Patents

Literature

242results about How to "Quick pour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

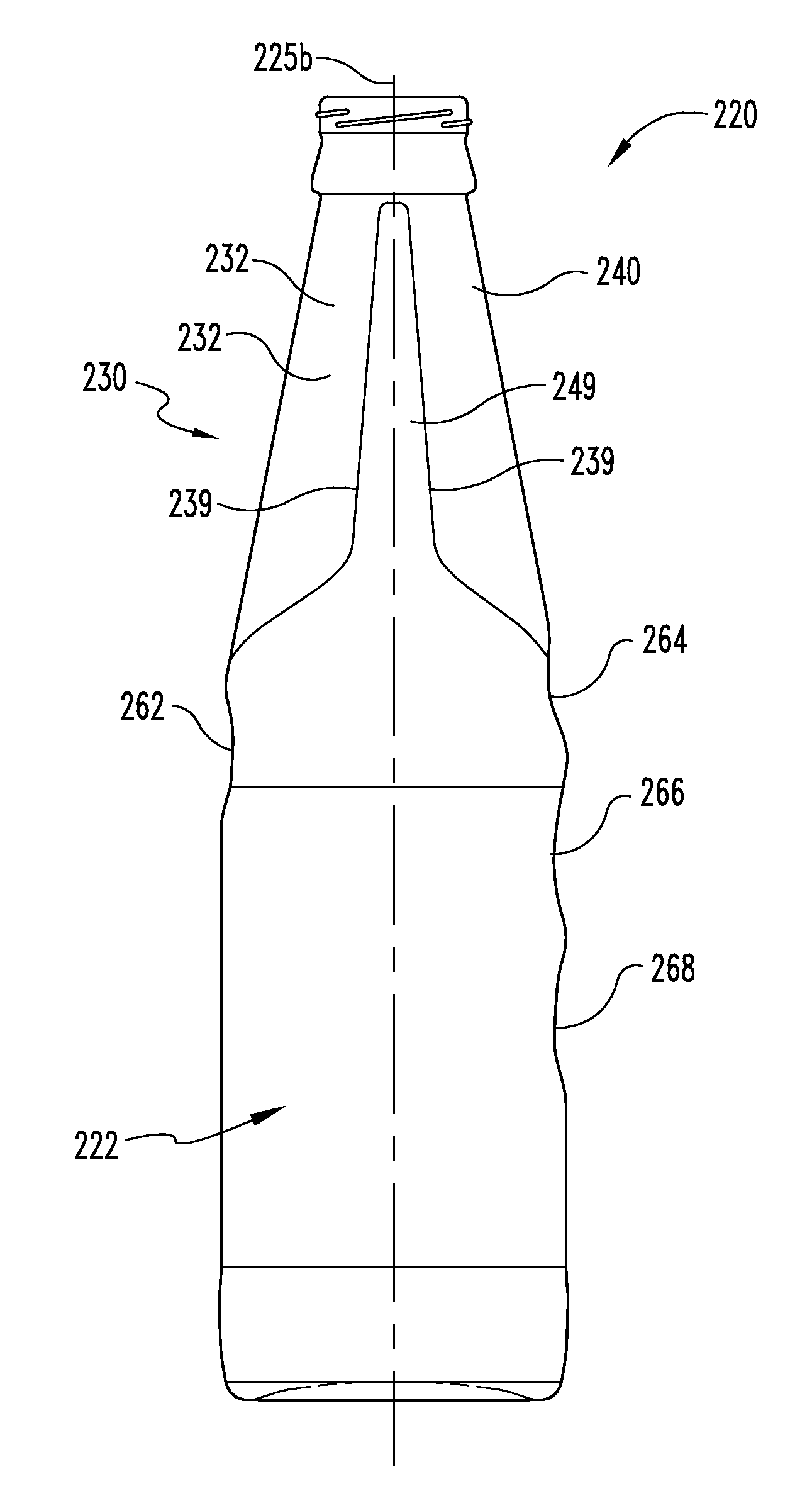

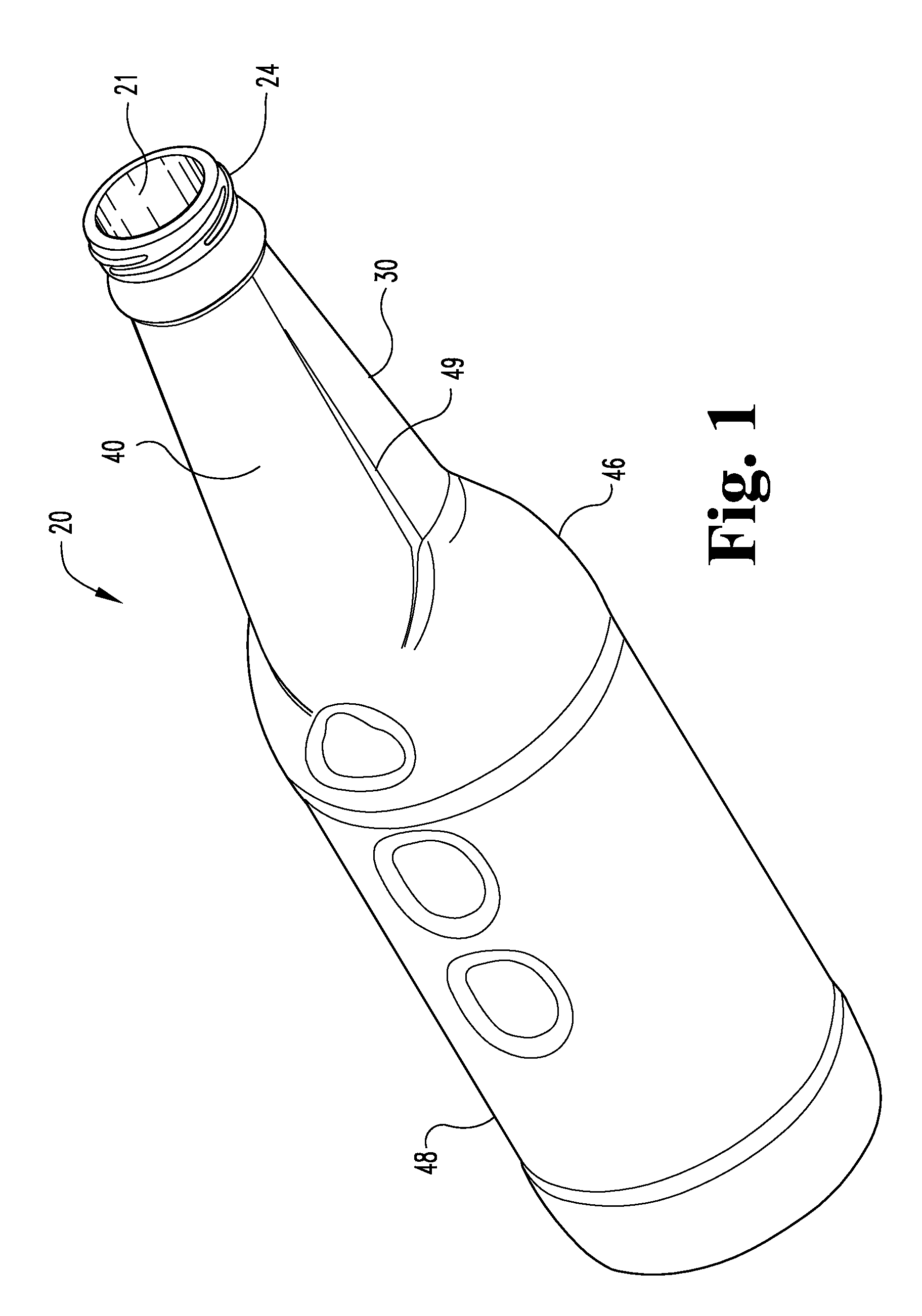

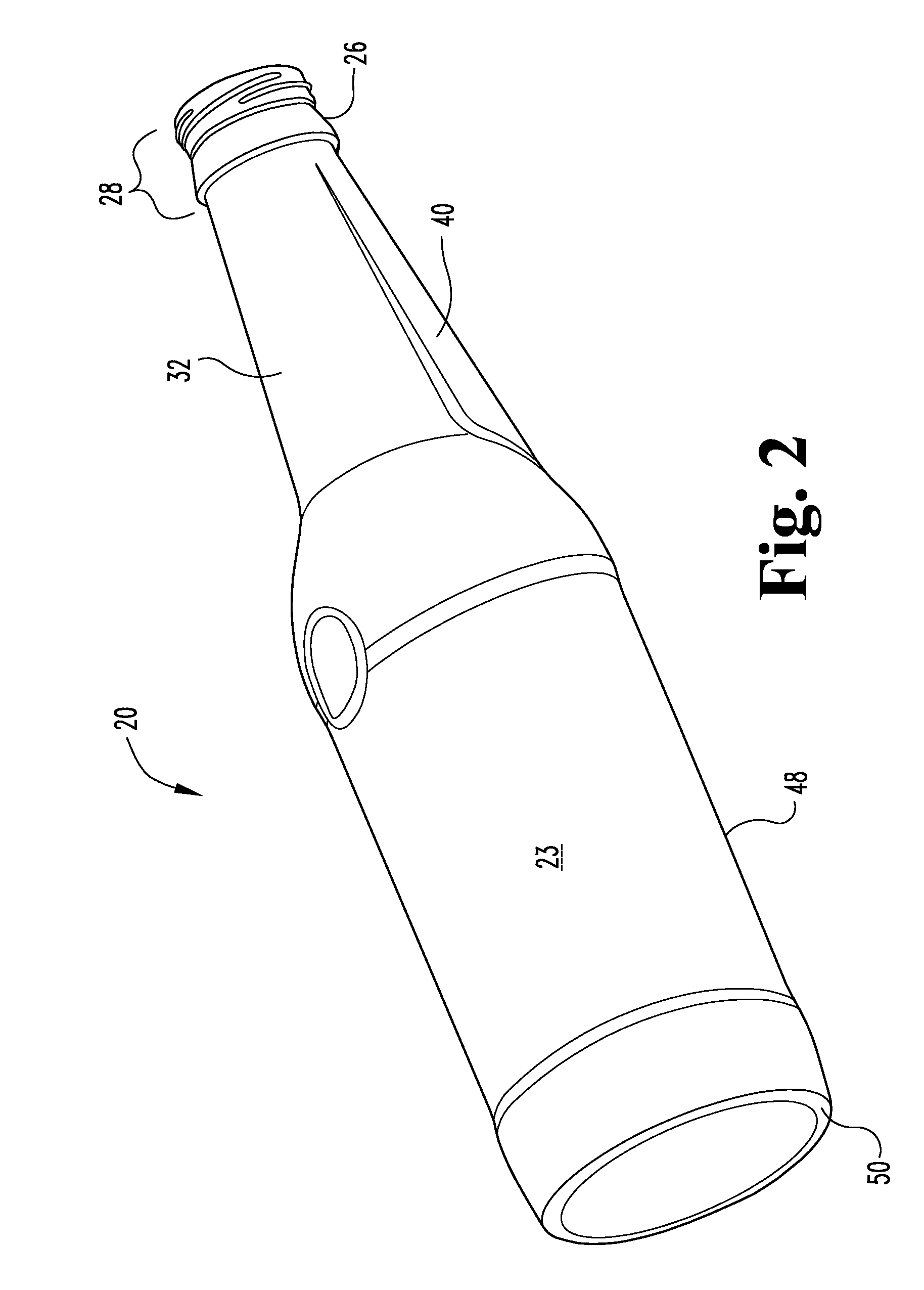

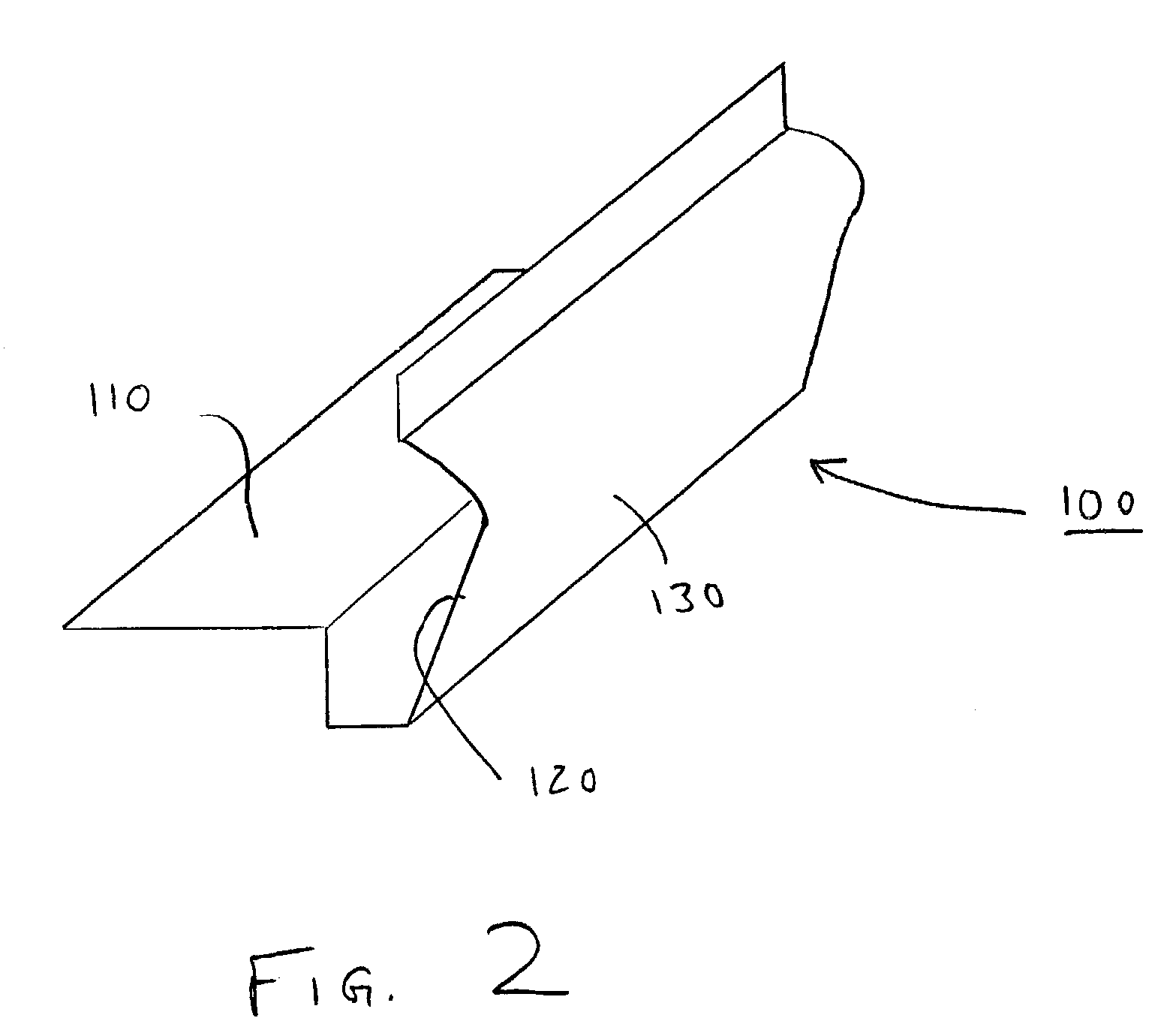

Free flowing bottle

A glass bottle with improved pouring characteristics. In some embodiments the bottle can hold pressurized liquid. The bottle includes a neck with a non-circular cross section. The cross sectional shape of the neck is adapted and configured to provide less turbulence in the liquid being poured out of the bottle, and further to assist in separating the in flow of single phase liquid from the turbulent mixed flow of two phase, gas-liquid substances.

Owner:SAINT GOBAIN CONTAINERS

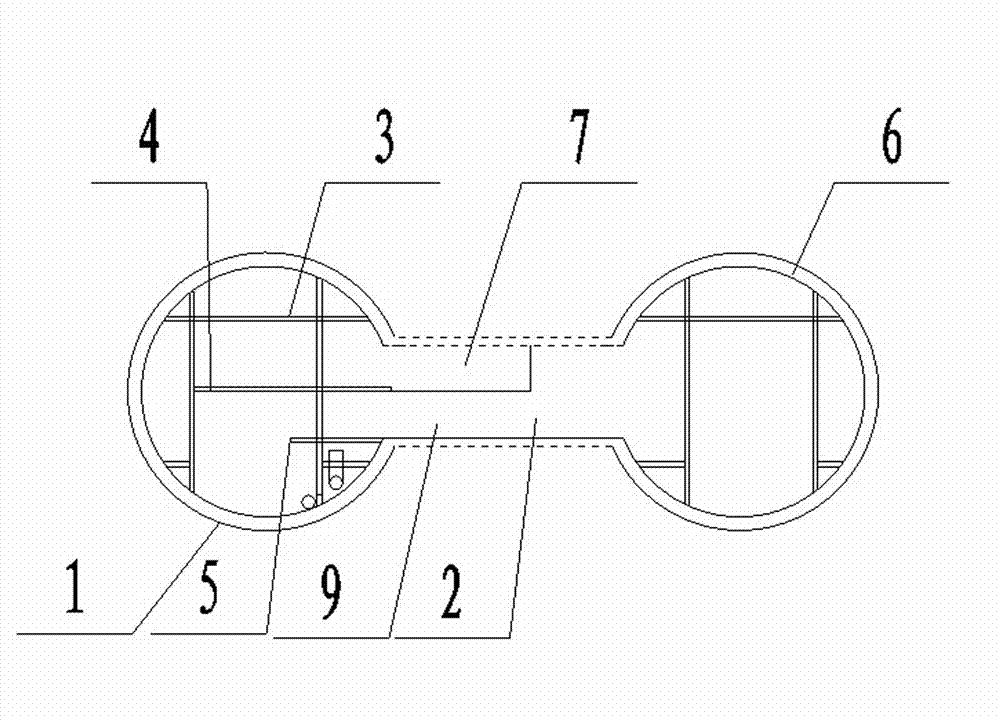

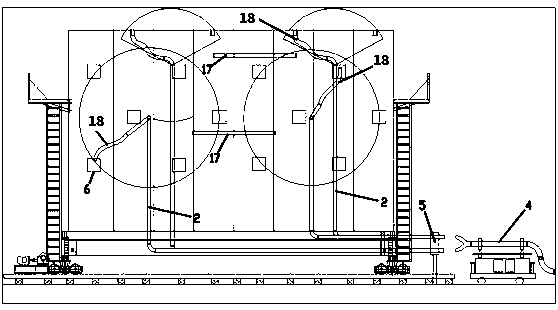

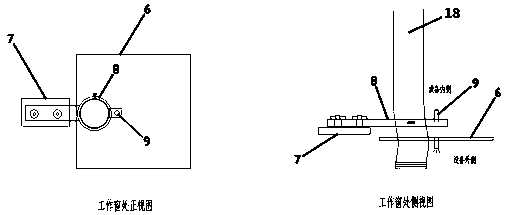

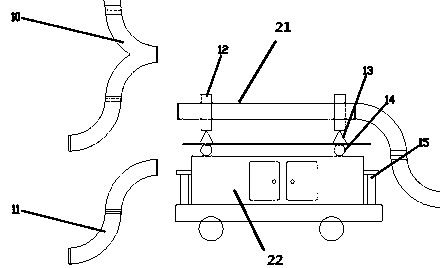

Urban subway mudstone stratum connected aisle and shield tunneling parallel construction method

ActiveCN103032073ASolve the inability to realize the construction of the communication channelSolve the technical problems of shield tunnelingUnderground chambersTunnel liningSocial benefitsArchitectural engineering

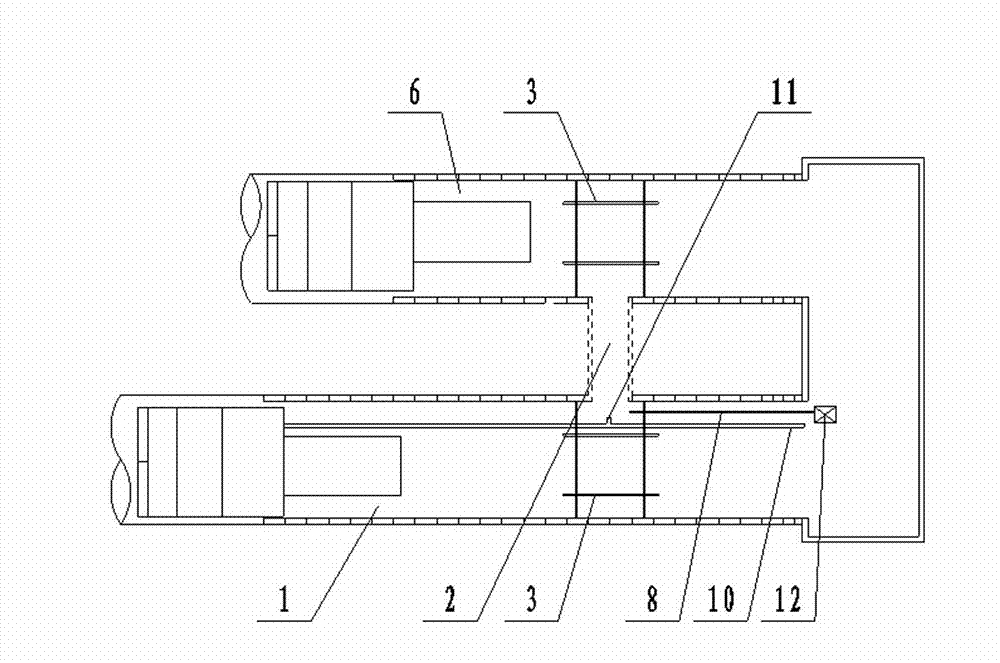

The invention relates to the field of tunnel shield construction, in particular to an urban subway mudstone stratum connected aisle and shield tunneling parallel construction method, and solves the problems that due to the adoption of a blasting method in the prior art, the period is long, traffic recovery is delayed, interference to shield tunneling is generated and the blasting method and the shield tunneling cannot be constructed in parallel. The urban subway mudstone stratum connected aisle and shield tunneling parallel construction method comprises the following steps of: carrying out temporary supporting and reinforcement at an opening of a connected aisle; constructing upper steps of the connected aisle; constructing lower steps of the connected aisle; and carrying out second liner construction. A construction platform which is temporarily erected is sufficiently utilized and an air compressor is arranged in a station to provide the air pick excavating condition for the connected aisle and reduce interference to shield tunneling; a roller is welded under a conventional conveying pump and a rail concrete tank wagon is applied to rapidly carry out concreting when shield tunneling is shut down to carry out repair and maintenance. The urban subway mudstone stratum connected aisle and shield tunneling parallel construction method has the advantages of simple process, advanced technology, flexible process arrangement, strong practicality, shortening of the construction period and the like, a gap of an urban subway mudstone stratum connected aisle and shield tunneling parallel construction technology in China is filled and excellent economic benefits and social benefits can be obtained.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Self-flow castable for filling back seam of side wall of aluminium electrolytic bath

The invention discloses a self-flow castable capable of filling a seam between a shell and a side wall brick of an electrolytic bath, is designed special for an aluminium electrolytic bath and mainly comprises the following components: a carborundum material, a high alumina material, silica micropowderl, aluminium oxide powder and a calcium aluminate cement. The carborundum raw material used by the self-flow castable has high purity, high SiC content, relatively good bath electrolyte erosion resistance and compression strength; high heat conduction coefficients can eliminate a thermal barrierbetween the bath shell and the side wall brick and are favourable for promoting the forming of a side wall brick furnace upper; and good fluidity can guarantee that the castable uniformly fill the seam. Through the features, the self-flow castable can effectively prolong the service lives of the aluminium electrolytic bath and the side wall brick, is not limited by a construction space in castingconstruction, can quickly cast and is not fired at a high temperature in a production process. Therefore, the self-flow castable is a high-efficiency, energy-saving and environment-friendly refractory material.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

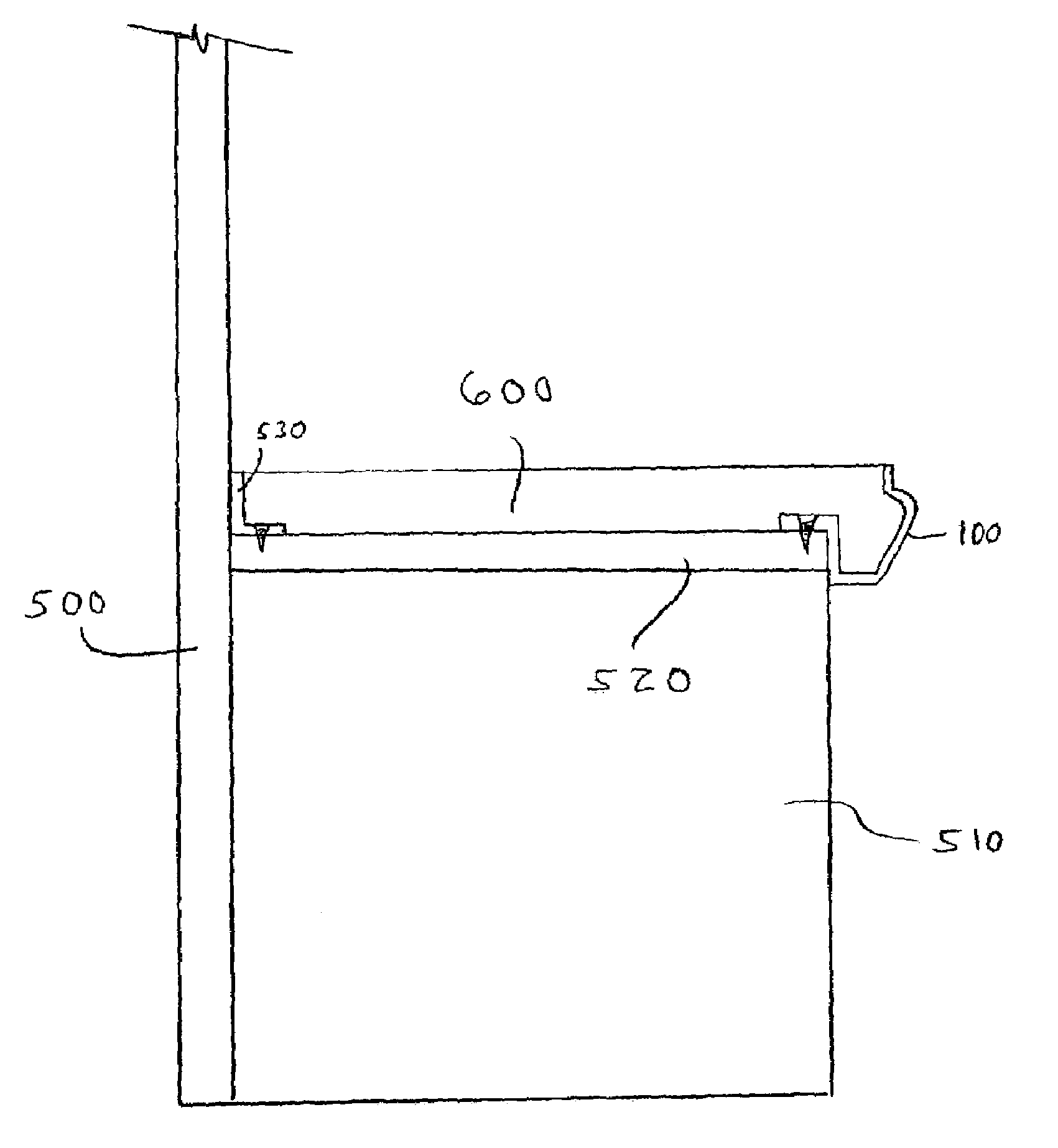

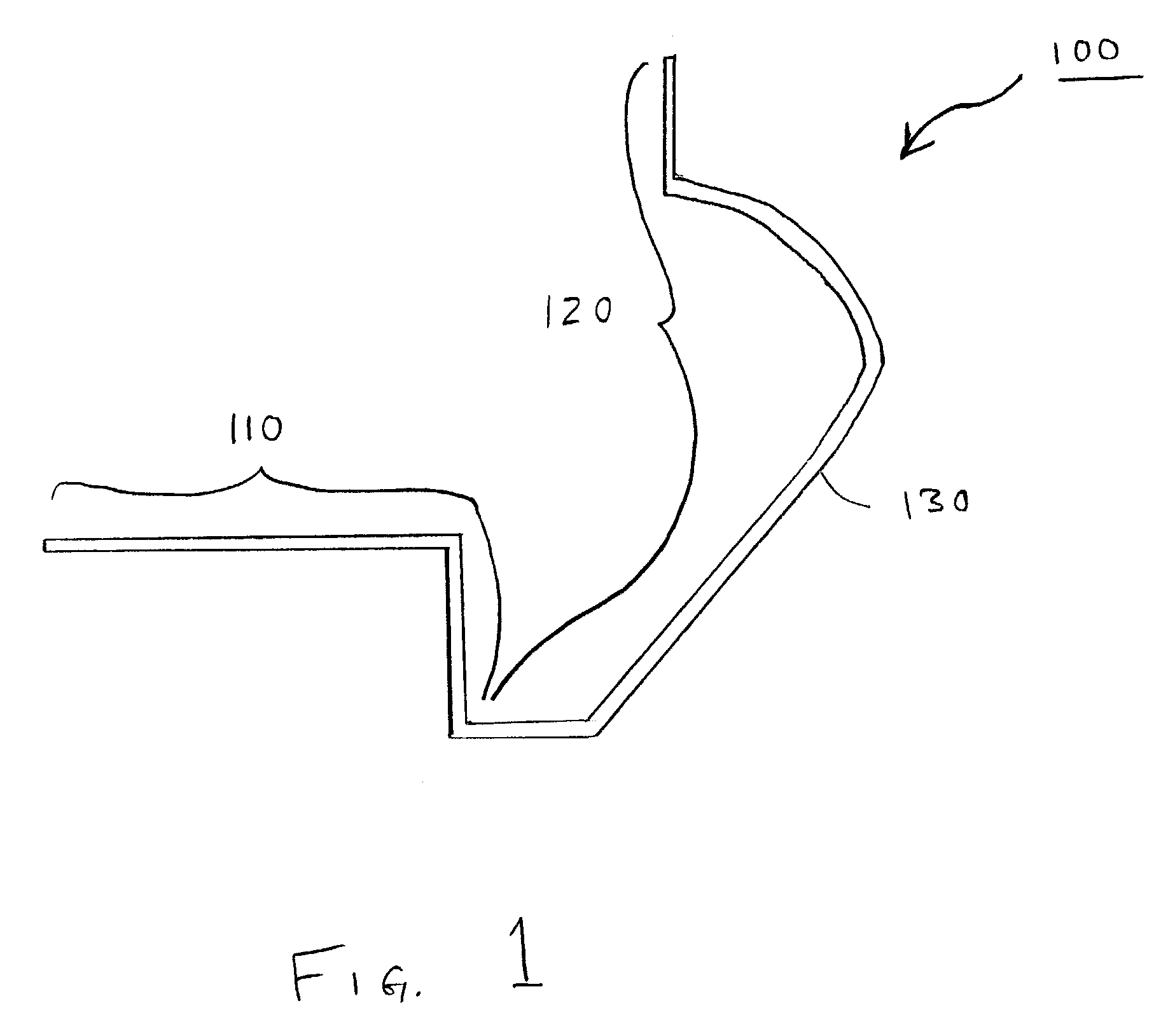

Counter top mold and method of using same

ActiveUS7001558B2Easy to useQuick pourConfectioneryStereotype platesMechanical engineeringEngineering

