Method and system for detecting paint spraying defects of five-star feet based on machine vision

A technology of machine vision and detection method is applied in the field of detection methods and systems for spray paint defects of five-star feet, which can solve the problems of low reliability of detection results and low degree of automatic detection, and achieves high degree of automation, simple structure, and convenient use and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

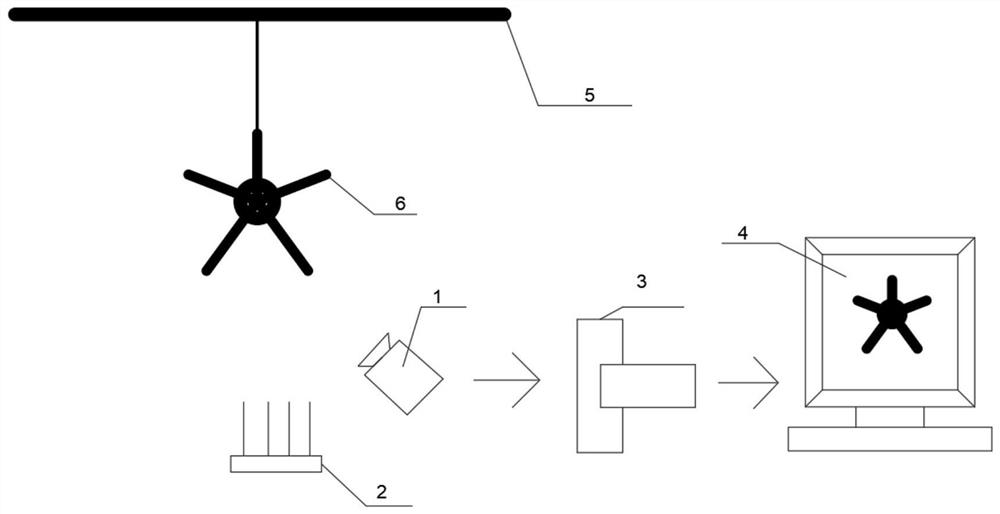

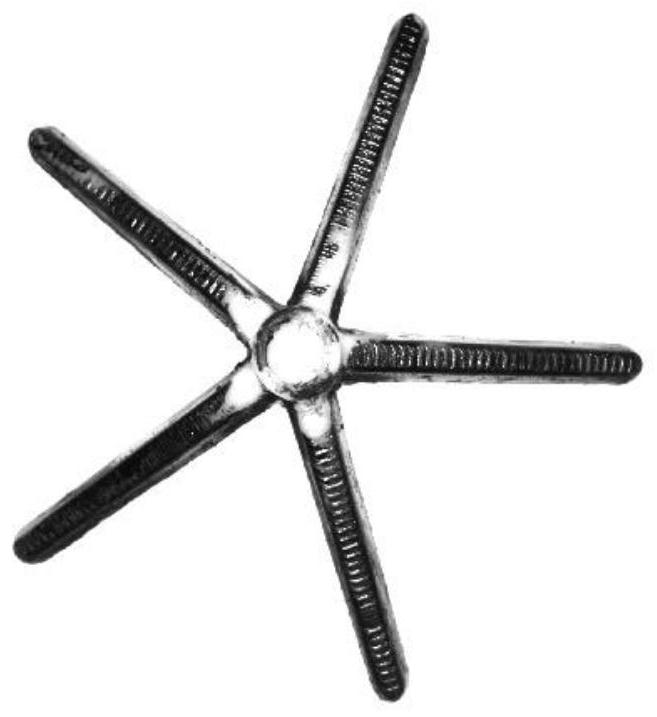

[0038] The present embodiment provides a kind of detection system based on machine vision five-star base paint defect, such as figure 1 As shown, it includes camera 1, lighting module 2, image acquisition module 3, main control module 4, transmission device 5, parts to be detected 6 and other parts; wherein, the camera is connected with the image acquisition module, and the image acquisition module is connected with the main control module ; The part to be detected is set on the conveying device.

[0039] The camera adopts a CCD camera, and the CCD camera mainly has the advantages of not being disturbed by strong light, small distortion, and fast shooting speed, and is used for image acquisition of the part 6 to be inspected;

[0040] The lighting module 2 is used for accurate lighting compensation on the surface of the part 6 to be detected;

[0041] The image acquisition module 3 is an image acquisition card, which is used to utilize the CCD camera to acquire images, and th...

Embodiment 2

[0057] This embodiment provides a machine vision-based detection method for five-star foot paint defects, including steps:

[0058] S1. Adjust the parameters of the detection device and turn on the camera;

[0059] S2. Obtain the image of the part to be detected by the camera;

[0060] S3. Perform median filter processing on the collected image of the part to be detected to obtain an image after median filter processing;

[0061] S4. Convert the image processed by the median filter into a binarized image, and perform a fixed threshold binarization process on the binarized image to obtain an area with a gray value;

[0062] S5. Calculating the area of the region with the gray value to obtain the area of the part to be detected;

[0063] S6. Perform template matching on the image after the median filtering process obtained in step S3 to obtain similarity;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com