Intelligent garment achieving body data measurement through tension sensors

A tension sensor and smart clothing technology, applied in the field of clothing production, can solve problems such as time-consuming or cost-consuming, difficult high-frequency measurement, time-consuming, etc., achieve high accuracy and scientificity, solve subjective deviation, and eliminate subjective effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

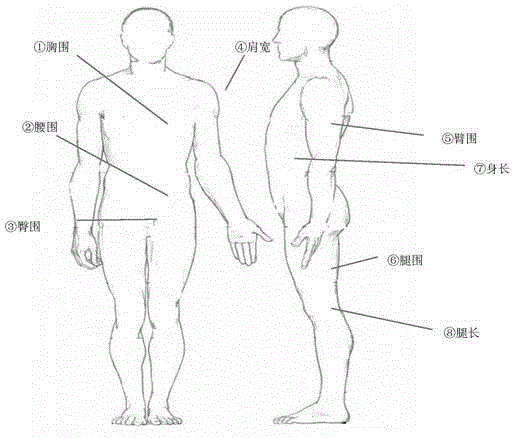

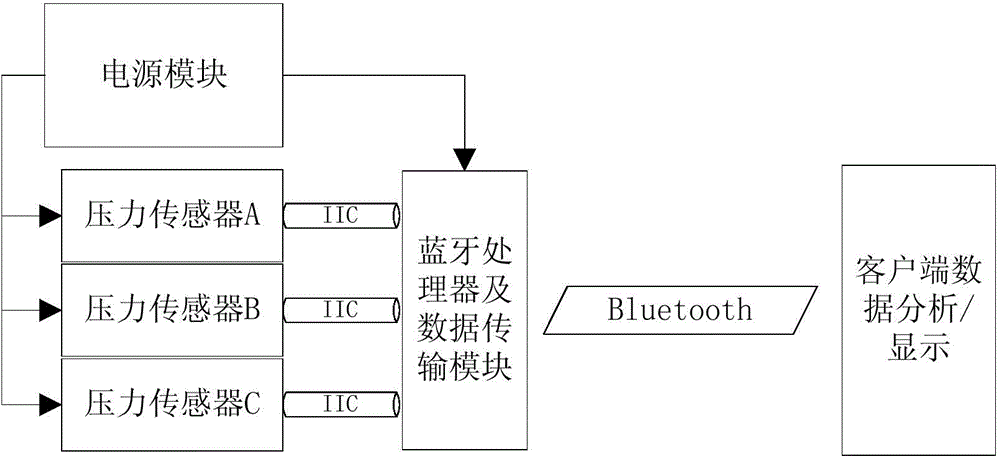

[0038] Set the polymer elastic material line: SS type 20D / 1 special wire produced by Hyosung Spandex at each measurement point of a pre-made elastic tight T-shirt, such as the chest, waist, and shoulders. The setting method is: put The smooth thin tube with elastic inside is fixed on the designated clothing part by means of seams or adhesion, and then the elastic polymer material thread passes through the thin tube to protect the polymer elastic material thread. function, and ensure that the resistance generated around the elastic polymer material is minimal and calculable. The pressure sensor freescale MPX2053 and the polymer elastic material at these positions are fastened together through structural devices, that is, the tension sensor is connected to the end of each elastic polymer material through a structural member, and the sensor is combined with the elastic material to form a strip Or ring, used to sense the deformation of the corresponding elastic material embedded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com