Paver

A paver and frame technology, applied in roads, road repairs, roads, etc., can solve the problems of large investment in construction resources, slow progress, narrow construction scope, etc., and achieve the effects of improving construction quality, easy operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

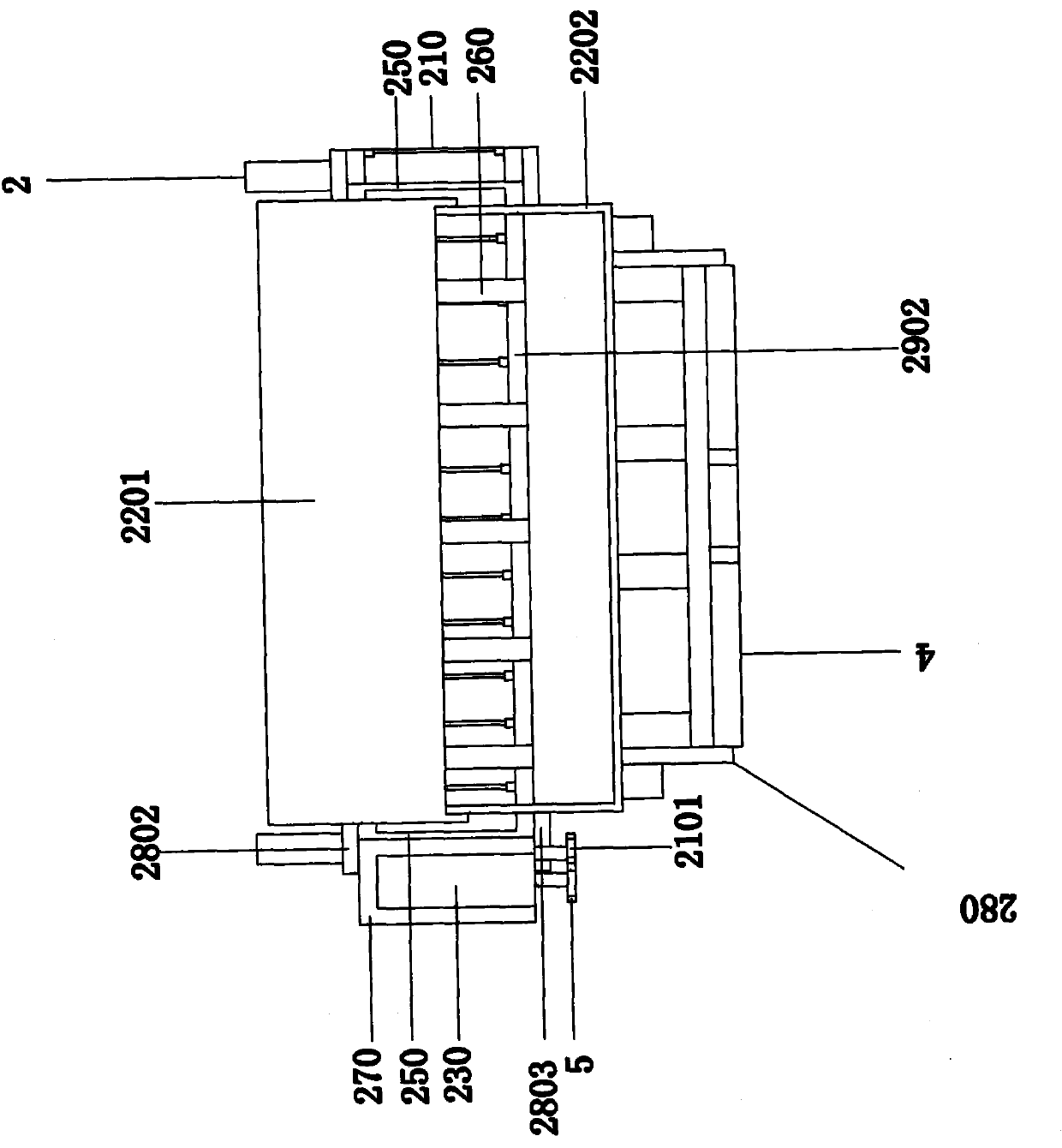

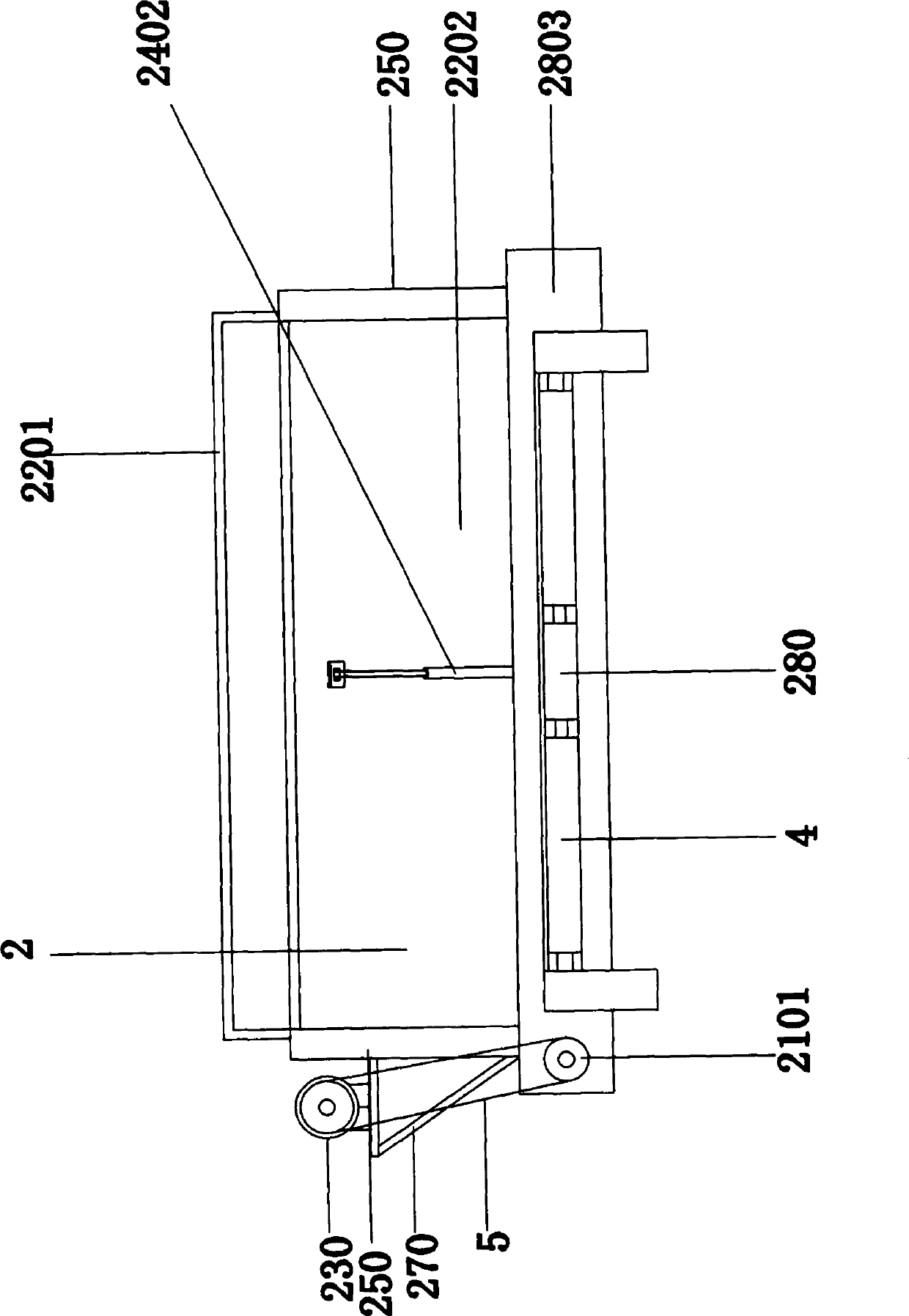

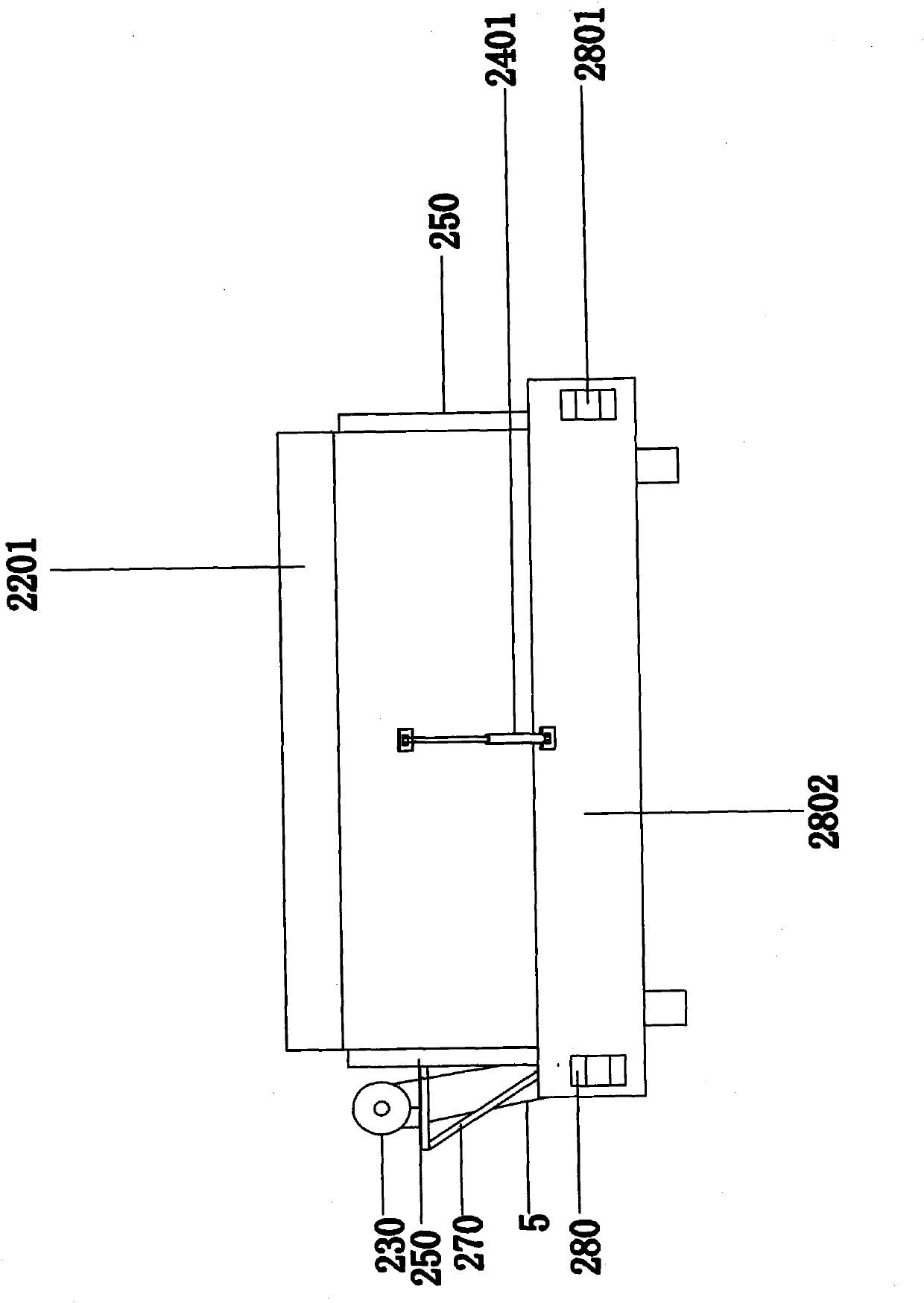

[0036] Such as Figure 1-8As shown, during the road shoulder construction, the paver 1 is started, and the dump truck with the shoulder fill soil is placed close to the buffer drum 4 of the paver 1, and the dump truck unloads the shoulder fill soil to the front end of the paver 1 In the collecting hopper 220 of the installed road shoulder distributing machine 2, the operator of the paver 1 starts the engine electrical control and hydraulic electrical control in the electrical control system, drives the speed regulating motor 230 and the rollover hydraulic cylinder 240 to work, and the rollover hydraulic cylinder Under the support of 240, the two movable bucket walls 2201 and 2202 of the collecting hopper 220 are connected with the upper end surface of the rear beam 2802 of the frame 280 and the middle beam of the frame 280 respectively by the two movable bucket walls 2201 and 2202. The hinged part of the upper end surface of 2803 is the axial inward turning bucket walls 2201 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com