Quickly-moving type concrete mixing station

A mobile concrete technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve problems affecting work efficiency, concrete workability, and large floor space, so as to improve production efficiency and quality, Improve the overall stability and shorten the production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

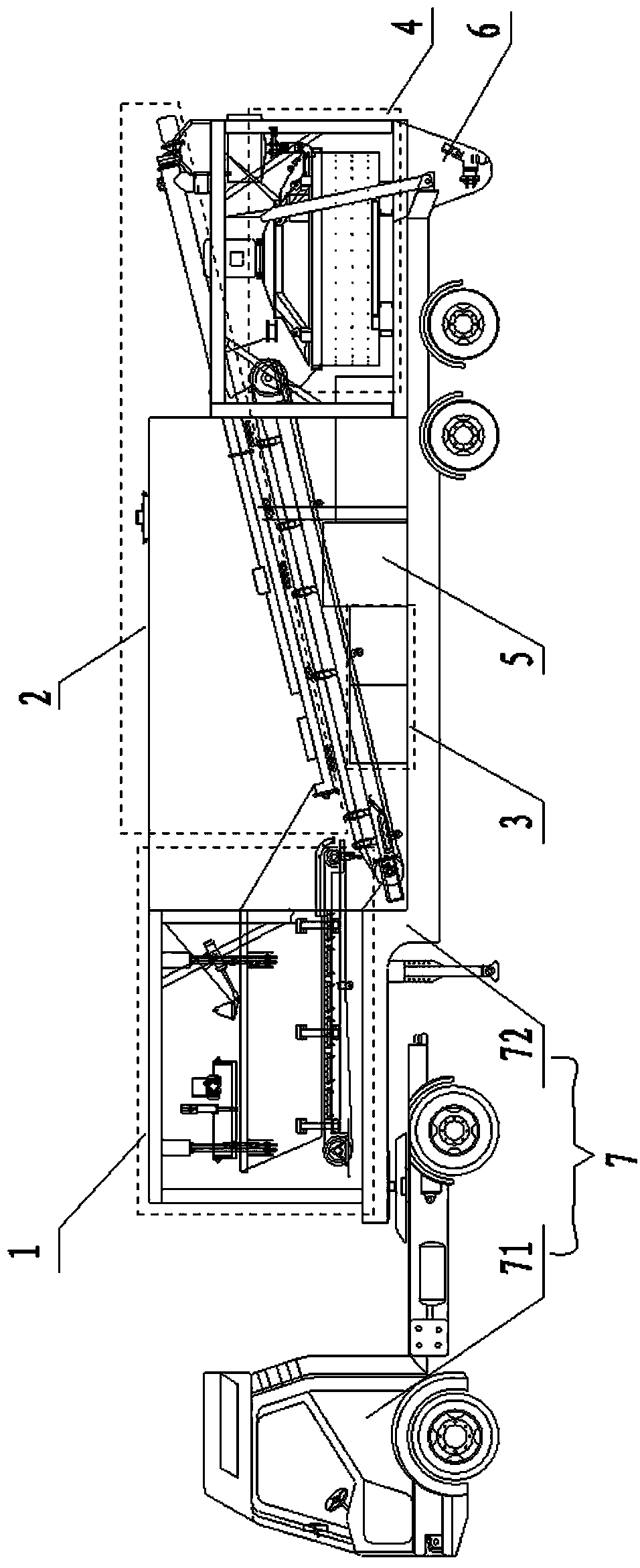

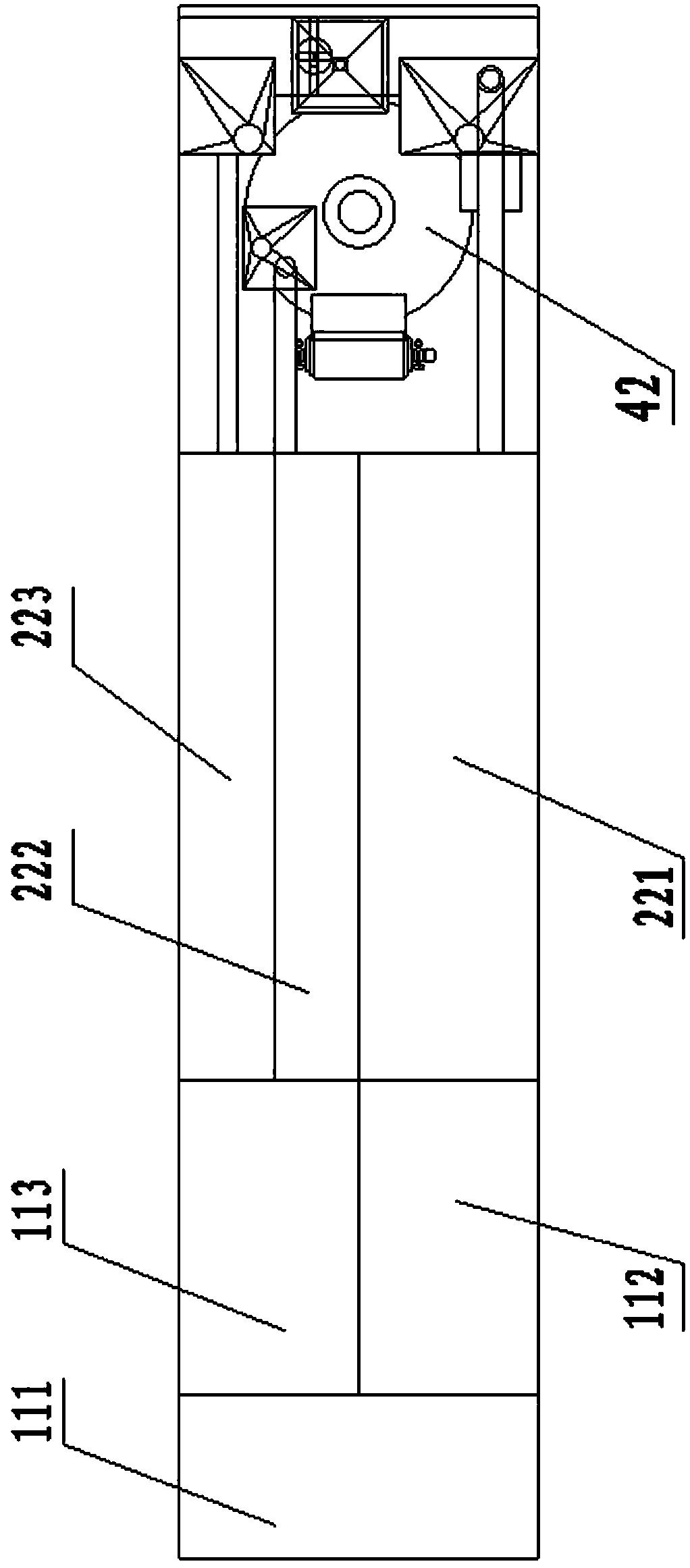

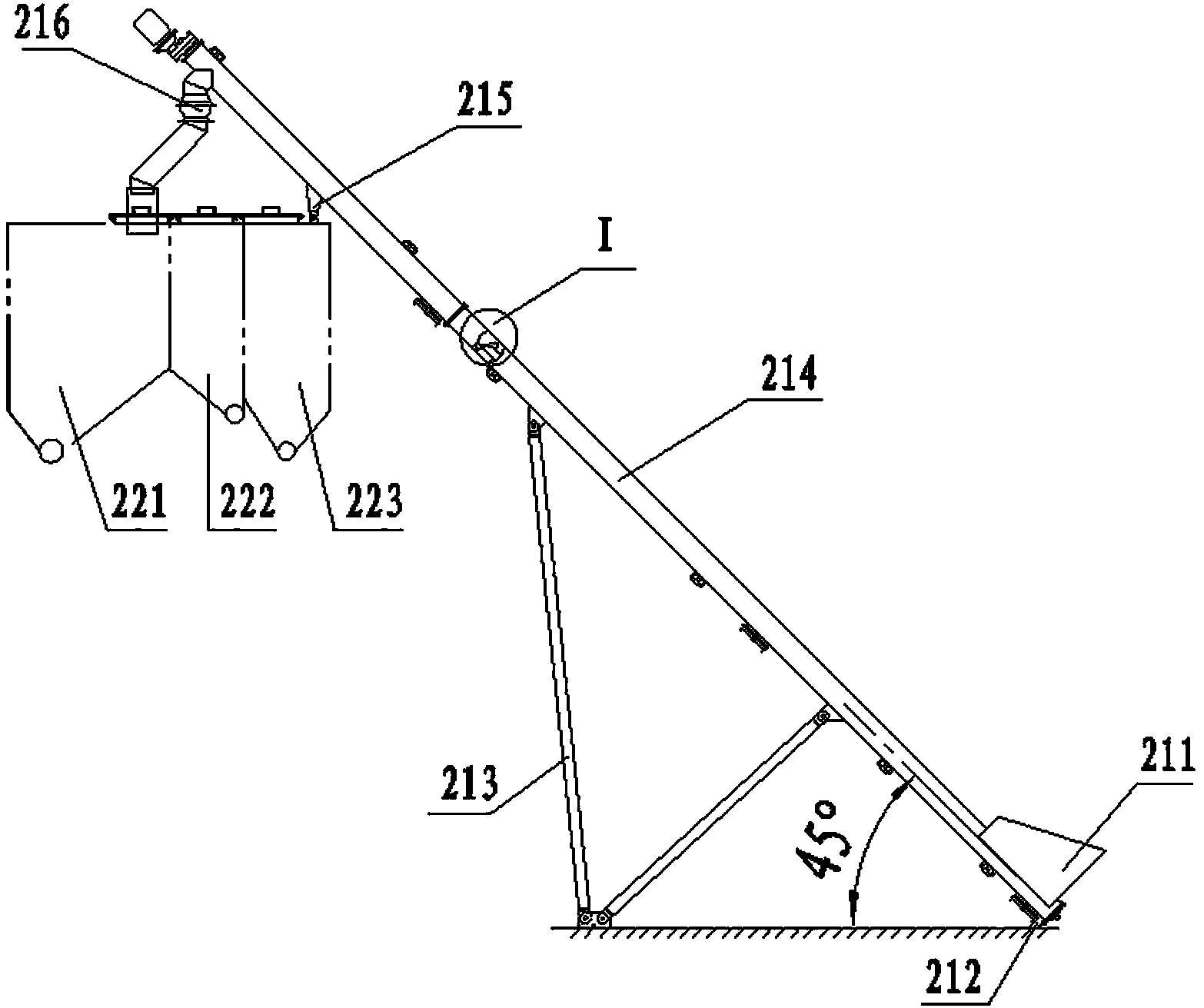

Embodiment 1

[0042] Trial example 1: In the trial construction of a highway bridge deck pavement, the on-site pavement is 6m wide, 15cm thick, and 500m long. The fast mobile high-performance concrete mixing plant is about 50km away from the construction site. Select the fast mobile concrete mixing plant, first use the traction device 71 to transport the fast