Screw-connected concrete wall block

A technology for concrete walls and connecting blocks, which is used in building components, earthquake resistance, construction, etc., can solve the problems of non-occlusion of blocks, collapse of concrete walls, personal casualties, etc., to increase the contact surface of materials and reduce disasters. The effect of improving the seismic capacity and speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described progressively

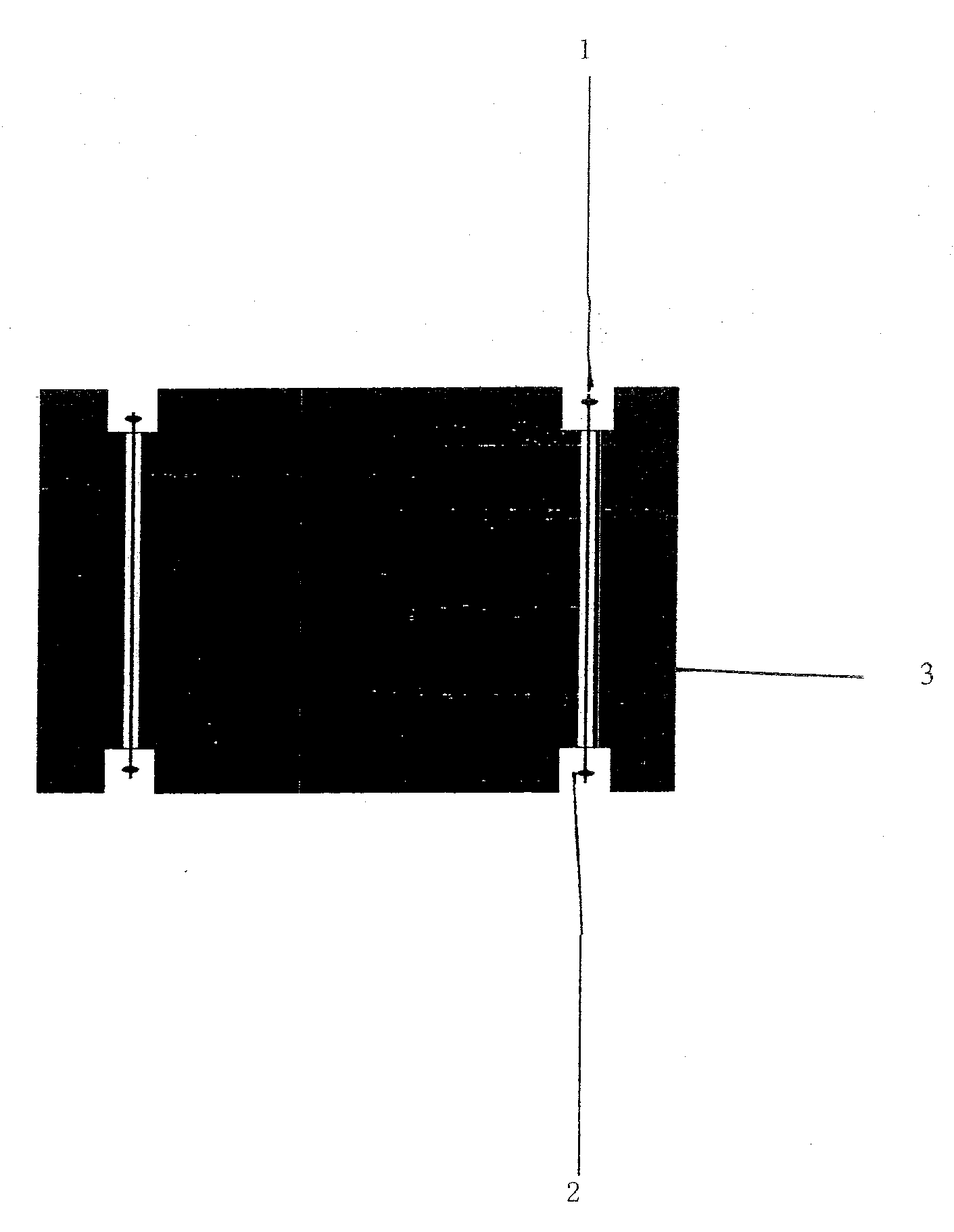

[0012] The picture shows the block screw connection 1. The screw connects the block screw joint 2. During construction, screw 1 and another block screw joint 2 together, and then fill the gap with mortar and cement to make each block screw connected. The blocks can be tightly snapped together, so that the entire concrete wall is snapped together, and the entire house and building become a whole, and the house structure is firm. Therefore, the ability of earthquake resistance and disaster reduction has been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com