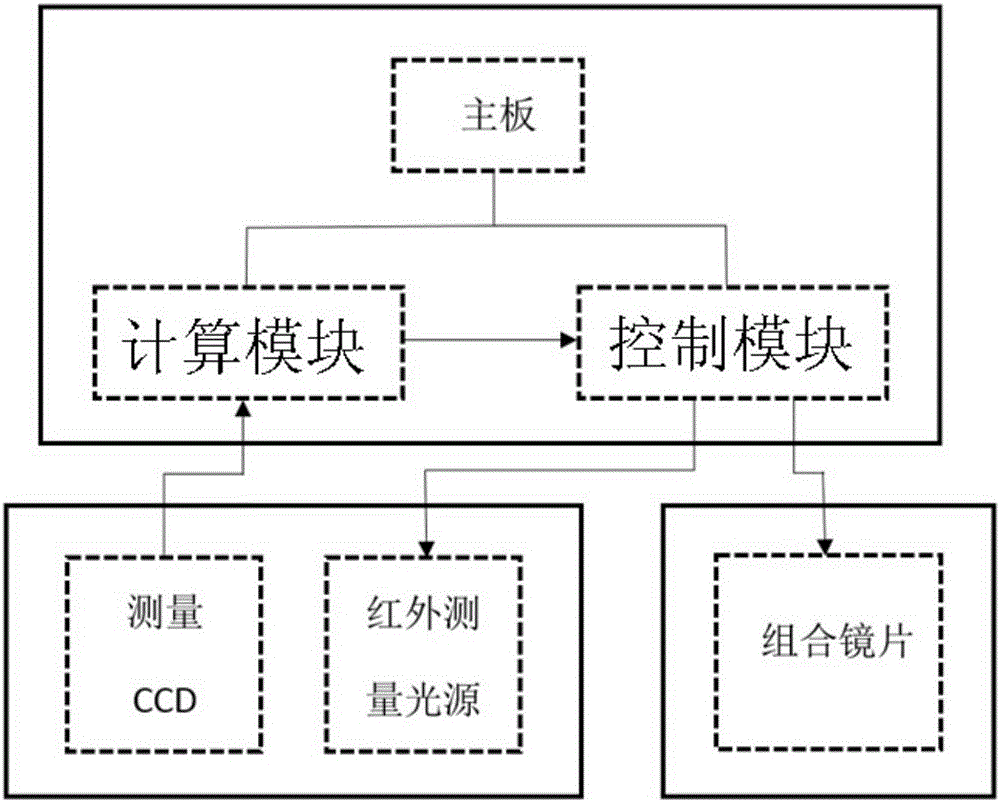

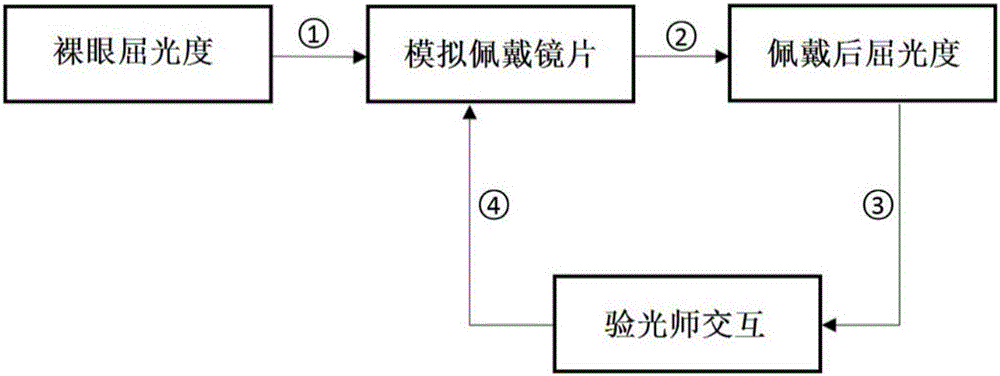

Full-automatic comprehensive optometry unit

InactiveCN105942971AImprove optometry efficiencyEliminate subjective errorsRefractometersSkiascopesLight sourceSoftware

The invention relates to a full-automatic comprehensive optometry unit. A conventional comprehensive optometry unit has long optometry period, a patient needs several rests during the period, and constant communication between an optometrist and a patient is required. Since the optometry period cost more time and has a certain subjectivity, the optometric result has a poor accuracy. The full-automatic comprehensive optometry unit comprises a hardware part and a software part, and is characterized in that the hardware part comprises an assembled lens, a visual chart, an infrared measurement light source, a collimation lens, a spectroscope, a reflector, a reticle and a measurement CCD; the software part comprises a control module and a calculation module; an infrared light emitted from the infrared measurement light source is projected to form a parallel beam through the collimation lens; the beam is reflected in the retina, goes through the reticle and is sampled by the measurement CCD; an image collected by the measurement CCD is analyzed and calculated by the calculation module to obtain a wearing diopter; and the control module is used for sending out a regulation command to correct the lens simulating wearing according to the analyzing and calculating result. The full-automatic comprehensive optometry unit has the advantage that the wearing diopter can be measured, and the optometry efficiency can be improved.

Owner:NINGBO MING SING OPTICAL R & D

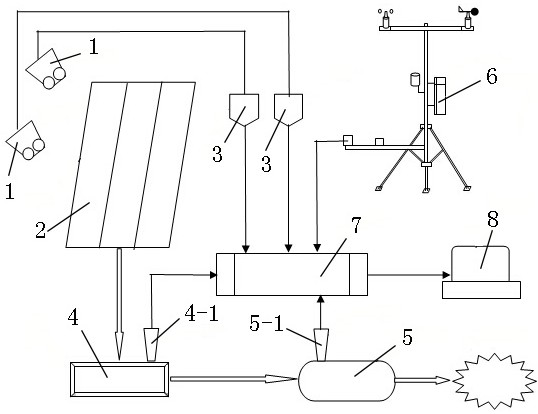

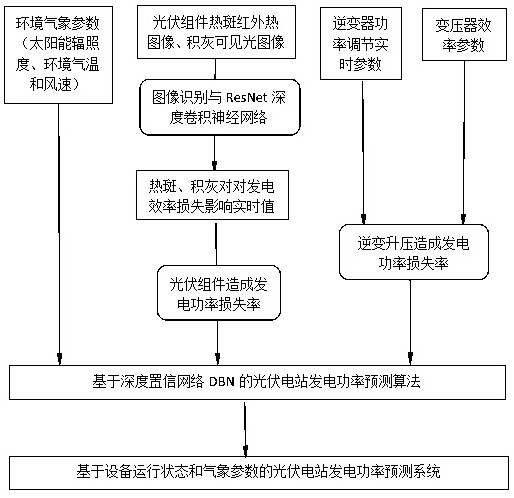

Power generation prediction system and method based on equipment operation state and meteorological parameters

PendingCN113890027AImprove accuracyImprove reliabilityGeneration forecast in ac networkSingle network parallel feeding arrangementsImaging analysisEngineering

The invention relates to the technical field of photovoltaic power station generation power prediction, in particular to a power generation prediction system and method based on an equipment operation state and meteorological parameters. The power generation power prediction system based on the equipment operation state and the meteorological parameters comprises: a plurality of visible light-infrared thermal imaging integrated cameras, which are used for shooting a photovoltaic module to obtain an ash deposition visible light image and a hot spot infrared thermal image; and a plurality of image analysis modules, which are connected with the visible light-infrared thermal imaging integrated cameras in a one-to-one correspondence manner and are used for analyzing the ash deposition visible light image and the hot spot infrared thermal image so as to obtain the power generation power loss rate caused by the photovoltaic module. The generation power of the photovoltaic power station is jointly predicted by combining the dust deposition and hot spot conditions of the photovoltaic module, the maximum power adjustment real-time parameters of the inverter of the photovoltaic module and the efficiency parameters of the transformer on the basis of the environmental meteorological parameters, and the accuracy and reliability of prediction of the generation power of the photovoltaic power station are effectively improved.

Owner:中核坤华能源发展有限公司

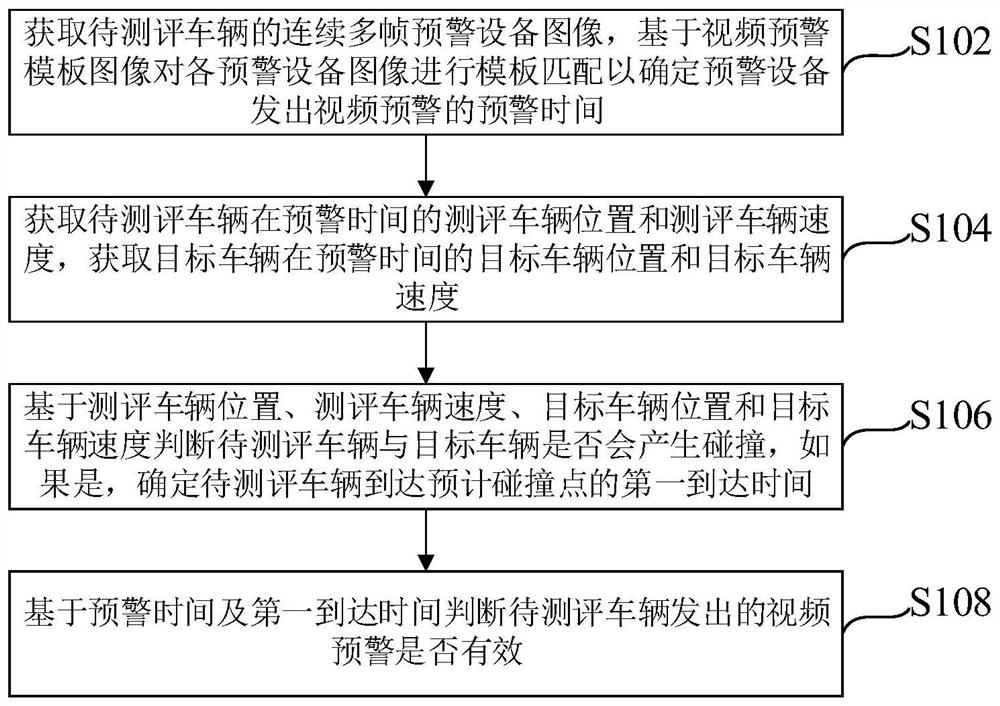

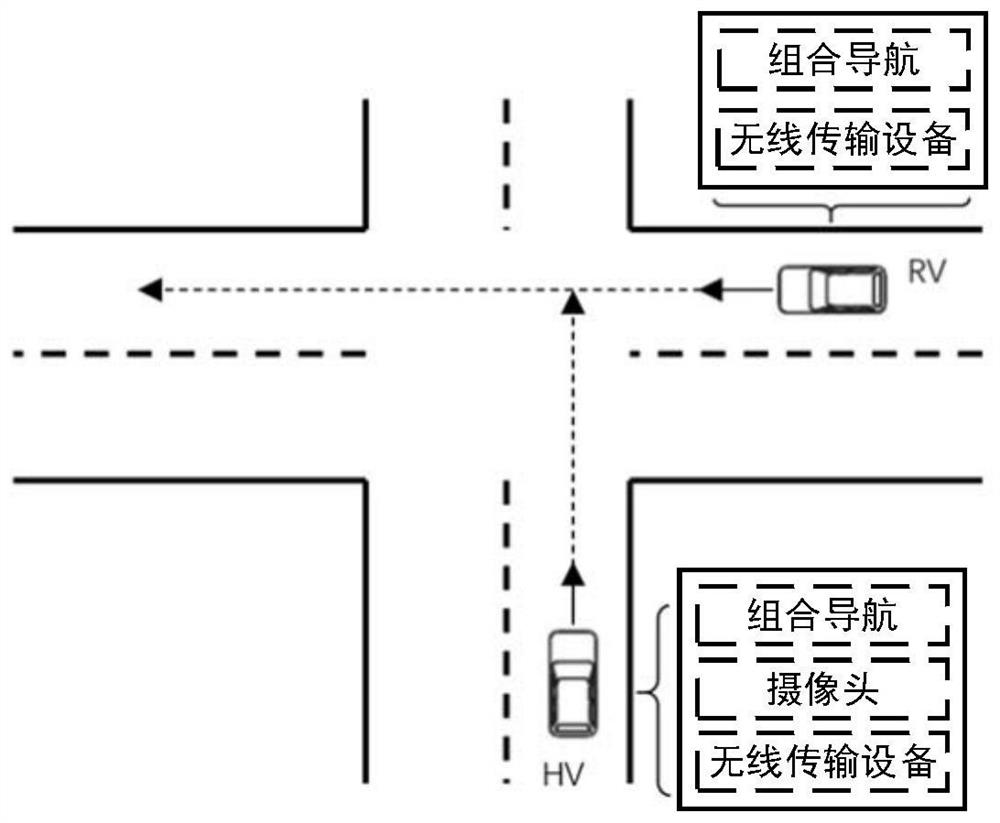

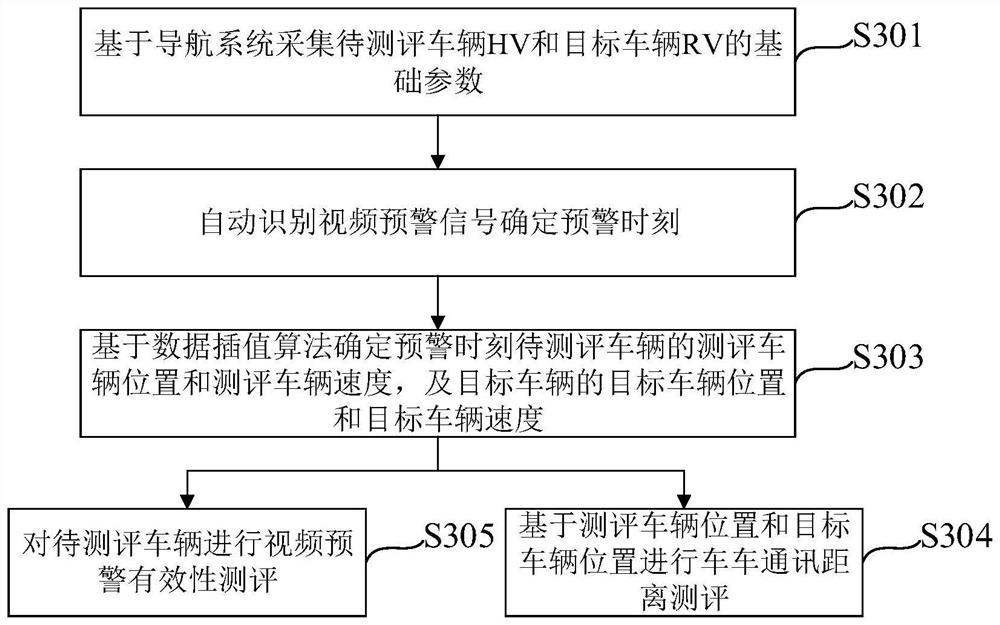

Intersection vehicle collision early warning evaluation method, device and system

ActiveCN114141057ARealize accurate evaluationImprove accuracyAnti-collision systemsTemplate matchingSimulation

The invention provides an intersection vehicle collision early-warning evaluation method, device and system, and the method comprises the steps: obtaining continuous multi-frame early-warning equipment images of a to-be-evaluated vehicle, and carrying out the template matching of each early-warning equipment image based on a video early-warning template image, so as to determine the early-warning time of the early-warning equipment for transmitting video early warning; acquiring an evaluation vehicle position and an evaluation vehicle speed of the to-be-evaluated vehicle at the early warning time, and acquiring a target vehicle position and a target vehicle speed of the target vehicle at the early warning time; based on the evaluated vehicle position, the evaluated vehicle speed, the target vehicle position and the target vehicle speed, whether the to-be-evaluated vehicle and the target vehicle will collide is judged, and if yes, the first arrival time when the to-be-evaluated vehicle arrives at the predicted collision point is determined; and judging whether the video early warning sent by the to-be-evaluated vehicle is valid based on the early warning time and the first arrival time. According to the invention, the accuracy of early warning time determination is improved, and accurate evaluation of vehicle video early warning effectiveness is realized.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

