Automatic calibrating device for pressure instrument and calibrating method thereof

A pressure instrument and verification device technology, applied in the field of pressure instrument automatic verification device, can solve problems such as weak automation capability and low versatility, and achieve the effects of improving efficiency, convenient use and operation, and improving detection accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

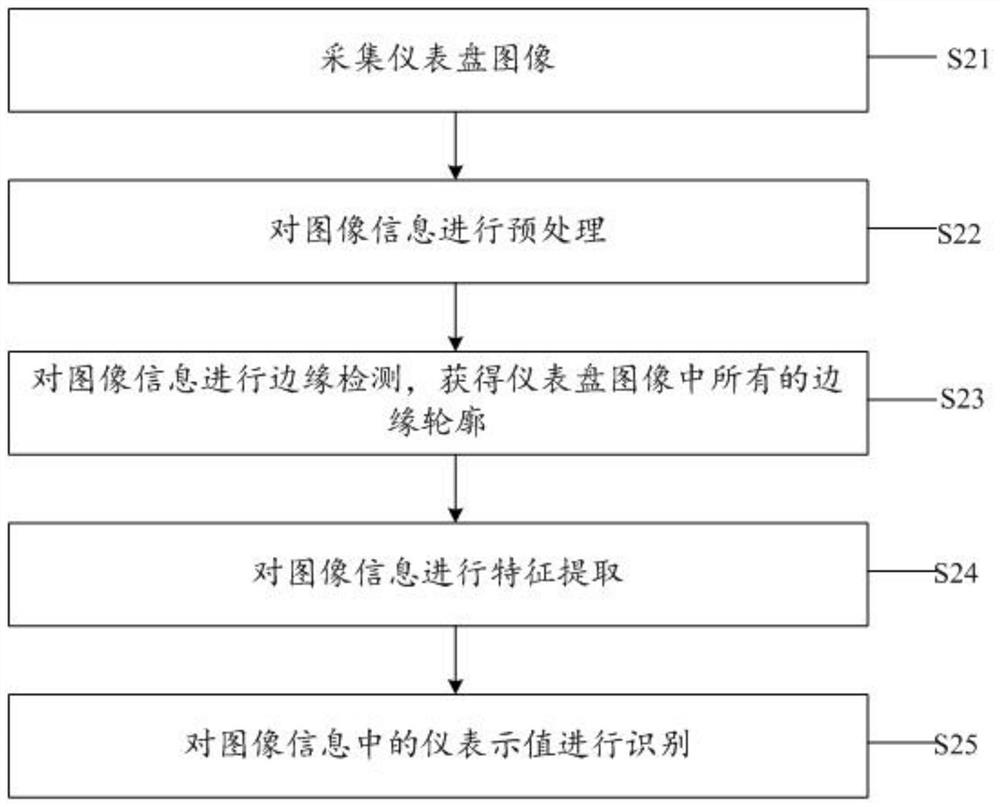

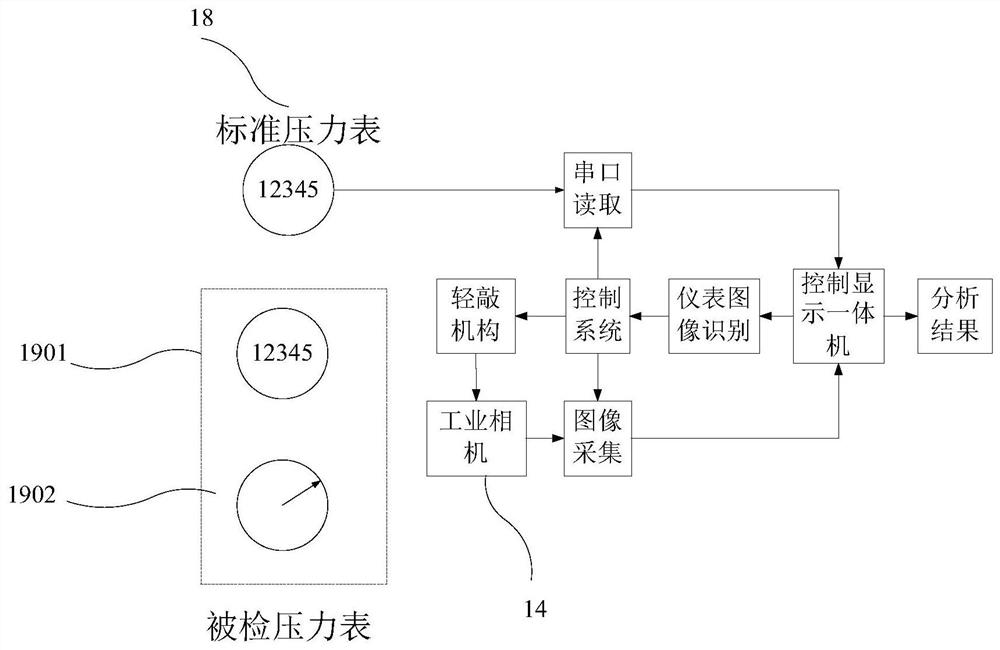

[0036]image 3 A number of digital pressure gauge images provided for the embodiment of the present invention is a schematic diagram. Referimage 3 , The detected pressure table 19 is a digital pressure table 1901, and the detected digital pressure table 1901 is fixed to the multi-channel pressure gauge passage test bench 16, and the operation control shows the position of the industrial camera 14 to adjust the position of the industrial camera 14. Its the axis of the detected digital pressure Table 1901 is on the line, the light intensity and focal length of the industrial camera 14 is adjusted, so that the industrial camera 14 can clearly identify the detected digital pressure gauge 1901 dial information, manual or automatic control pressurization device. 17. Start the acquisition process, trigger the industrial camera 14 to shoot the current pressure representation value. Standard Pressure Table 18 shows the connection to the control display one by serial port output.

[0037]In the a...

Embodiment 2

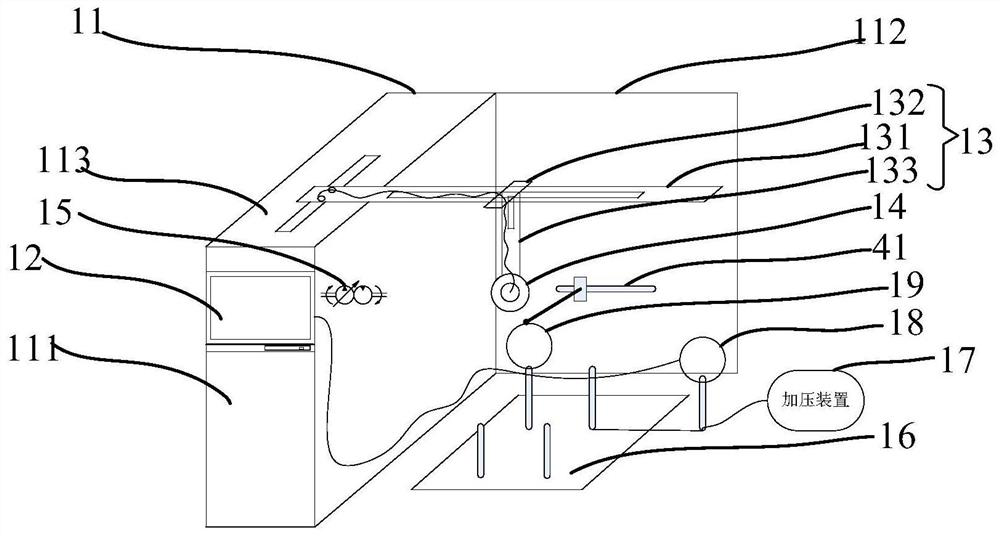