Owner:BALDONI EDWIN

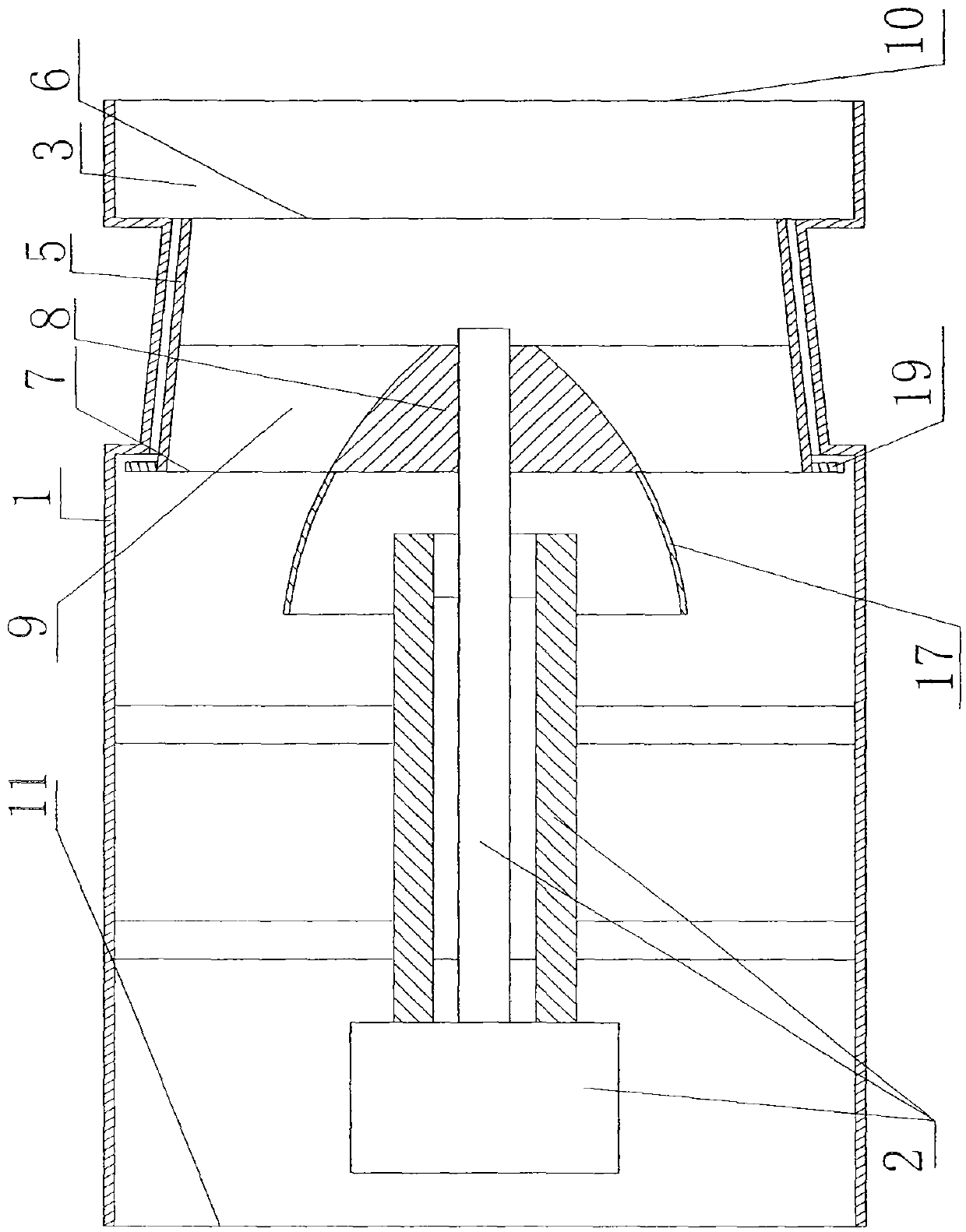

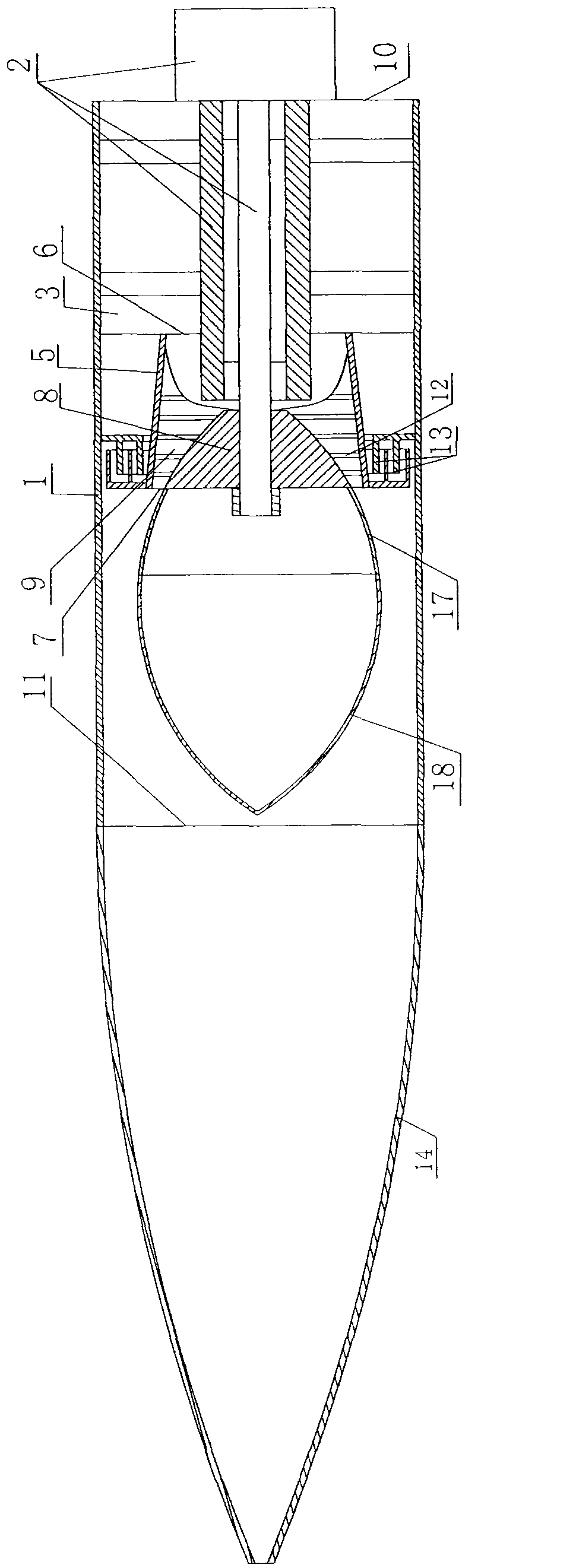

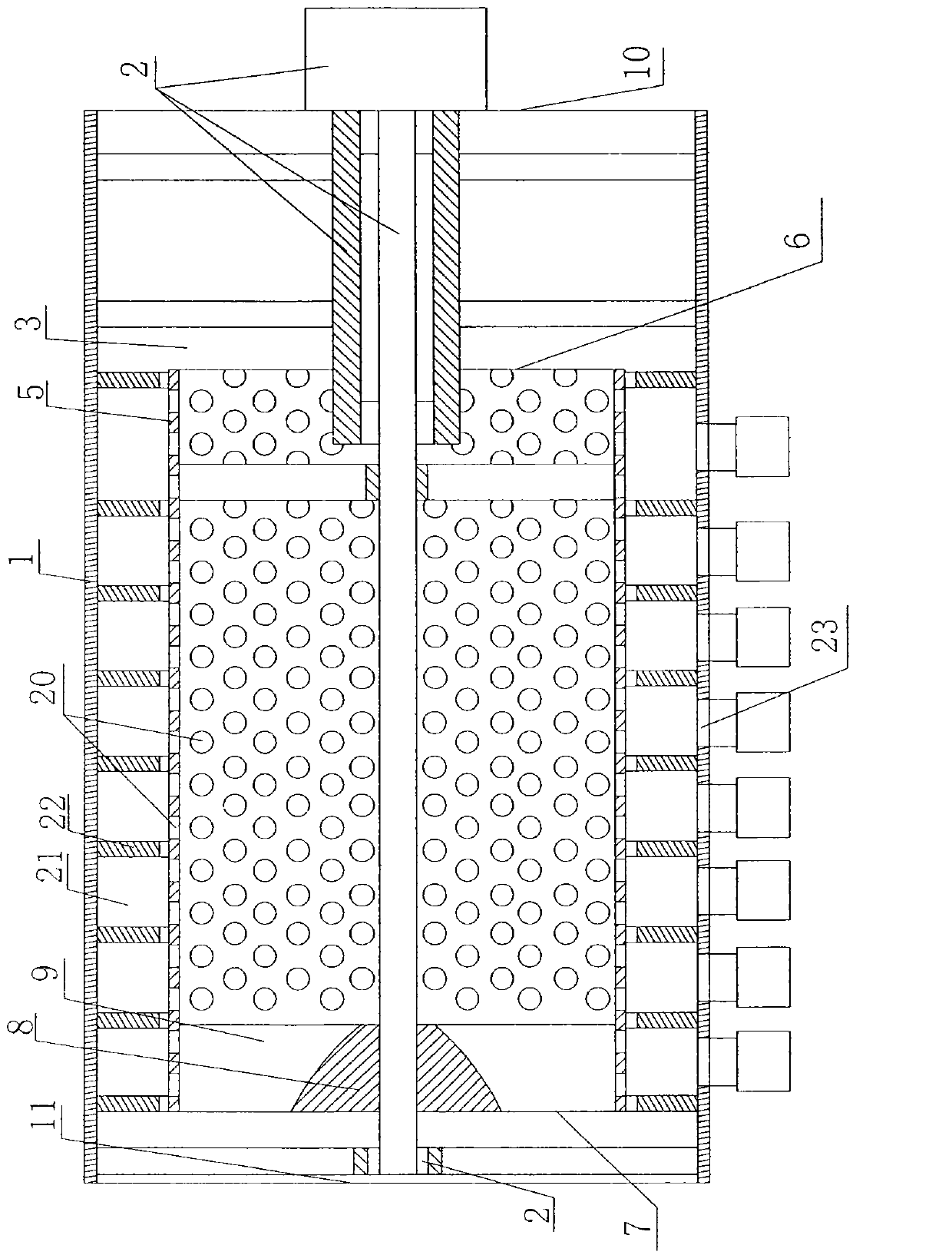

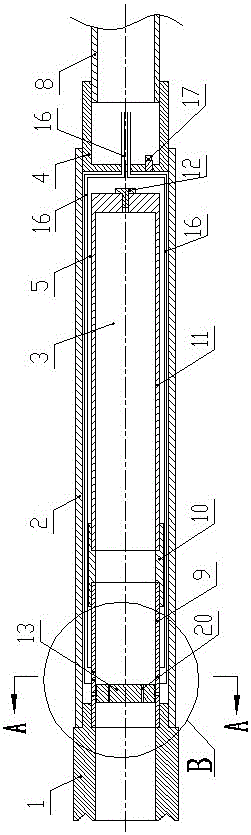

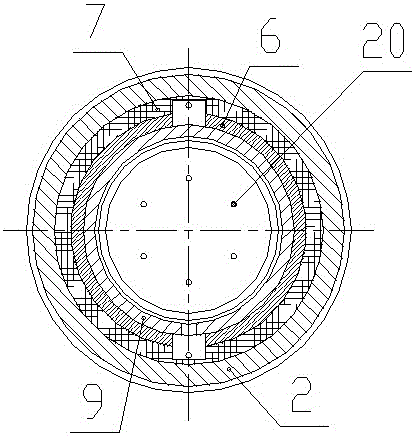

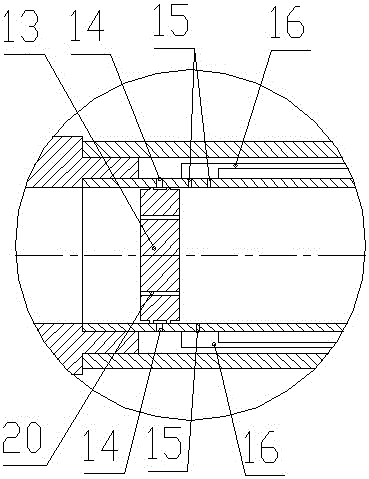

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

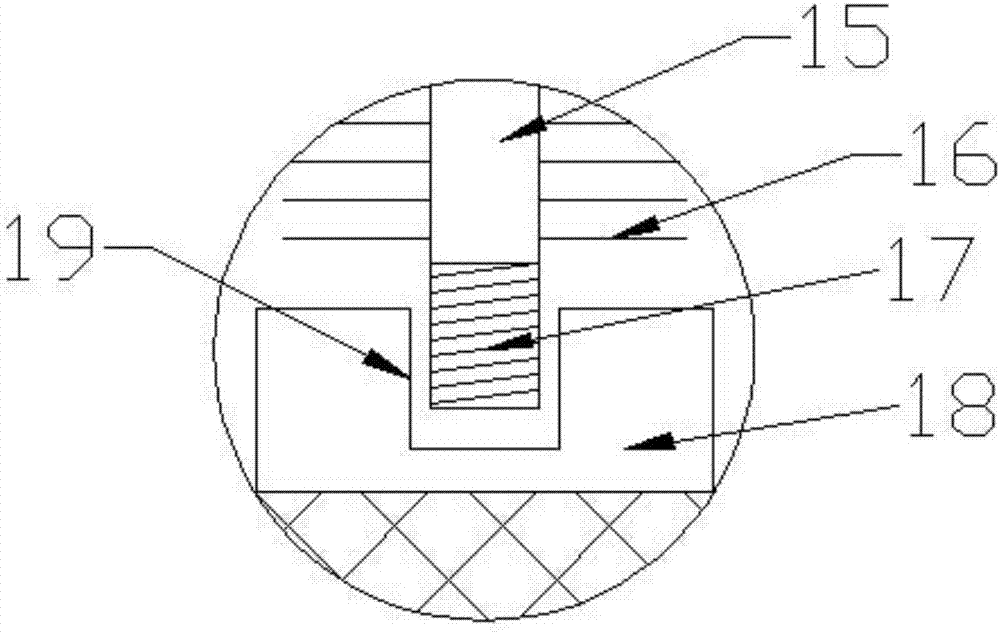

Coal seam low-temperature fixed-point frozen sampling device and use method thereof

ActiveCN106194168AGuaranteed preservationRealize the cooling effectBorehole/well accessoriesCore removalDry iceEngineering

The invention discloses a coal seam low-temperature fixed-point frozen sampling device and a use method thereof. The coal seam low-temperature fixed-point frozen sampling device comprises a through hole coring bit. The outer wall and the inner wall of the right end of the through hole coring bit are connected with a sampling drill pipe and a frozen low-temperature sample storing device correspondingly. The right end of the sampling drill pipe is connected with a drill pipe adapter. A dry ice cooling layer and a heat-insulation heat-preservation layer are arranged between the sampling drill pipe and the frozen low-temperature sample storing device. According to the sampling method, a drilled hole is constructed to the designed depth, the coal seam low-temperature fixed-point frozen sampling device is put into the bottom of the drilled hole and pushed towards a coal seam, a collected coal sample pushes a round baffle to enter an inner cavity of a low-temperature sample storing barrel and is cooled rapidly, meanwhile, water is supplied into a frozen sealed barrel, the coal sample mixed with water in the frozen sealed barrel is frozen rapidly in a low-temperature environment, dissipation of gas is lowered, a sealing bolt is detached after a drill is retreated, the internal coal sample is rapidly poured out by pushing the round baffle with a metal guide rod, and the coal sample is transferred into a coal sample tank to be sealed and stored. The coal seam low-temperature fixed-point frozen sampling device and the use method thereof realize low-temperature fixed-point frozen sampling, can effectively reduce the loss of gas in the sampling process, and are beneficial to improving the accuracy of the measured gas content of the coal seam.

Owner:HENAN POLYTECHNIC UNIV

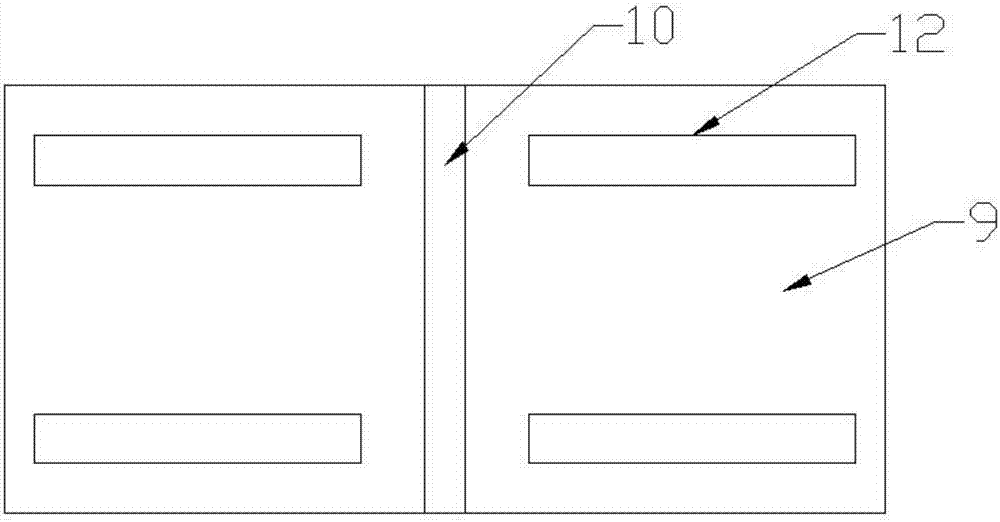

Efficient gluing device for plywood

InactiveCN110027066AApply glue evenlyGood gluing effectGlue gunsLoading/unloadingEngineeringAutomation

The invention belongs to the field of plywood processing, and particularly relates to an efficient gluing device for plywood. The efficient gluing device for the plywood aims to solve the problems that an existing gluing device is not uniform in gluing, and automatic feeding and discharging cannot be realized. The device comprises a base, a feeding conveying belt, a supporting frame and a gluing mechanism, wherein a plurality of first telescopic rods are fixed at one end of the base, and the output shaft of the first telescopic rods are connected with a feeding plate with an L-shaped verticalsection; a mounting groove is formed in the top end of the feeding plate, and a rodless air cylinder is arranged in the mounting groove; the output shaft of the rodless air cylinder is connected witha material pushing plate slidably connected to the top end of the feeding plate, one end of the feeding plate is provided with the feeding conveying belt, and one end of the feeding conveying belt isarranged on the base; the upper end face of the feeding conveying belt and the upper end face of the feeding plate are located on the same plane, and a gluing mechanism positioned on one side of the feeding plate is arranged above the feeding conveying belt; according to the device, the automation degree is high, the automatic feeding and discharging of plates can be realized, the gluing is uniform, and the gluing effect is good.

Owner:融安县华荣木业有限公司

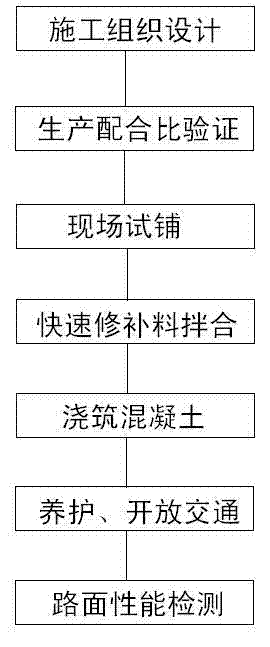

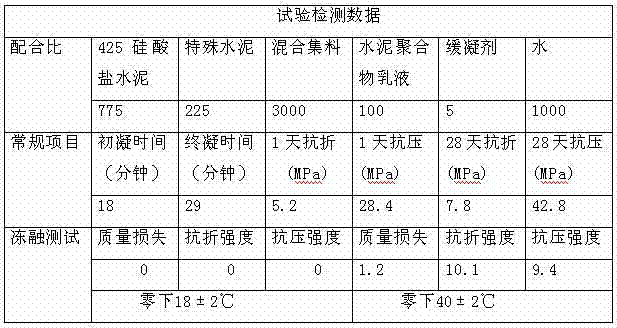

Quick repairing method of old cement concrete pavement

InactiveCN104499395ARapid build-up of strengthRapid self-compactingIn situ pavingsPortland cementStructural engineering

The invention discloses a quick repairing method of an old cement concrete pavement. High-grade Portland cement or special cement, a mixed aggregate, a self-made aqueous polymer emulsion and a retarder are manually or mechanically mixed at normal temperature, a high-adhesion quick-drying powerful ultrathin cover surface can be rapidly formed by adopting a quick scraping or spraying method, and is tightly combined with an old concrete surface layer into a whole. The quick repairing method disclosed by the invention is applied to quick repairing of a municipal administration cement pavement; the characteristic that a conventional cement concrete road reaches design strength by curing for 28 days when being repaired is changed, the old cement concrete pavement is finally settled at temperature of 25 DEG C for 2-4h by adopting the quick repairing method disclosed by the invention, the problem of traffics is solved; meanwhile, the repaired old cement concrete pavement is convenient to construct and powerful in adhesion, and resists heat and frost.