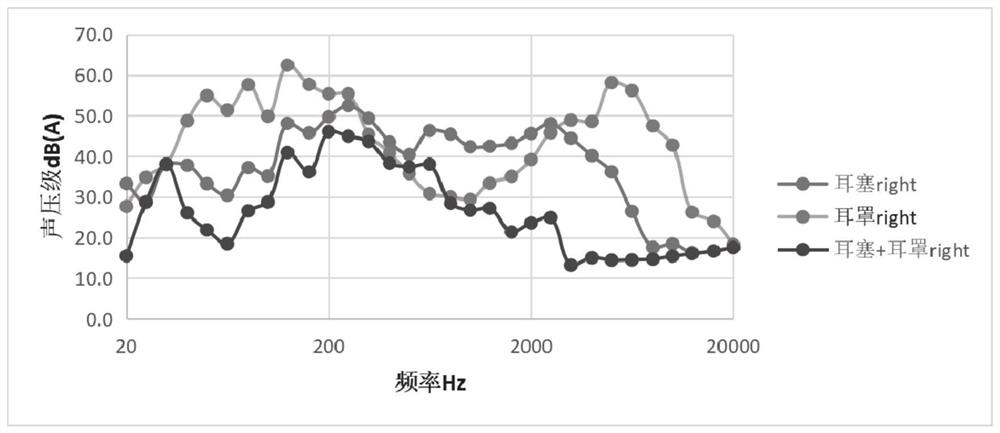

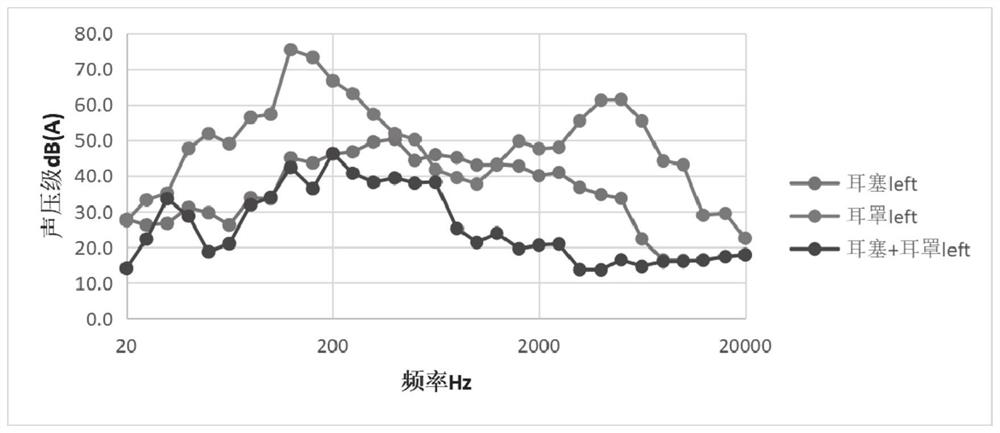

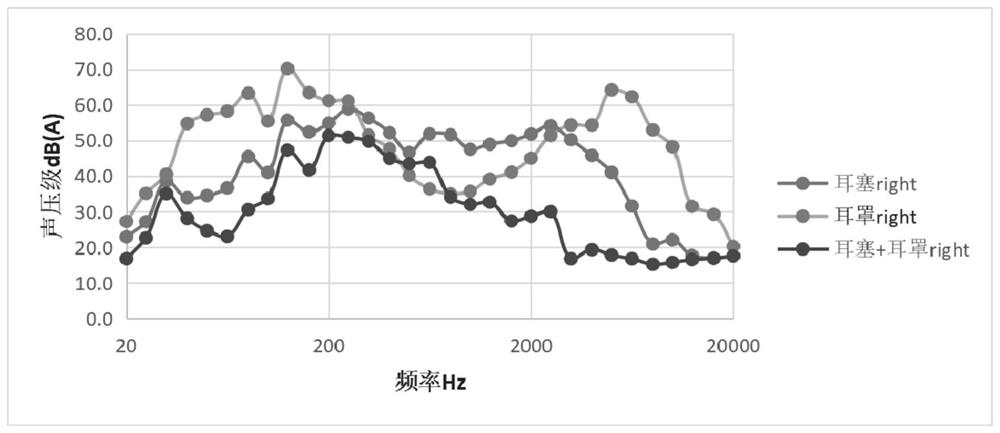

Joint effect evaluation method and system for anti-noise earplugs and earmuffs in workplace

PendingCN113776801AEliminate subjective errorsNo protectionMachine part testingSubsonic/sonic/ultrasonic wave measurementEngineeringEarmuffs

The invention provides a joint effect evaluation method and system for anti-noise earplugs and earmuffs in workplace. The method comprises the following steps: measuring insertion loss of each frequency band of an anti-noise earplug; measuring the insertion loss of each frequency band of an anti-noise earmuff; and measuring the insertion loss of each frequency band when the anti-noise earmuff and the earplug are worn at the same time. The artificial head simulator is used for measuring the insertion loss of the earplug, subjective errors are removed, and the method and system are simpler and more convenient.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

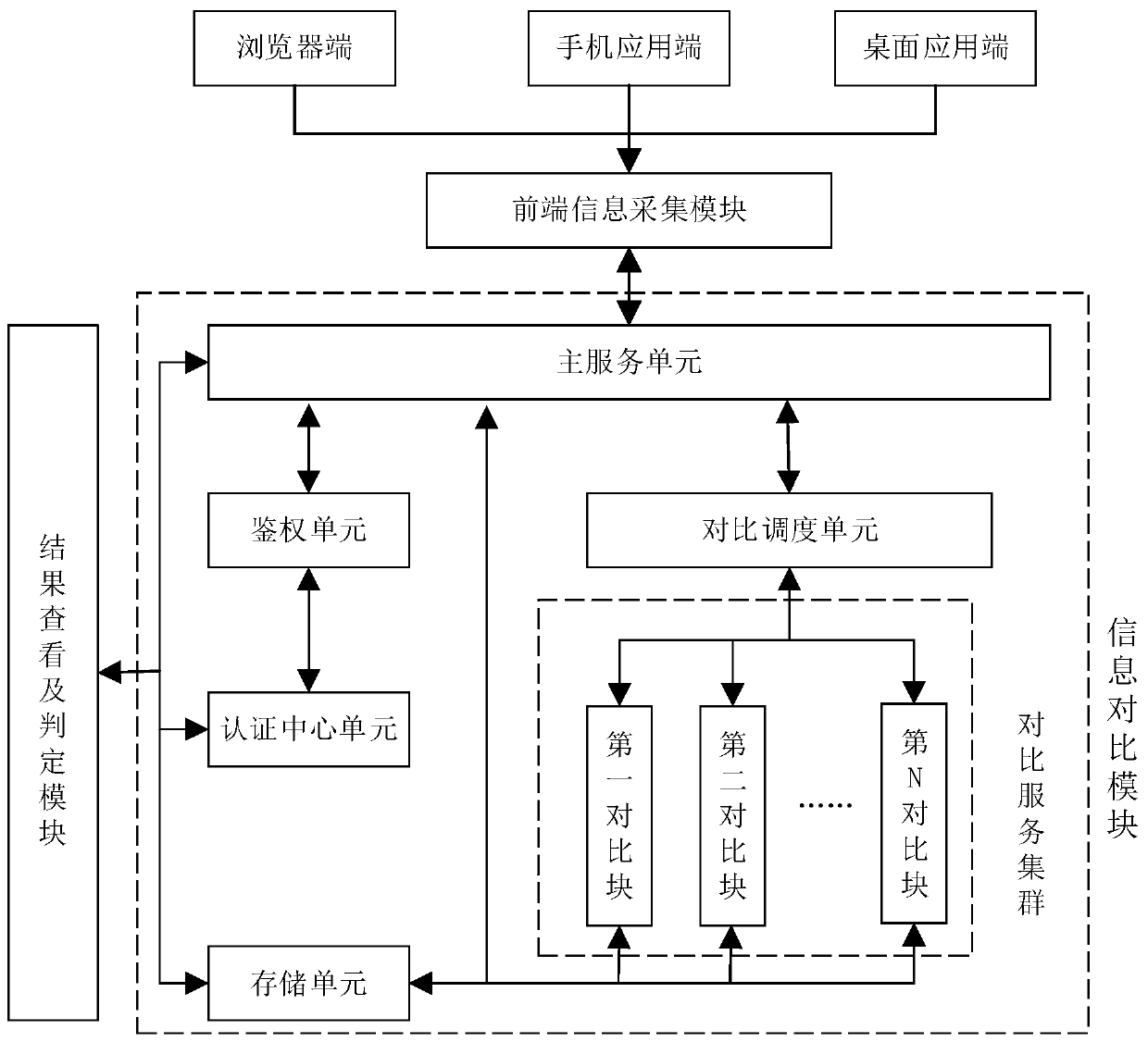

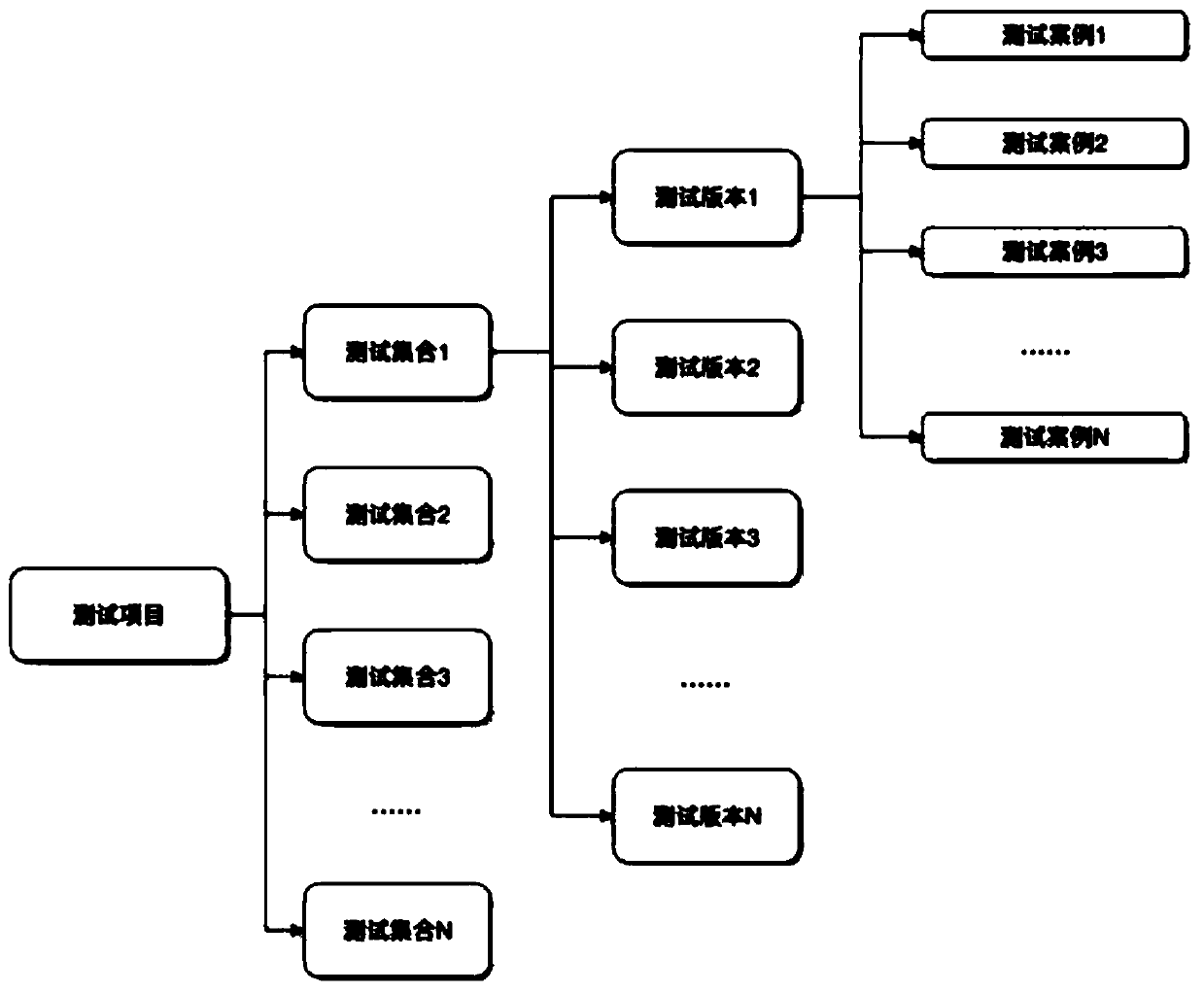

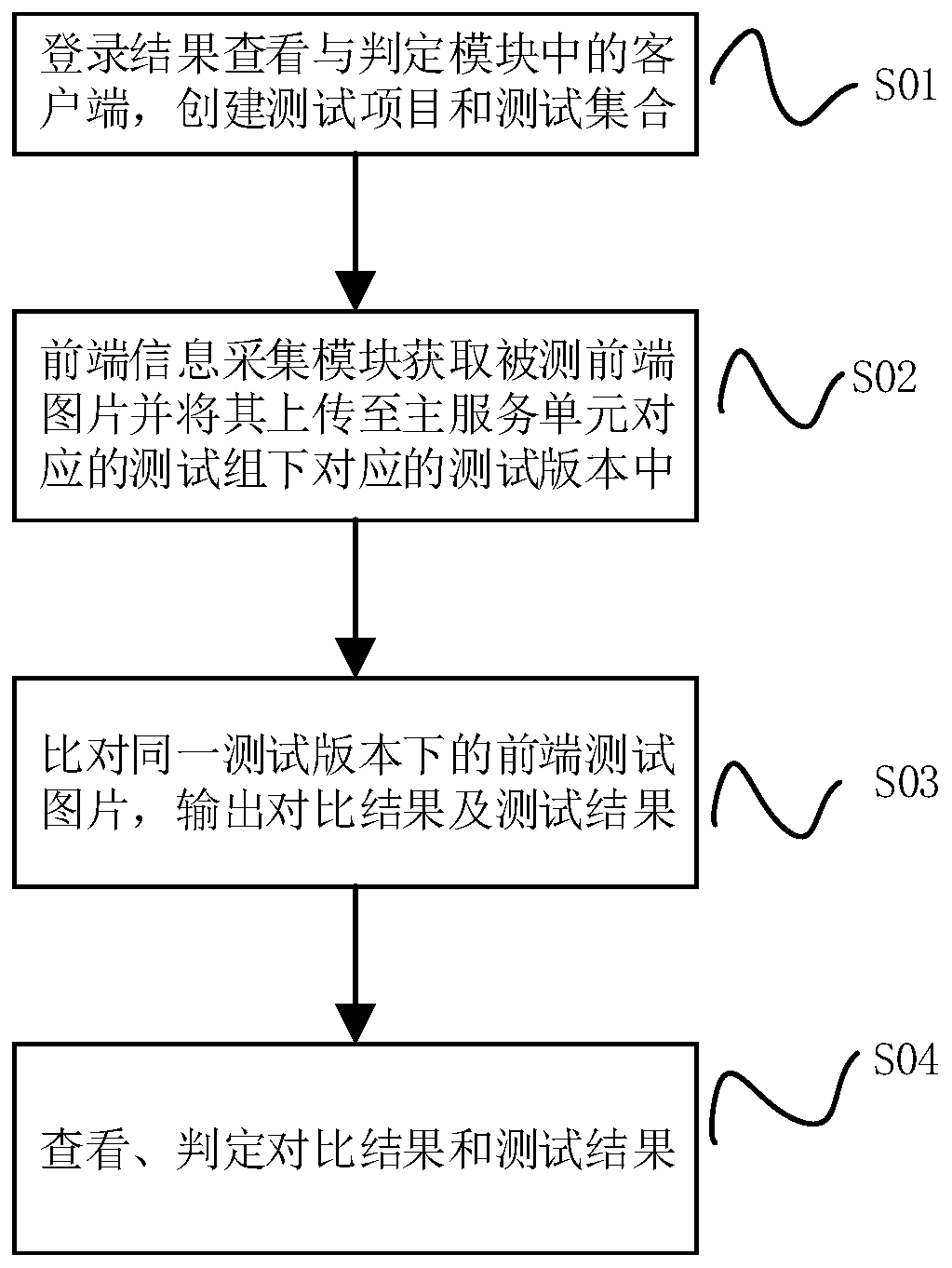

Front-end automatic regression testing system and method based on picture comparison technology

PendingCN110737599ASimplify workReduce the chance of misjudgmentCharacter and pattern recognitionSoftware testing/debuggingRegression testingAlgorithm

The invention discloses a front-end automatic regression test system and a method based on a picture comparison technology, and belongs to the technical field of the Internet, and the method comprisesa tested front-end picture comparison step: comparing whether a test picture and a standard reference picture under the same test group meet a first preset condition; if not, further judging whetherthe test picture and the anti-error reference picture meet a second preset condition; if yes, outputting a comparison result of test success, otherwise, outputting a comparison result of test failure,and outputting a test result of the test group according to a plurality of comparison results; wherein the anti-error reference picture comprises a custom feature picture conforming to certain customfeatures, an interference picture generating interference during screenshot and a picture in development in the development process. According to the method, the problems that in traditional front-end automatic testing, the test case preparation workload is large, the adaptive demand change is poor, only forward expected testing can be conducted, a benchmark version is difficult to prepare, and atest scheme cannot well reflect the test service value can be solved.

