Power generation prediction system and method based on equipment operation state and meteorological parameters

A technology for power generation and equipment operation, applied in the field of power generation prediction of photovoltaic power stations, can solve problems such as large errors in power generation prediction results, damage to photovoltaic cell packaging materials, and inaccurate power generation prediction results, so as to eliminate subjective errors and improve accuracy. Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

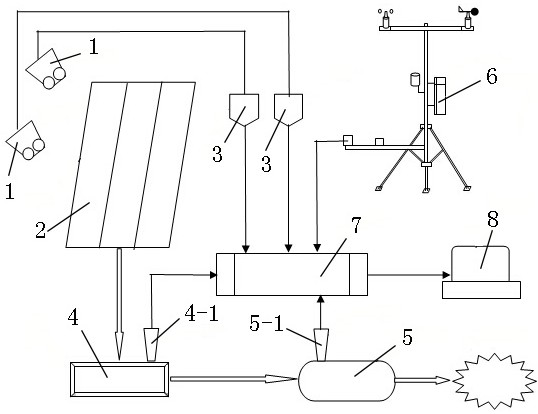

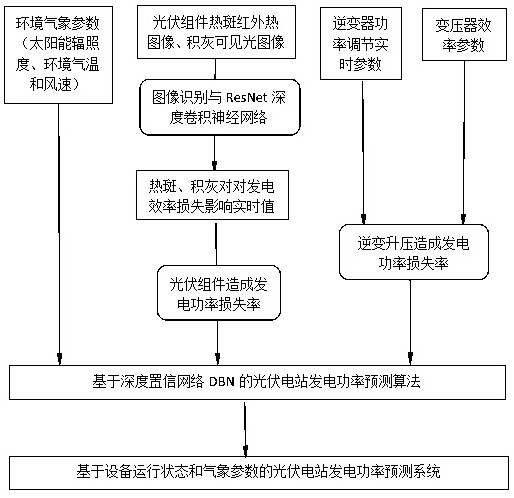

[0042] Embodiment one: if figure 1 , figure 2 As shown, a power generation prediction system based on equipment operating status and meteorological parameters includes several visible light-infrared thermal imaging integrated cameras 1, several image analysis modules 3, inverters 4 and inverter parameter collectors 4-1, Transformer 5 and transformer parameter collector 5-1, weather station 6, data acquisition card 7 and industrial control computer 8.

[0043] Visible light-infrared thermal imaging integrated camera 1 is equipped with a first lens (visible light lens) and a second lens (infrared thermal lens), the first lens is used to capture the "dust accumulation" image of the photovoltaic module 2 (that is, to obtain the visible light image of dust accumulation) , the second lens is used to take the "hot spot" image of the photovoltaic module 2 (that is, to obtain the infrared thermal image of the hot spot). Each photovoltaic panel of the photovoltaic module 2 is corresp...

Embodiment 2

[0055] Embodiment two: if figure 1 , figure 2 As shown, a power generation prediction method based on equipment operating status and meteorological parameters, the following steps are performed through the power generation prediction system

[0056] S1 obtains the loss rate of power generation caused by photovoltaic modules. The S1 specifically includes S11 shooting the photovoltaic module 2 through the visible light-infrared thermal imaging integrated camera 1 to obtain visible light images of dust accumulation and infrared thermal images of hot spots, and S12 analyzing the described Visible light images of dust accumulation and infrared thermal images of hot spots are used to obtain the loss rate of power generation caused by photovoltaic modules. Visible light-infrared thermal imaging integrated camera 1 is equipped with a first lens (visible light lens) and a second lens (infrared thermal lens), the first lens is used to capture the "dust accumulation" image of the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com