Owner:南通福伦利新材料有限公司

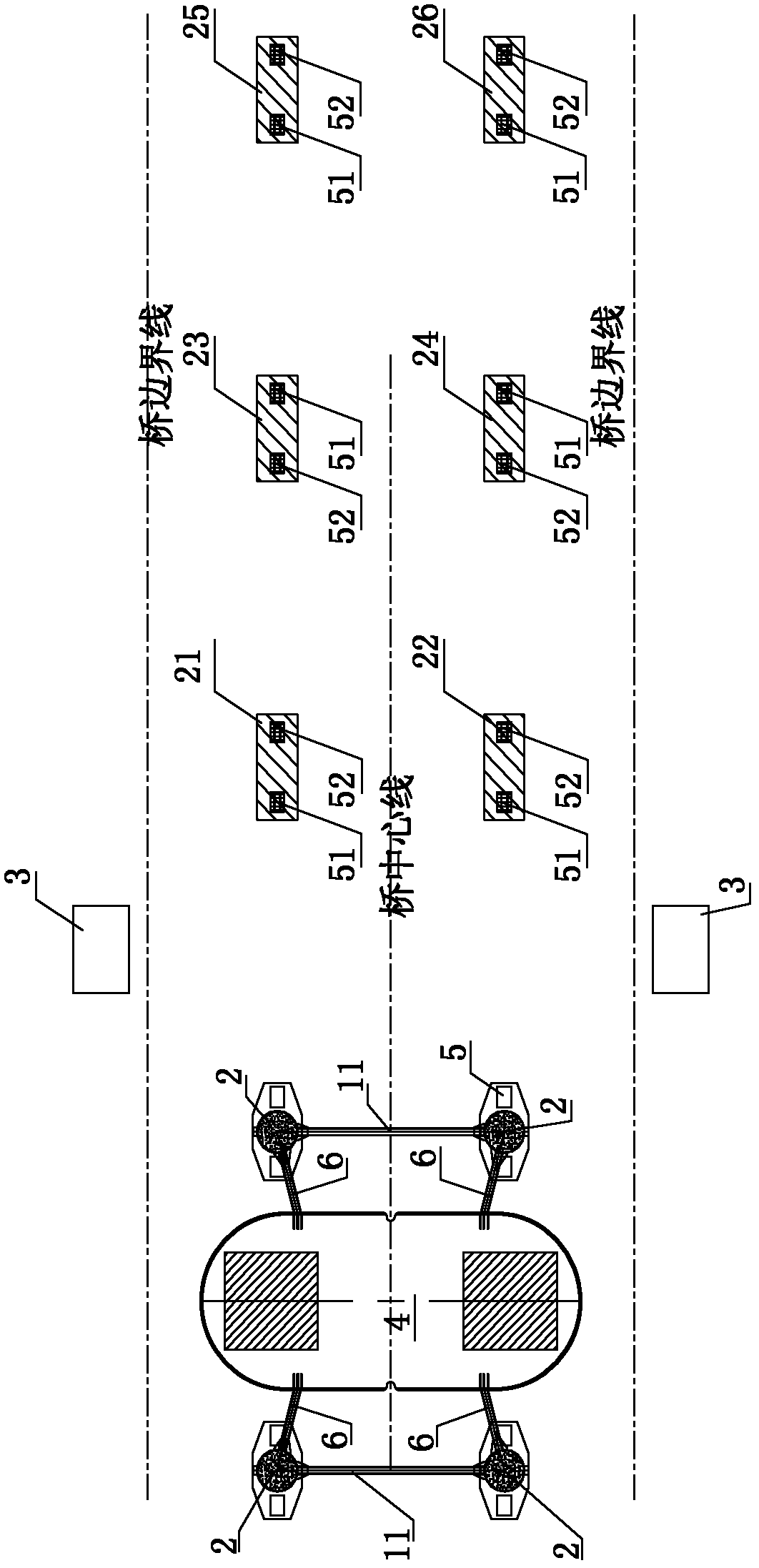

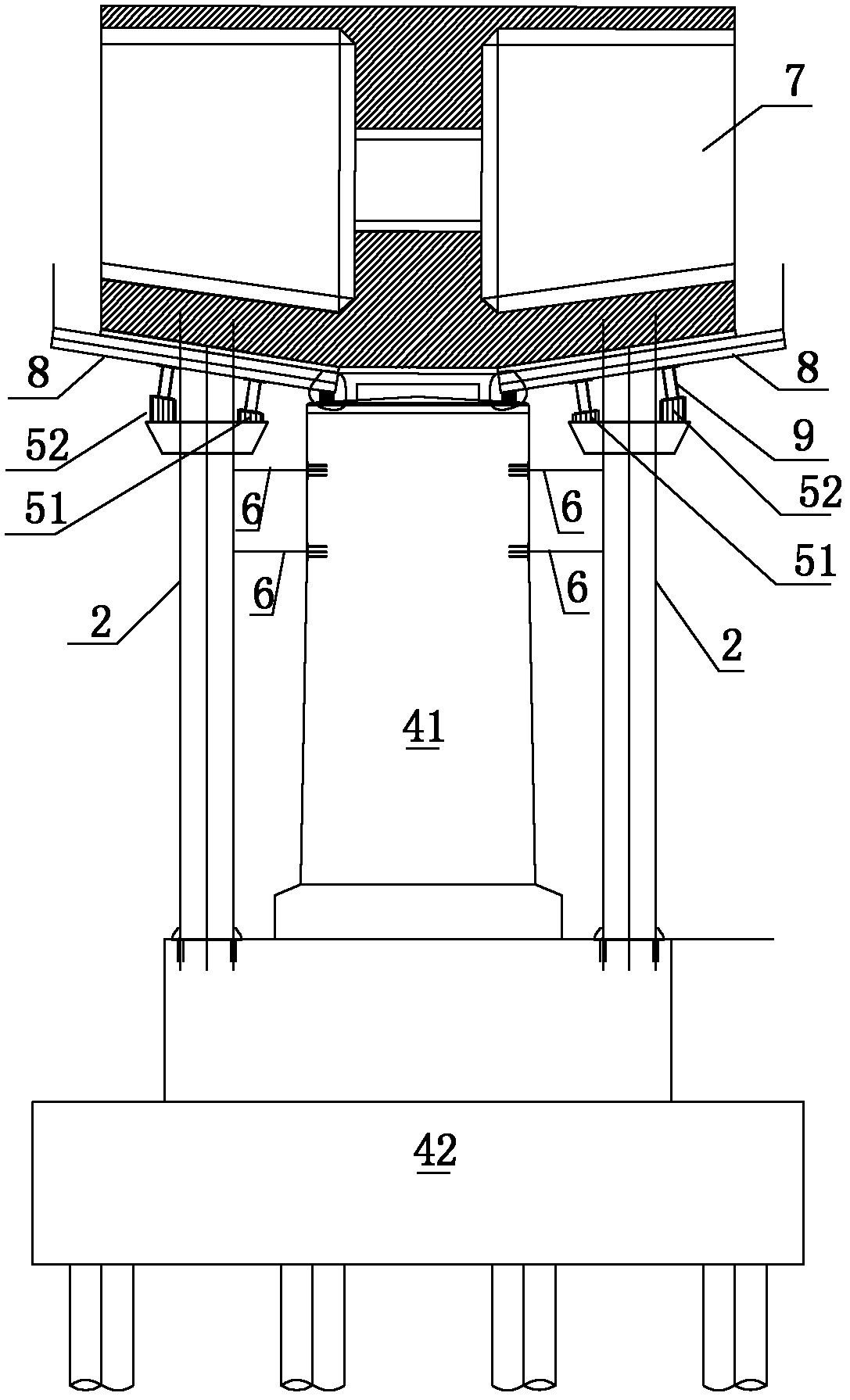

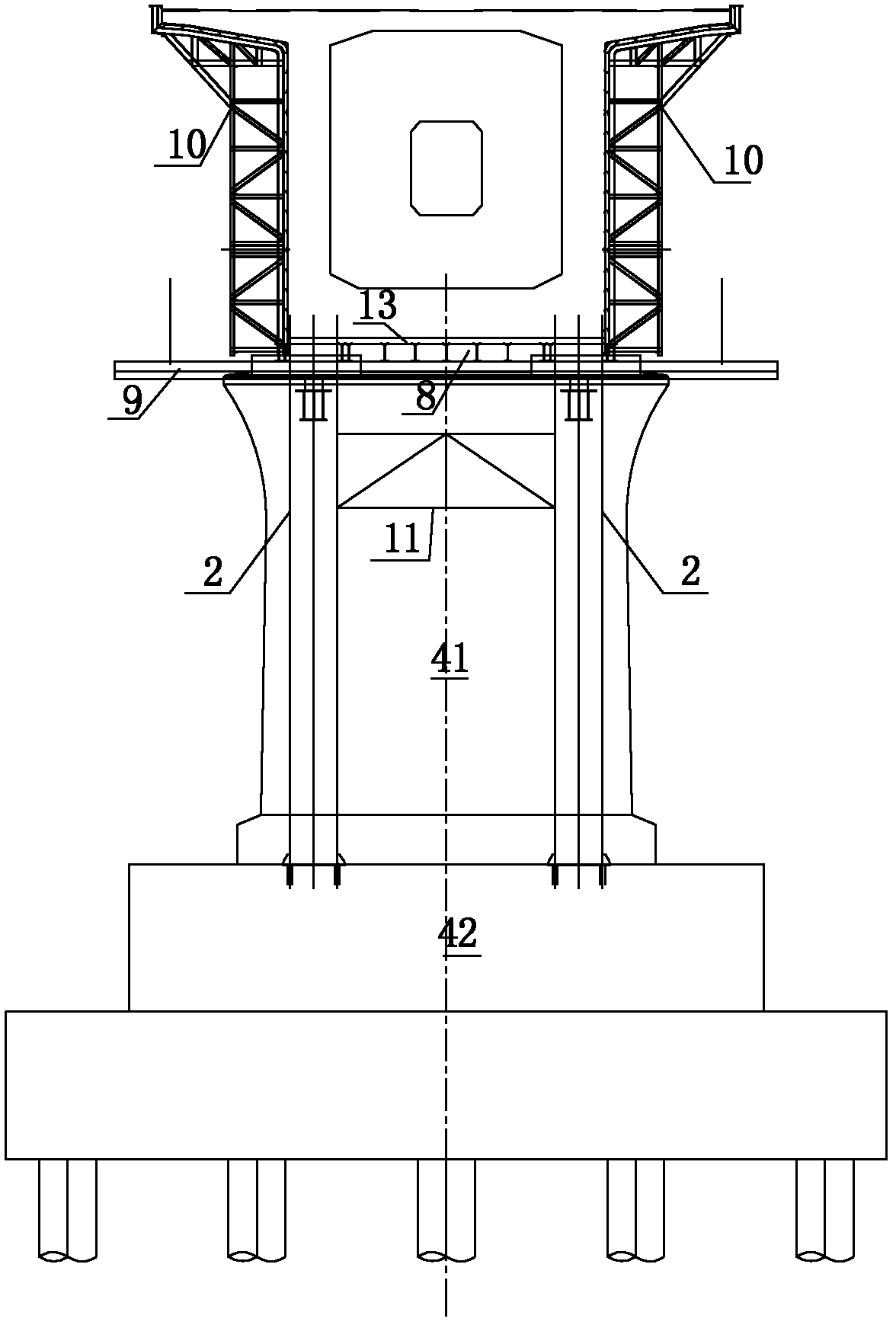

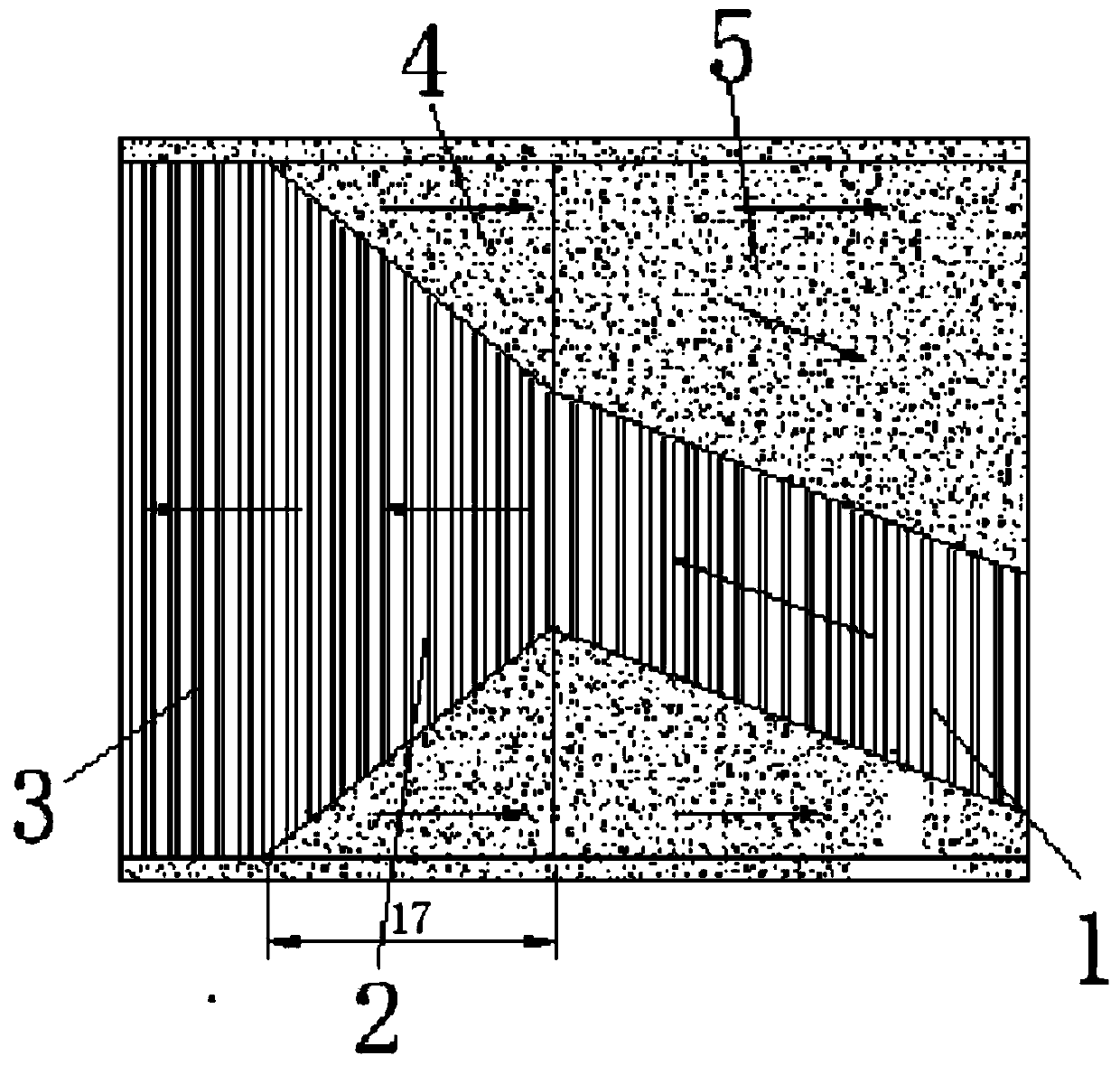

Quick construction method for segment No.0 of continuous beam

ActiveCN102493363AShorten the construction periodQuick pourBridge erection/assemblyContinuous beamEngineering

The invention discloses a quick construction method for a segment No.0 of a continuous beam, which includes: A10, constructing an assembly foundation along a bridge beside a main pier, wherein the assembly foundation is used for assembling an integral lifting platform for reinforced forms of the segment No.0; A20, synchronously constructing the integral lifting platform for the reinforced forms of the segment No.0 during construction of the main pier, wherein the integral lifting platform for the reinforced forms of the segment No.0 is complete before the main pier is complete; A30, lifting the integral lifting platform for the reinforced forms of the segment No.0 to the top of the main pier, and performing girder concreting with the segment No.0 and performing tensioning and grouting for a bridge body. By the method, the integral lifting platform for the reinforced forms of the segment No.0 is assembled and the forms are mounted and tied with rebars when construction of the main pier cap and a pier body starts, no interference with construction of the body of the main pier exists, and accordingly, construction period can be shortened greatly.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

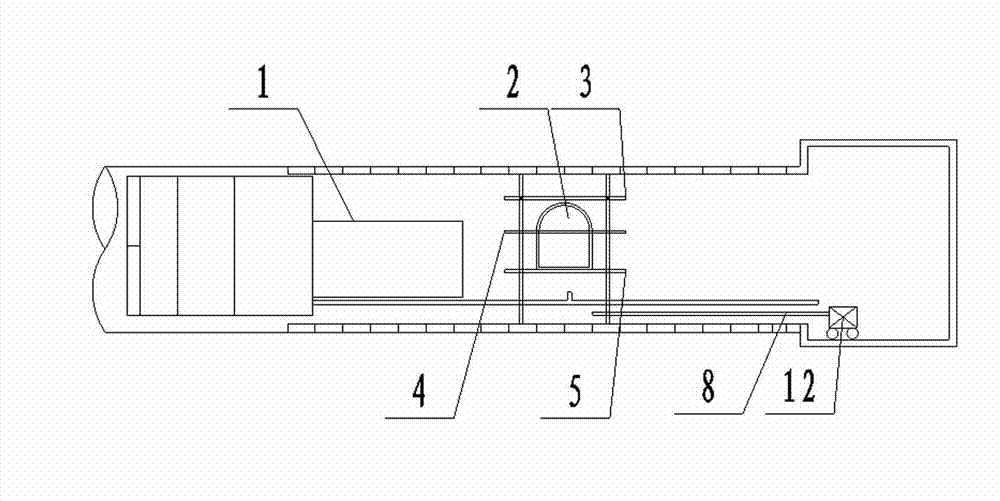

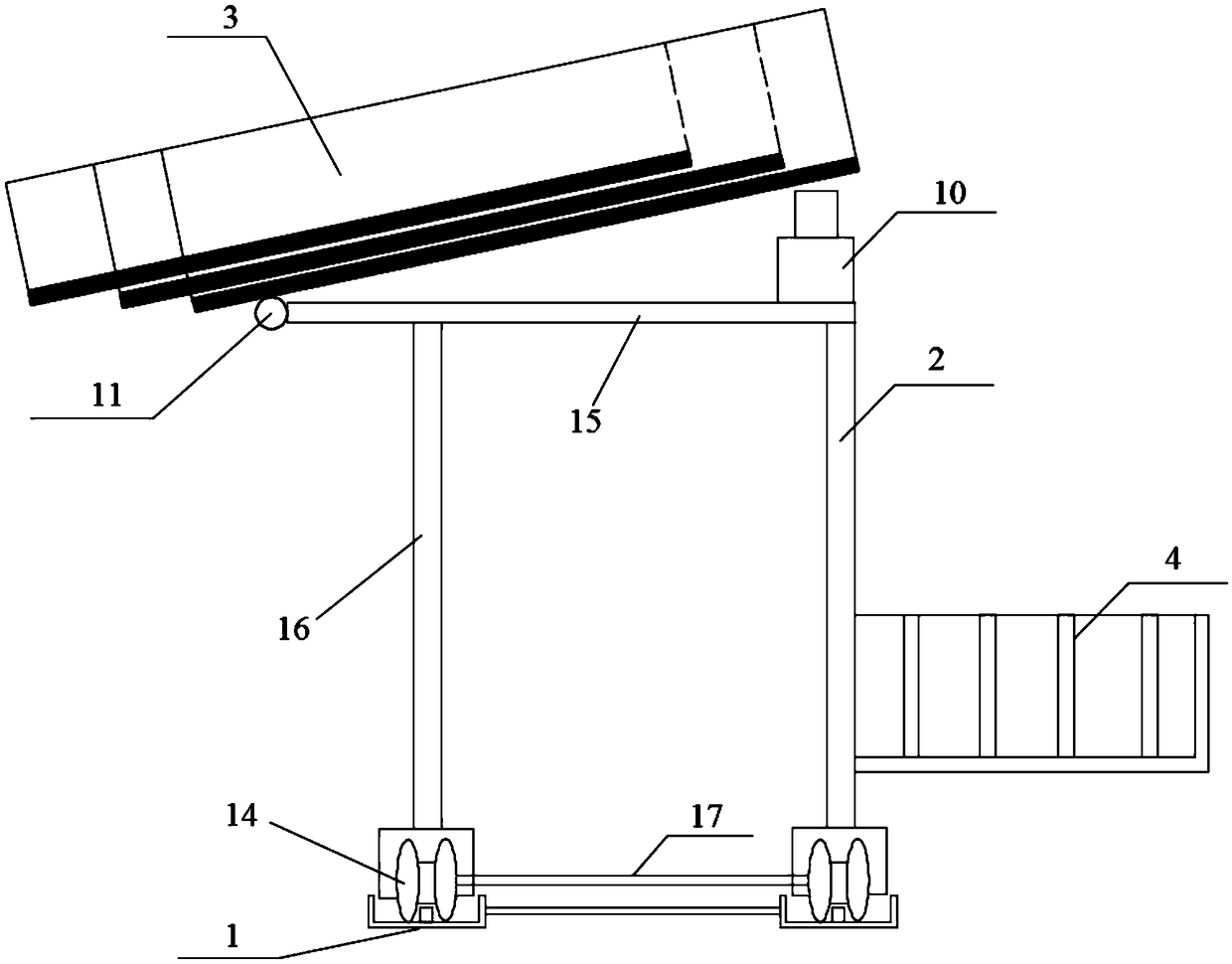

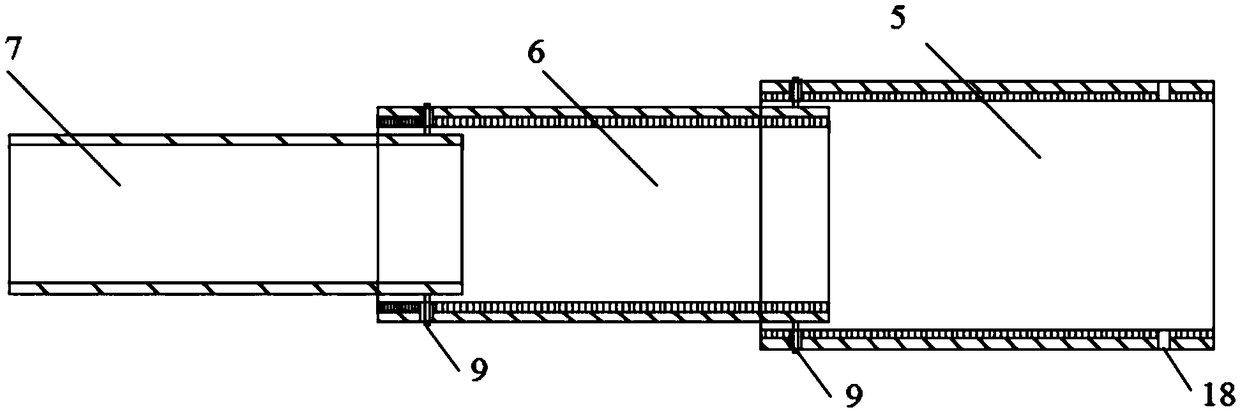

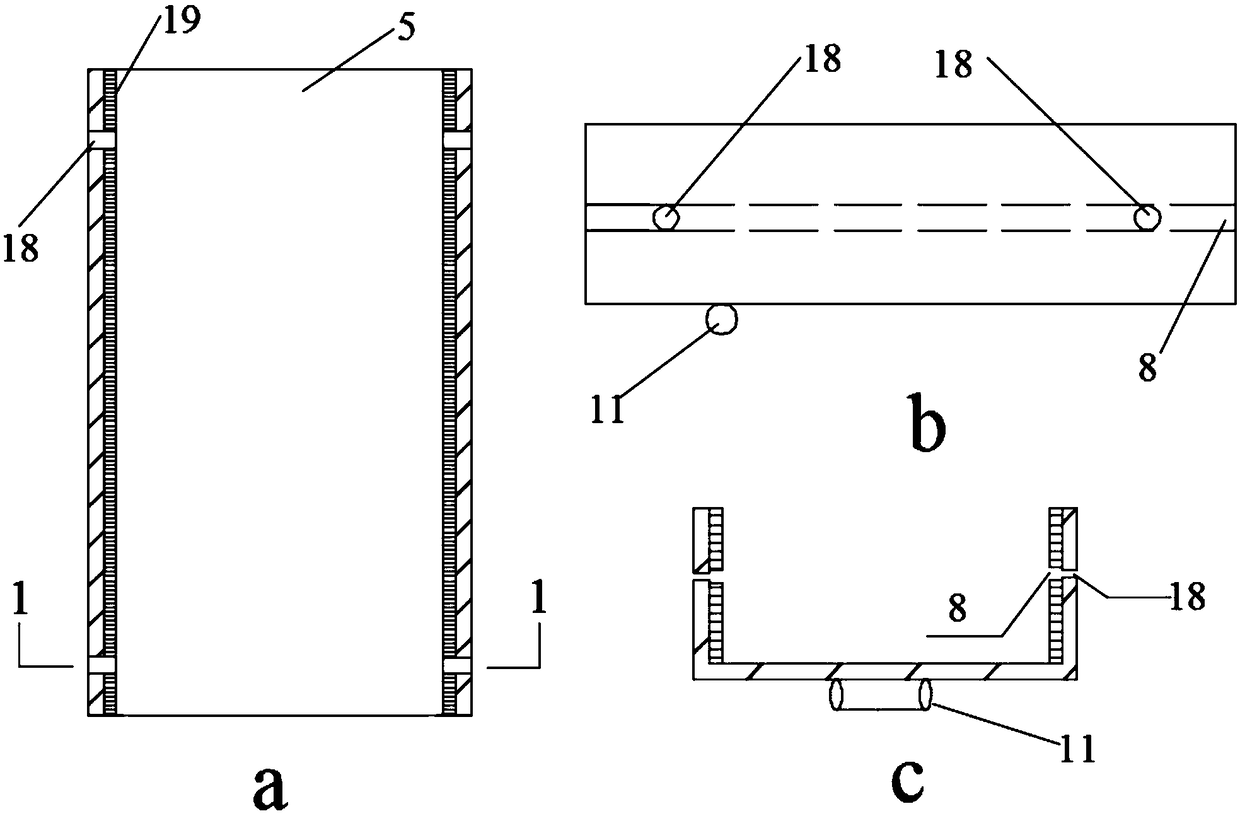

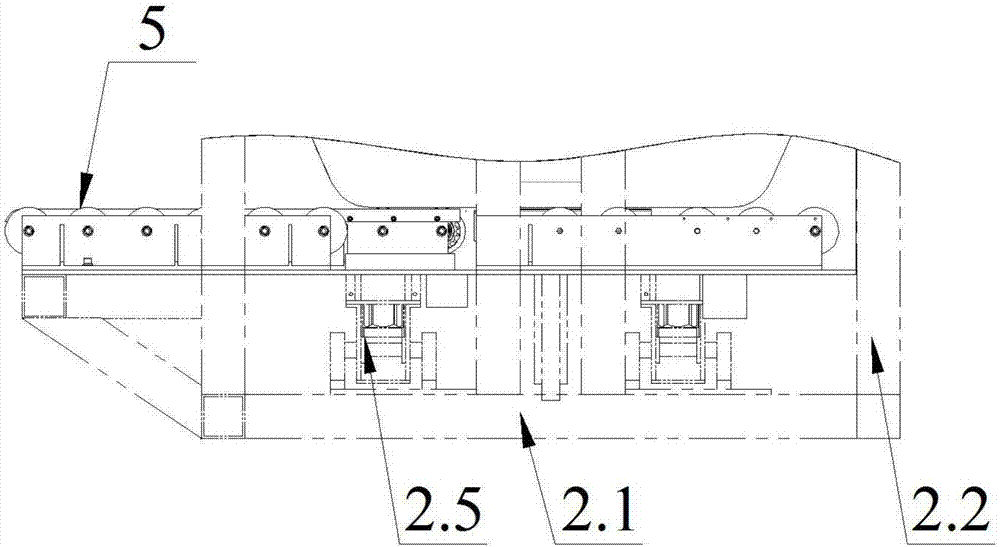

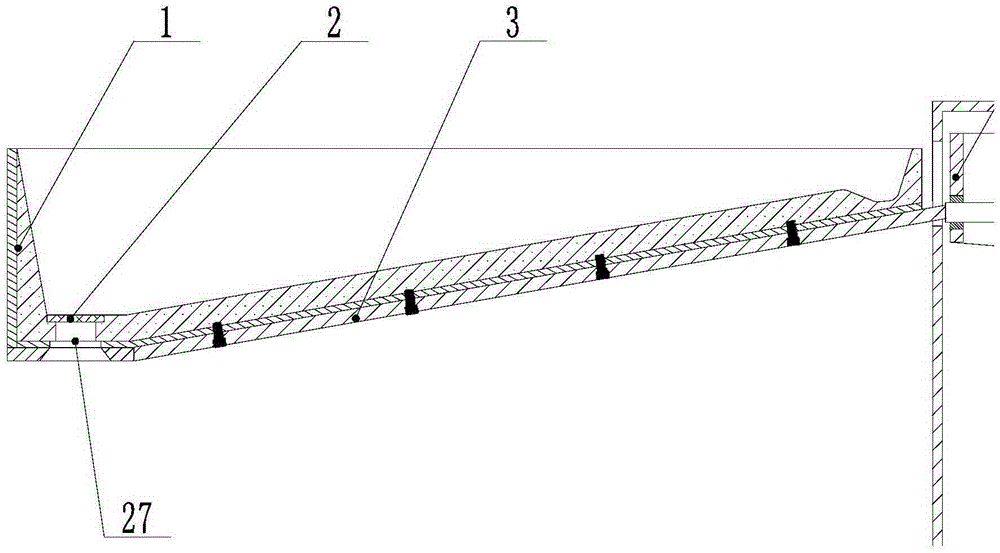

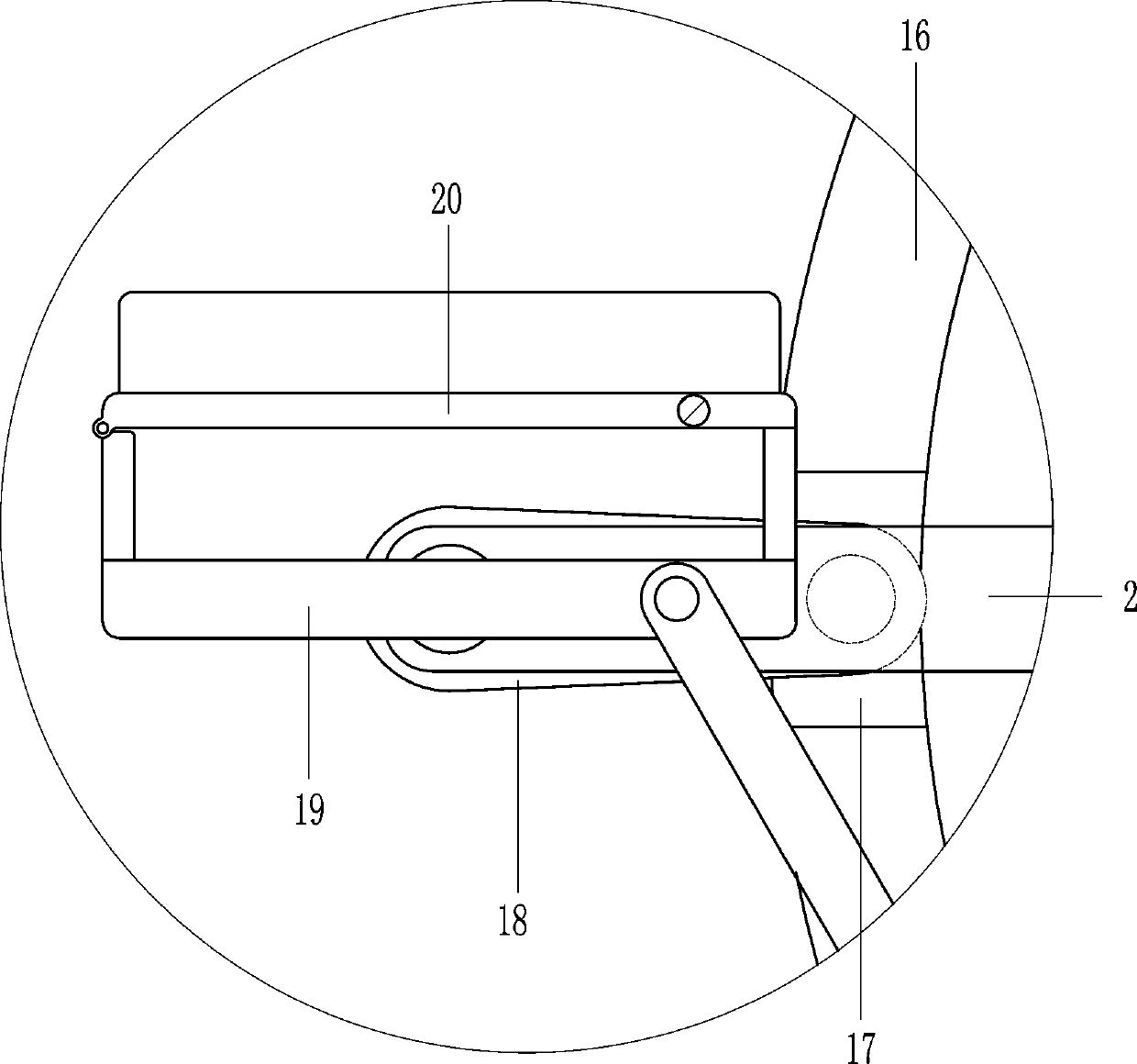

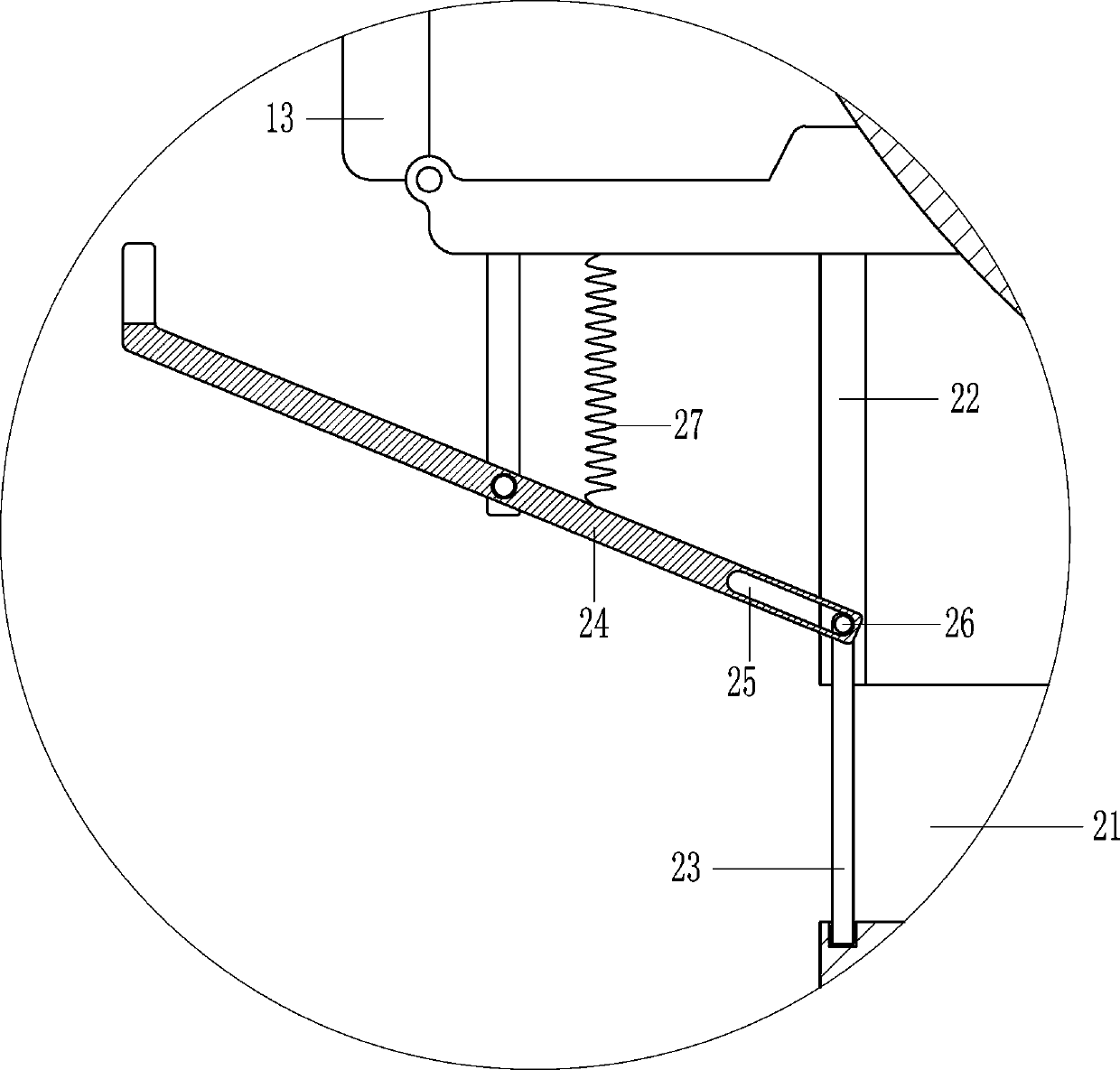

Track movable stretchable chute

InactiveCN109296051ASimple and efficient operationPouring position is accurateSewer pipelinesTrackwayEngineering

The invention discloses a track movable stretchable chute. The chute comprises a track, a movable support and a stretchable chute. The track is installed along a to-be-poured pipe groove, the movablesupport is installed on the track through a walking wheel, the stretchable chute comprises a plurality of U-shaped grooves which are sleeved and stacked, wherein the sizes of the U-shaped grooves aresequentially decreased, the U-shaped grooves are sequentially sleeved and stacked through cooperation of a sliding groove and a sliding column, wherein the front end of the first U-shaped groove is hinged to the movable support, the rear end of the first U-shaped groove is supported to the movable support through a lifting device, the middle U-shaped grooves and the tail U-shaped grooves are sequentially formed inside the first U-shaped groove, the tail U-shaped grooves are aligned to the to-be-poured pipe groove when stretching out, and the inclined angle of the stretchable chute can be adjusted through a lifting device. The adopted materials are simple and are all commonly-used materials on a construction site, the construction device operation method is simple and easy to control, deepfoundation pit pipeline concrete pouring can be easily, conveniently, rapidly and accurately performed, and the working efficiency is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