Owner:付彪

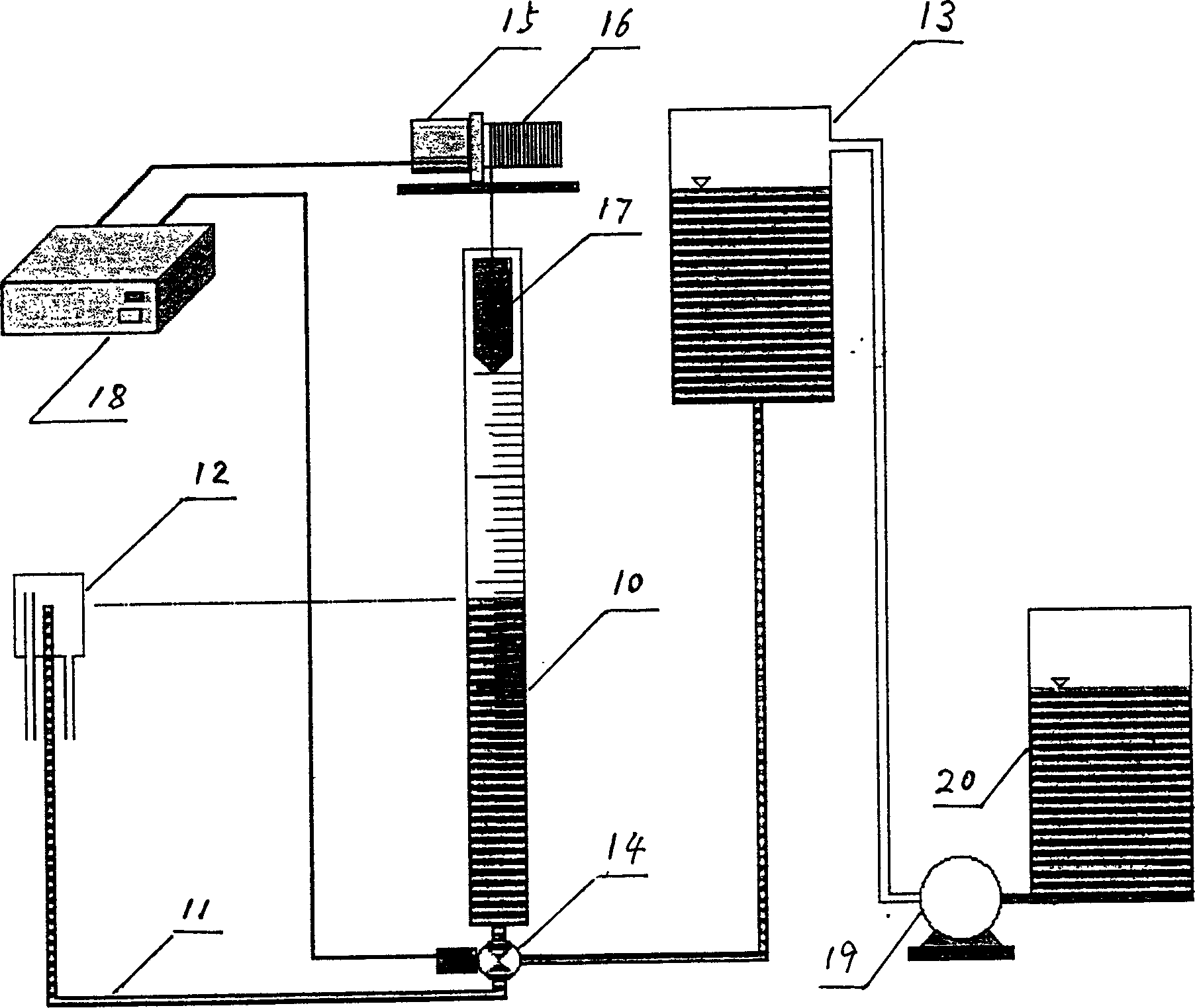

Water hexavalent chromium detection method based on machine vision

InactiveCN112082983AReduce Uncertain InterferenceGood precisionMaterial analysis by observing effect on chemical indicatorMachine visionProcess engineering

The invention discloses a water body hexavalent chromium detection method based on machine vision. The method adopts an automatic liquid adding device to make the liquid adding process more precise, avoids improper manual operation, and reduces the risk of manual use of chemicals; meanwhile, a machine vision device is designed, and interference caused in the image acquisition process is effectively reduced by optimizing the image acquisition process; Retinex-based color recovery multi-scale MSRCR image enhancement is adopted, so that the image color can be kept clear, the influence of illumination in image acquisition can be reduced, and a good effect of the acquired image can be ensured; and finally, a hexavalent chromium detection modeling method based on a color difference model is constructed to replace a traditional modeling method with the maximum correlation of image features and hexavalent chromium concentration, the color features of the image are more comprehensively considered, and the established color difference model is higher in robustness and higher in accuracy.

Owner:ZHEJIANG UNIV OF TECH

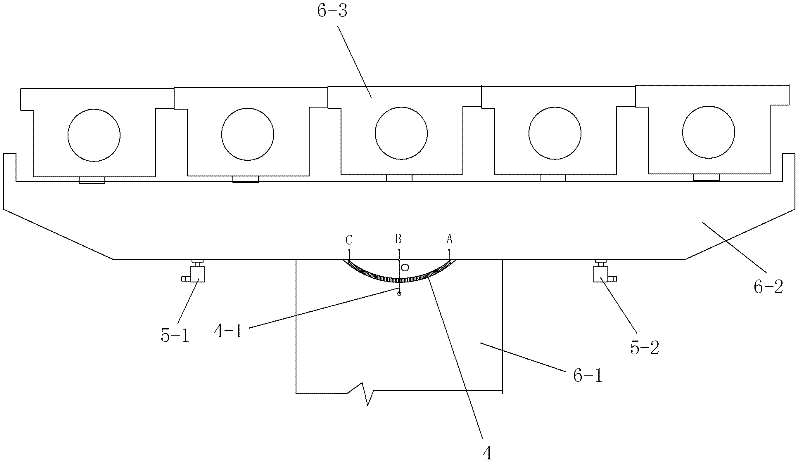

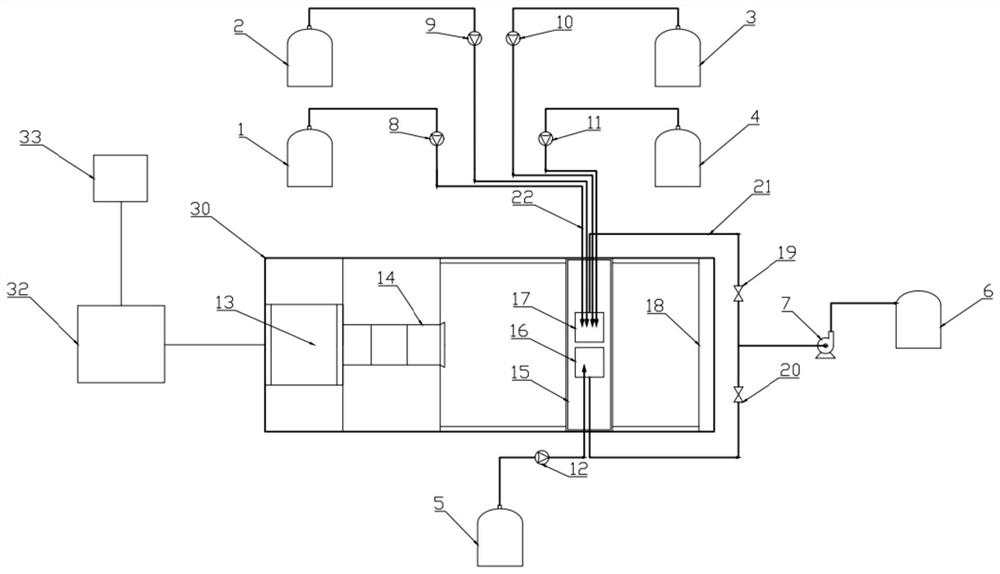

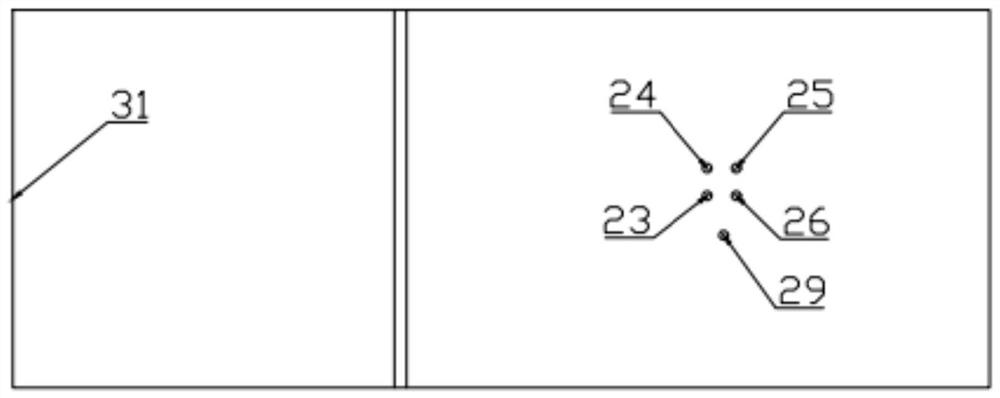

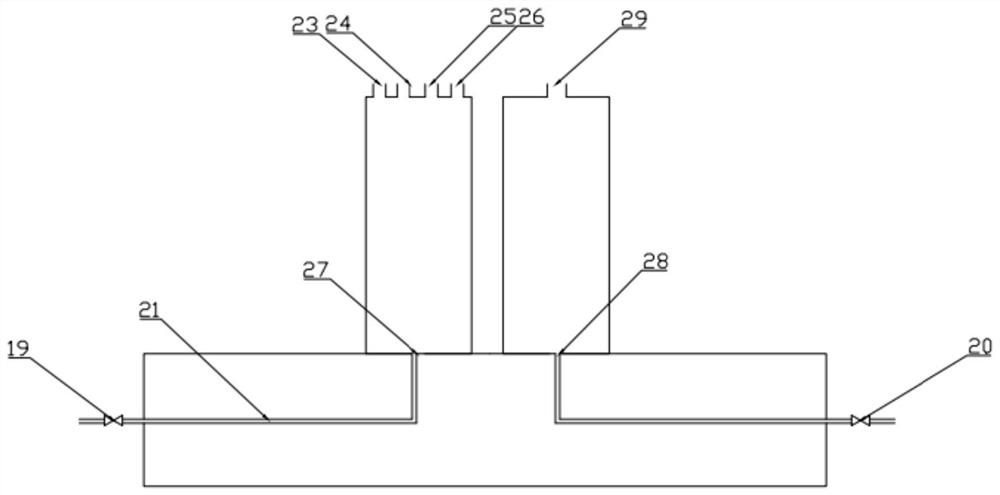

Reciprocating sealed foundation test system and method

ActiveCN109253130AStrong contrastImprove test efficiencyFluid-pressure actuator testingFuel tankForce curves

The invention provides a reciprocating sealed foundation test system and method. A piston rod of a first test cylinder and a piston rod of a second test cylinder in the reciprocating sealed foundationtest system are connected with a piston rod of a driving cylinder; an input end of a first main pump is connected with a first oil tank, an output end of the first main pump communicates with a portP of a first electromagnetic reversing valve, a port A of the first electromagnetic reversing valve communicates with an oil inlet of the driving cylinder through a first test branch circuit, an oil outlet of the driving cylinder communicates with a port B of the first electromagnetic reversing valve through a second test branch circuit, and a port T of the first electromagnetic reversing valve isconnected with a first oil tank; and an input end of a second main pump is connected with a second oil tank, an oil inlet of the first test cylinder and an oil inlet of the second test cylinder communicate with an output end of the second main pump, an oil outlet of the first test cylinder and an oil outlet of the second test cylinder are connected with an input end of a first overflow valve, andthe output end of the first overflow valve is connected with the second oil tank. By the system, a frictional force curve, a kinetic friction force curve and a leakage-cycle index curve can be obtained.

