Indoor piling wall support structure and construction method therefor

A technology for supporting structures and pile walls, which is applied in the direction of foundation structure engineering, sheet pile walls, underwater structures, etc., can solve problems such as endangering the main building, and achieve the effects of preventing potential danger, eliminating common quality problems, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described in conjunction with the following examples.

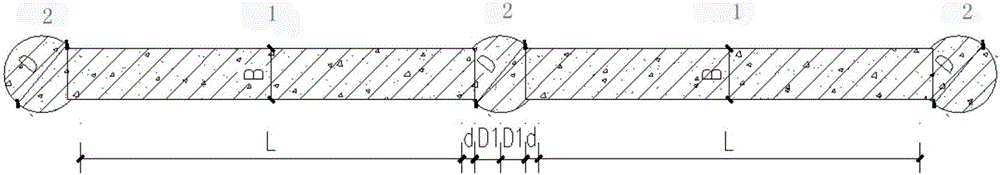

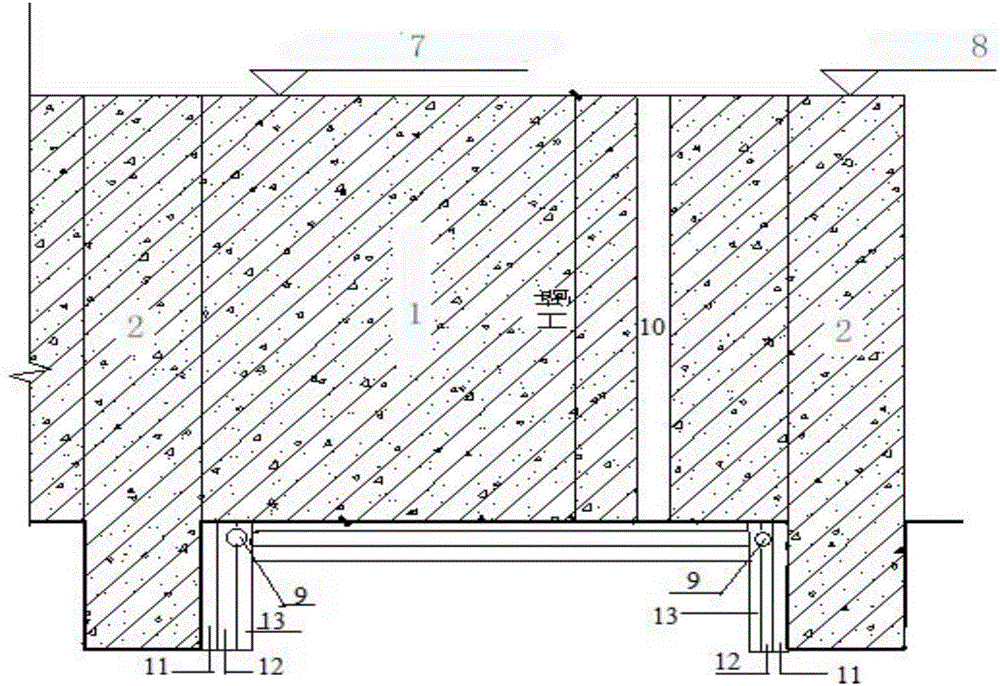

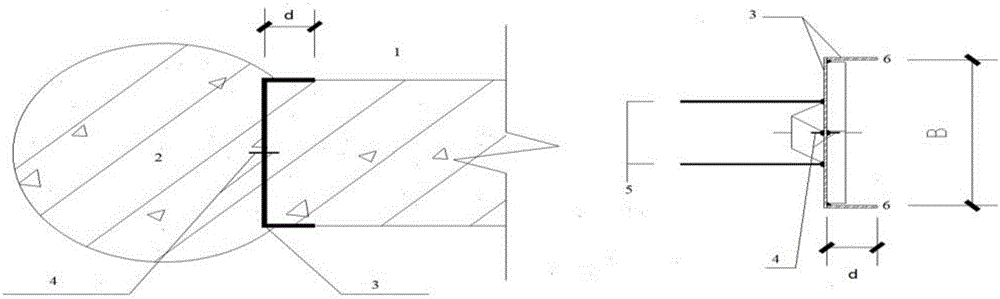

[0033] An indoor pile wall support structure provided by an embodiment of the present invention includes several ground connection walls 1 and several cast-in-situ piles 2 . The ground connection wall 1 is formed by a stirring method, a rotary spraying method or a compact grouting method. Cast-in-situ piles 2 are respectively arranged on both sides of each ground connection wall 1, and each ground connection wall 1 is connected to form a pile wall support structure by filling piles 2; Embedded part 3 overlaps and occludes; both ends of embedded part 3 extend horizontally along the outer surface of ground connection wall 1, and are folded to form embedded part flange 6 perpendicular to and parallel to the main body of embedded part 3; A water-stop component 4 is arranged on the part 3; the ground connection wall 1, the cast-in-place pile 2 and the water-stop component 4 form a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com