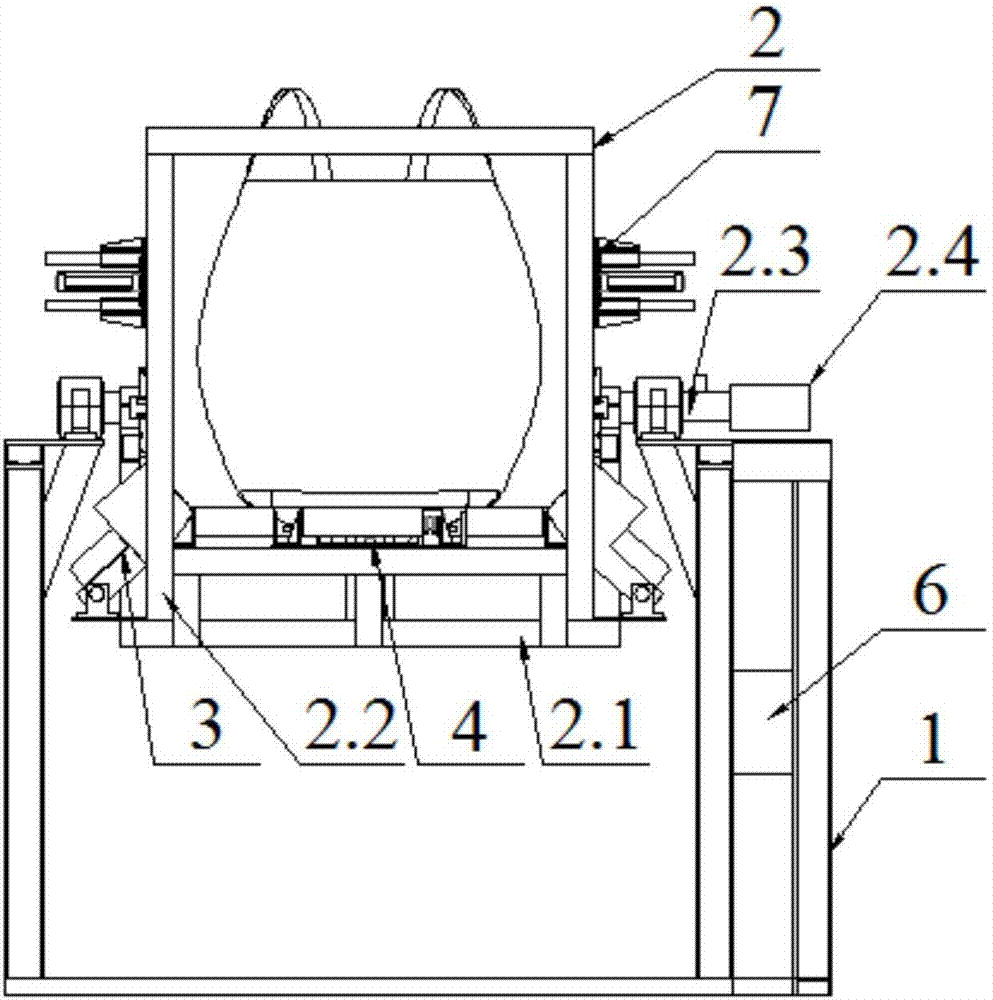

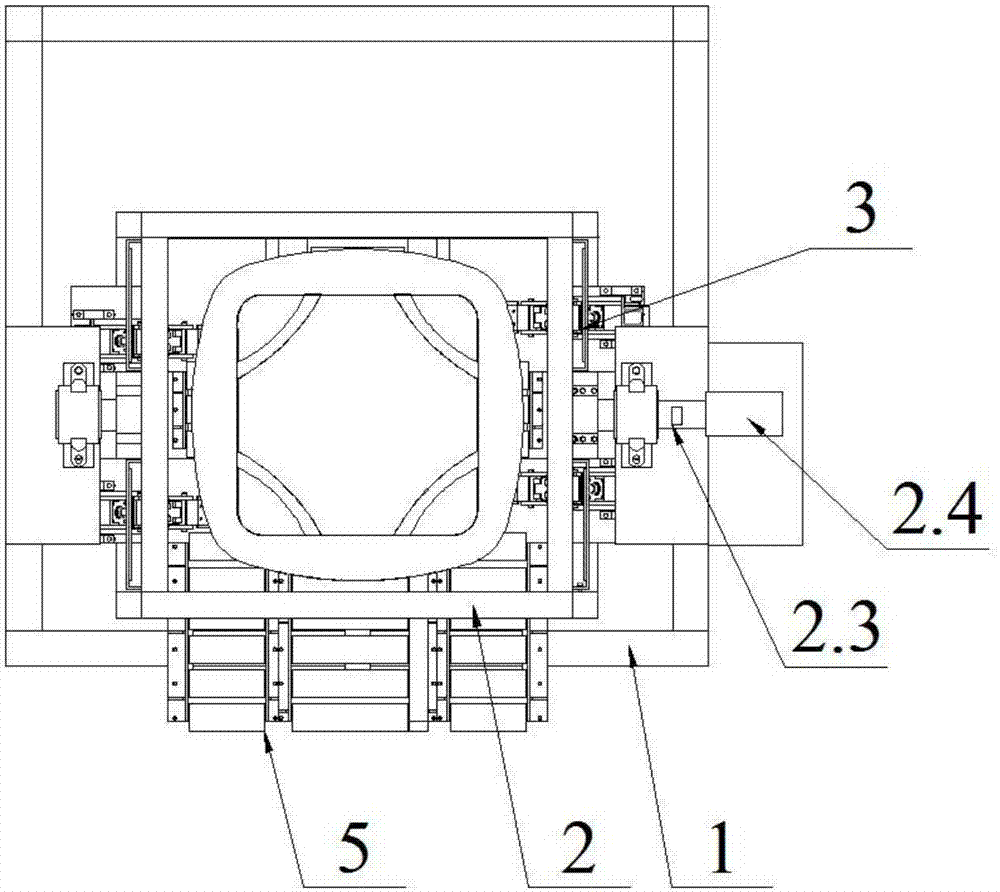

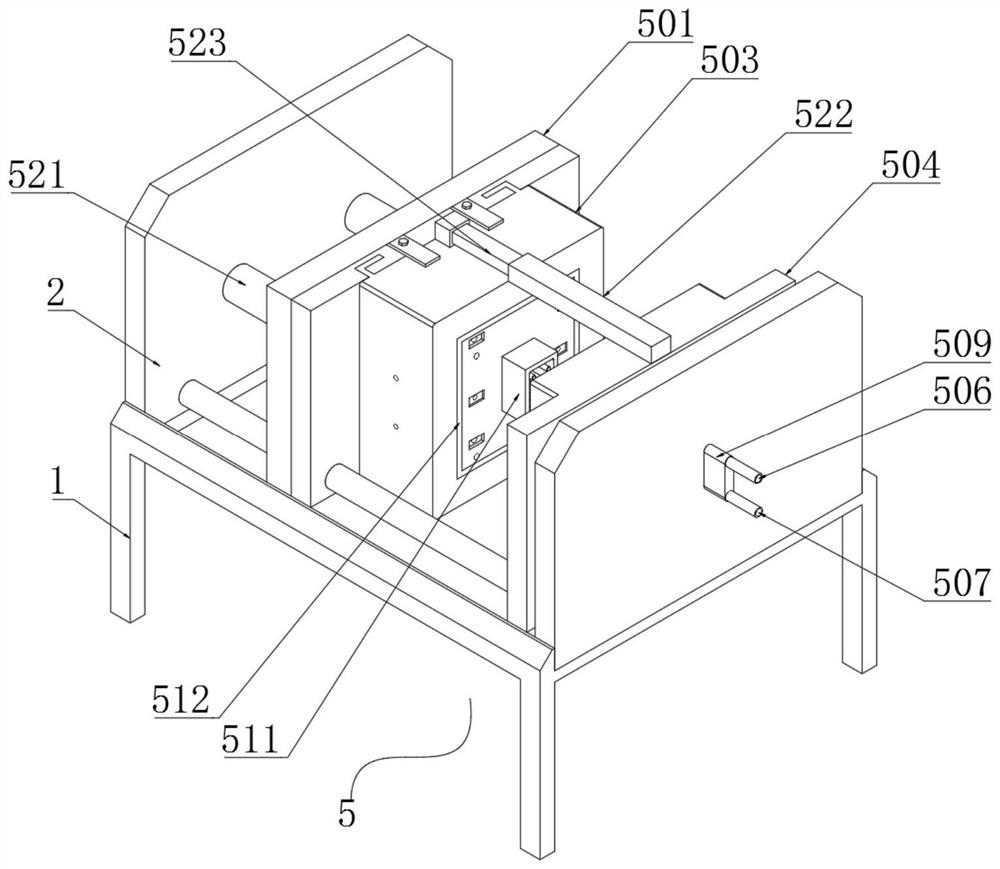

Self-adaption gripper type discharge device and discharge method

ActiveCN107285055AImprove efficiencyIncrease unloading rateBottle emptyingLoading/unloadingSelf adaptiveEngineering

The invention relates to the technical field of ton bag discharge device structures, in particular to a self-adaption gripper type discharge device and a discharge method. The self-adaption gripper type discharge device comprises a rack, wherein the rack is provided with an overturning frame which is used for containing ton bags, and the overturning frame is of a frame structure which can be rotationally hinged to the rack and is provided with at least one opening. The self-adaption gripper type discharge device further comprises a fixing device which is used for fixing the ton bags, wherein the fixing device comprises a ton bag side wall fixing device and a ton bag bottom fixing device, the ton bag side fixing device comprises a plurality of pairs of opposite side suction cups which are arranged on the inner side of the overturning frame, and the ton bag bottom fixing device comprises a plurality of pairs of gripper devices which are arranged on the two sides of the bottom of the overturning frame and used for clamping the bottoms of the ton bags. The self-adaption gripper type discharge device is simple in structure, convenient to operate and capable of discharging materials in the ton bags completely and rapidly, the ton bags cannot be damaged, collection and recirculation of the ton bags are facilitated, the discharging difficulty is greatly lowered, and great popularization value is achieved.

Owner:HUBEI UNIV OF TECH

Variable cross section tunnel excavation construction method based on climbing pilot tunnel

ActiveCN109915149AAvoid disunityFlexible constructionUnderground chambersTunnel liningMechanical equipmentEngineering

The invention discloses a variable cross section tunnel excavation construction method based on a climbing pilot tunnel. The variable cross section tunnel excavation construction method comprises thefollowing steps that 1, a small pilot tunnel climbing a slope and topping; topping from a small section to the center line direction of a large section tunnel by adopting a pilot tunnel mode, and digging the pilot tunnel obliquely upwards in an equal section manner until the pilot tunnel and an arch crown of the large section tunnel are positioned at the same elevation; 2, expanding and excavatinga transition section; continuing excavating the top of the pilot tunnel forwards to form the transition section; 3, excavating a standard section; excavating forwards from the transition section witha uniform section to form a working section of mechanical equipment; 4, excavating a transition section back; digging a middle step surface downwards on the horizontal plane of the transition section; 5, excavating the climbing section of the small pilot tunnel; expanding and excavating from the small pilot tunnel to the small section; and 6, excavating forwards from the variable cross section, forming a lower step surface, forming three steps, and constructing according to a three-step method. The construction time and cost are greatly reduced in variable cross section construction, and themethod can be widely applied to the field of building construction.

Owner:CCCC SECOND HARBOR ENG +1

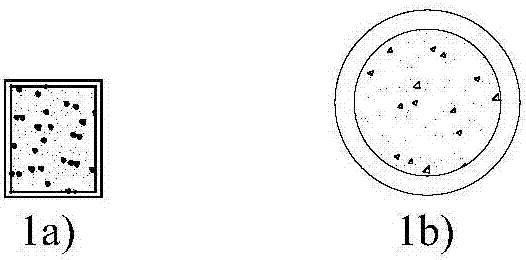

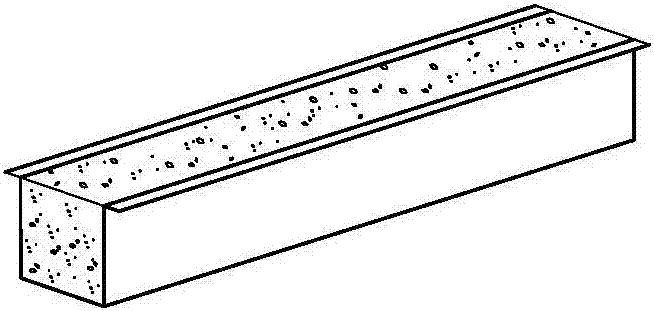

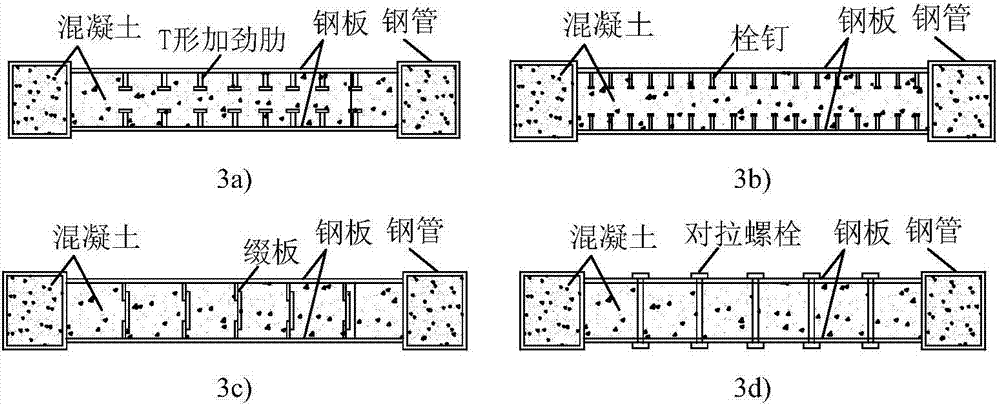

Fabricated super-high-rise steel-concrete combination residence

InactiveCN107882178AOvercome stiffnessOvercome the defect of poor ductilityStrutsWallsResidenceBuckling-restrained brace

The invention belongs to the technical field of buildings and particularly relates to a fabricated super-high-rise steel-concrete combination residence. The advantages that formworks are omitted, ductility is good and the rigidity is large of a steel-concrete combined structure are utilized, the defects that as for a fabricated concrete structure, the resistant-lateral rigidity is small and the ductility is poor, as for a fabricated steel structure, deformation is large, and as for an existing fabricated steel-concrete combination structure prefabricated member, the structure is complex and cast-in-place shear walls are adopted are overcome, and an innovated fabricated steel-concrete combination structure system is applied to the fabricated super-high-rise residence. The fabricated super-high-rise steel-concrete combination residence is composed of concrete-filled steel pipe combination columns, externally-wrapped steel-concrete combination beams, steel plate combination shear walls and energy-dissipation-type concrete-filled steel pipe combination buckling constraint supports to serve as the structure system of the super-high-rise residence, and thus the defects that as for the fabricated concrete structure, the resistant-lateral rigidity is small and the ductility is poor, and as for the fabricated steel structure, deformation is large are overcome.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

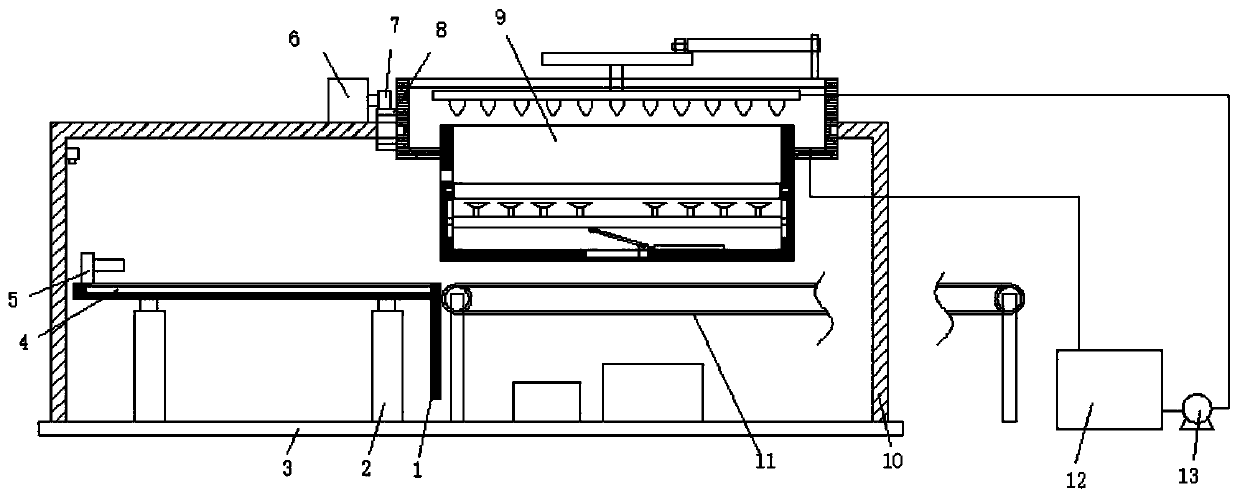

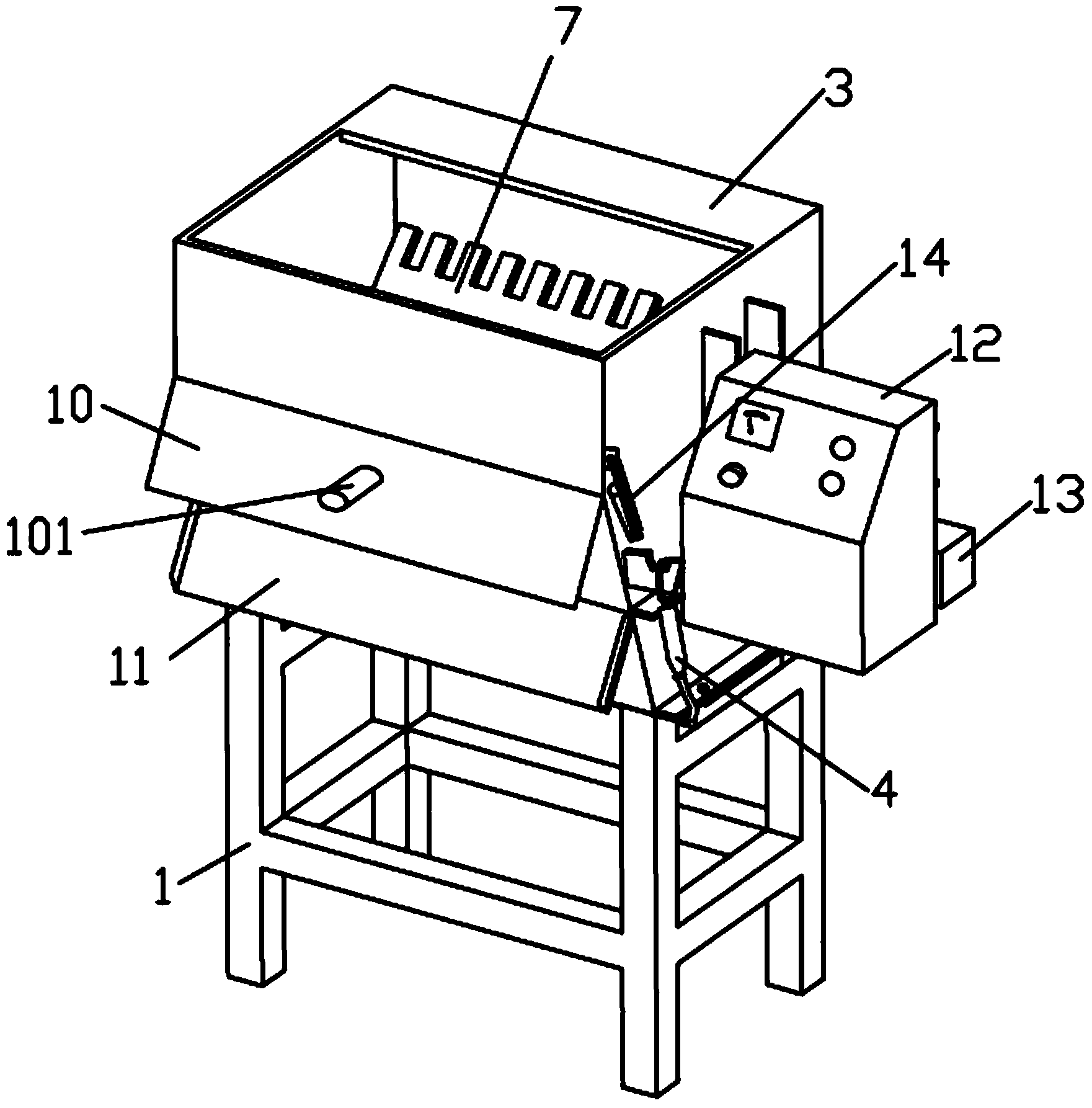

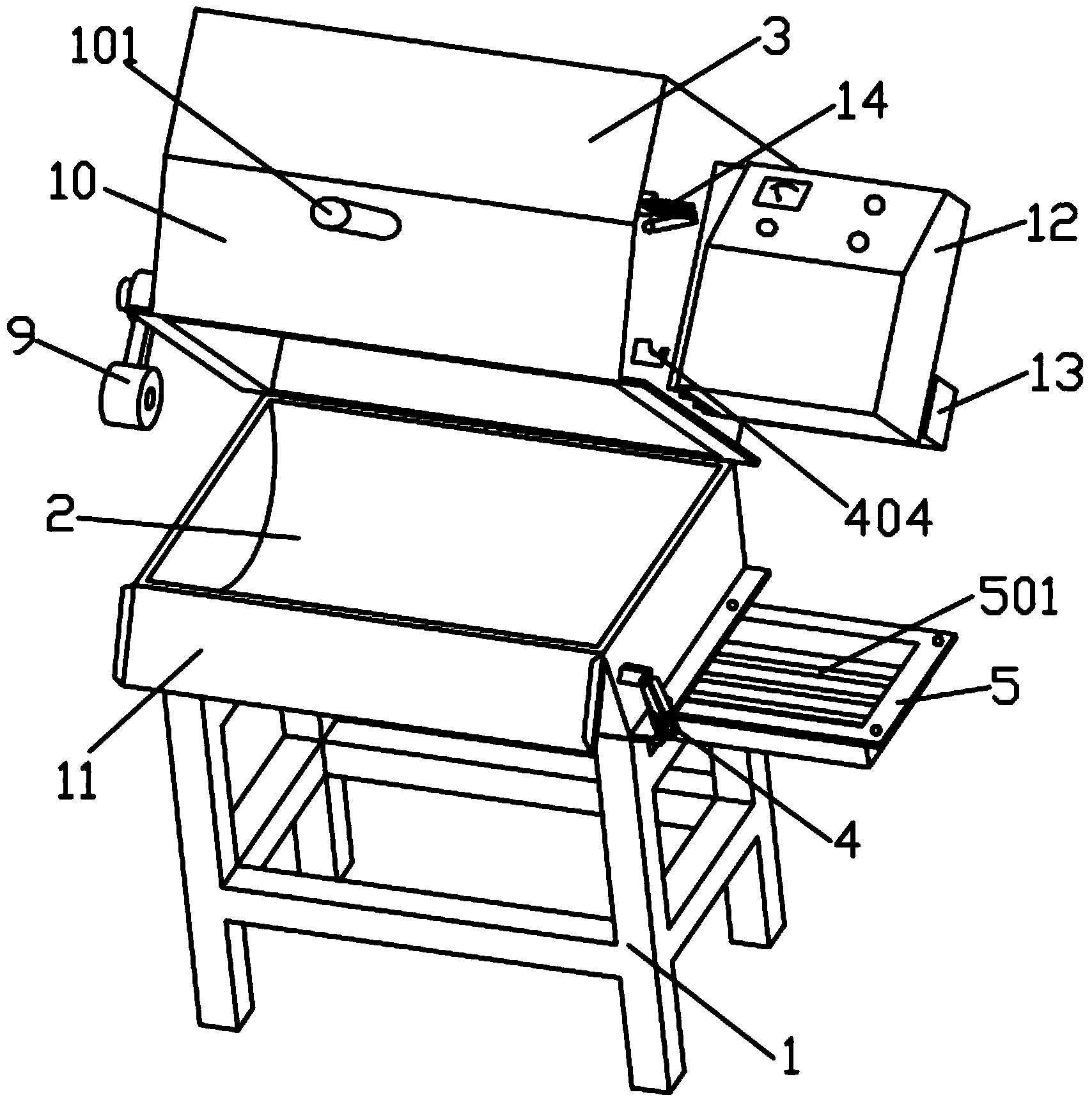

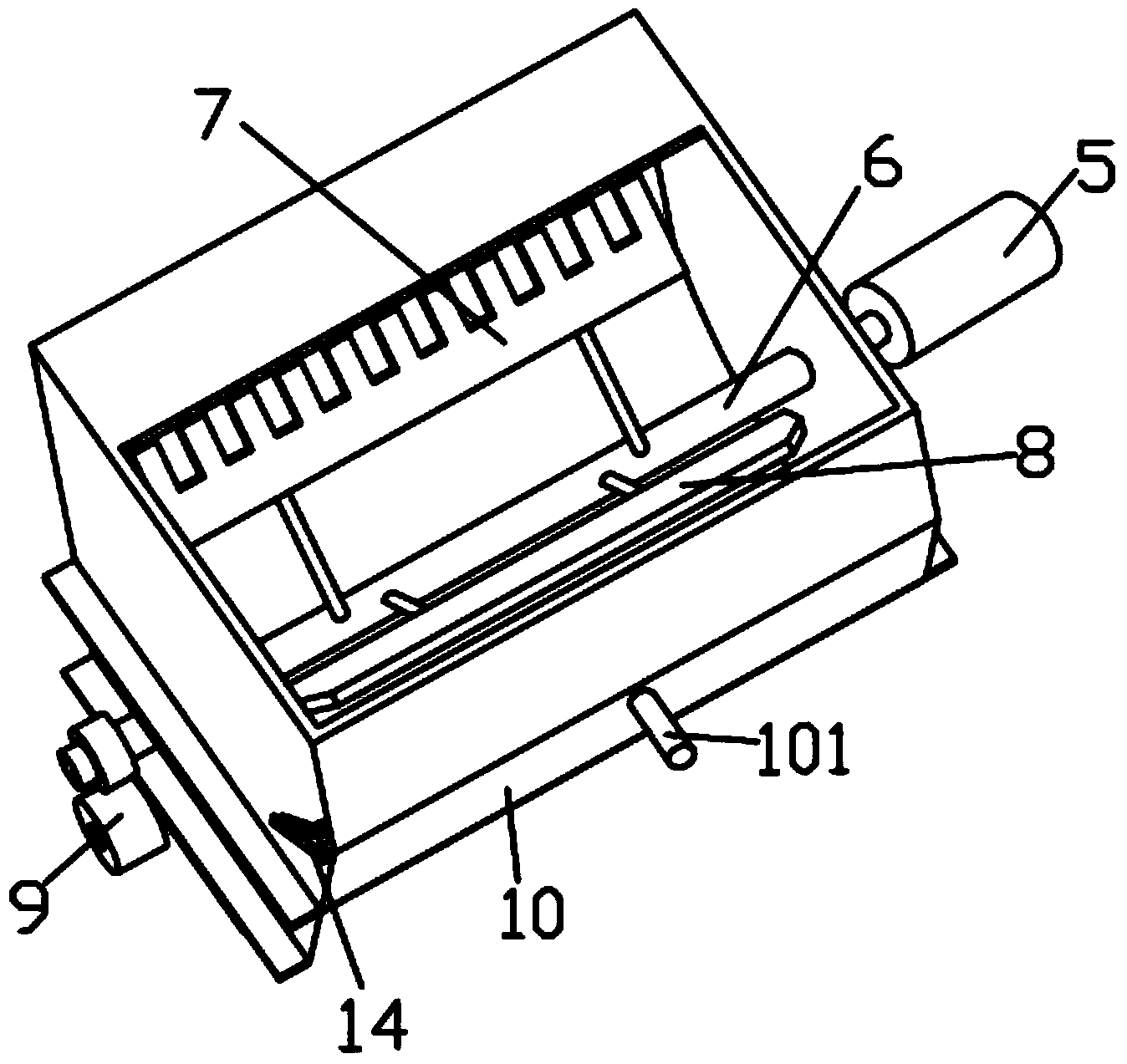

Tea frying machine

The invention discloses a tea frying machine which comprises a rack (1) and a pot body arranged on the rack (1), wherein the pot body of a long-trough shaped structure of which the bottom is circular arc shaped; the pot body is internally provided with a frying handle (8) and a frying harrow (7) which make circling motion along the bottom of the pot body; a plurality of frying claws (71) for scattering tea leaves are arranged at intervals at the front end contacting the bottom of the pot, of the frying harrow (7). The tea frying machine disclosed by the invention is simple in structure, low in cost, applicable to small-scale domestic tea leaf frying, convenient to use and high in efficiency, tea leaves can be uniformly fried, the fried tea leaves are good in quality, and thus the tea frying machine is relatively high in practicability.