Owner:江阴市洪腾机械有限公司

Reciprocating seal basic test system and test method

ActiveCN109253130BStrong contrastImprove test efficiencyFluid-pressure actuator testingEngineeringOil intake

Owner:江阴市洪腾机械有限公司

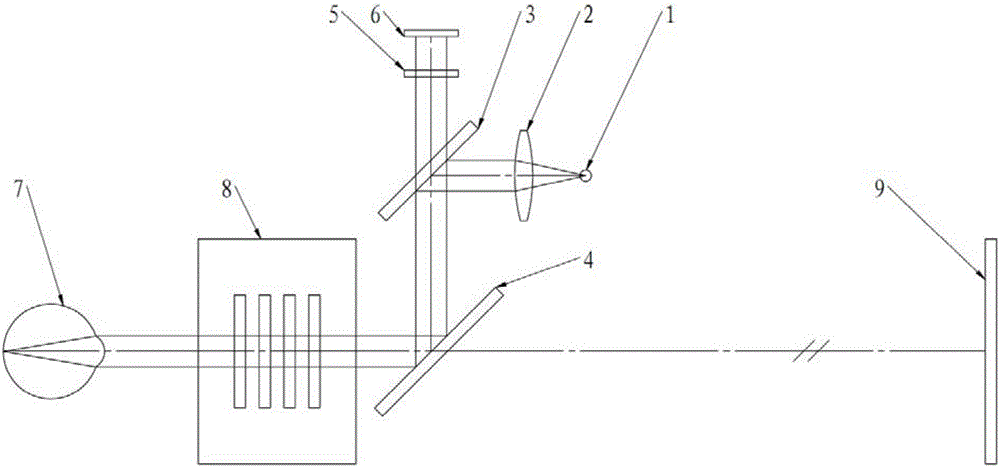

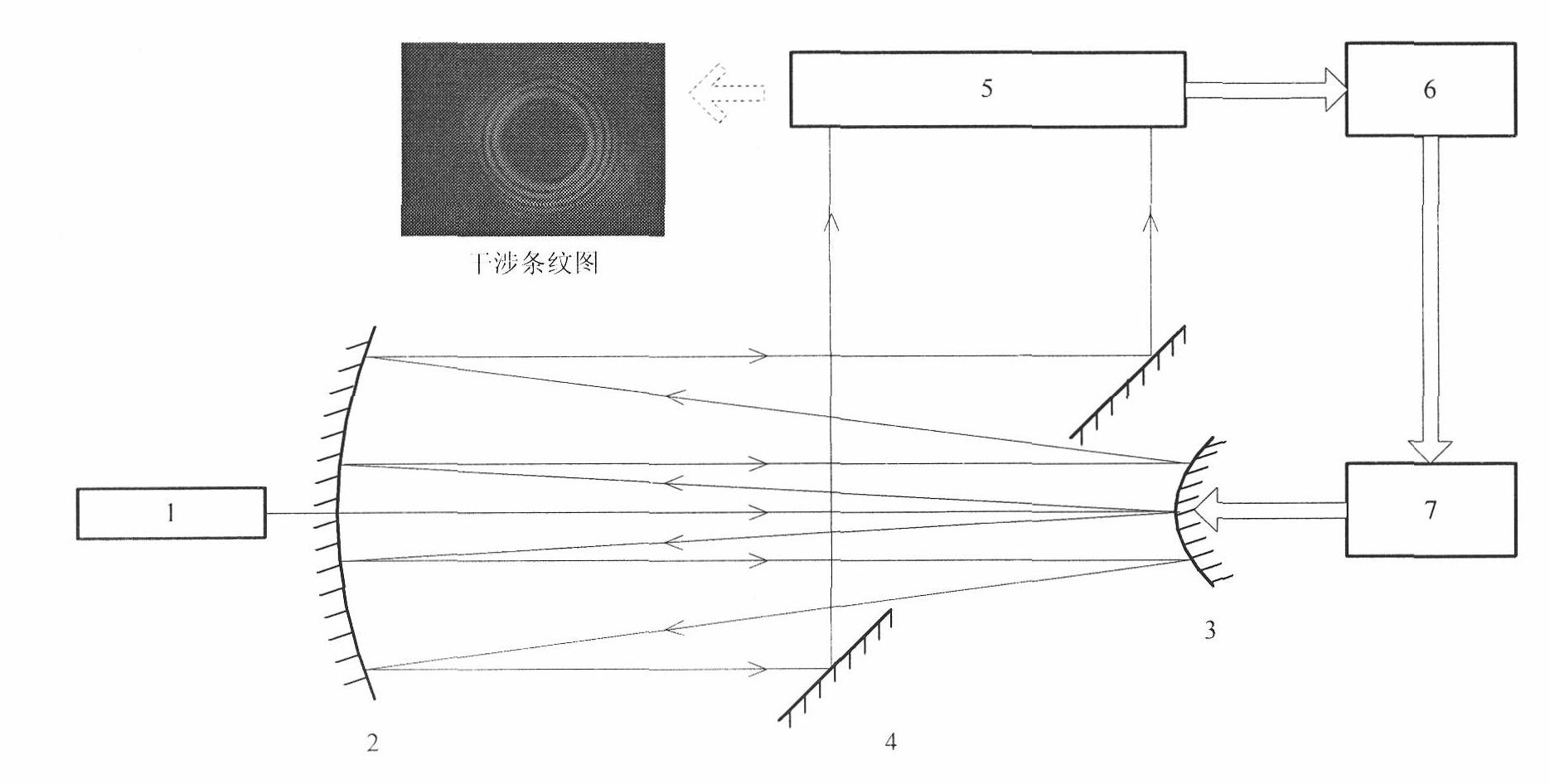

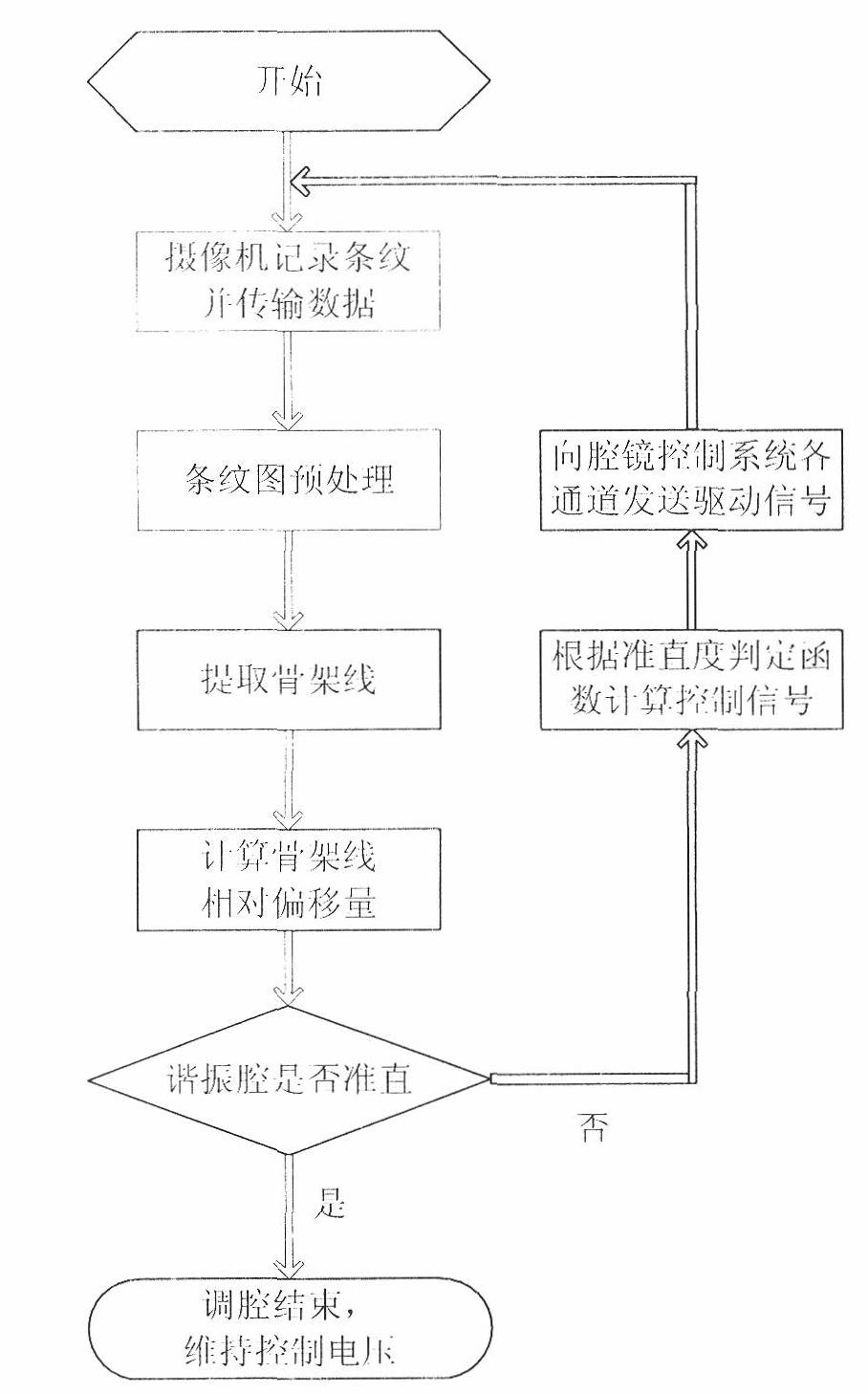

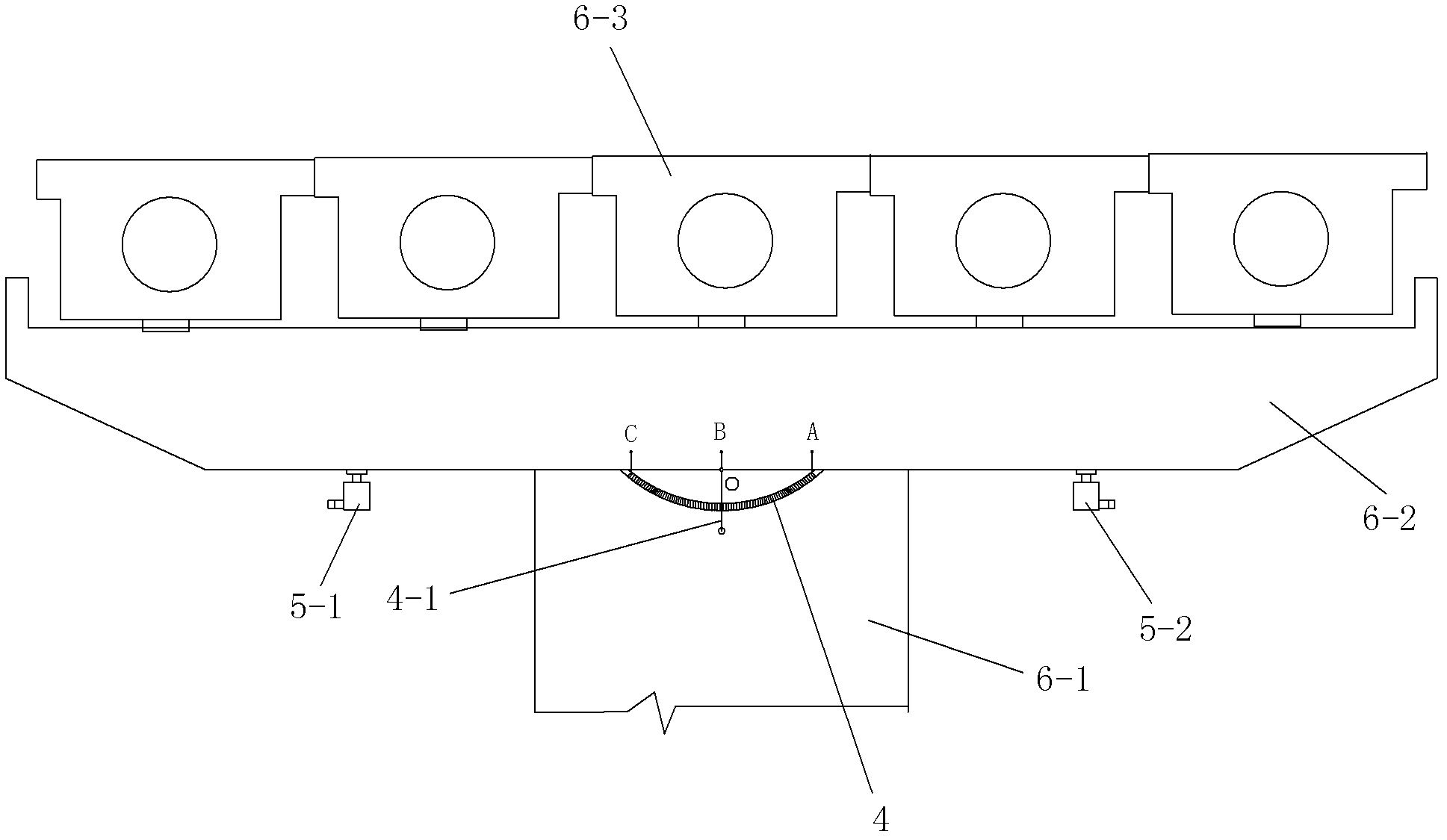

Laser resonant cavity automatic cavity adjusting system and method based on interference fringe picture skeleton line processing

InactiveCN101710667BEliminate subjective errorsHigh precisionLaser detailsComputer controlResonant cavityControl signal

The invention discloses laser resonant cavity automatic cavity adjusting system and method based on interference fringe picture skeleton line processing. The automatic cavity adjusting system comprises a guide light laser, a laser resonant cavity, a coupling output mirror, a camera, a computer and a cavity mirror control system, wherein the laser resonant cavity comprises an adjustable cavity mirror. The invention also provides an automatic cavity adjusting method corresponding to the automatic cavity adjusting system, which can perform rapid and precise judgment on the alignment of the laserresonant cavity and provide a control signal in real time for the cavity mirror control system, thereby achieving the aim of rapidly and automatically adjusting a cavity. By adopting the cavity adjusting system and the cavity adjusting method, the precision, speed and repeatability of the traditional manual cavity adjusting method can be effectively improved. In addition, the method can be further popularized and applied to the automatic adjustment of an optical system with an interference fringe of an output light field.

Owner:NAT UNIV OF DEFENSE TECH

An Image Processing Method for Automatic Recognition of Pointer Meter Readings

ActiveCN104392206BSmall amount of calculationHigh positioning accuracyCharacter and pattern recognitionComputer graphics (images)Full scale

An image processing method for automatic recognition of pointer instrument readings disclosed by the present invention, the implementation steps are as follows: (1) Hough circle detection is performed on the image, the center and radius of the dial are located using the weighted average method, and a square image of the dial area is extracted; (2) Image preprocessing, extracting the binary value of the instrument pointer to refine the image; (3) Use the center projection method to determine the pointer angle; (4) Extract the zero scale line, full scale line position template, and calibrate the starting point and end position of the range; (5) Use the template Match to get the angle of zero scale line and full scale line; (6) Calculate the pointer reading according to the pointer angle, zero scale line angle and full scale line angle. The invention solves the problem that the relative position of the camera and the pointer meter is not fixed, which leads to the problem that the position of the meter dial on the collected image is not fixed, not only can eliminate the subjective error caused by manual reading of the meter reading, but also can improve the efficiency and accuracy , Guarantee the safety of personnel, wide application range and strong robustness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electronic Camera Tool Presetting Equipment and Measuring Method

ActiveCN105922080BThe test result is accurateDetection speedAutomatic control devicesMeasurement/indication equipmentsGratingComputer module

The invention relates to an electronic camera shooting type tool presetting device and measurement method. The electronic camera shooting type tool presetting device is characterized in that the device comprises a Y-direction horizontally-moving mechanism, a detection mechanism, an X-direction horizontally-moving mechanism, a Z-direction main shaft mechanism and a drive module; the upper portion of the X-direction horizontally-moving mechanism is fixedly connected with the lower portion of the Y-direction horizontally-moving mechanism; the detection mechanism is connected with the Y-direction horizontally-moving mechanism; the Z-direction main shaft mechanism is arranged below the detection mechanism; the Y-direction horizontally-moving mechanism, the detection mechanism, the X-direction horizontally-moving mechanism and the Z-direction main shaft mechanism are controlled by the drive module to act; the Y-direction horizontally-moving mechanism comprises a stand column, a Y-direction servo motor, a Y-direction synchronous belt, a Y-direction toothless threaded rod, a Y-direction grating ruler, a Y-direction guide rail, a Y-direction slide block, a Y-direction slide table, a Y-direction limiting switch, a Y-direction limiting baffle, a connection belt, bearings, a Y-direction fine adjustment wheel and a detection mechanism balancing weight; the stand column is a rectangular frame, wherein the back face of the stand column is in a U shape; the Y-direction guide rail is installed on the front face of the stand column; and the Y-direction slide table is fixed to the Y-direction guide rail through the Y-direction slide block.