mobile concrete mixing plant to the bottom of the required construction bridge deck, and the traction device 71 pulls the fast mobile concrete mixing plant to travel at a speed of 50km per hour, 1 It is transported to the site in one hour, the trailer board 72 and equipment are supported by outriggers 73, quickly connected, assembled, debugged, and put into production, which is completed within 6 hours. Because carry out the concrete production of bridge deck pavement construction, so powder one selects cement for use, powder two selects fly ash for use, powder three selects mineral powder for use, carry out powder addition with powder ...

Embodiment 2

[0043] Trial example 2: The bridge deck of a highway is seriously damaged, and the old concrete on the bridge deck needs to be chiseled out before the bridge deck concrete repair construction is tried. The design strength of the bridge deck pavement repair concrete is C50, the design thickness is 20cm, the width is 7.5 meters, and the length is 500 meters. The fast mobile concrete mixing plant is about 120km away from the construction site. The traction equipment 71 transports the fast mobile concrete mixing plant to the underside of the bridge deck required for maintenance. The traction equipment 71 drives the fast mobile concrete mixing plant at a speed of 40km per hour, transports it to the site in 3 hours, and uses the outrigger 73 to pull the trailer The board 72 and the equipment are supported, quickly connected, assembled and debugged, and completed within 6 hours. Because of concrete production for bridge deck maintenance, cement is used as the first powder, fly ash is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com