Owner:梅为民

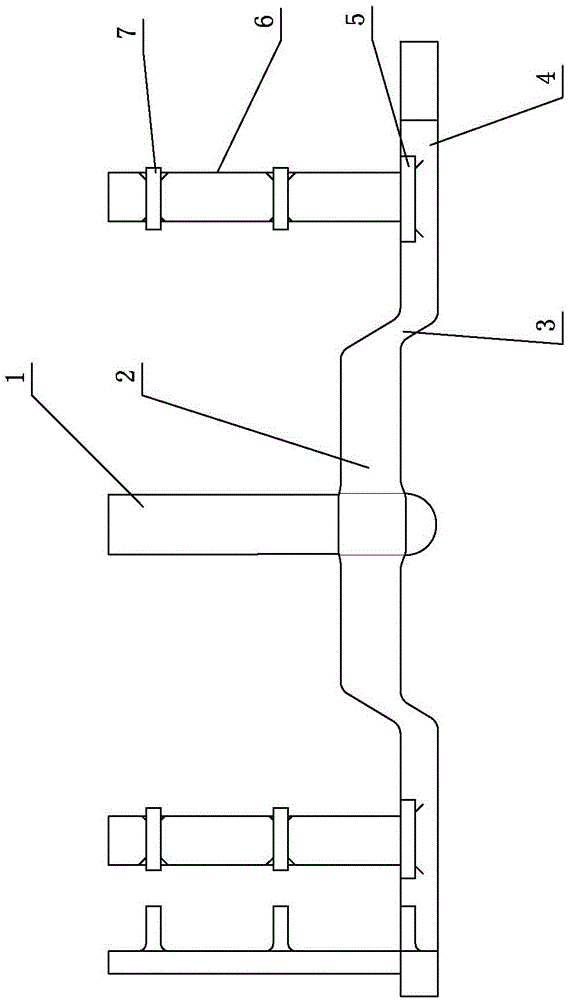

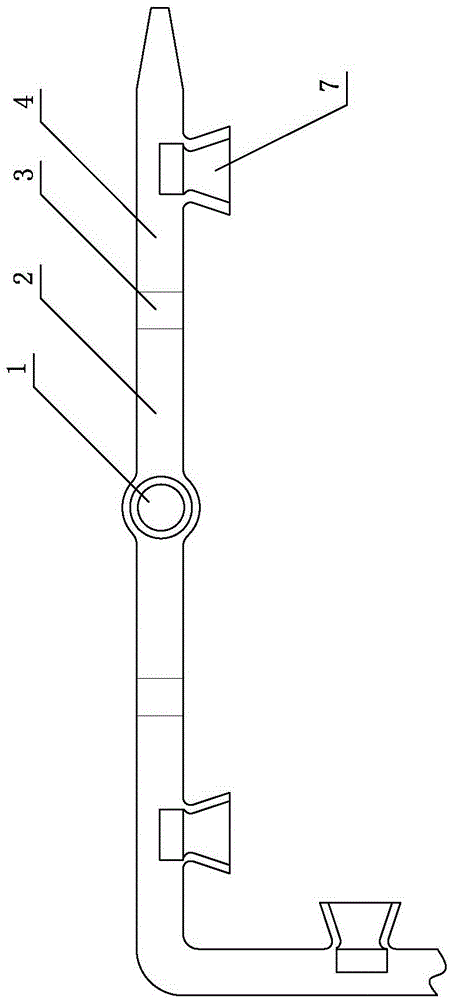

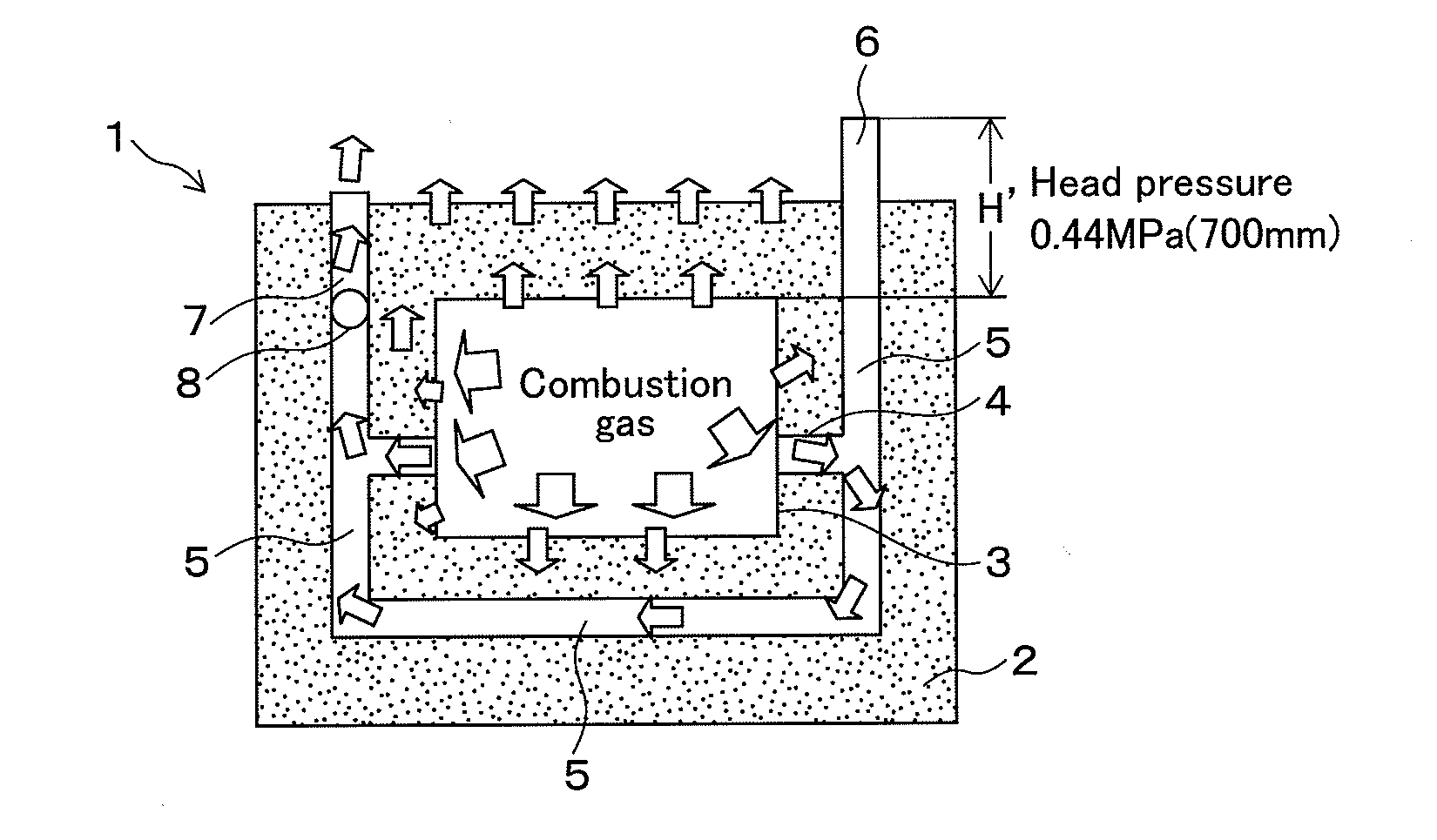

Reverse rising type evaporative pattern casting system

ActiveCN105081219AReduce temperature dropHigh densityFoundry mouldsFoundry coresCombustionMulti point

The invention relates to a reverse rising type evaporative pattern casting system which can achieve multi-point inflow, large-area combustion, rapid casting and rapid solidification in the technical field of casting. The reverse rising type evaporative pattern casting system comprises a sprue, transverse runners and inner runners. The sprue, the transverse runners and the inner runners are made of evaporative pattern materials. The transverse runners include the first-stage transverse runner and the second-stage transverse runner which are sequentially connected with the bottom of the sprue. The first-stage transverse runner and the second-stage transverse runner are in transition connection through a flow blocking section with the narrowed section. The second-stage transverse runner is lower than the first-stage transverse runner. A plurality of bottom layer inner runners and reverse rising runners extending upwards are horizontally arranged on the second-stage transverse runner. The reverse rising runners are led out upwards from the top side of the second-stage transverse runner. The inner runners horizontally extending in the evaporative pattern direction are arranged at the positions, at different heights, on the reverse rising runners. The bottom layer inner runners and the inner runners face the evaporative pattern direction and are connected with an evaporative pattern.

Owner:KOCEL EQUIP

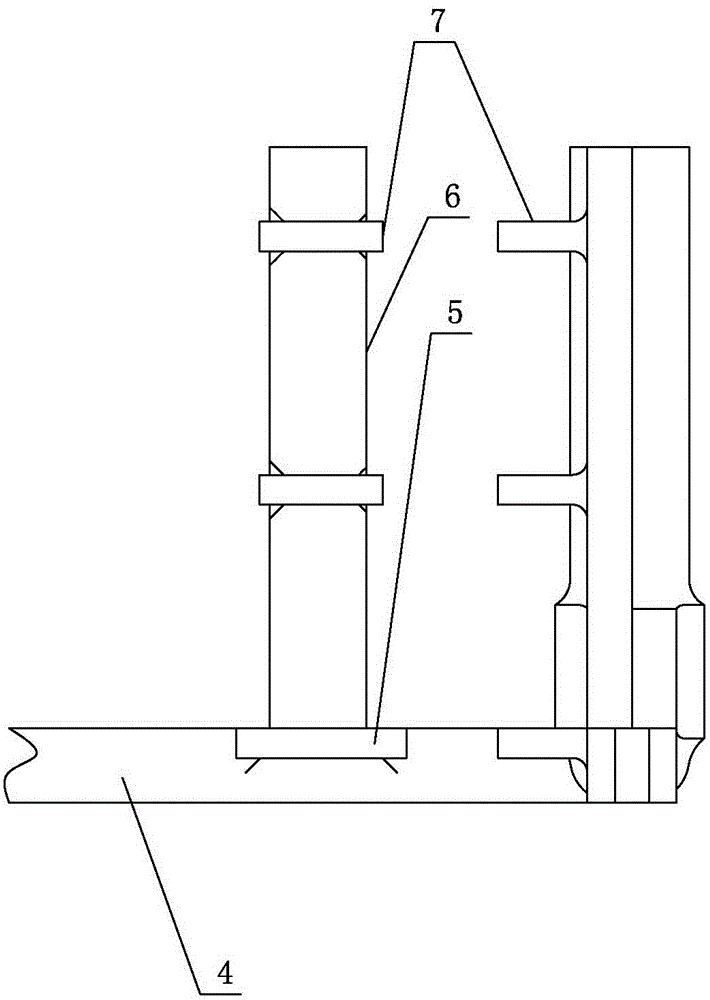

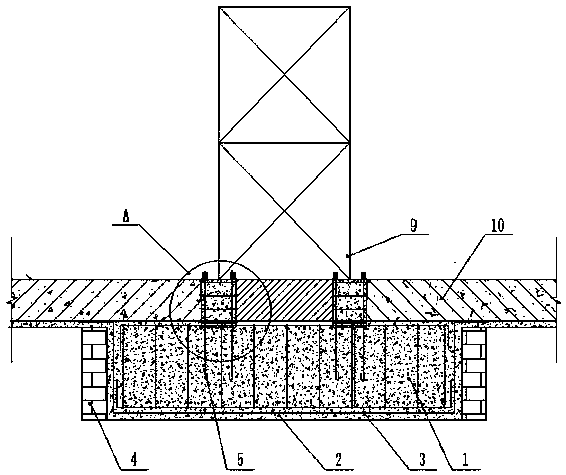

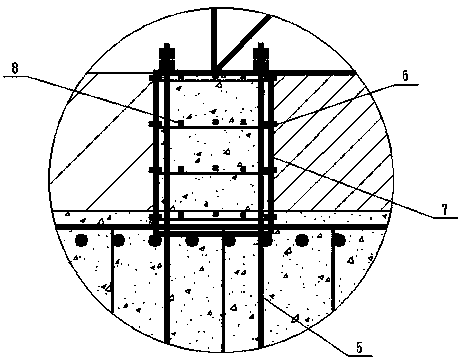

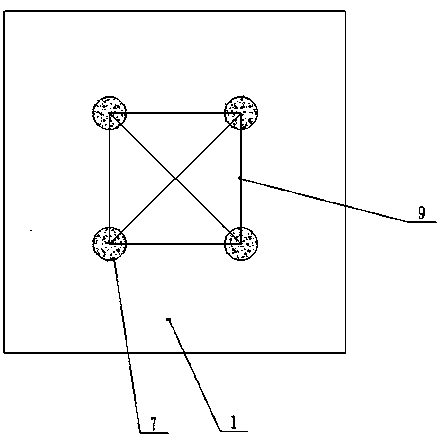

Construction method for basement raft foundation with tower crane foundation

ActiveCN111042185AQuick pourWon't overflowFoundation engineeringArchitectural engineeringTower crane

The invention discloses a construction method for a basement raft foundation with a tower crane foundation. The construction method specifically comprises the following steps: excavating a tower cranefoundation pit, arranging double-layer reinforcing steel bars of the tower crane foundation, pre-embedding four groups of pre-embedded foundation bolts, separately sleeving four steel sleeves at theouter sides of each group of pre-embedded foundation bolts, welding the lower ends of the steel sleeves to upper-layer reinforcing steel bars of the tower crane foundation, and enabling the upper endsof the steel sleeves to be as high as top elevation of a to-be-constructed raft foundation; pouring concrete into the tower crane foundation pit, integrally pouring and forming the steel sleeves andconcrete in the tower crane foundation, mounting a tower crane, separately connecting and fixing four connecting ends of a tower crane foundation section to the pre-embedded foundation bolts in the corresponding four steel sleeves, and enabling the tower crane to normally work; normally arranging ribs for the raft foundation, pouring concrete, performing once construction to accomplish the raft foundation, and curing and forming the raft foundation. The raft foundation in the construction method can be once integrally constructed, so that construction efficiency is improved, and the problems such as reinforcing steel bar binding, waterproof treatment, secondary hole filling and the like of a reserved area of the tower crane foundation.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Wool cleaning device for producing wool textiles

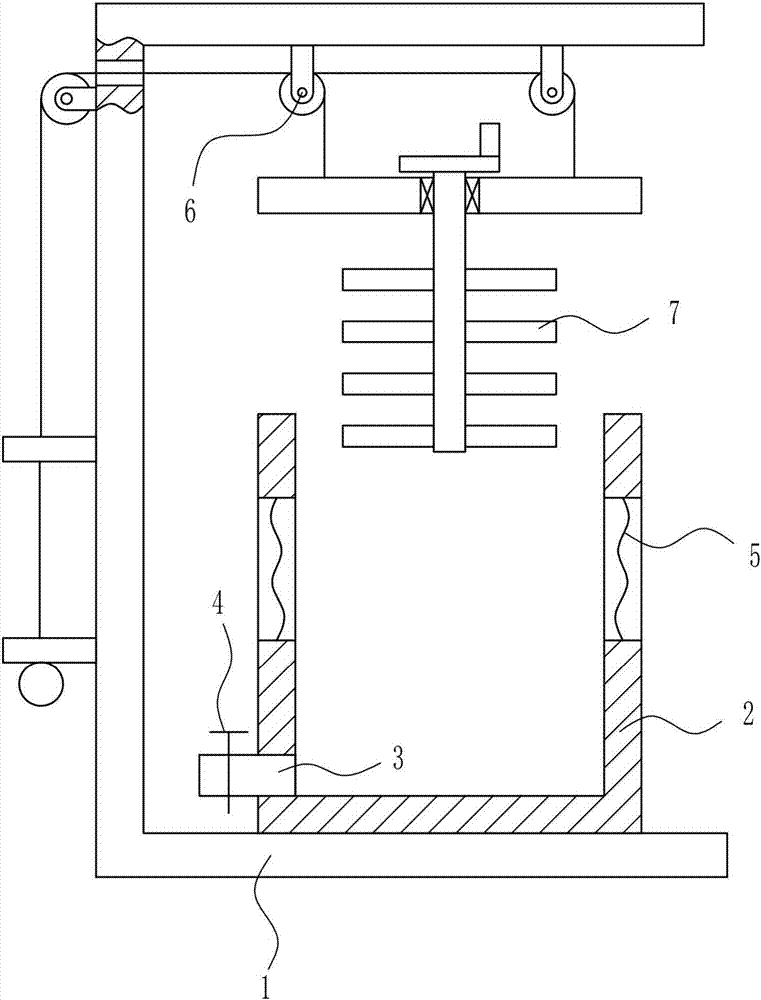

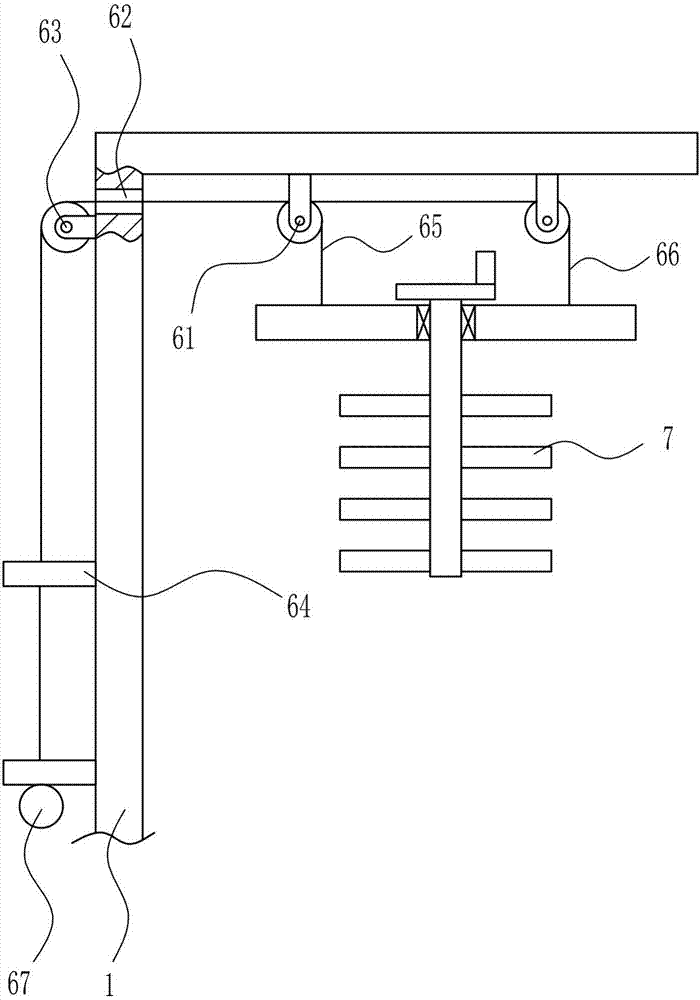

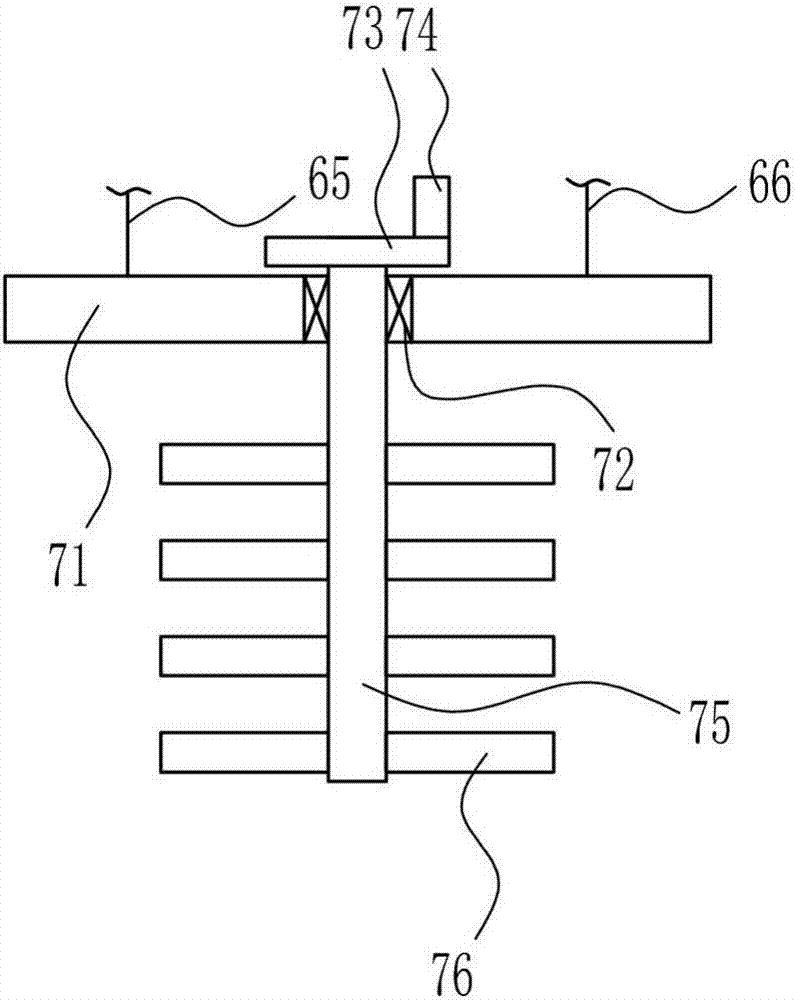

The invention relates to a cleaning device, in particular to a wool cleaning device for producing wool textiles. The wool cleaning device for producing the wool textiles is capable of rapidly cleaning wool; the wool cleaning device for producing the wool textiles in the technical scheme comprises an installing frame and the like; a frame is arranged at the inner bottom of the installing frame, a water discharging pipe is arranged at the lower portion of the left wall of the frame, a valve is arranged on the water discharging pipe, heating wires are arranged at the upper portion of the left wall and the upper portion of the right wall of the frame, a lifting device is arranged on the installing frame, and a stirring device is arranged at the bottom of the lifting device. According to the wool cleaning device for producing the wool textiles, a rocking rod is rotated to drive stirring rods to rotate, wool in the frame is stirred and cleaned, and the effect of increasing the cleaning speed is achieved; a net plate is arranged, the wool is cleaned at the top of the net plate accordingly.

Owner:赤峰圣伦绒毛制品有限公司

Peanut cleaning device for agriculture facilitating soil sedimentation

The invention discloses an agricultural peanut cleaning device which is convenient for soil precipitation, which comprises a cleaning box, a support frame, a mesh basket, a cylinder and a water tank; a connection bracket is fixed on one side of the support frame, and the connection bracket is fixedly connected to a horizontal cylinder; An inclined mud deflector is fixedly arranged on the inner wall of the cleaning box, a blanking plate is arranged between the mud deflectors on both sides, a horizontal rotating shaft is fixedly installed in the middle of the blanking plate, and the upper surface of the blanking plate A first wedge block is fixed, and a second wedge block is fixed on the upper supporting frame corresponding to the first wedge block. The present invention enables the washed peanuts to be quickly poured out through the set separate net basket, without consuming a lot of labor and time, and improves the efficiency of peanut cleaning; It can also drive the lower cutting plate to swing, and guide the cleaned sludge into the lower sedimentation chamber.

Owner:苏清凉

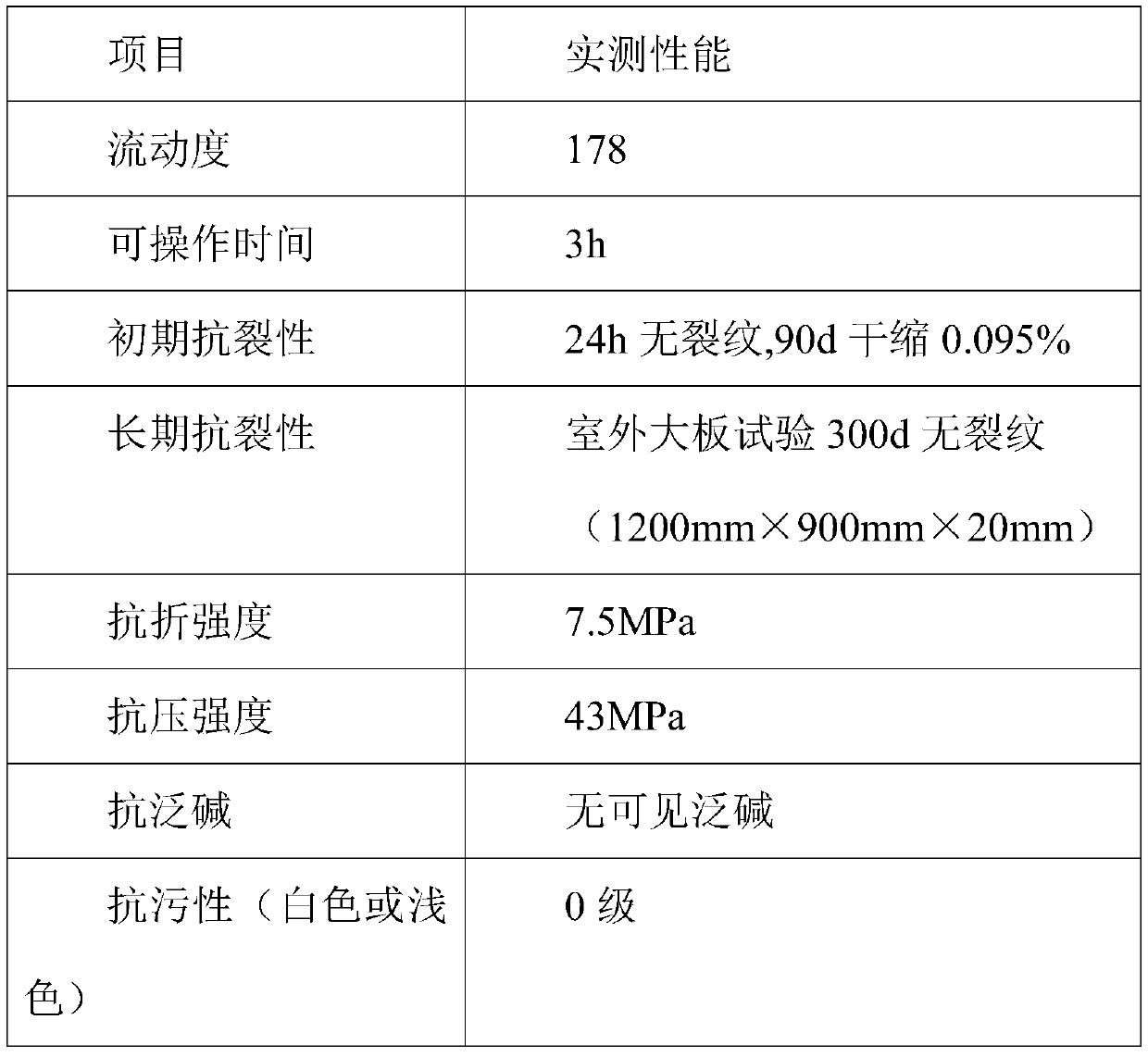

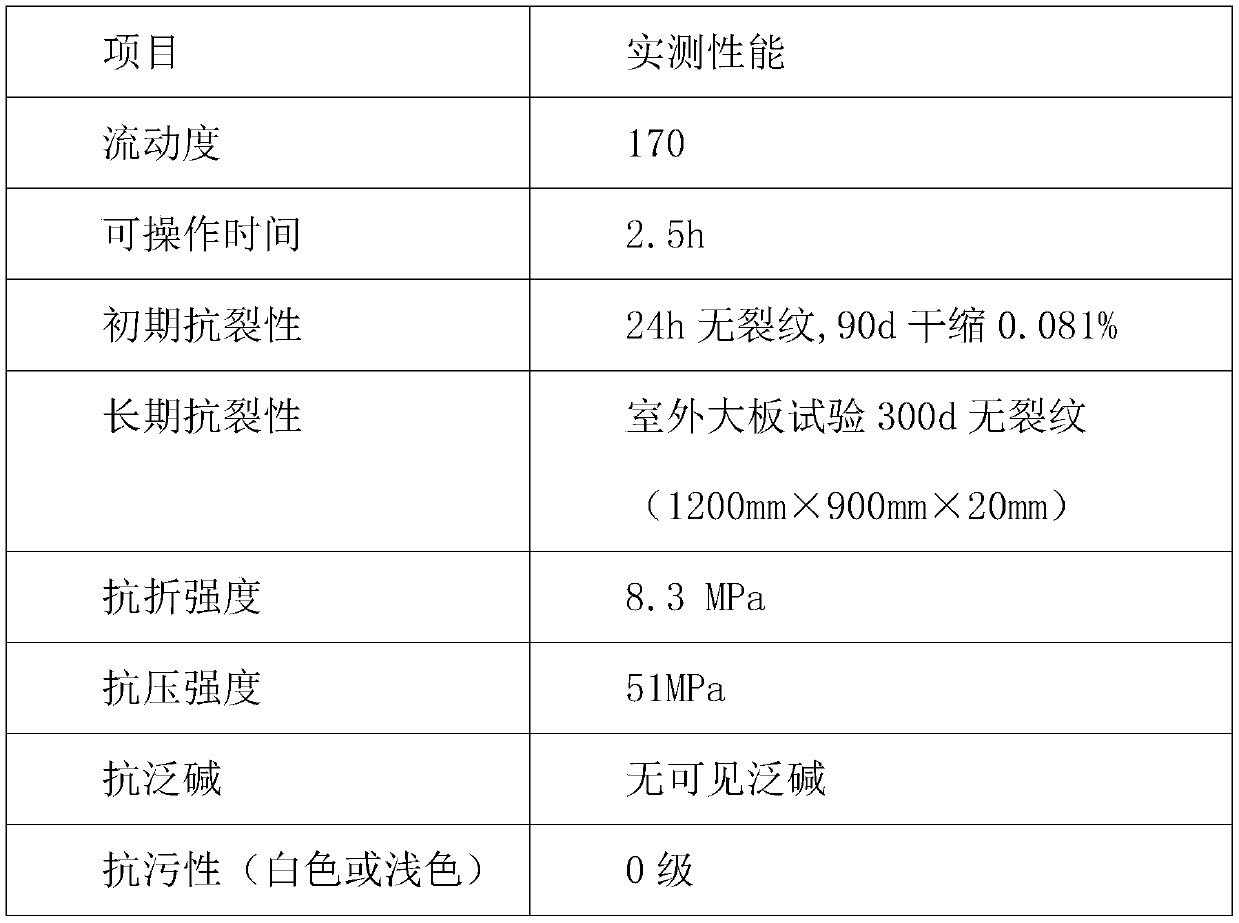

Self-cleaning high-crack-resistance self-leveling veneer mortar and preparation method

The invention discloses a self-cleaning high-crack-resistance self-leveling veneer mortar. The mortar is prepared from, by weight, 25-35% of white cement, 0.5-1.0% of a water reducing agent, 1-2% of an expanding agent, 0.2-0.5% of nano titanium dioxide, 2-6% of alkali activation pulverized fuel ash and 10-13% of water. The sum of the weight percentage of all the raw materials is 100%. The invention further discloses a preparation method of the self-cleaning high-crack-resistance self-leveling veneer mortar. The method comprises the following steps that after the titanium dioxide and the alkaliactivation pulverized fuel ash are mixed and stirred, the mixture, white Portland cement, metakaolin, redispersible emulsion powder and the expanding agent are added into a stirrer according to a proportion, white sand is added for stirring for one minute, and finally fibers are added for stirring for 3-5 minutes. The self-cleaning high-crack-resistance self-leveling veneer mortar has better crack resistance, fluidity and self-cleaning performance and can be widely applied to large-size outer wall face layers of assembly-type buildings, and the social and economic benefits are obvious.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