Owner:TIANJIN TIANMEN JINBAO TECH CO LTD

Remotely-measuring remotelly-controlled rertical displacement meter

InactiveCN1186588CReduce laborEliminate subjective errorsBarrages/weirsElectrical/magnetic solid deformation measurementRemote controlElectromagnetic valve

Two portions of large dam horizontal-vrtical displacement meter are respectively improved, the horizontal portion, the counterpoise for measuring steel wire is changed into electric measurement, the internally-mounted small type hoist can be used for controlling suspension and put-down of the counterpoise, and the displacement can be read out by coder, and the horizontal measurement portion, a liquid-supplying box is added, an electromagnetic valve is set and is connected with level meter, and a controller is used for controlling electromagnetic valve to supply liquid. It also includes the components of stepper motor and plumb, and can make two displacement measurements so as to implement automation, remote measurement and remote control, and can raise the measurement accuracy.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

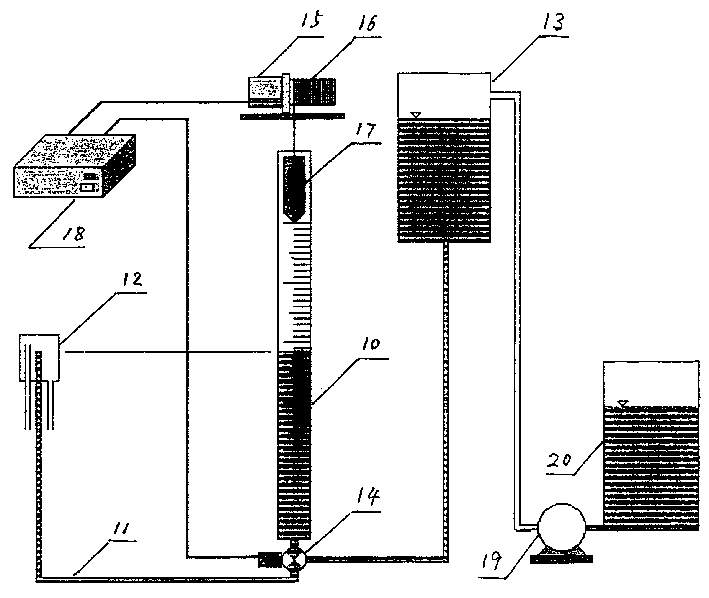

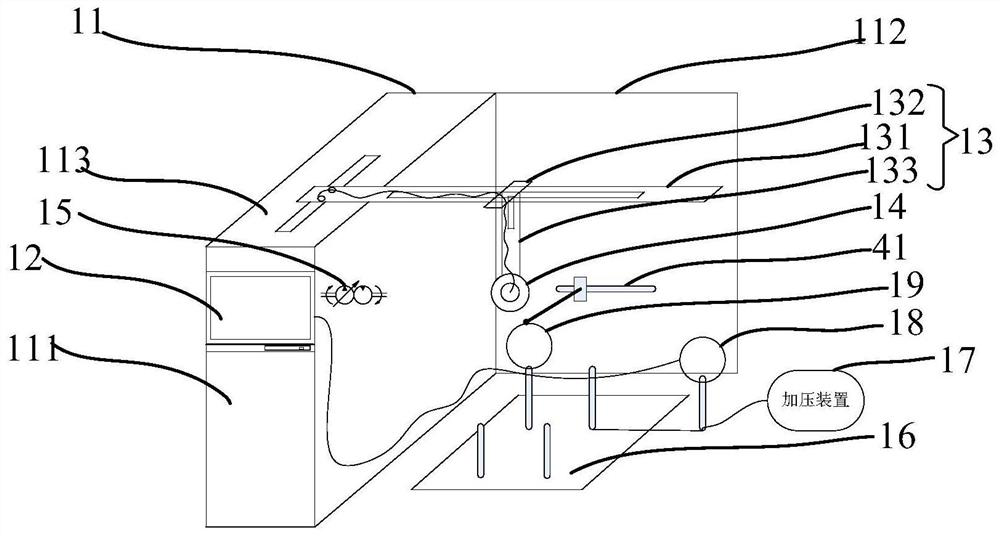

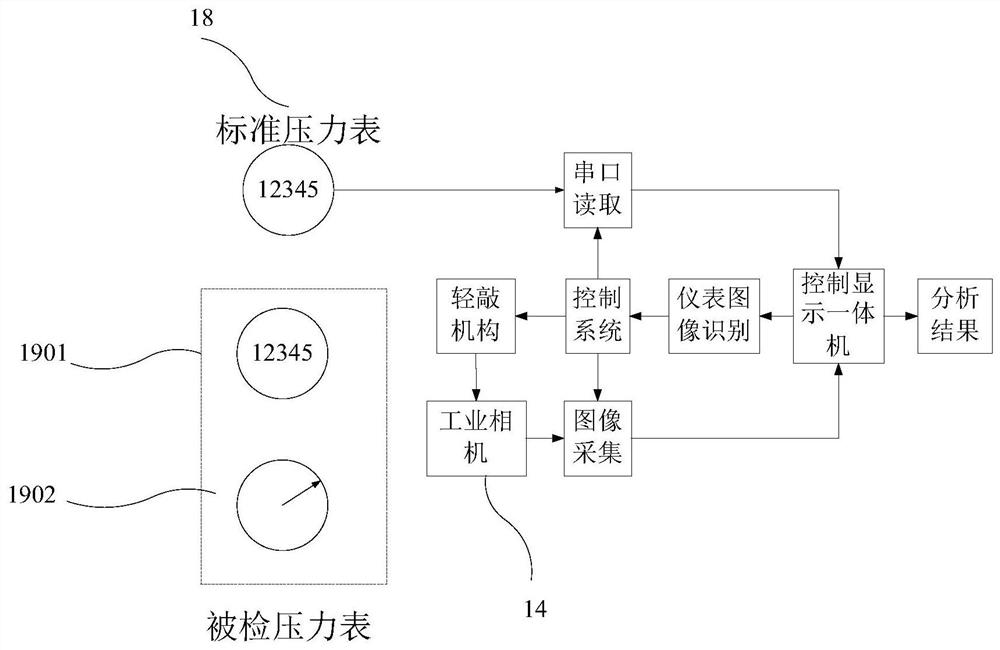

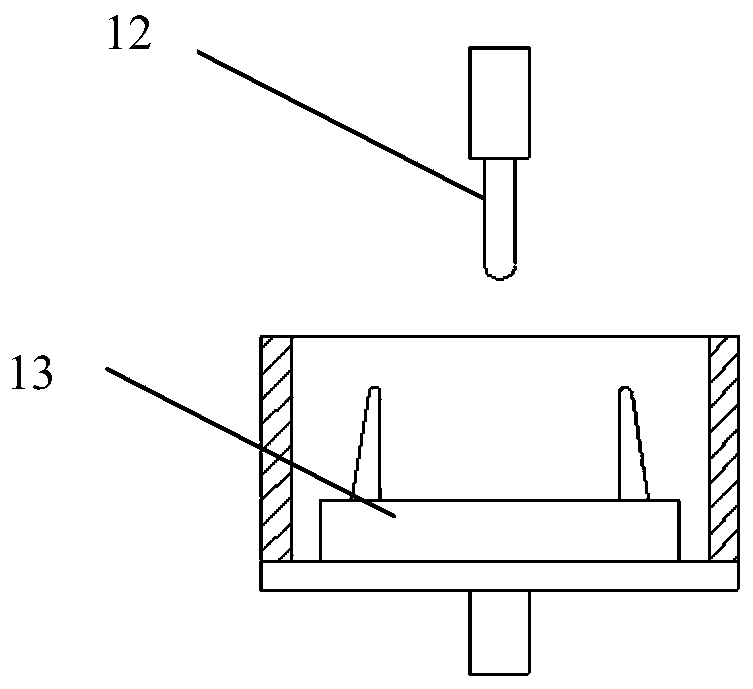

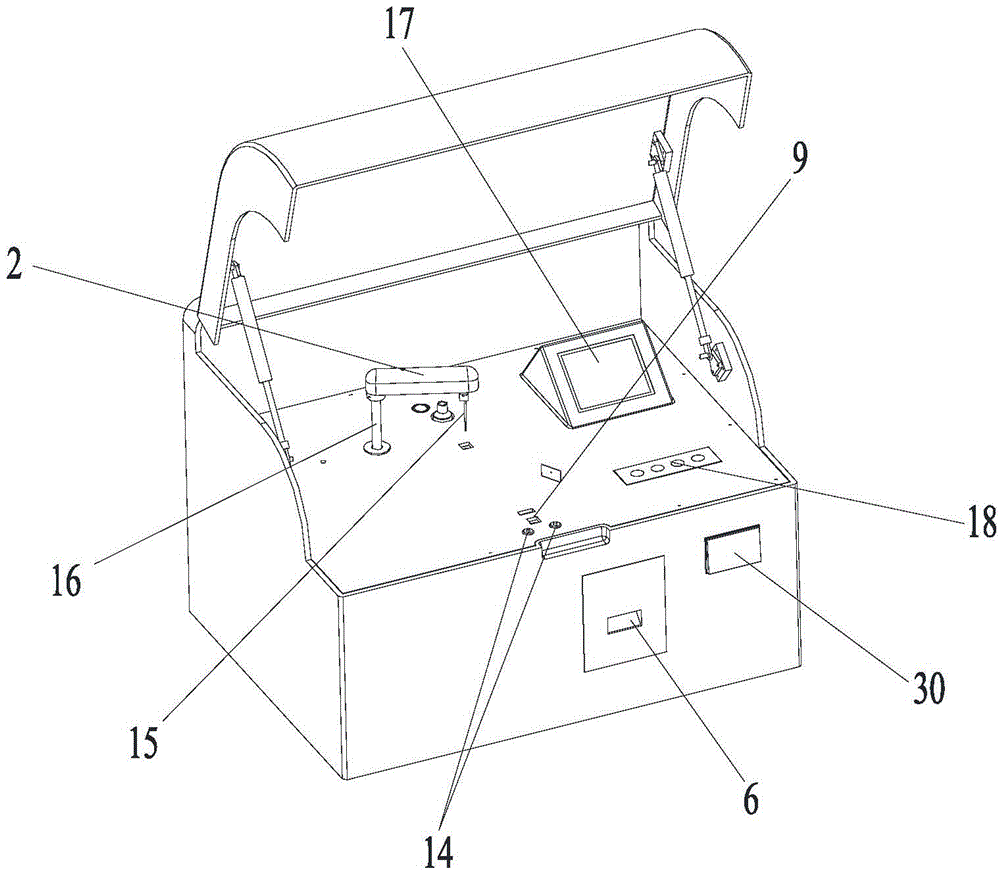

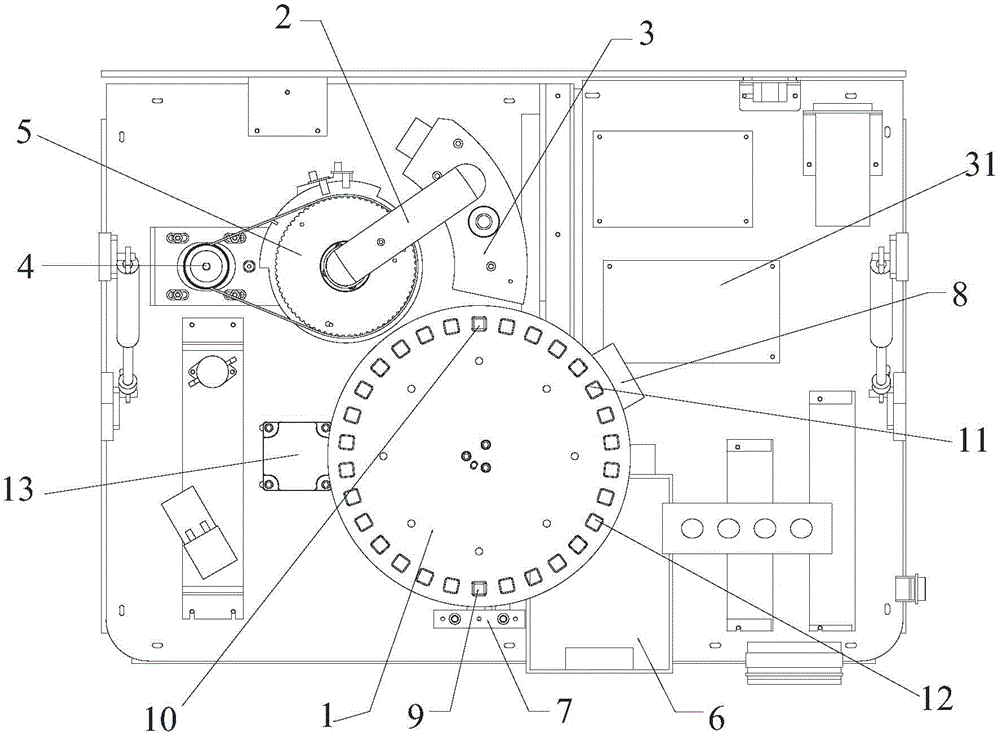

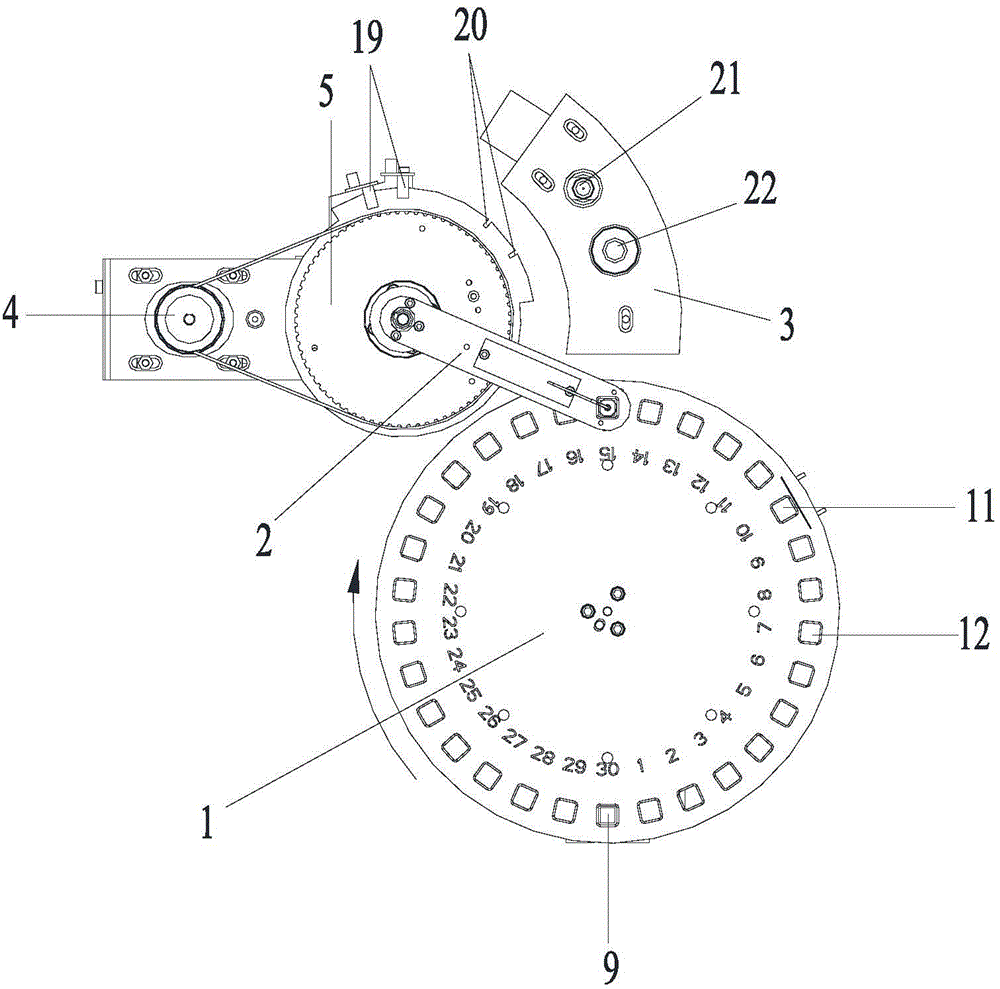

Automatic calibrating device for pressure instrument and calibrating method thereof

PendingCN112633291AImprove test efficiencyEliminate subjective errorsCharacter and pattern recognitionNeural learning methodsMachine visionControl engineering