[0046]Figure 4 A schematic structural diagram of a pointer-type pressure gauge image provided in the second embodiment of the present invention. ReferFigure 4 The detected pressure table is the pointer pressure Table 1902, and the detected pointer pressure table 1902 is fixed to the multi-channel pressure gauge check bench 16, and the operation control display all-in-one drive adjustment motor 15 adjusts the position of the industrial camera 14 to make it The axis of the detected needle pressure Table 1902 adjusts the light intensity and focal length of the industrial camera 14, so that the industrial camera 14 can clearly identify the detected pointer-type pressure gauge 1902 dial information, start the acquisition process. Manually or automatically controls the pressurizing device 17, stops pressurization at each verification point position, driving the tap mechanism 41 tap the instructions of the needle pressure table 1902 dial housing, and triggers the industrial camera 14 to sh...

Embodiment 3

[0056]Figure 5 A two-channel pointer-type pressure gauge image acquisition is a schematic structural diagram of a dual-channel pointer-type pressure gauge image provided in the first embodiment of the present invention. ReferFigure 5 The detected pressure table is a dual-channel pointer pressure Table 1902, and two detected needle pressure table 1902 are fixed to the multi-channel pressure gauge check bench 16, and the operation control display all-in-one drive adjustment motor 15 adjusts the industrial camera 14 Location, it is possible to simultaneously observe the two-detected pointer pressure Table 1902, adjust the light intensity and focal length of the industrial camera 14, so that the industrial camera 14 can clearly identify two detected pointer-type pressure gauge 1902 dial information, start collecting procedures . Manually or automatically controls the pressurizing device 17, stops pressurization at each verification point position, driving the tap mechanism 41 tap the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com