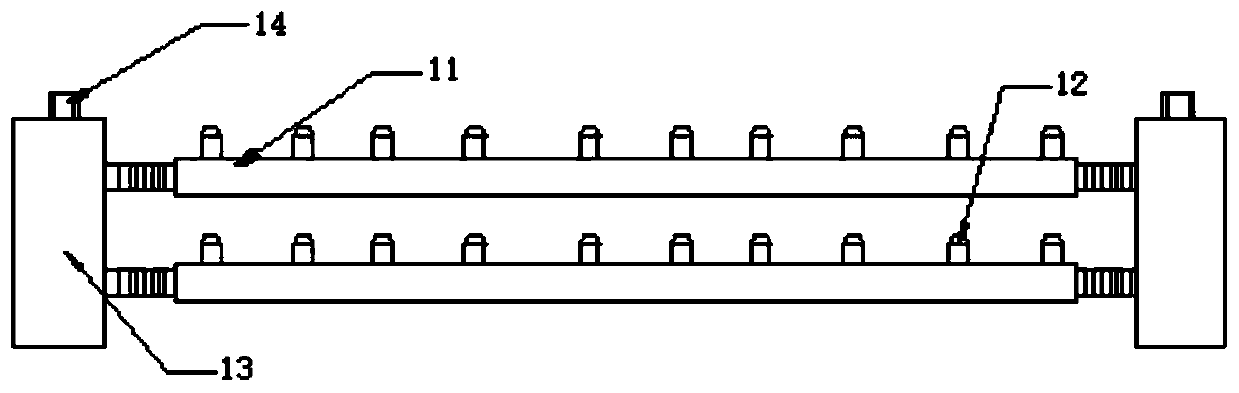

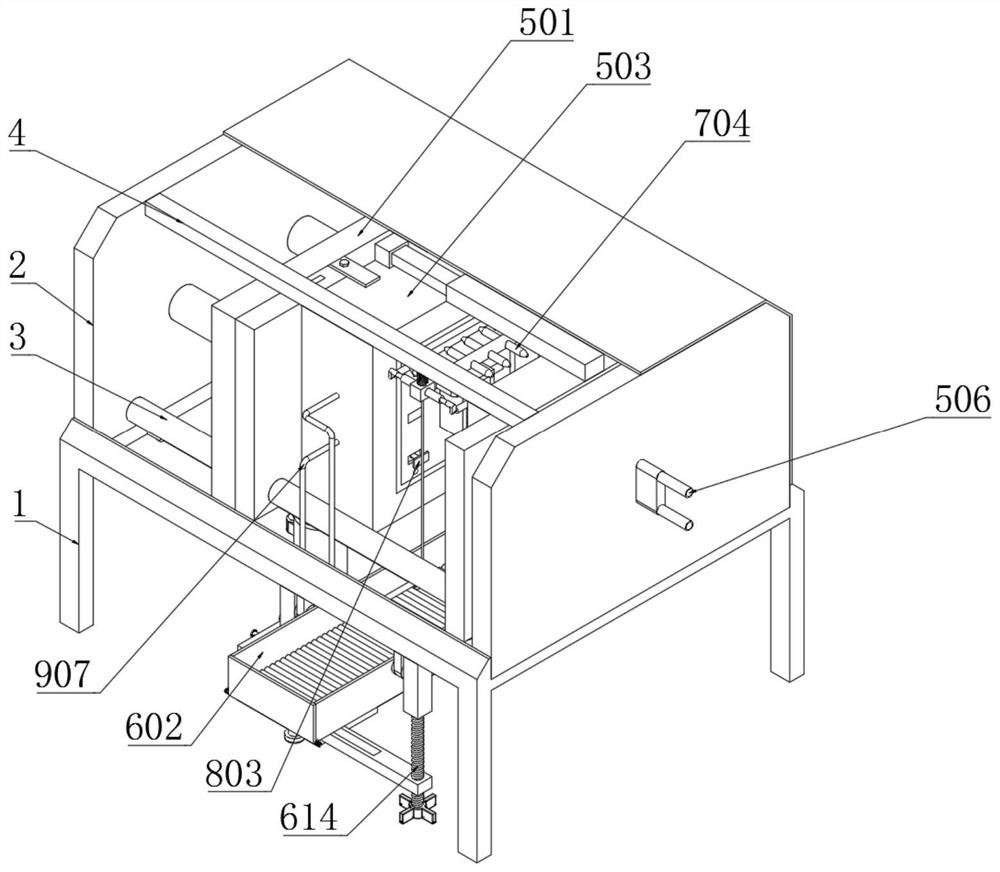

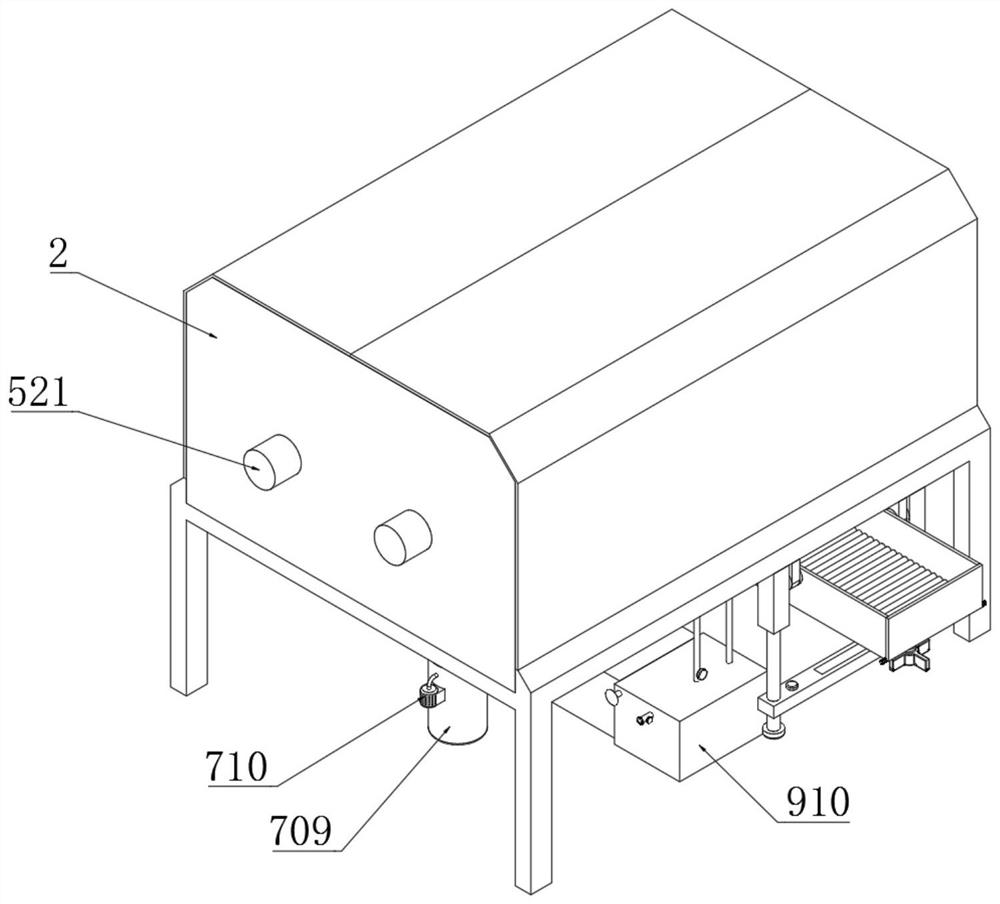

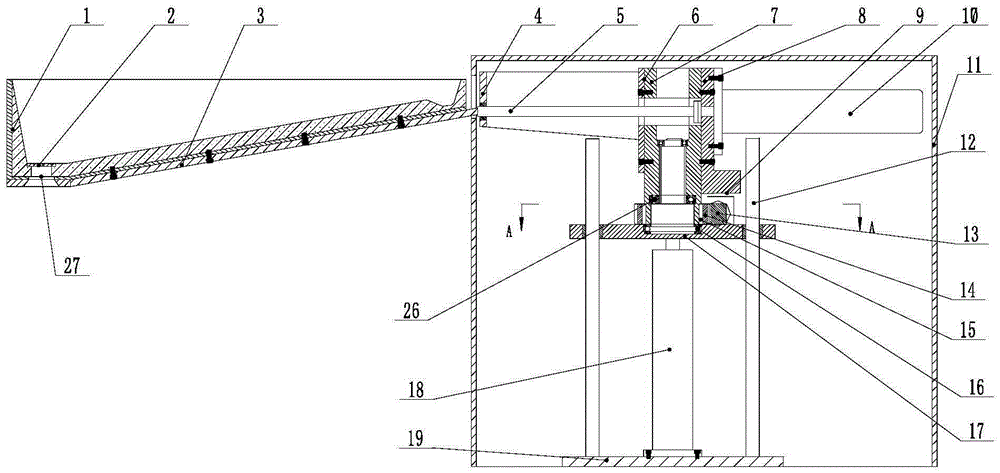

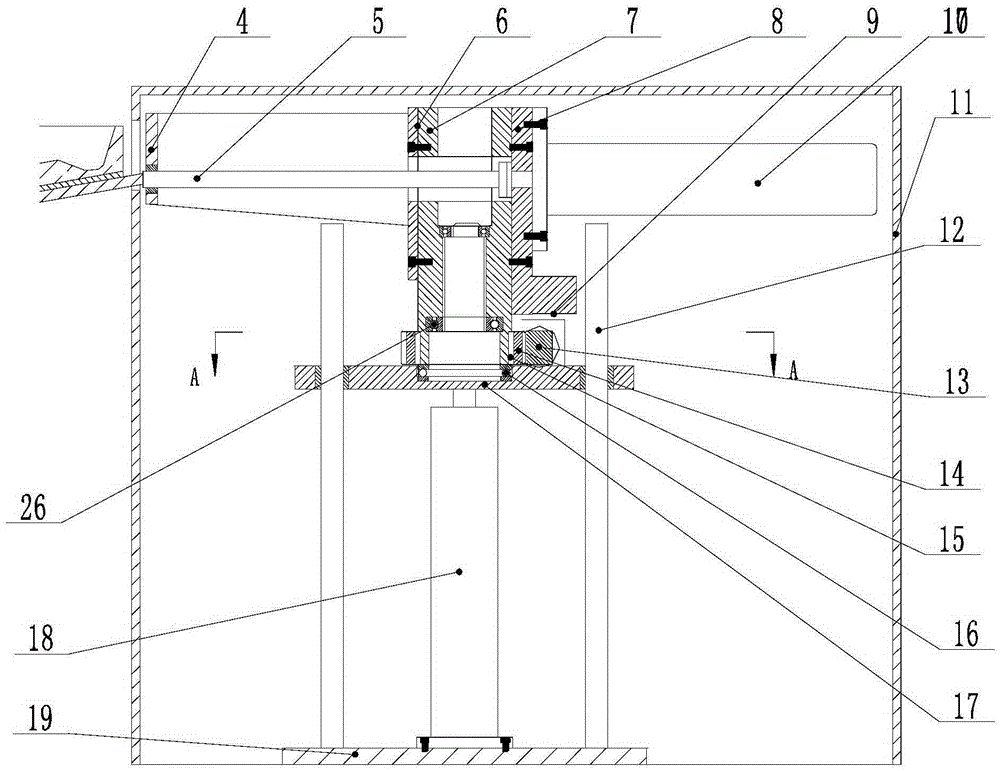

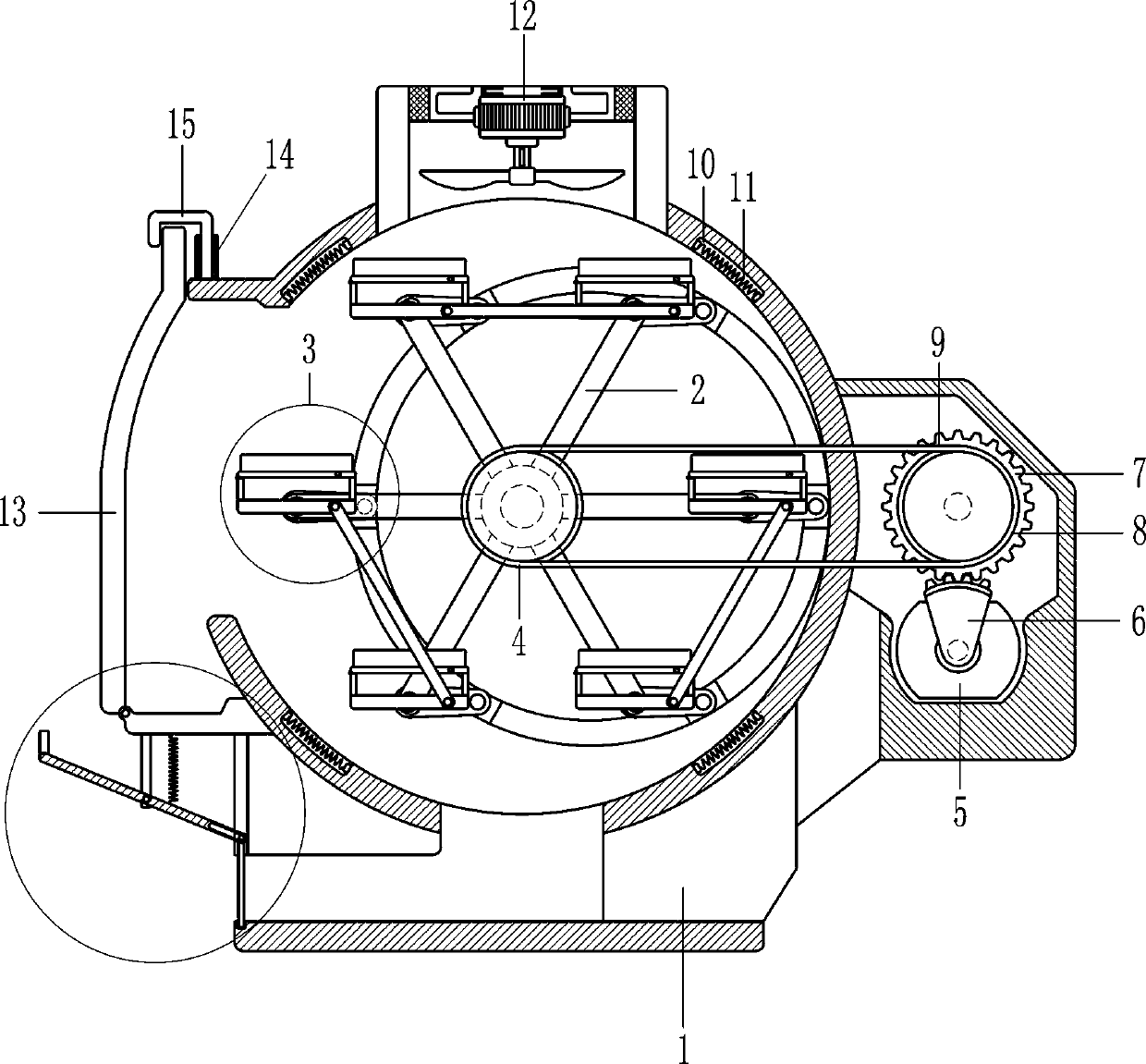

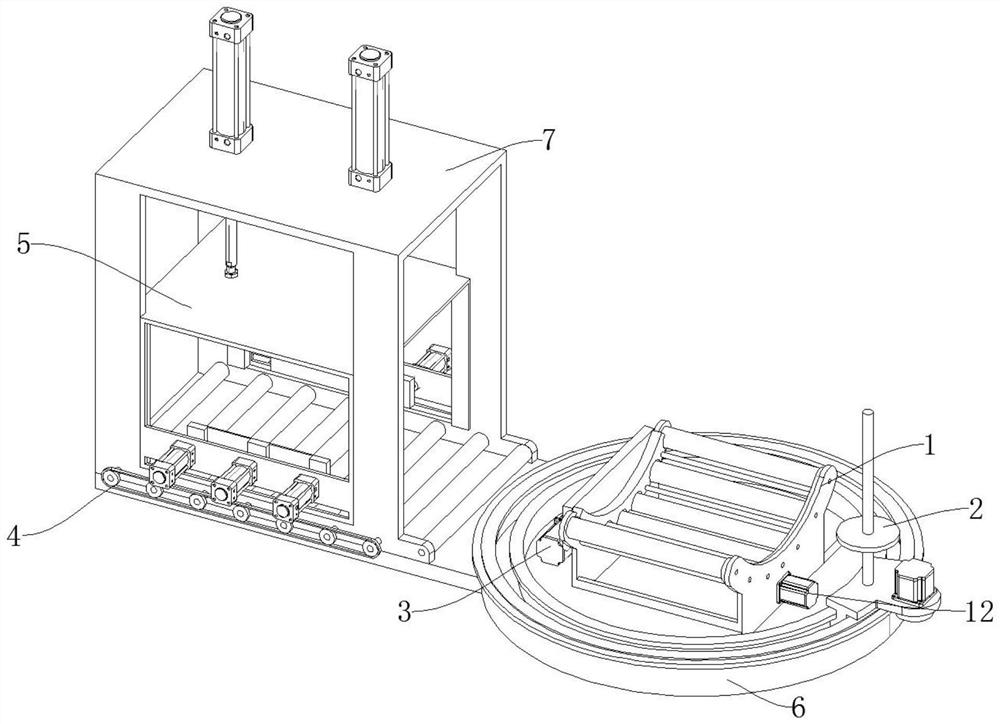

Casting machine and casting method for liquid forging

InactiveCN105344989AZoom outReduce openingMolten metal supplying equipmentsControl systemEngineering

The invention discloses a casting machine and casting method for liquid forging and belongs to the technical field of special forging techniques and equipment. The casting machine comprises a machine base, a rotating mechanism, a lifting mechanism, a telescopic mechanism, a flow guiding system, a hydraulic system and a control system. The flow guiding system is connected to the telescopic mechanism. The telescopic mechanism is installed on the rotating mechanism. The rotating mechanism is fixed to the lifting mechanism. The lifting mechanism is installed on the machine base. The hydraulic system is used for driving to achieve rotational movement, rising and falling movement and stretching and retracting movement. Casting outside the machine is achieved through the steps of adjusting a casting position, preheating a flow guiding groove, rotating the flow guiding groove to the casting position, conducting casting, and restoring the flow guiding groove, and the manufacturing cost and the use cost of a liquid forging machine can be remarkably reduced. The casting machine and casting method can be used for liquid forging of large pieces and rapid and stable casting, can decrease the defective rate and is wide in application range.

Owner:BEIJING JIAOTONG UNIV

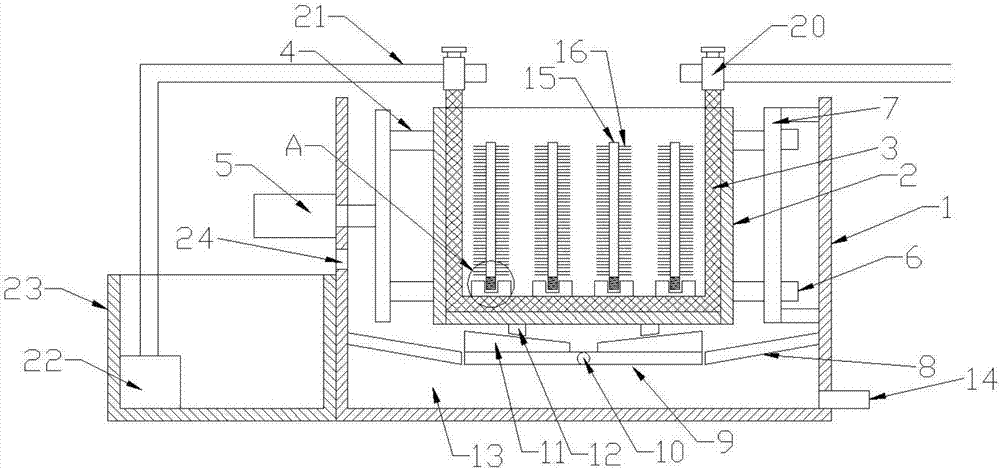

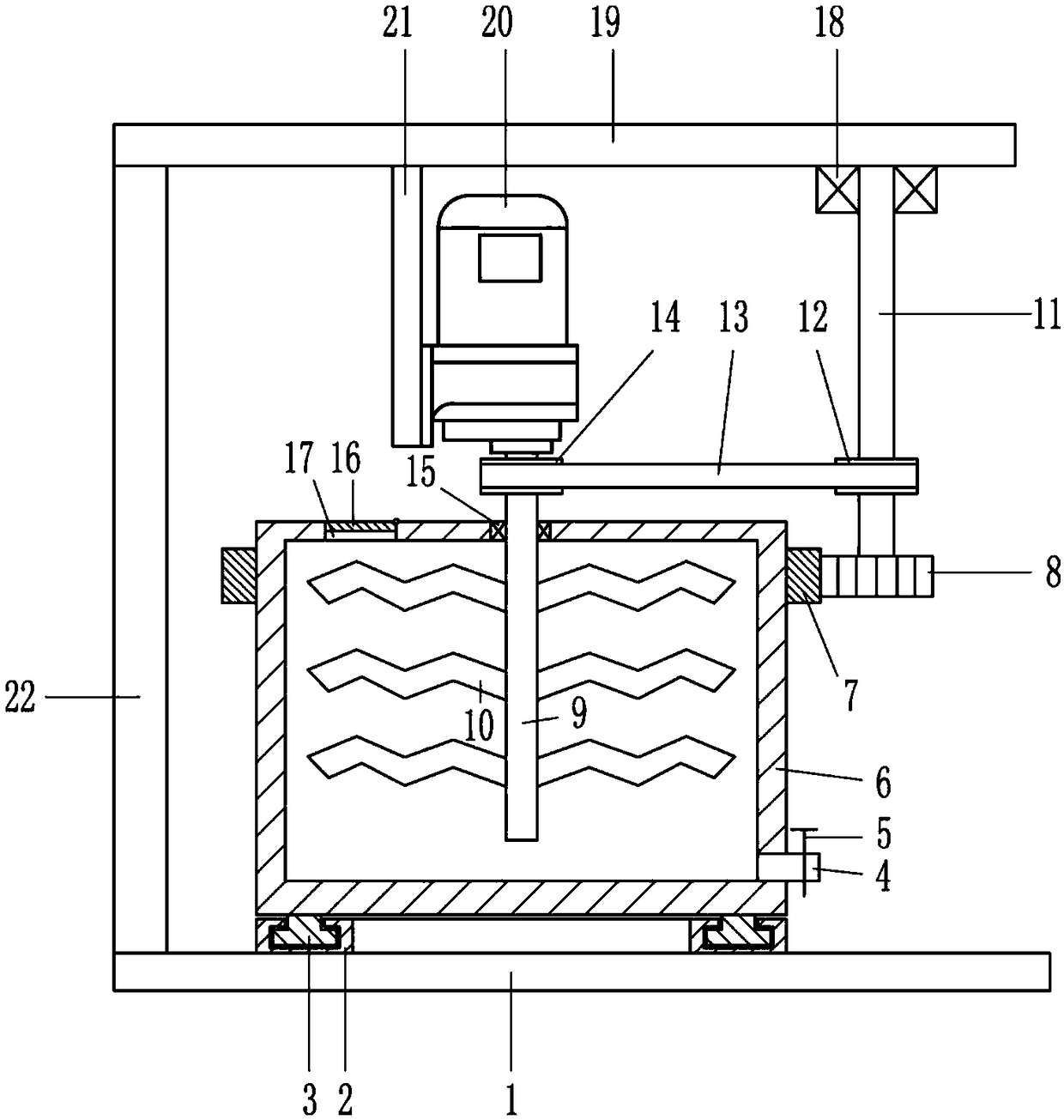

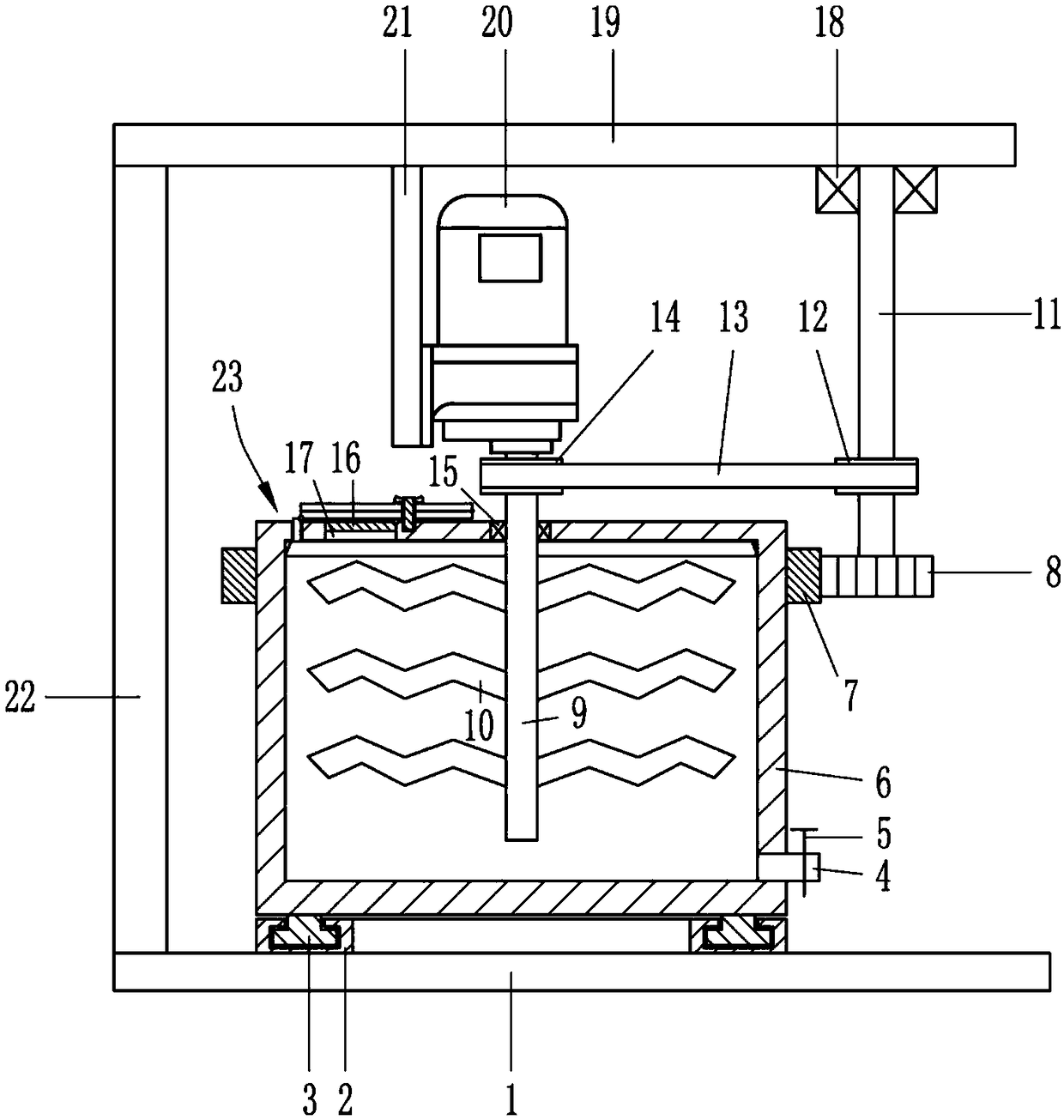

Dispersing and stirring apparatus for producing oil paint

PendingCN108854760AStir quicklyStir wellRotating receptacle mixersTransportation and packagingRapid mixingOil paint

The invention belongs to the field of production of oil paint, and particularly relates to a dispersing and stirring apparatus for producing oil paint. The invention aims at providing a dispersing andstirring apparatus, which can rapidly mix and stir the oil paint and can ensure the dispersing quality of the oil paint, for producing the oil paint. The dispersing and stirring apparatus for producing the oil paint comprises a first installation plate, annular slide rails, slide blocks, a stirring frame, an outer gear ring, a first gear, a stirring rod, first stirring blades, a third installation plate and a side plate; and the side plate is fixedly connected to one side part of the first installation plate, the annular slide rails are fixedly connected to the top of the first installation plate, the stirring frame is connected with the annular slide rails in a sliding manner by virtue of the slide blocks, and a discharging pipe is fixedly connected to one side part of the stirring frame. The dispersing and stirring apparatus for producing the oil paint has the beneficial effects that the oil paint production raw materials can be rapidly and uniformly stirred, the oil paint is not adhered to the inner wall of the stirring frame when being poured out, and the excessive surplus oil paint can be avoided.

Owner:毛学兰

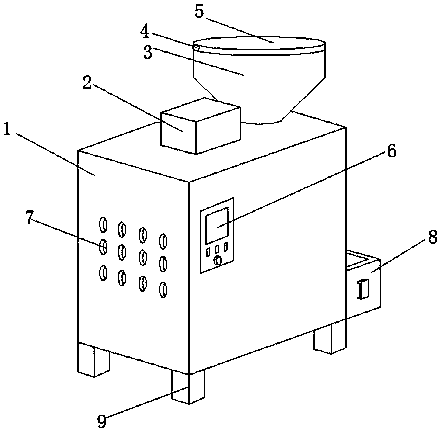

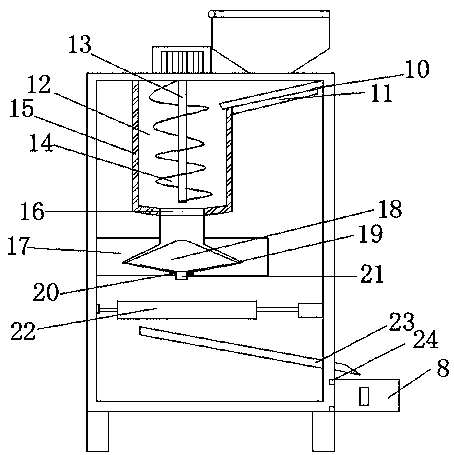

Household whole-grain grinding device

The invention discloses a household whole-grain grinding device. The household whole-grain grinding device comprises a device main body, a feeding hopper, a material receiving box, a weighing plate, acrushing chamber, a grinding chamber and a rolling device. A cover plate is arranged above the feeding hopper so that dust can be prevented from falling into the household whole-grain grinding device, the sanitation inside the household whole-grain grinding device is ensured, meanwhile, the weighing plate can be used for weighing raw materials input from the feeding hopper, the weighing result isdisplayed on a display screen on an operation panel, the usage amount of various raw materials can be intuitively and accurately mastered, in addition, the crushing chamber, the grinding chamber andthe rolling device are arranged inside the device main body, the raw materials with the relatively large whole-gain particle sizes can be chopped, moreover, whole grains of various kinds of saccharides kind, oil kind and starch kind are uniformly mixed, and are fed into the grinding chamber and the rolling device for grinding work after being uniformly mixed, an electric heating wire is fixedly arranged on the inner wall of the crushing chamber so that the whole grains can be baked and cooked, then the processing time is saved, the grinding effect is good, the effects of being simple and convenient are achieved, and popularization and generalization are facilitated.