The invention provides an automatic calibrating device for a pressure instrument. The automatic calibrating device comprises a device body framework; a control and display all-in-one machine embedded in a front panel; position adjusting sliding rails of a camera arranged in the X direction, the Y direction and the Z direction respectively; an industrial camera arranged on the position adjusting sliding rails of the camera; an adjusting motor which is connected with an acquisition controller and comprises three linear motors, and the three linear motors drive the position adjusting sliding rails of the camera to move in the X direction, the Y direction and the Z direction respectively; a multi-channel pressure gauge inspection bench; a pressurizing device connected with the multi-channel pressure gauge inspection bench; and a standard pressure gauge connected with the control and display all-in-one machine through serial port output. The invention further provides a calibrating method of the automatic calibrating device for the pressure instrument. According to the automatic calibrating device for pressure instrument and calibrating method thereof, the machine vision technology is utilized, the image acquisition processing identification method is adopted to replace a traditional human eye identification method, subjective errors caused by a manual observation method are eliminated, and the detection precision and efficiency are improved.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST

Multifunctional oral cavity material testing machine

PendingCN110376097AAchieve replacementImprove versatilityFlow propertiesUsing mechanical meansMaterials testingEngineering

The invention provides a multifunctional oral cavity material testing machine. In an existing oral cavity material evaluation test, a test device has a single function, and each device can only test single performance of a single material; traceability is difficult, the existing test device is mostly designed temporarily, there is no corresponding design specification, there is no verification orcalibration specification, and a measurement result is difficult to trace; and an subjective influence is difficult to avoid, the existing test device is mostly the simple device which requires manualoperation, sometimes, the device needs to be used together with displacement measuring equipment, timing equipment and the like, and the influence of a human subjective factor is difficult to avoid.The testing machine can be widely used in the performance evaluation field of different oral cavity medical devices.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

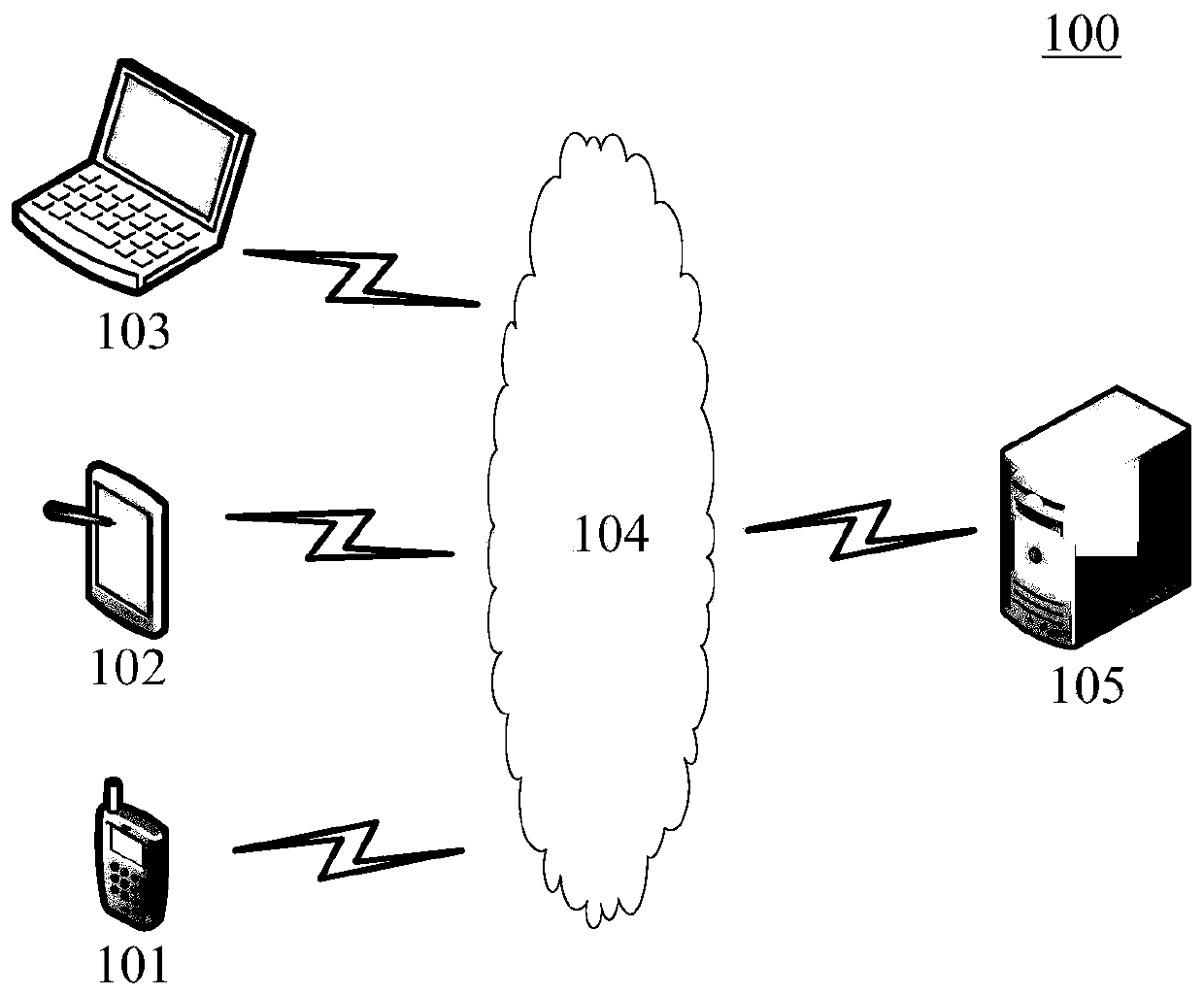

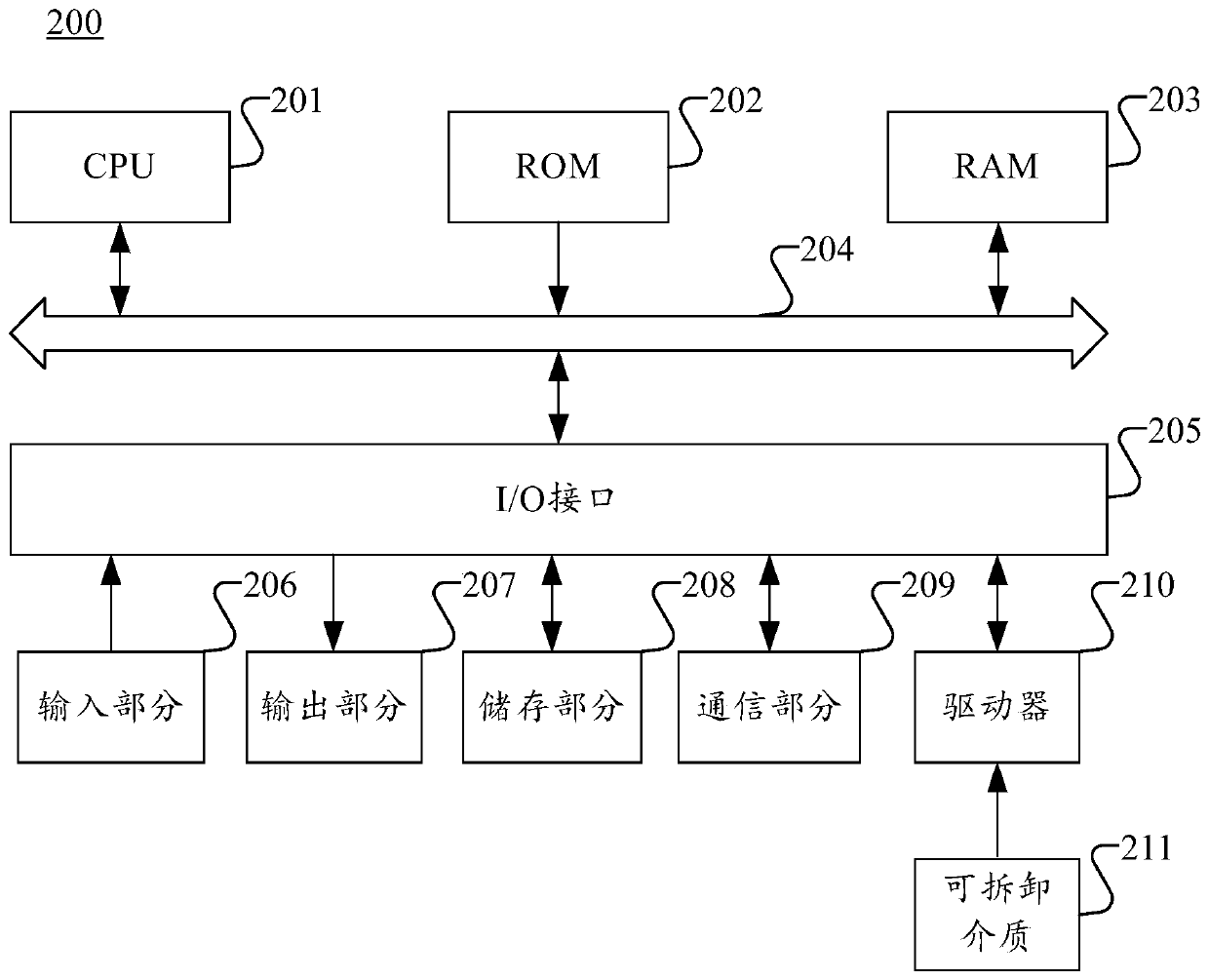

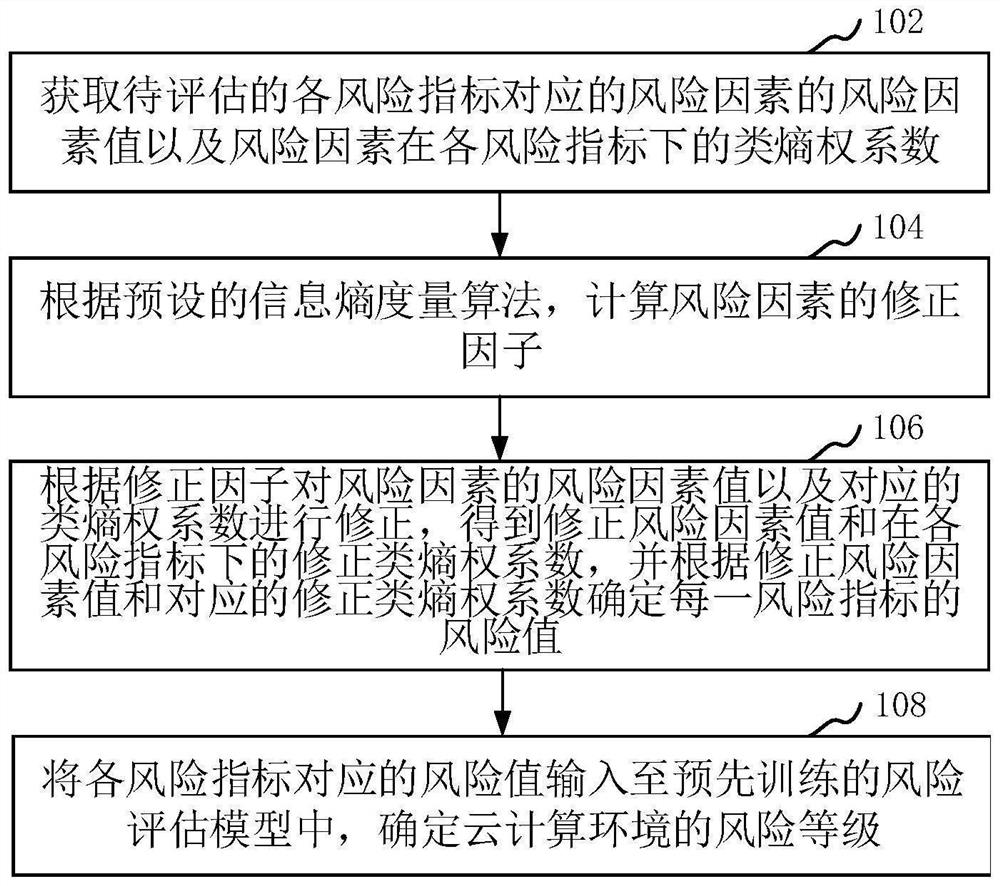

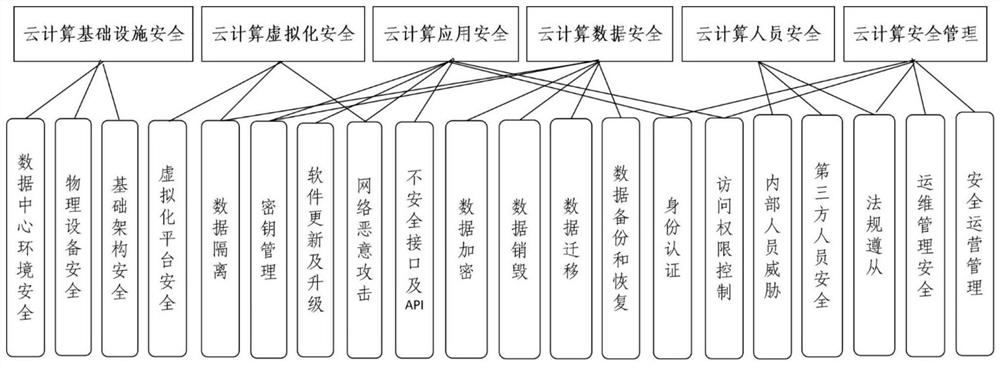

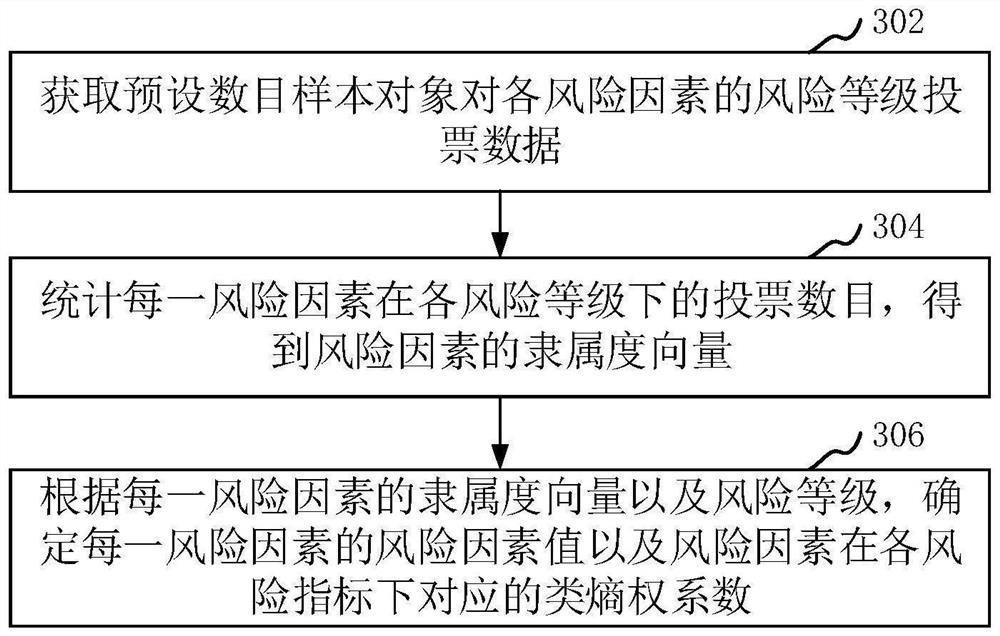

Risk assessment method and device, computer equipment and storage medium

PendingCN114363004AImprove accuracyImprove reliabilityPlatform integrity maintainanceNeural architecturesAlgorithmRisk indicator

The invention relates to a risk assessment method and device, computer equipment, a storage medium and a computer program product. The method comprises the following steps: acquiring a risk factor value of a risk factor corresponding to each risk index to be evaluated and a class entropy weight coefficient of the risk factor under each risk index; calculating a correction factor of the risk factor according to a preset information entropy measurement algorithm; correcting the risk factor value of the risk factor and the corresponding class entropy weight coefficient according to the correction factor to obtain a corrected risk factor value and a corrected class entropy weight coefficient under each risk index, and determining a risk value of each risk index according to the corrected risk factor value and the corresponding corrected class entropy weight coefficient; and inputting the risk value corresponding to each risk index into a pre-trained risk assessment model, and determining a cloud computing environment risk level. By adopting the method, the accuracy and reliability of risk assessment are improved.

