Laser resonant cavity automatic cavity adjusting system and method based on interference fringe picture skeleton line processing

A laser resonant cavity and interference fringe technology, applied in the field of lasers, to overcome the complex structure, improve speed and repeatability, and eliminate subjective errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

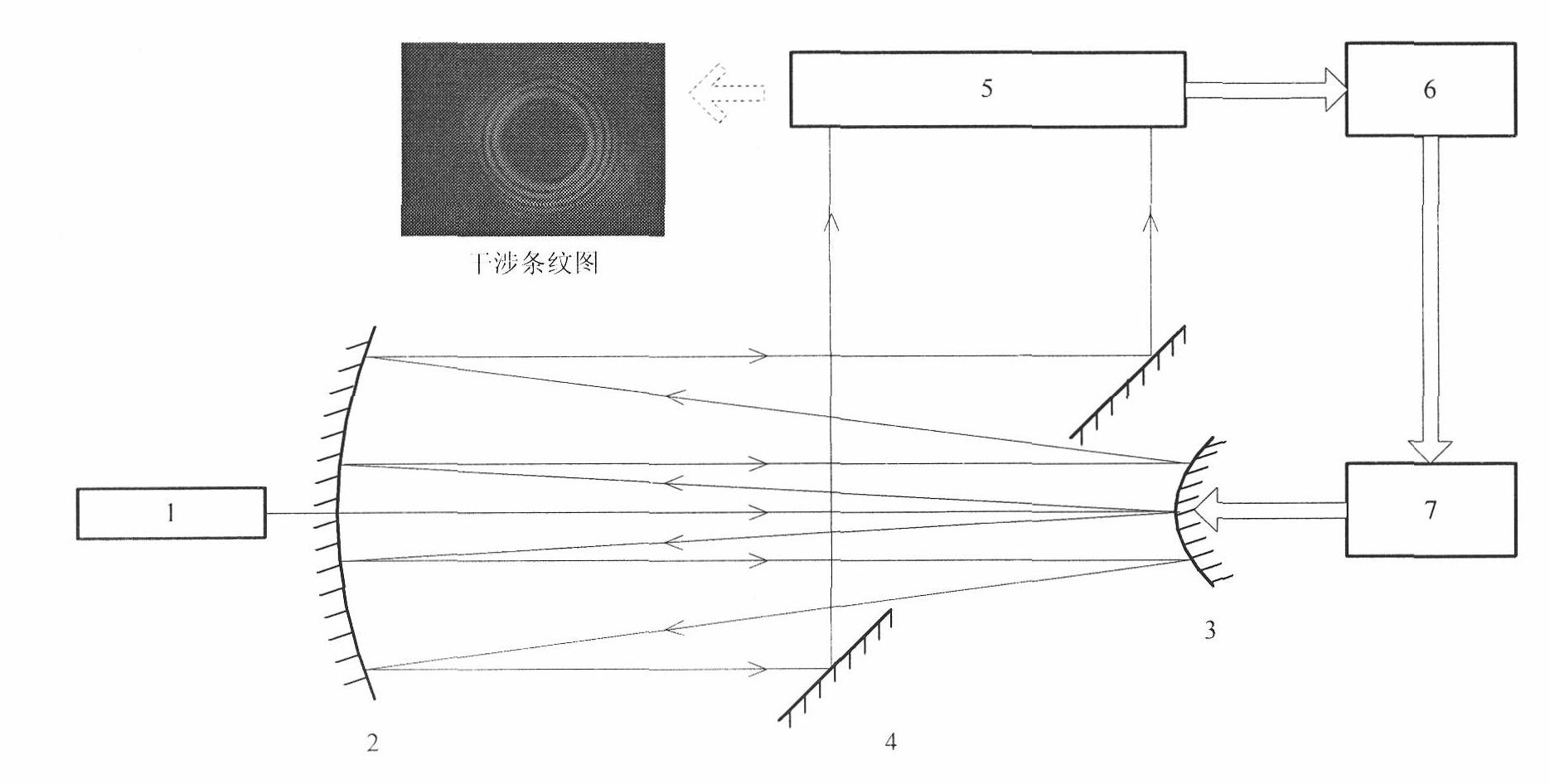

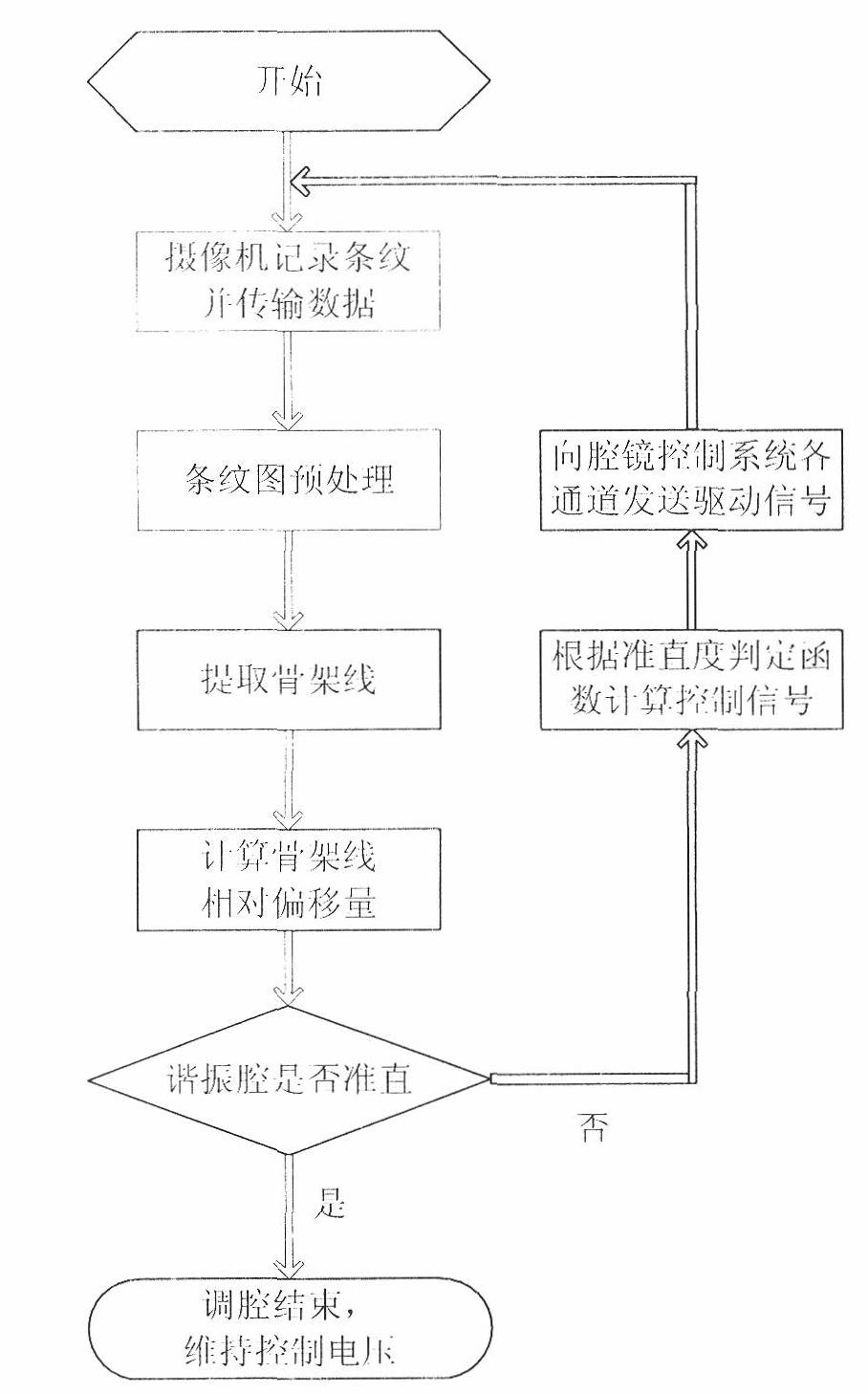

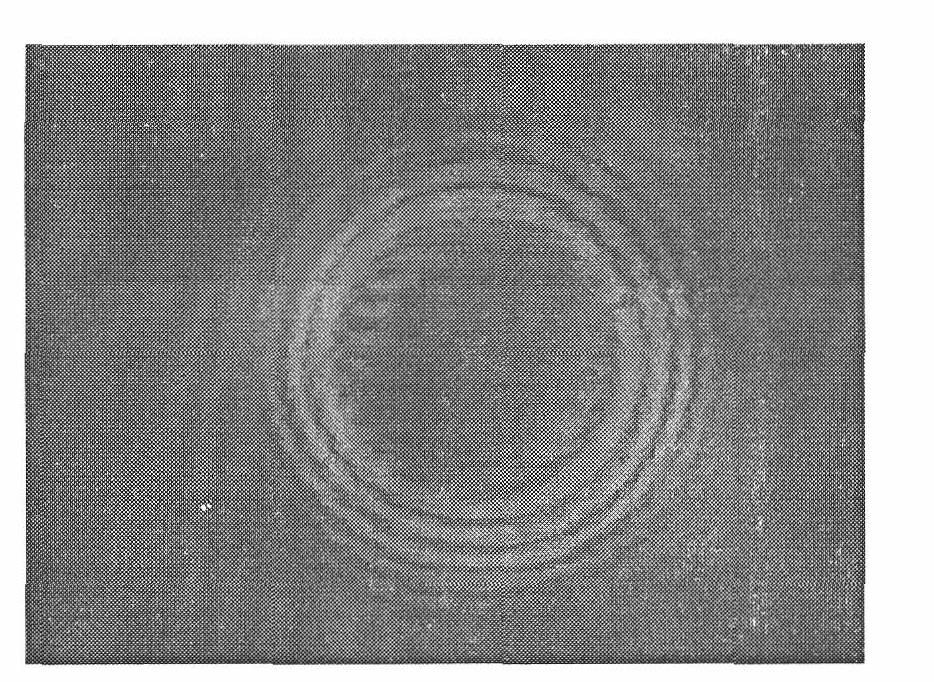

[0044] The laser resonator has various structure types, and the present embodiment is as follows figure 1 The concave-convex cavity structure shown is an example. The concave mirror 2 and the convex mirror 3 constitute a laser resonator, and the distance between them meets the cavity length requirement of the resonator. The convex mirror 3 is installed on a five-dimensional (front and back, left and right, up and down, pitch, yaw) adjustable electric mirror frame and is driven by a control circuit. The adjustable electric mirror frame and the control circuit together constitute the cavity mirror control system 7 . The concave mirror 2 remains stationary. The outcoupling mirror 4 is mounted on a mechanically adjustable optical support, placed at an angle of 45 degrees to the axis of the resonator, and has a rectangular or oval large hole in the center; the outcoupling mirror is placed close to the convex mirror; the guiding laser 1 is made of He -Ne laser, placed behind the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com