Owner:徐海连

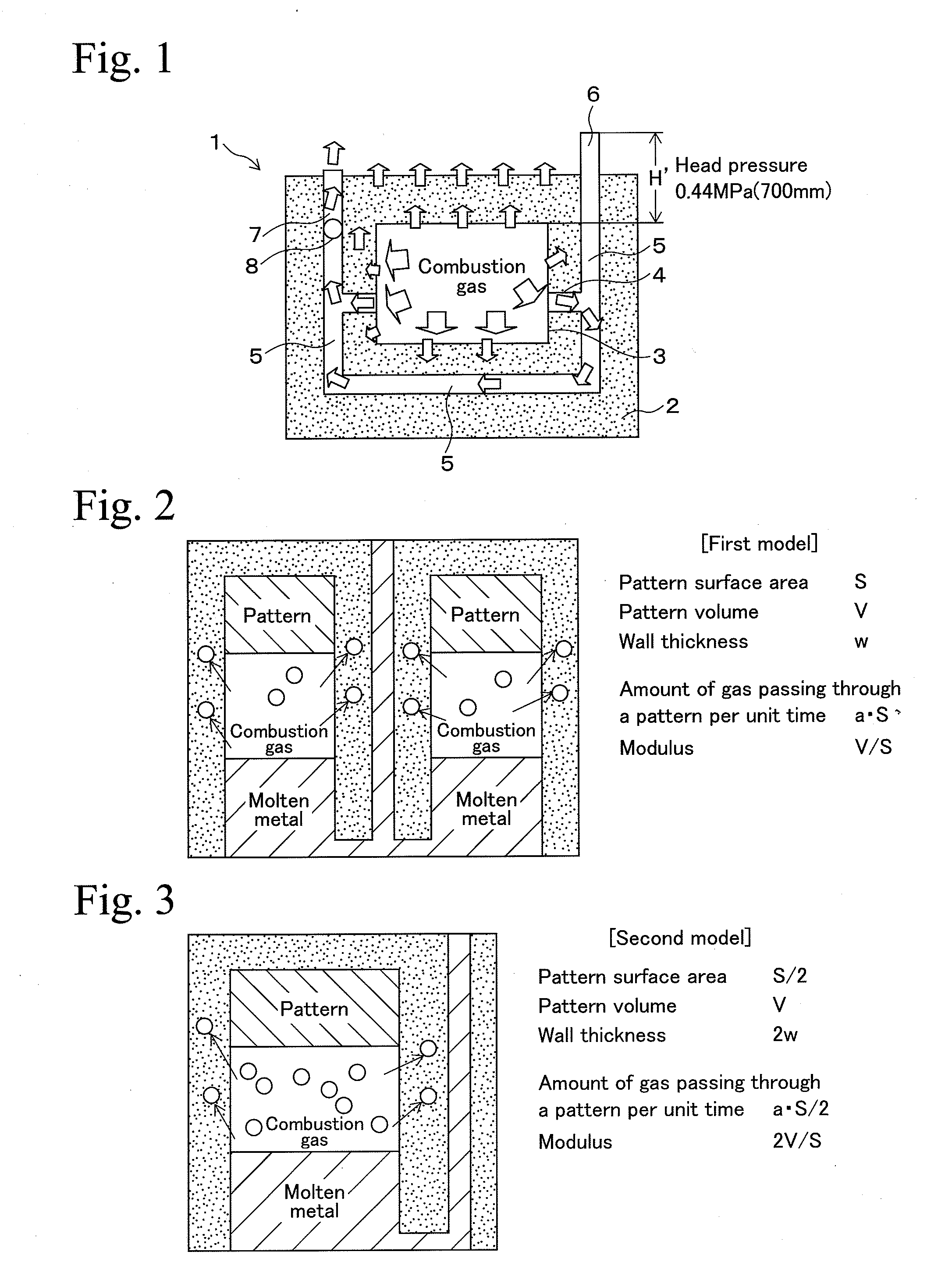

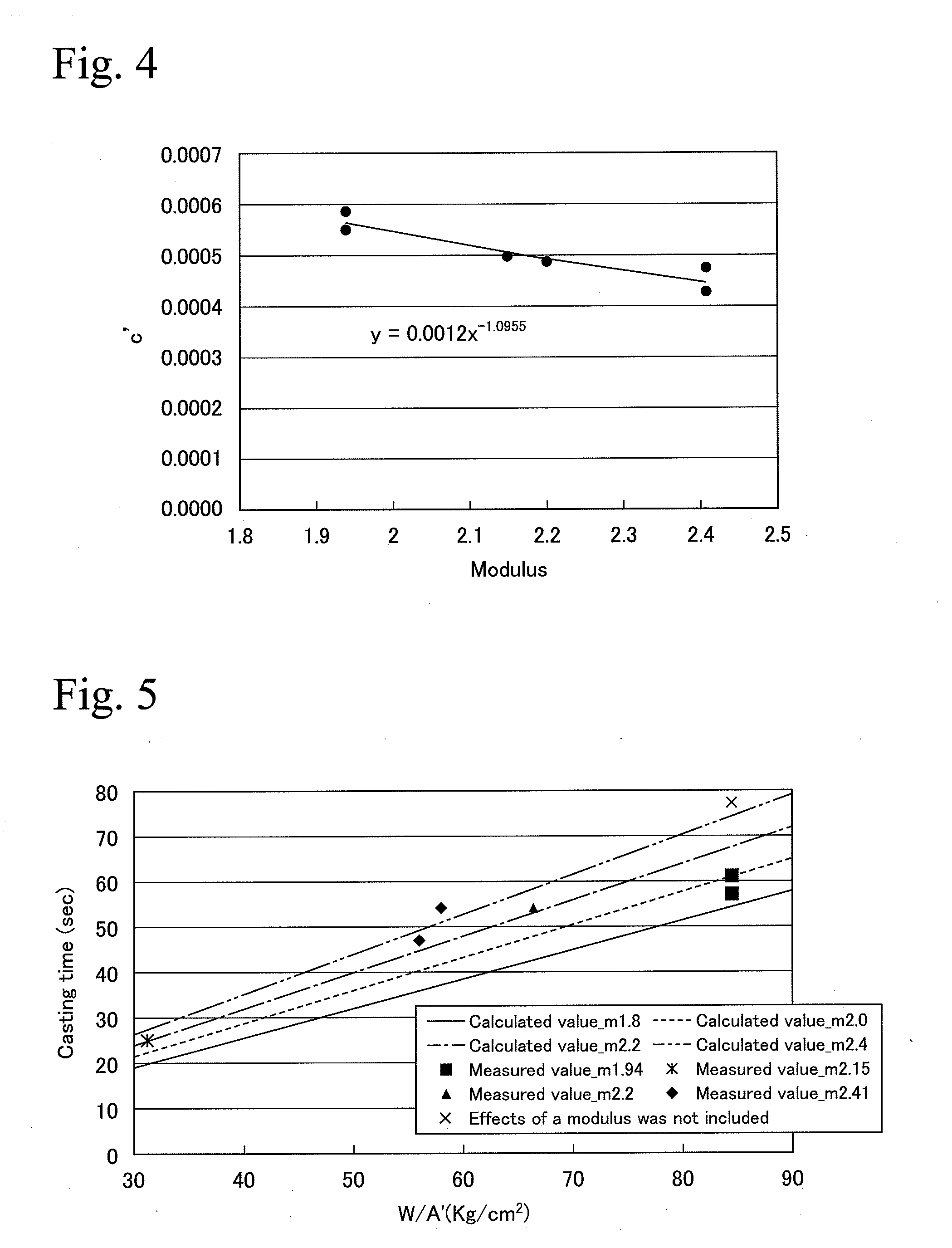

Evaporative pattern casting process

ActiveUS20120273151A1Accurate settingQuality improvementFoundry mouldsFoundry coresMetallurgyMaterials science

An evaporative pattern casting process includes forming a mold by burying a pattern made of resin foam in casting sand, pouring molten metal into the mold, and evaporating the pattern with the molten metal and thereby casting a product. In the evaporative pattern casting process, casting time during founding is set according to a modulus (pattern volume÷pattern surface area) of the pattern. Accordingly, the casting time in the evaporative pattern casting process is accurately set with high precision.

Owner:HONDA MOTOR CO LTD

Rotating type drying device for sheet-like food

InactiveCN111023760ADry evenlySpeed up dryingDrying gas arrangementsDrying chambers/containersMechanical engineeringFood item

The invention relates to a drying device, in particular to a rotating type drying device for sheet-like food. According to the technical problem to be solved, the rotating type drying device for the sheet-like food can dry the sheet-like food uniformly and reduce the loss. The rotating type drying device for the sheet-like food comprises an installing box, a rotating rod, a power assembly, food placing assemblies, a heating wire, a fan and the like. The rotating rod is arranged in the middle in the installing box in a rotating manner. The rotating rod is provided with at least two food placingassemblies. The power assembly for driving the rotating rod to rotate through a transmission manner is installed on the right side of the installing box. At least two grooves are formed in the innerside of the installing box. According to the rotating type drying device, by means of cooperation between the food placing assemblies and the power assembly, the food can be dried uniformly, under theeffect of the fan, flow of air in the installing box is accelerated, and the drying speed of the food can be increased.

Owner:杨家荣

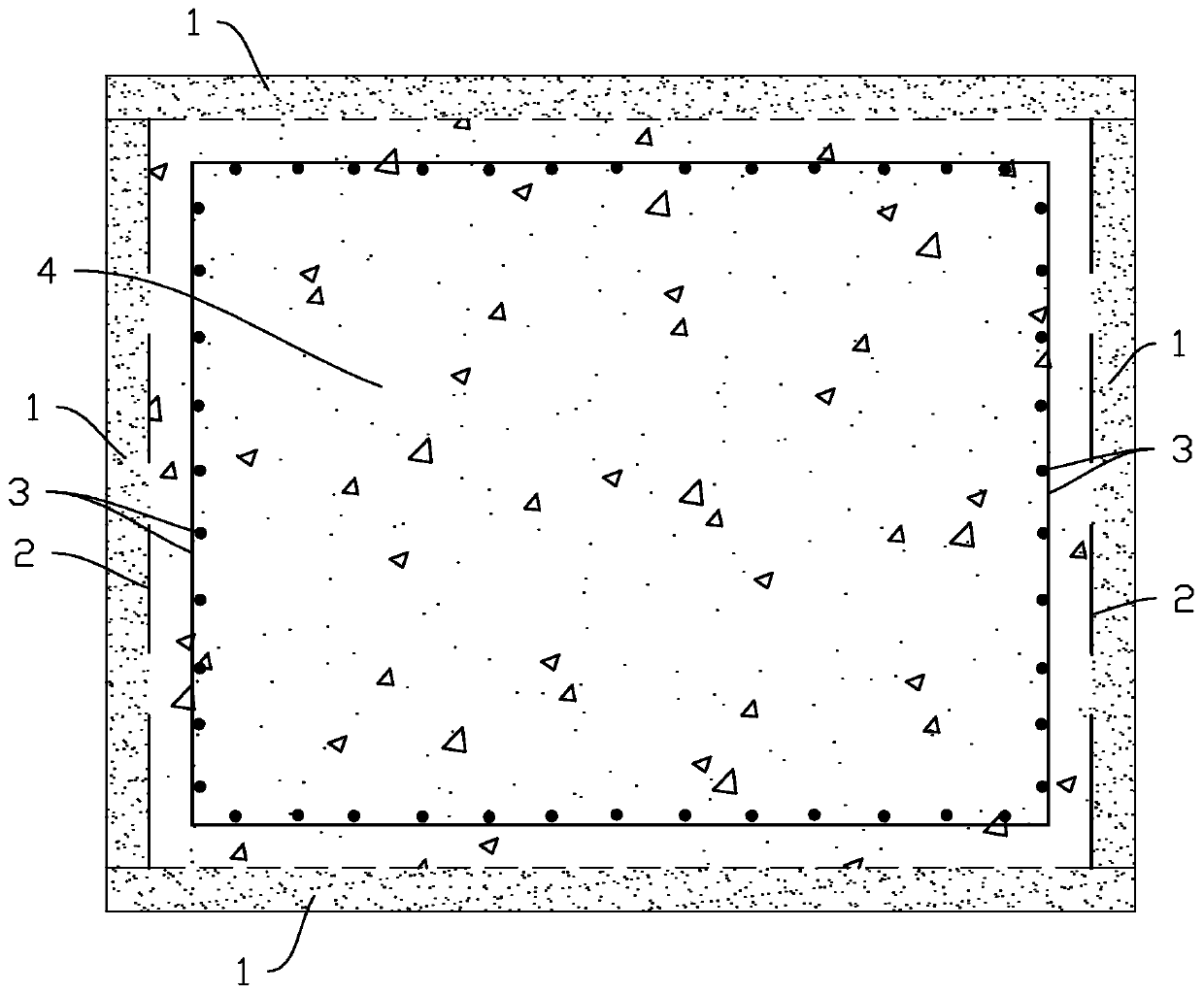

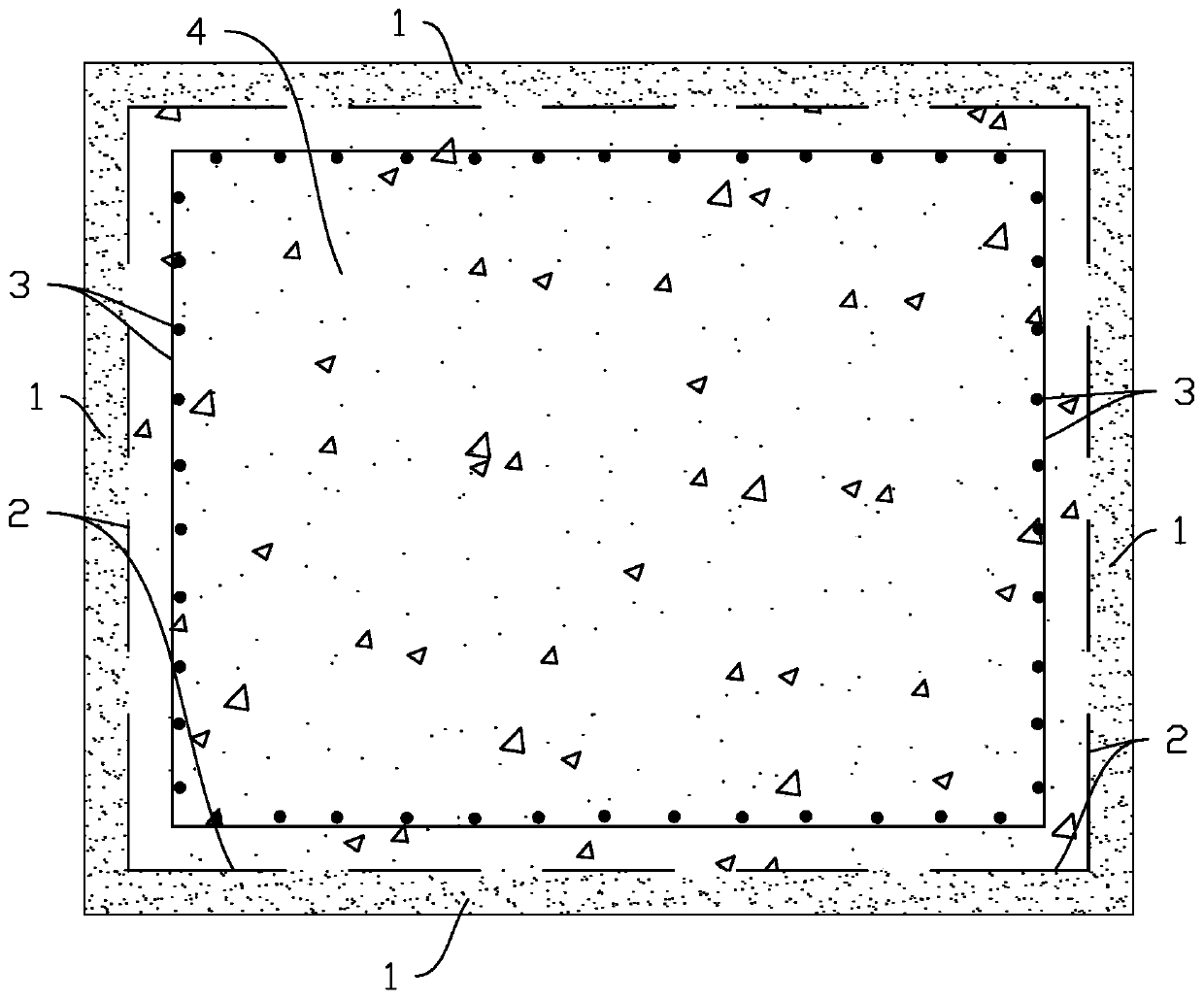

Seawater corrosion-resistant reinforced concrete structure, construction structure and construction method

PendingCN109811768AImprove seawater corrosion resistanceExtended service lifeProtective foundationReinforced concreteMetal framework

The invention discloses a seawater corrosion-resistant reinforced concrete structure, a seawater corrosion-resistant reinforced concrete construction structure and a seawater corrosion-resistant reinforced concrete construction method, and relates to the field of coastal reinforced concrete structures. The seawater corrosion-resistant reinforced concrete structure comprises an ordinary reinforcedconcrete layer, wherein a removal-free metal framework is arranged outside the peripheral side surface of the ordinary reinforced concrete layer; a ultrahigh-performance concrete layer is positioned on the outer side surface of the removal-free metal framework and at the bottom end and the top end of the ordinary concrete layer; the ordinary reinforced concrete layer bears the load on the structure, and the ultrahigh-performance concrete layer resists erosion of chlorine ions in seawater, so that the seawater corrosion resistance of the structure can be improved and the service life of the structure can be prolonged. The reinforced concrete construction structure is convenient for quickly pouring the reinforced concrete structure. By the reinforced concrete construction method, the spacingbetween the removable-free metal framework and a reinforcement cage is guaranteed by cushioning cushion blocks for fixing the position of the removal-free metal framework, and pouring of the reinforced concrete structure can be quickly achieved through layer-by-layer pouring, so that the construction period is shortened.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

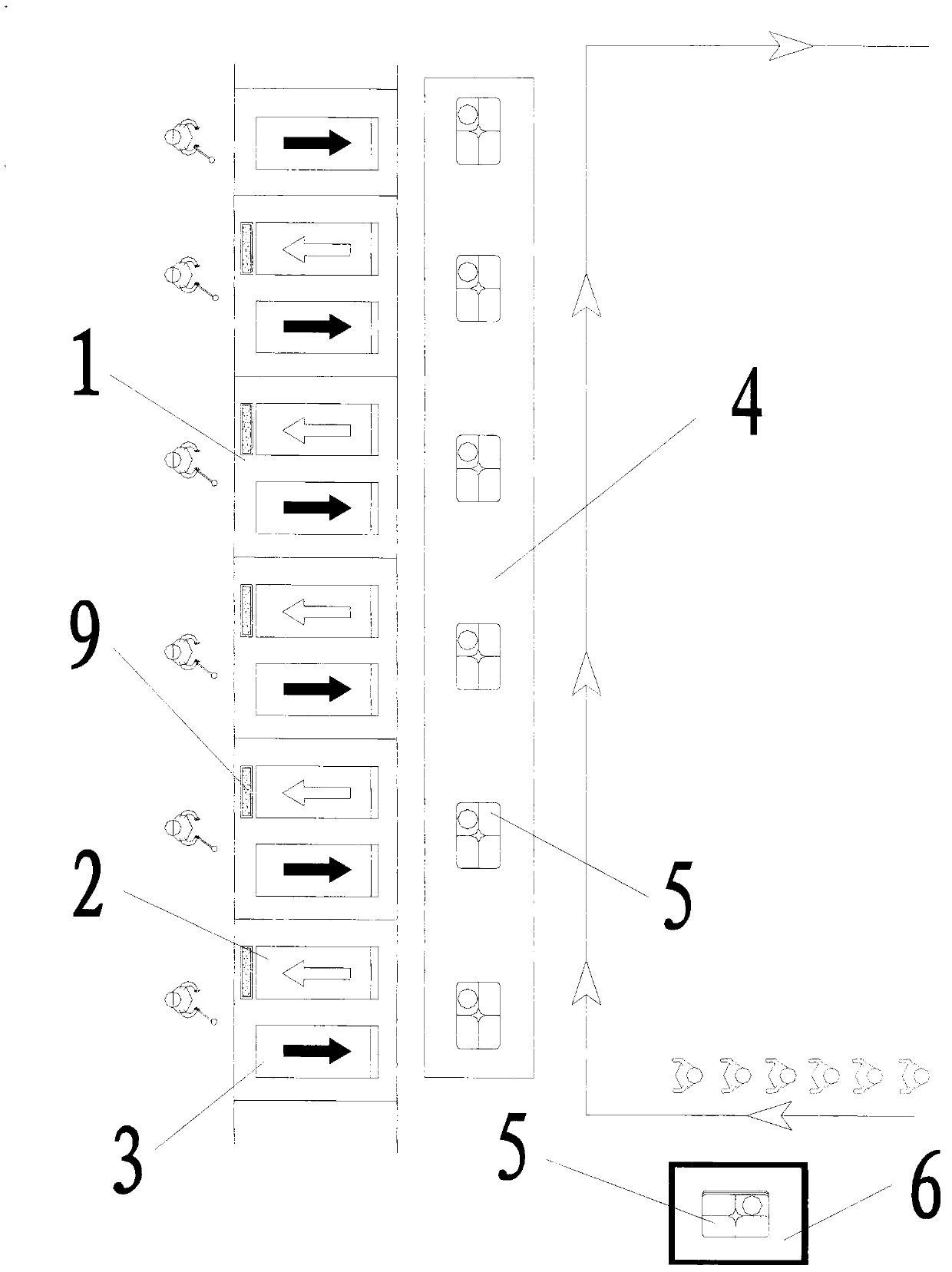

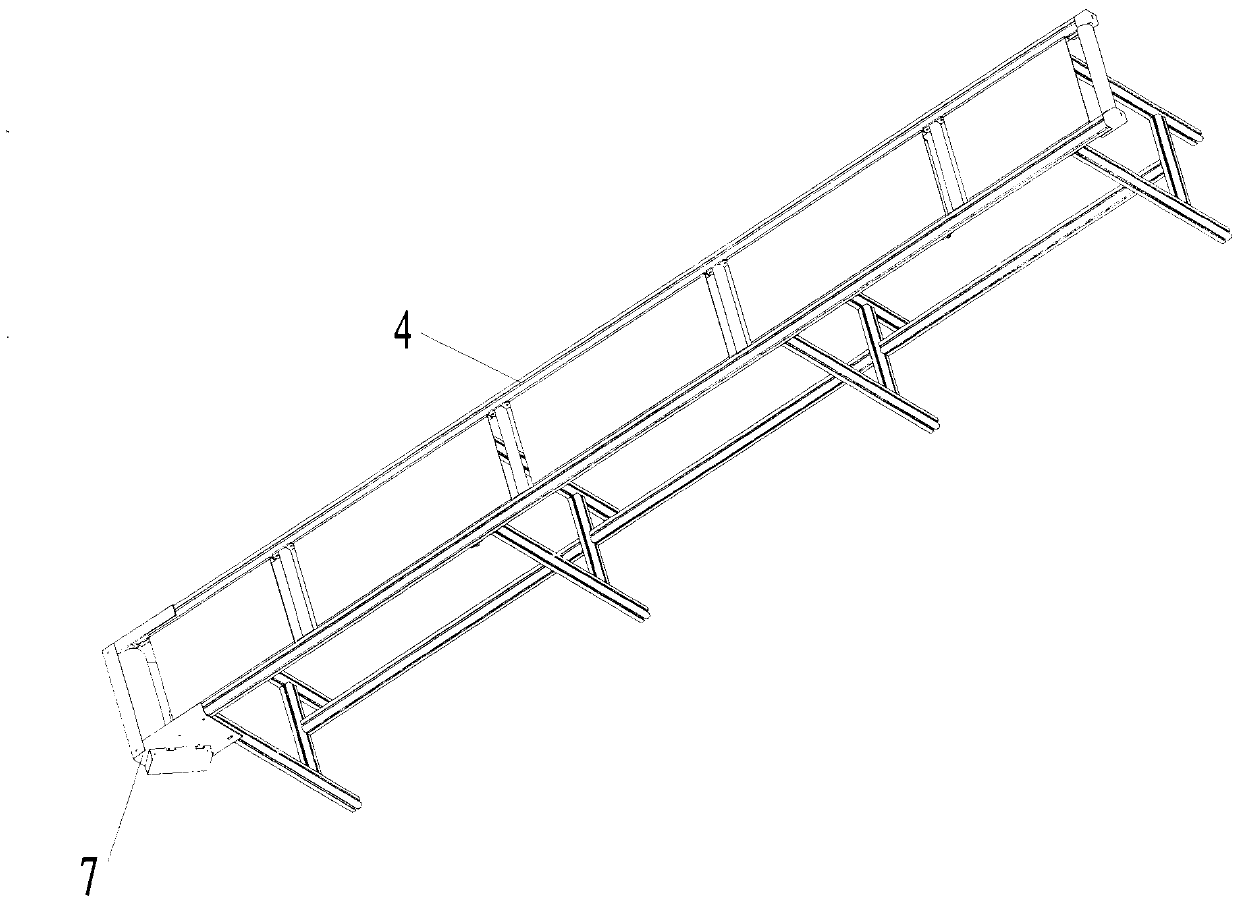

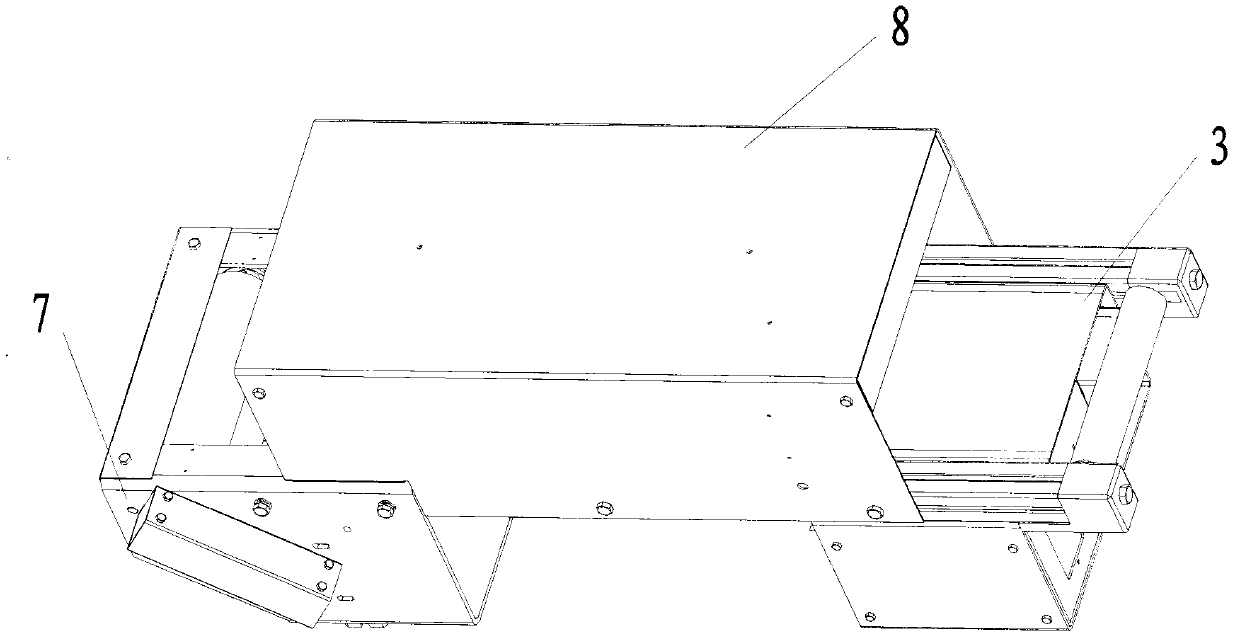

Meal conveying system used in dining hall

InactiveCN103150692AQuick pourGuaranteed temperatureData processing applicationsConveyorsEngineeringConveyor belt

The invention relates to a meal conveying system used in a dining hall. The meal conveying system used for the dining hall comprises a plurality of windows providing the meal, a dinner plate conveyor belt device and a dinner plate placing cabinet. A meal conveyor belt device and an empty bowl conveyor belt device are arranged on the windows. A heat insulation device is arranged on the meal conveyor belt device. The meal is conveyed to a dining person by working staff inside the windows through the meal conveyor belt device. The conveying direction of the empty bowl conveyor belt device is opposite to the conveying direction of the meal conveyor belt device. The dining person takes out of a dinner plate on the dinner plate placing cabinet and the dinner plate is placed on the dinner plate conveyor belt device. The dining person takes down the meal from the meal conveyor belt device and pours the meal into his own dinner plate when the dinner plate is conveyed to the windows with the required meal. The empty bowl is placed on the empty bowl conveyor belt device of the windows. According to the meal conveying system used for the dining hall, the dining person can take the meal by lining up for one time. Time is saved and the temperature of the meal is guaranteed. The dining environment is integrated at the same time.