Owner:SHANGHAI PUDONG DEVELOPMENT BANK

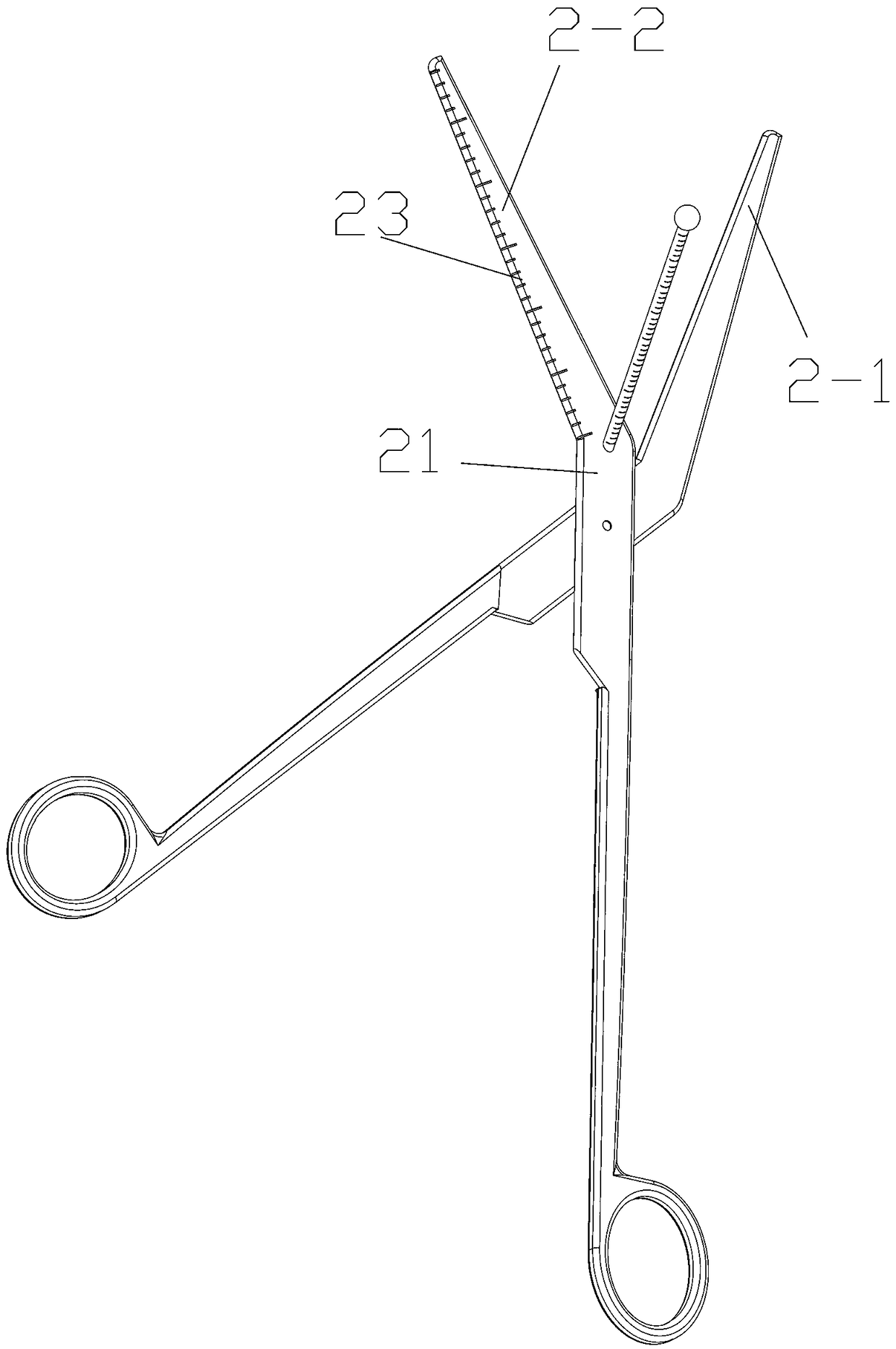

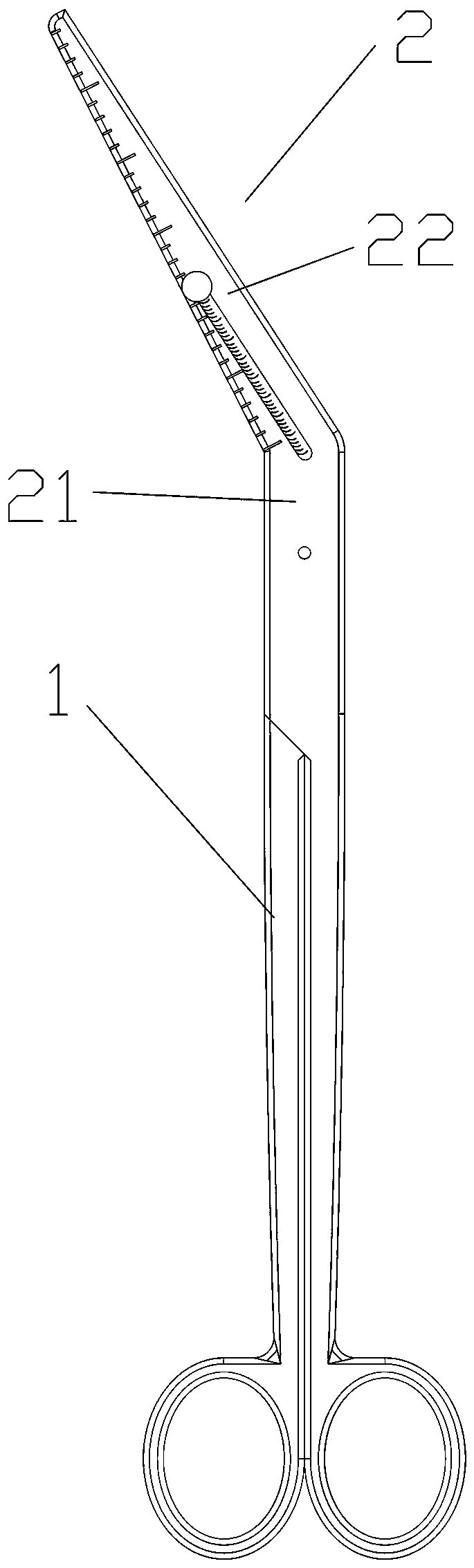

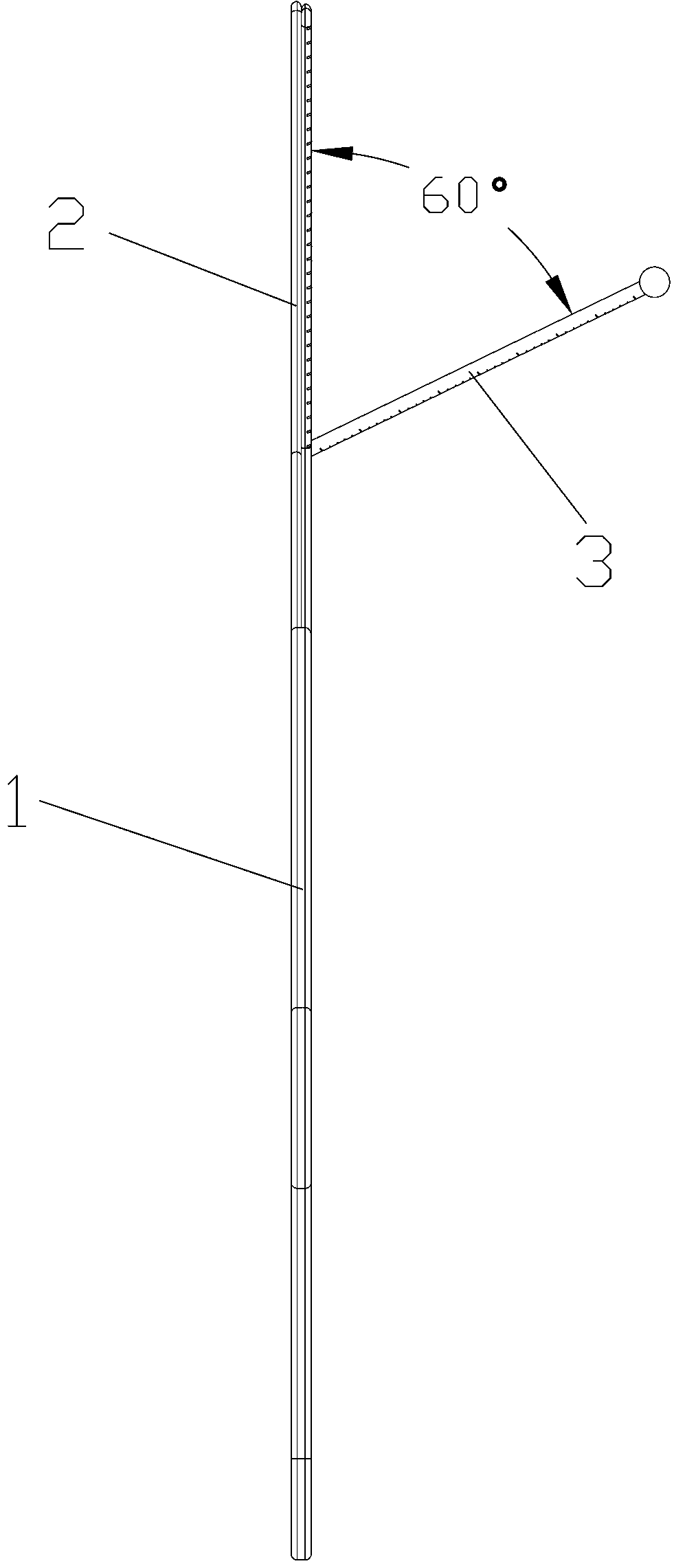

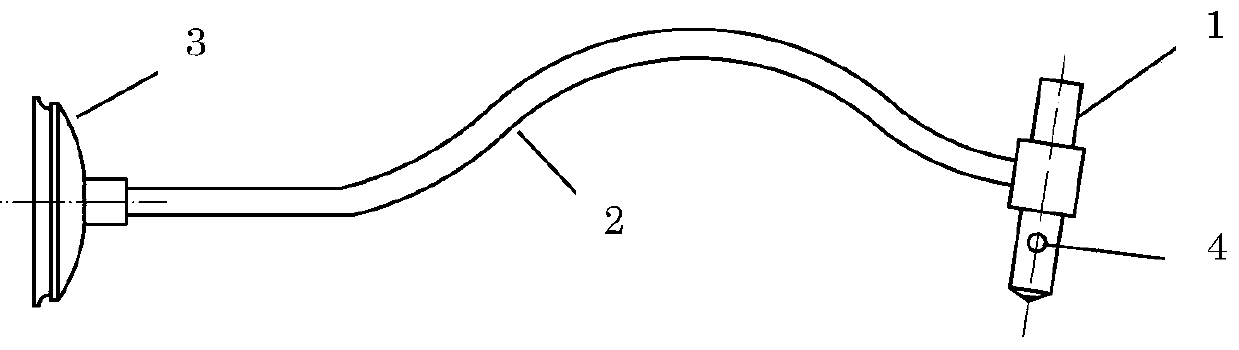

Episiotomy shear

PendingCN108742788AReduce tissue damageEliminate subjective errorsSurgical scissorsObstetrical instrumentsPerineal structureEngineering

The invention belongs to the field of a medical tool, and particularly relates to an episiotomy shear. The episiotomy shear comprises two shearing arms, wherein the two shearing arms are mutually hinged; each shearing arm comprises a shearing part and a handle part; the shearing part is positioned at the front part of a hinging point and is provided with a shearing edge; the handle part is positioned at the back part of the hinging point; the shearing part comprises a connecting section and a shearing section; the connecting section is formed by extending in the length direction of the handlepart; the shearing section is formed by bending and upwards raising the front end of the connecting end; the shearing edge is arranged on the shearing section;the shearing parts on the two shearing arms respectively are devided into a lower shearing part 2-1 extending into the perineum and an upper shearing part 2-2 positioned outside the perineum; a marker rod is erected on the outer side surface, backing to the lower shearing part, of the upper shearing part; an included angle between the marker rod and the upper shearing part is 60 degrees. Through the arrangement of the marker rod, the marker rod and the upper shearing part are positioned outside the perineum in the use process; the perineum length can be simply, fast and conveniently evaluated; through the positioning of the marker rod vertical to the anus, the episiotomy shear placing position, i.e., the 60-degree angle of the episiotomy can be accurately and fast positioned; the episiotomy angle is fixed.

Owner:ATTACHED OBSTETRICS & GYNECOLOGY OSPITAL MEDICALCOLLEGE ZHEJIANG UNIV

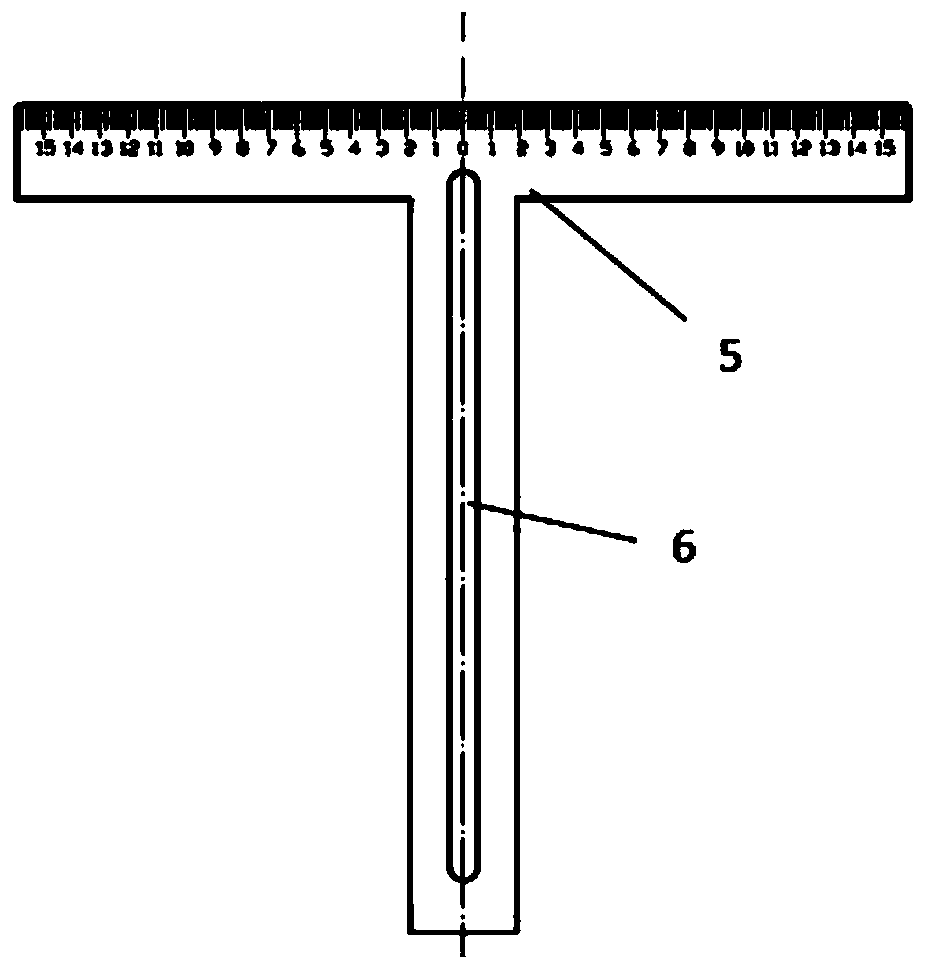

Auxiliary tool and method for quickly centering axis of steering wheel

ActiveCN109877745AIn line with the principle of opticsHigh precisionWork holdersMetal-working hand toolsSteering wheelEngineering

The invention provides an auxiliary tool and a method for quickly centering the axis of a steering wheel and relates to the technical field of manufacturing and debugging of vehicles. The auxiliary tool comprises light positioning components and T-shaped rulers, wherein each light positioning component comprises a fixed base, a flexible connecting part and a linear light source, wherein each fixedbase is fixed to a glass window of a vehicle; each flexible connecting part is connected with the corresponding fixed base; each linear light source is installed at the movable end of the corresponding flexible connecting part; each T-shaped ruler comprises a horizontal ruler and a vertical ruler which is connected with the horizontal ruler; the central axis of the length of each vertical ruler is perpendicular to the central axis of the length of the corresponding horizontal ruler and passes through the midpoint of the central axis of the length of the corresponding horizontal ruler, whereineach horizontal ruler is provided with a length scale; each vertical ruler comprises a lathy through hole formed in the direction of the central axis of the length; and the center line of each lathythrough hole is overlapped with the central axis of the length of the corresponding vertical ruler. The auxiliary tool provided by the invention fully utilizes the existing equipment such as an adapter of which the horizontal scroll has a hole; the used auxiliary equipment only includes two light positioning components and two T-shaped rulers; linear light is used as reference for observation andcollimation, so the auxiliary tool preferably satisfies the principles of optics and is high in precision.