Owner:WUHU JUNTAI INTELLIGENT MACHINERY TECH

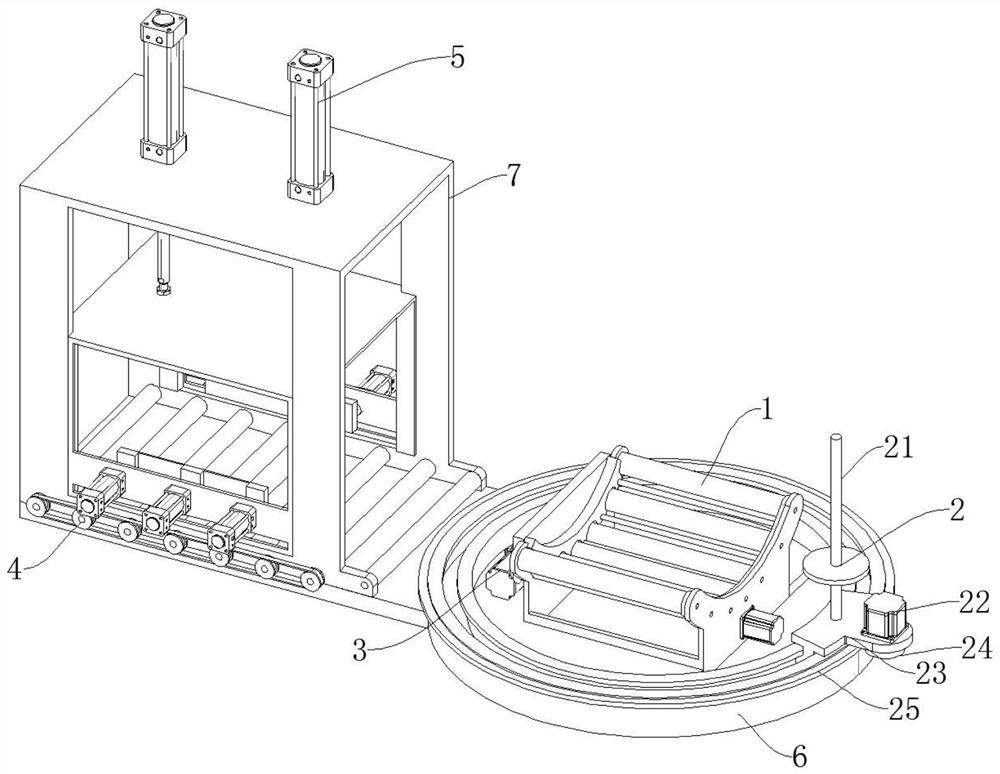

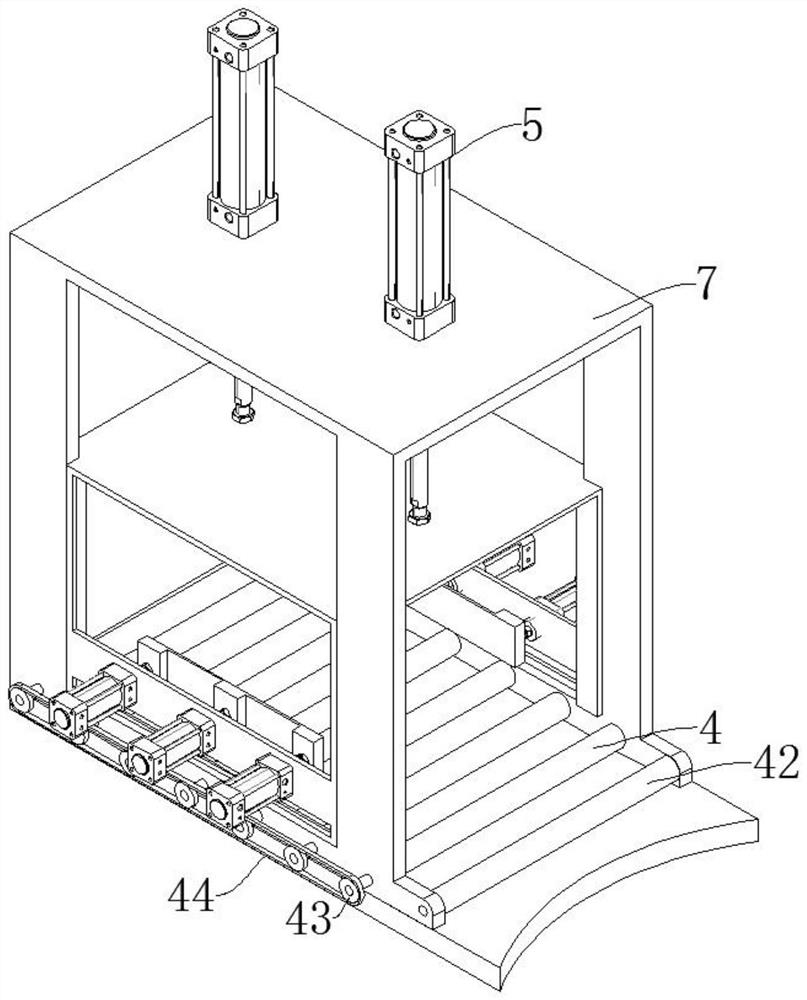

Total mixed ration (TMR) wrapping machine for livestock feed preparation

InactiveCN112550796AQuick pourReduce the frequency of moving feedWrapping with article rotationStacking articlesAnimal scienceAgricultural science

The invention discloses a total mixed ration (TMR) wrapping machine for livestock feed preparation. The TMR wrapping machine comprises a rotating mechanism, a wrapping mechanism, a conveying mechanismfor conveying wrapped feed, a track disc and a support frame, the support frame is arranged on one side of the track disc, the rotating mechanism is arranged in the center of the track disc, the wrapping mechanism is arranged on the outer side of the track disc, and the conveying mechanism is arranged on the inner side of the support frame. An overturning seat is driven to rotate through a rotating part of an overturning motor, meanwhile, the overturning seat is used for driving an overturning frame to overturn, then the wrapped feed can be rapidly poured out, accordingly, feed bags can be rapidly poured out, a stacking air cylinder is used for driving a stacking support to vertically move, meanwhile, a telescopic part of a clamping air cylinder is used for pushing a clamping seat to clamp and stack the wrapped feed bags, so that the frequency of carrying the feed by an operator is reduced, and the labor intensity is reduced.

Owner:石春林

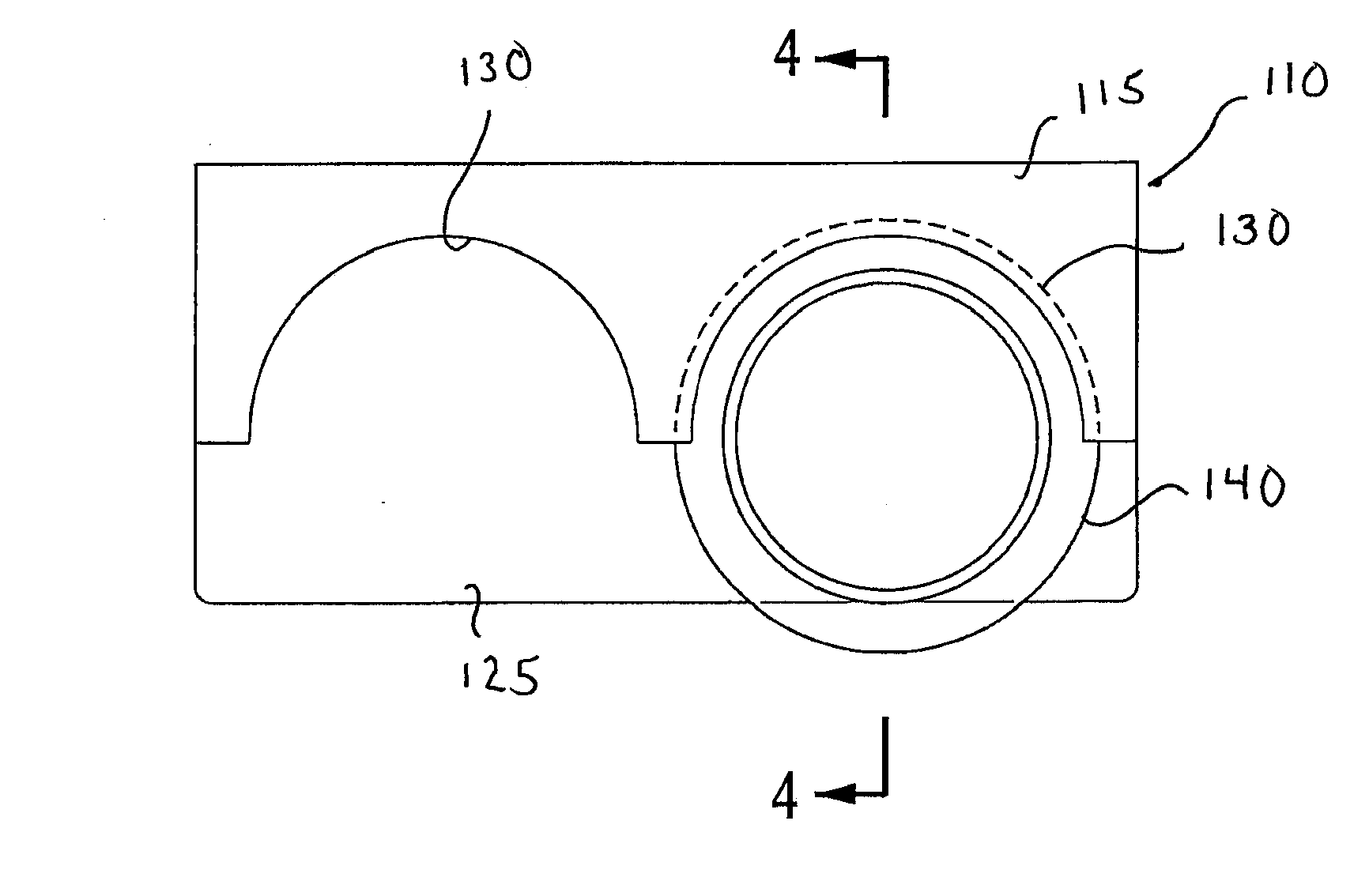

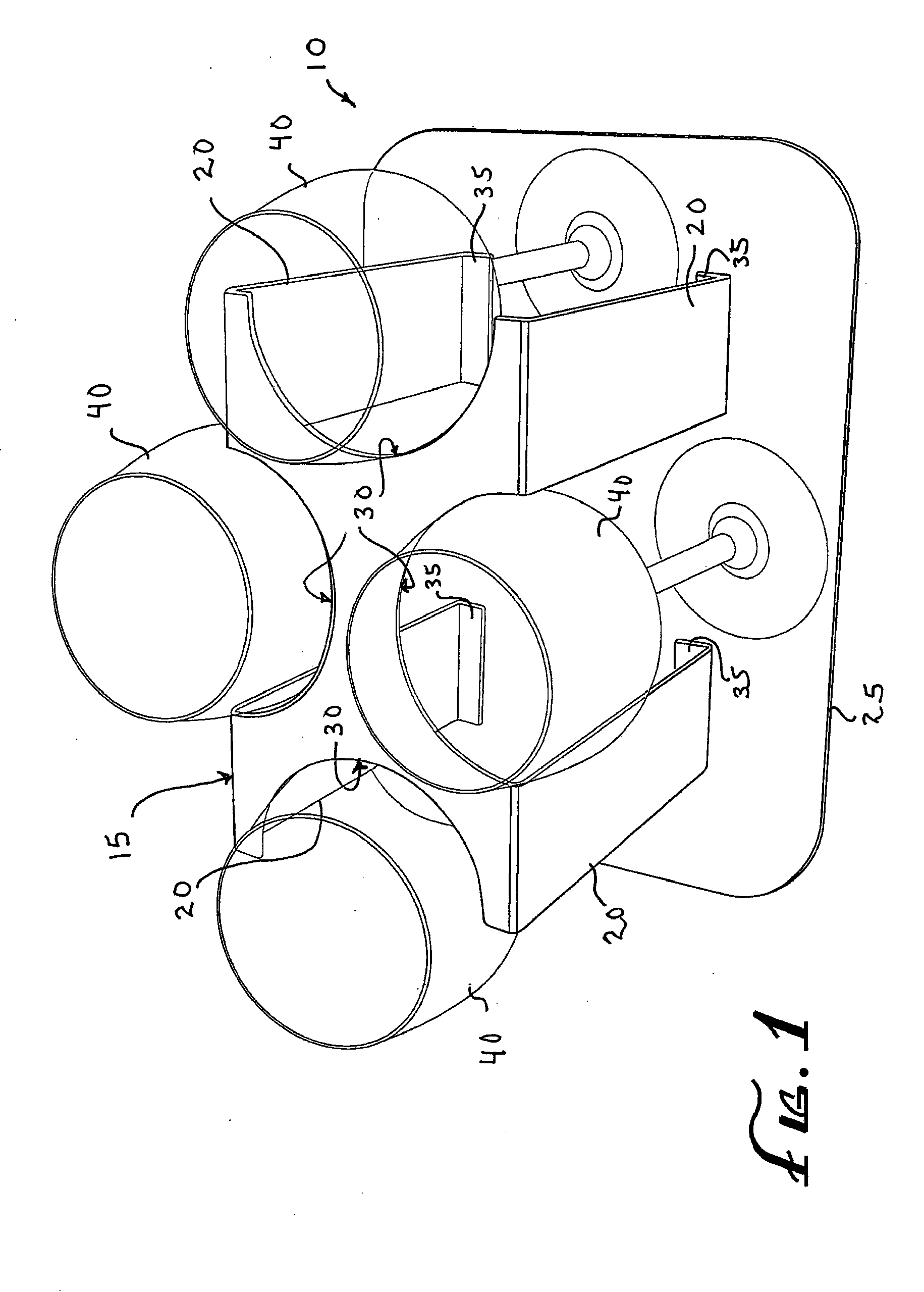

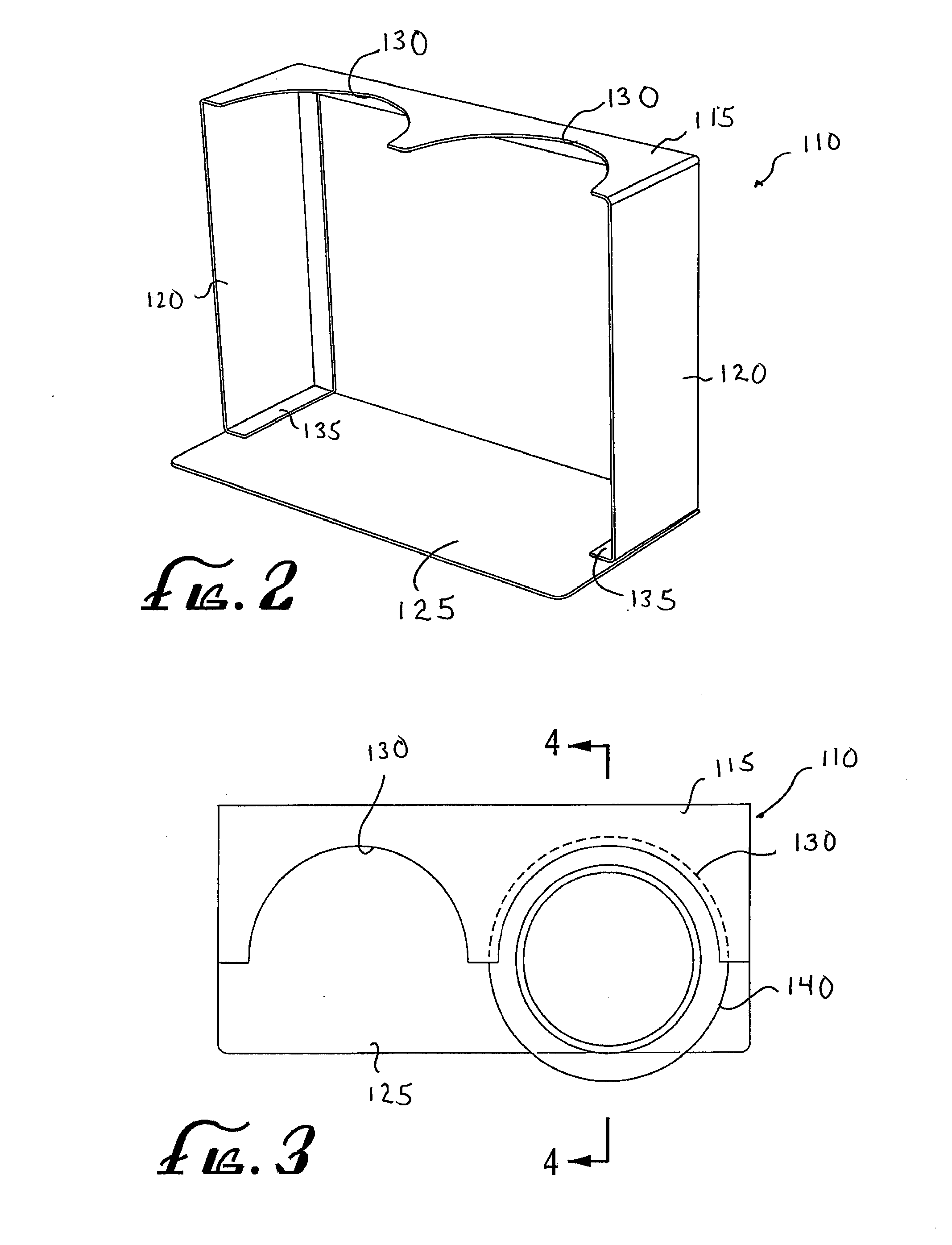

Portable Liquid Gauge

InactiveUS20070272012A1Quick pourImprove visualizationKitchen equipmentCapacity measurement calibrationMeniscusEngineering

The present invention provides a portable liquid gauge that allows a person to quickly pour a precise amount of liquid directly into a glass. In an embodiment, the liquid gauge comprises a top, four sides, and a base. The top is connected to the base by the sides, which support the top above the base. The top has a plurality of inward semicircular edges, where each semicircular edge is dimensioned to fit around a portion of a glass. The height of the top is chosen so that, when a glass is placed into one of the semicircular edges, the edge aligns with the meniscus of liquid in the glass when a precise amount of the liquid is poured into the glass.

Owner:SUBNICK HOWARD D

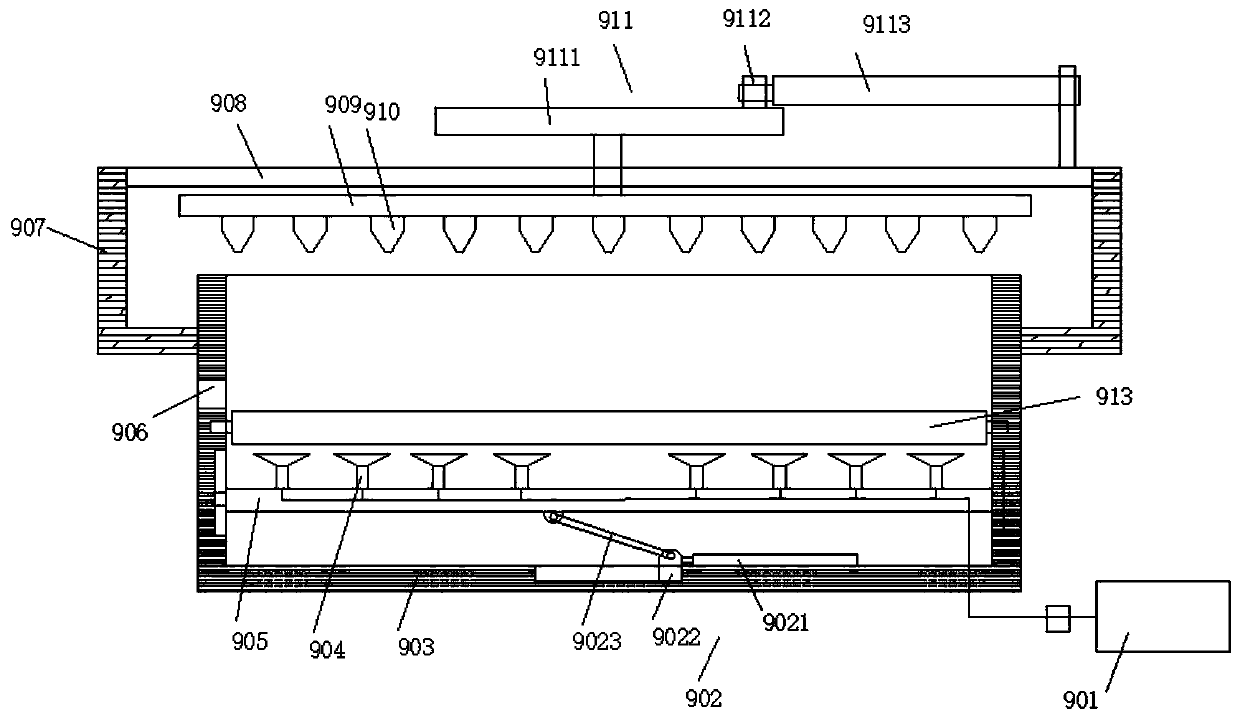

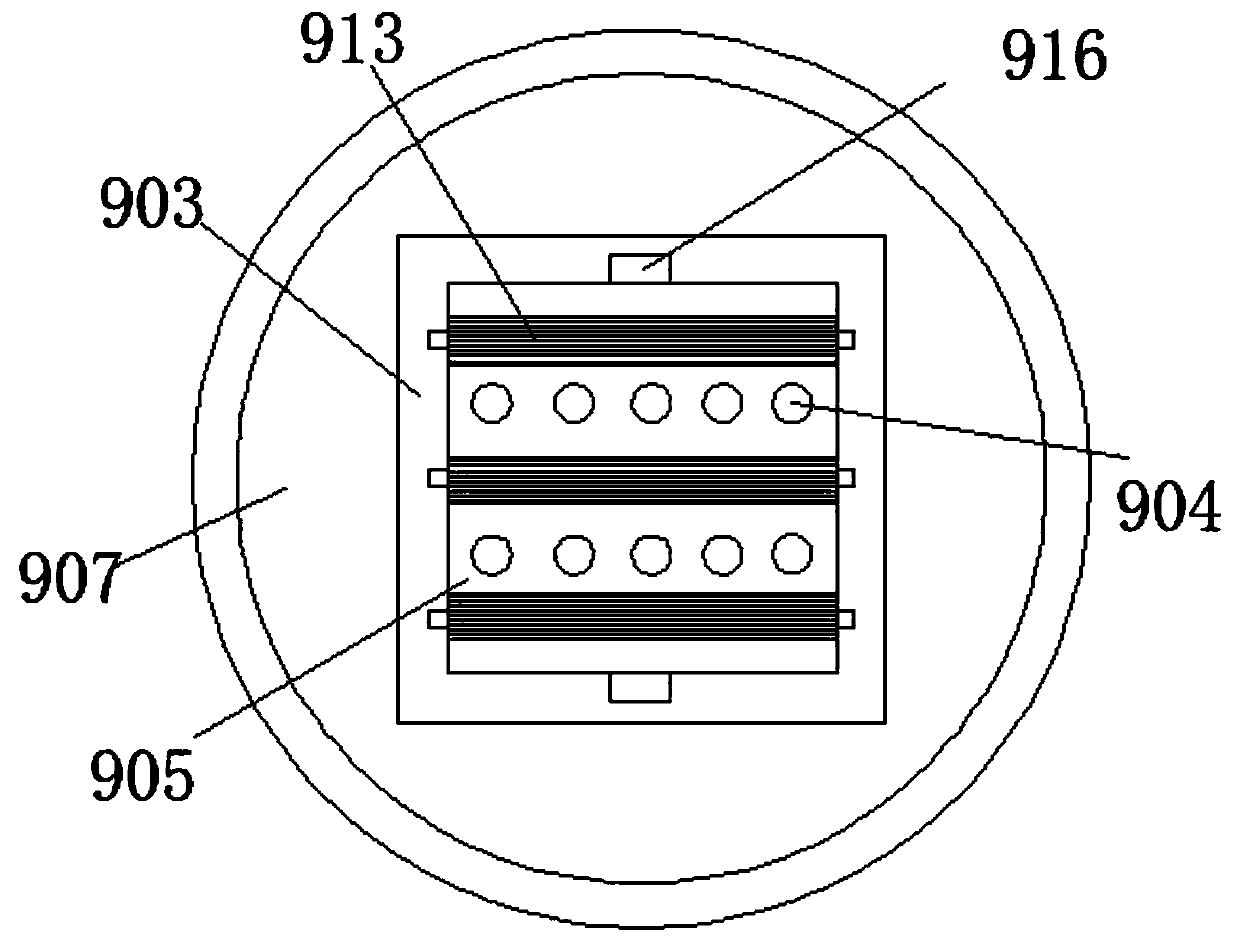

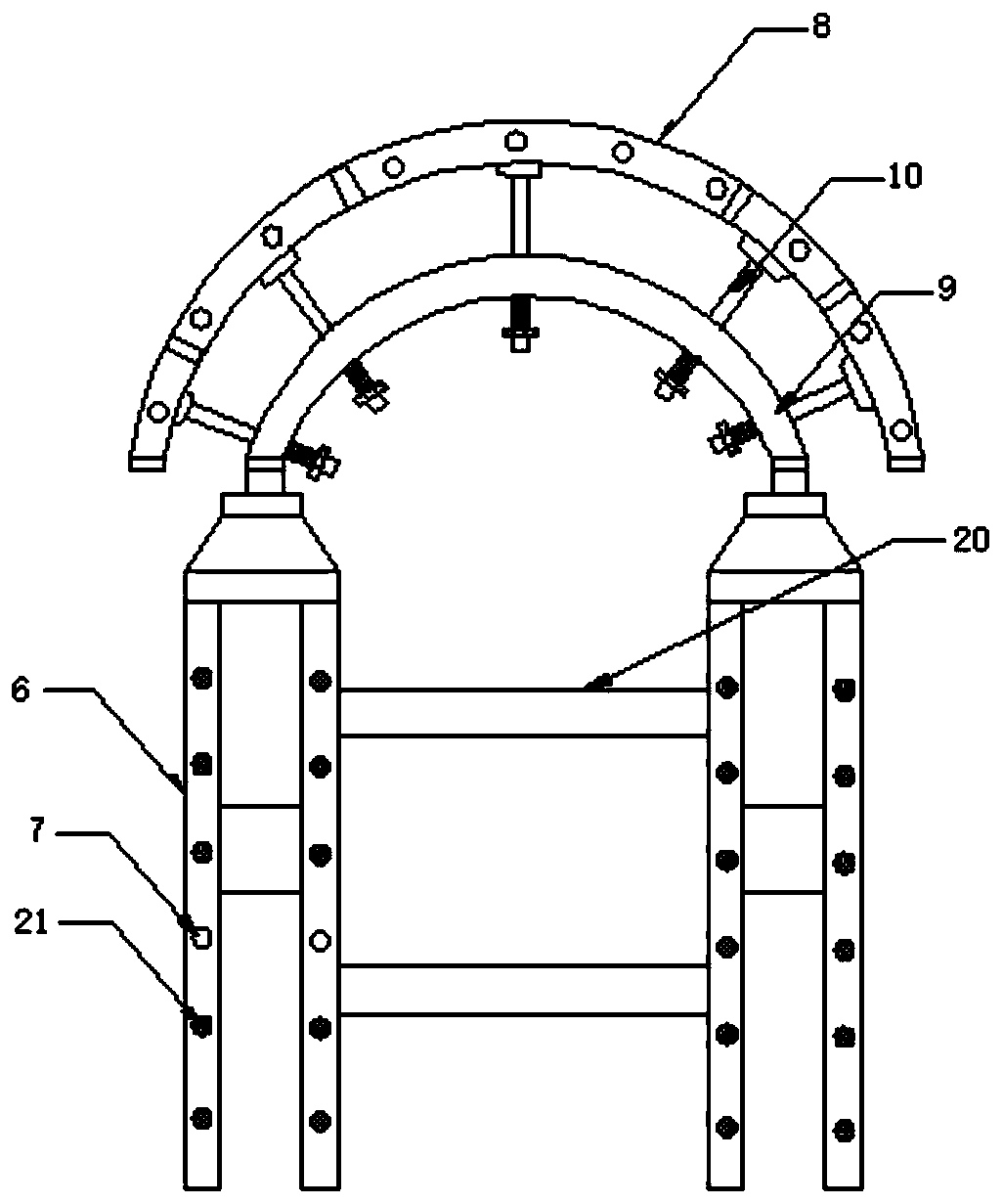

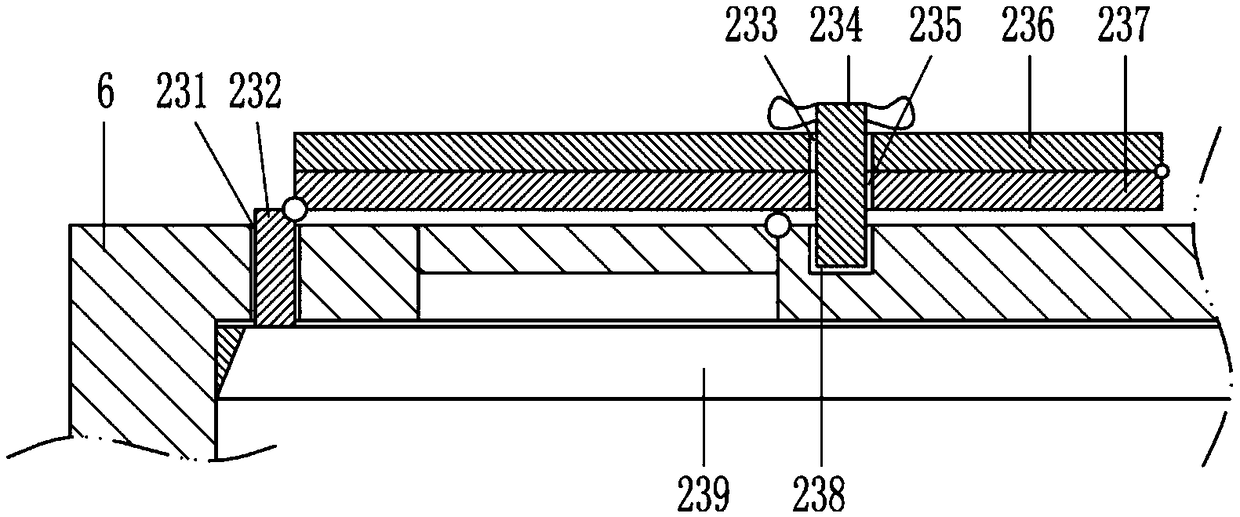

Process and device for pouring concrete under pressure by tunnel lining trolley

PendingCN108661675ASimple designHigh degree of automationUnderground chambersTunnel liningEngineeringAutomation

The invention provides a process and device for pouring concrete under pressure by a tunnel lining trolley. The device for pouring concrete under pressure by the tunnel lining trolley comprises a material distributing machine, a plurality of distributing pipes, material distributing joints and material discharging nozzles fixing devices. The distributing pipes are arranged on the lining trolley, and the distributing pipes comprise distributing pipe material feeding nozzles and distributing pipe material discharging nozzles, wherein the distributing pipe material feeding nozzles are arranged onthe rear side of the lining trolley and the distributing pipe material discharging nozzles are arranged inside the lining trolley close to working windows of the lining trolley; movable joints are arranged at the tail ends of the distributing pipes, so that material discharging nozzles can be switched and inserted into different working windows nearby; the material discharging nozzles fixing devices comprise fixing fixtures and discharge outlet fixtures; and the material distributing machine and the material distributing joints are connected together, and the material distributing joints canbe connected with the material discharging nozzles. The process and device for pouring concrete under pressure by the tunnel lining trolley has the characteristics of simple design, high degree of automation, intuitive and convenient operation and control, and has the advantages of improving working efficiency and saving working time, and thus herringbone slopes and cold seams can be effectively prevented.

Owner:齐洪军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com