Owner:DONGFENG MOTOR CORP HUBEI

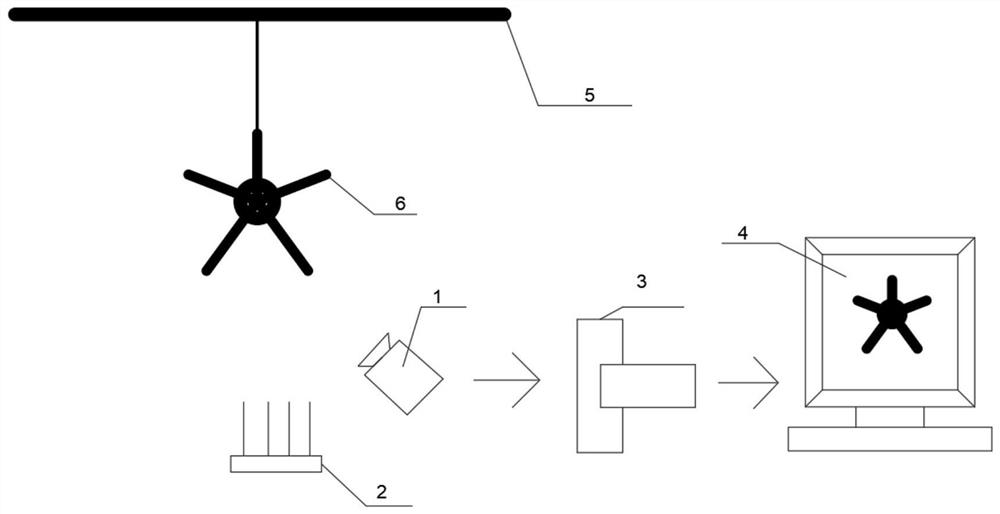

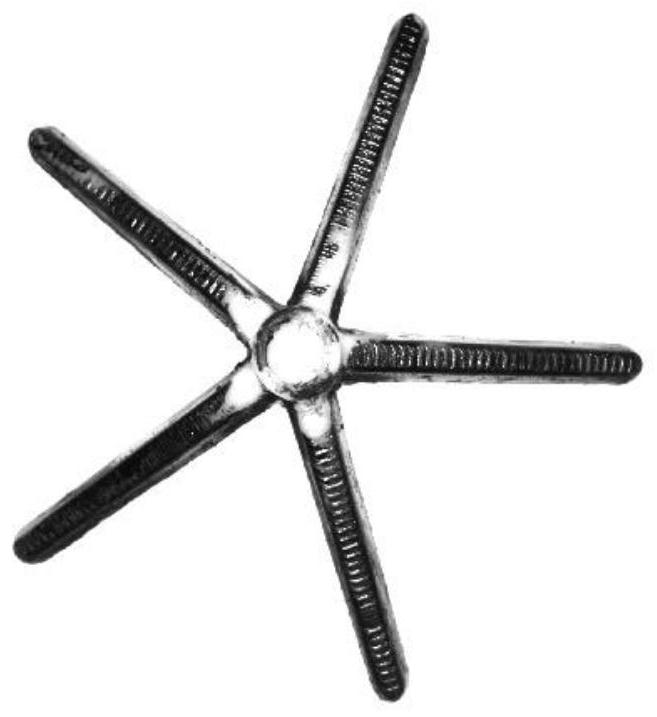

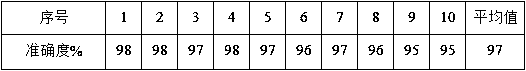

Method and system for detecting paint spraying defects of five-star feet based on machine vision

PendingCN113160154AAccurate identificationHigh measurement accuracyImage enhancementImage analysisTemplate matchingMachine vision

The invention discloses a method and system for detecting paint spraying defects of five-star feet based on machine vision, and the method comprises the steps: S1, adjusting parameters of a detection device, and turning on a camera; S2, acquiring an image of a to-be-detected part acquired by the camera; S3, performing median filtering on an image of the to-be-detected part to acquire an image after median filtering; S4, converting the processed image into a binarized image, and carrying out fixed threshold binarization on the binarized image to obtain an area with a gray value; S5, calculating the area of the area to obtain the area of the to-be-detected part; s6, performing template matching on the image after median filtering obtained in the step S3 to obtain similarity; and S7, calculating the difference between the area of the to-be-detected part obtained in the step S5 and the area of a standard part, and judging whether the to-be-detected part meets conditions or not according to the obtained similarity and the calculated difference to obtain a final detection result.

Owner:HANGZHOU DIANZI UNIV

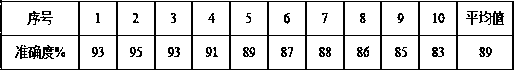

Method for improving accuracy of determining concentration of NMMO in premixed slurry

PendingCN109781662AAccurately reflect the real valueEliminate subjective errorsPhase-affecting property measurementsSingle sampleTemperature control

The invention provides a method for improving accuracy of determining concentration of NMMO in premixed slurry, and the method comprises the steps of stirring, sample putting and experimental result evaluation. According to the method, subjective factor errors of inspectors can be eliminated, operability is high, the real numerical value of the premixed slurry in large-scale production is accurately reflected, a digital display refractometer is adopted for automatic digital display constant-temperature control, and single sample detection of a sample is completed within one minute. The precision of the high-temperature visual inspection refractometer is 0.001, the precision of the digital display refractometer is 0.0001, the detection accuracy is improved from about 89% on average to 97%,and the sample detection error is set to be + / -0.2% according to the error of the high-temperature visual inspection refractometer.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642BReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Automatic bacterial vaginosis detector

ActiveCN103728460BFully automated detection is easy to operateHigh activityMaterial analysisFailure rateBacterial vaginosis

Owner:GUANGZHOU HONGQI OPTICAL INSTR TECH

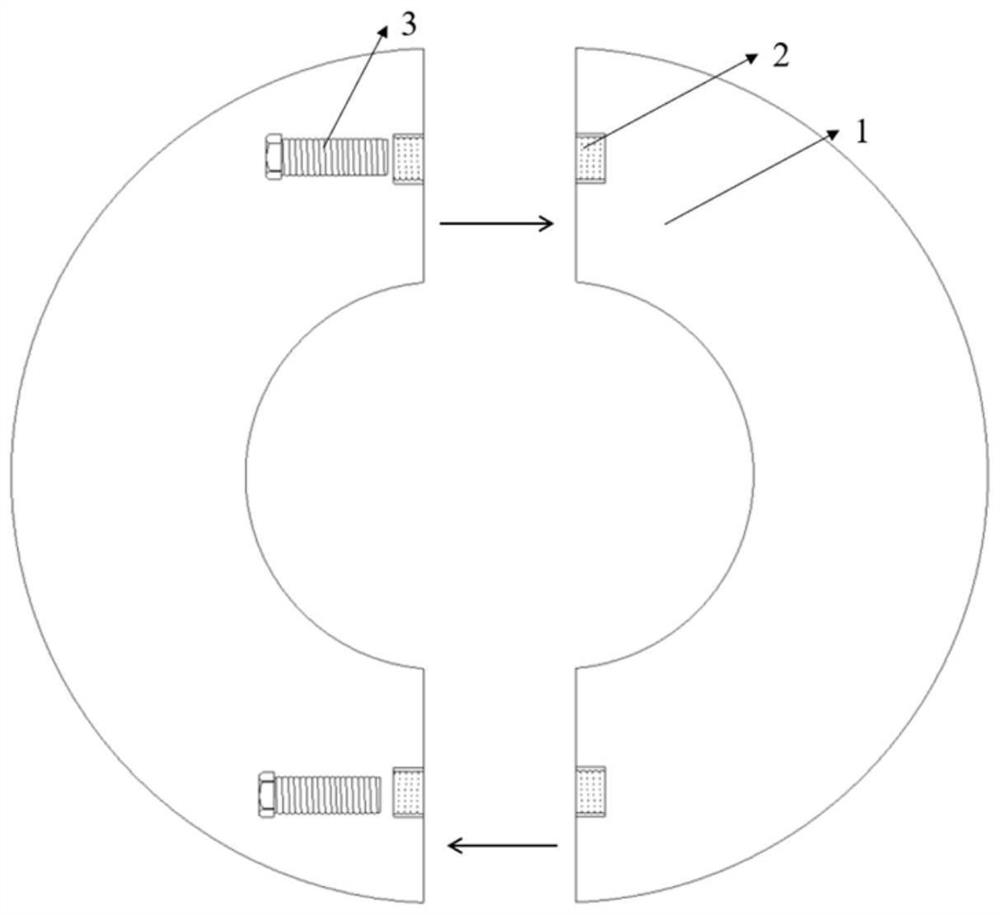

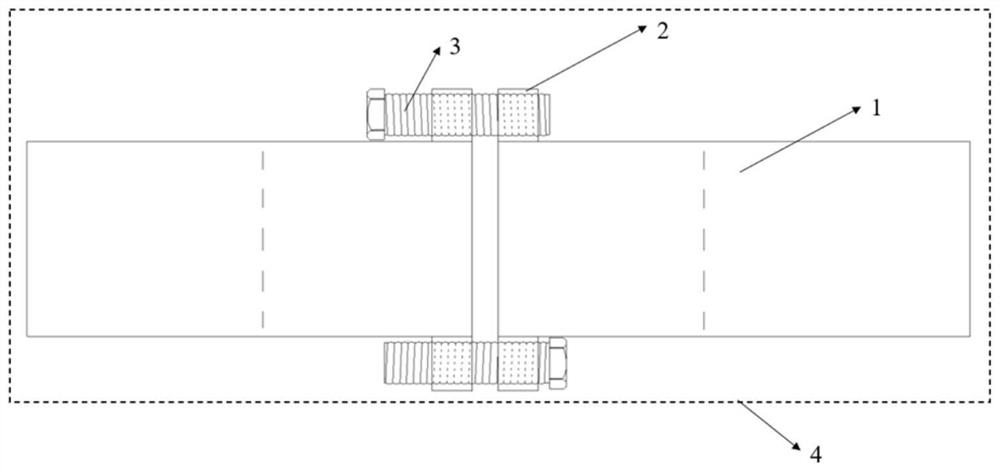

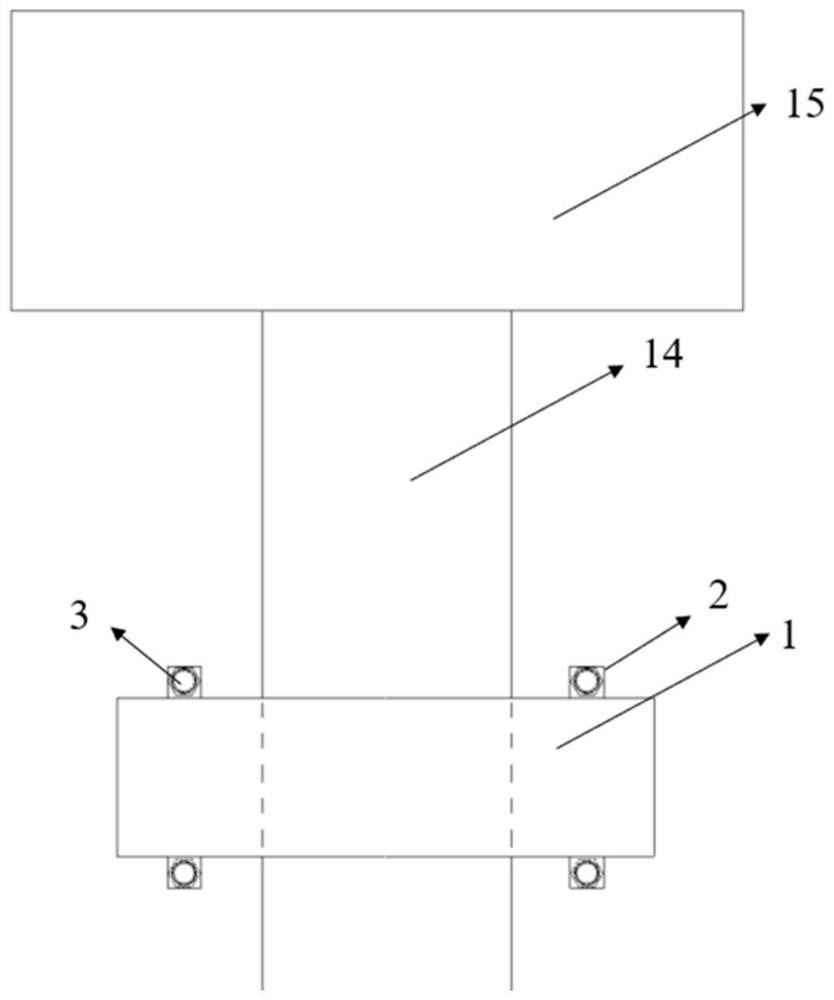

Non-eccentric vertical vibration device and method for pile foundation with cap based on snap-in device

ActiveCN113107025BEliminate difficultiesEliminates problems judging pile integrityFoundation testingVibration testingArchitectural engineeringStructural engineering

The invention discloses a non-eccentric vertical vibration device and method for a pile foundation with caps based on a buckle-type device. The present invention can use bolts to fix the half-type platform to a certain height of the pile body exposed on the ground surface, so that the half-type loading ring can be spliced at the pile body on the upper part of the platform, and the clamp can be used after it is assembled into a whole Lift the loading ring to a certain height, loosen the clamp, and the loading ring freely falls to the platform to apply excitation, which provides a non-eccentric vertical loading method for the pile foundation inspection under the existing cap. The loading method and device proposed by the present invention subtly overcome the disadvantage of being unable to perform vertical knocking on the top of the pile foundation to be tested with a cap in the traditional low-strain test, and the component connection has high repeatability and can be connected into various shapes , conveniently adjust the inner diameter of the loading ring to meet the positioning of workpieces of different shapes. The invention is suitable for the non-eccentric vertical excitation in the low-strain integrity detection of the pile foundation to be tested under the existing buildings.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com