Tea frying machine

A tea frying machine and frame technology, which is applied in the field of tea frying machines, can solve problems such as inconvenient use, uncontrollable frying speed, and poor tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

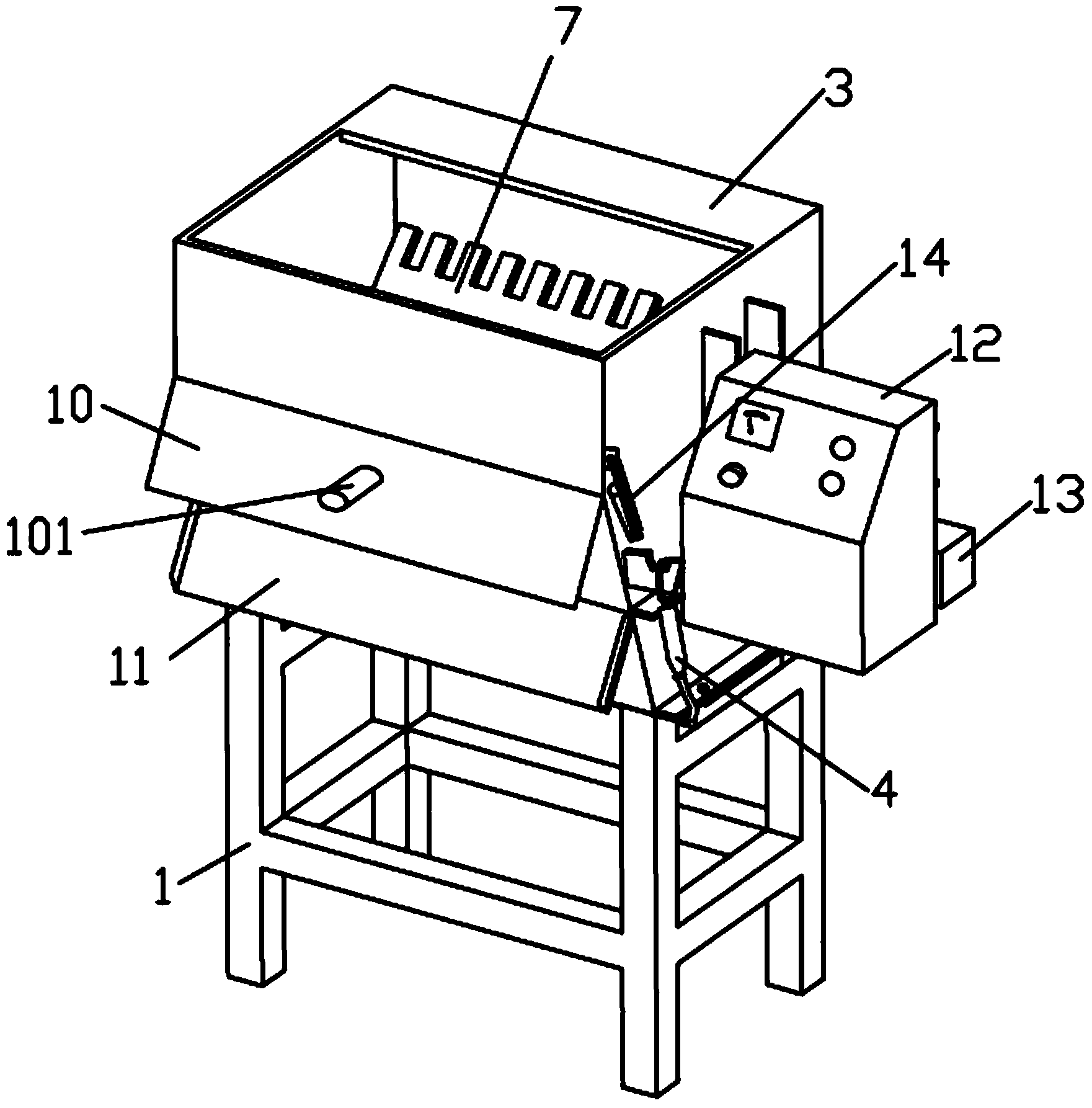

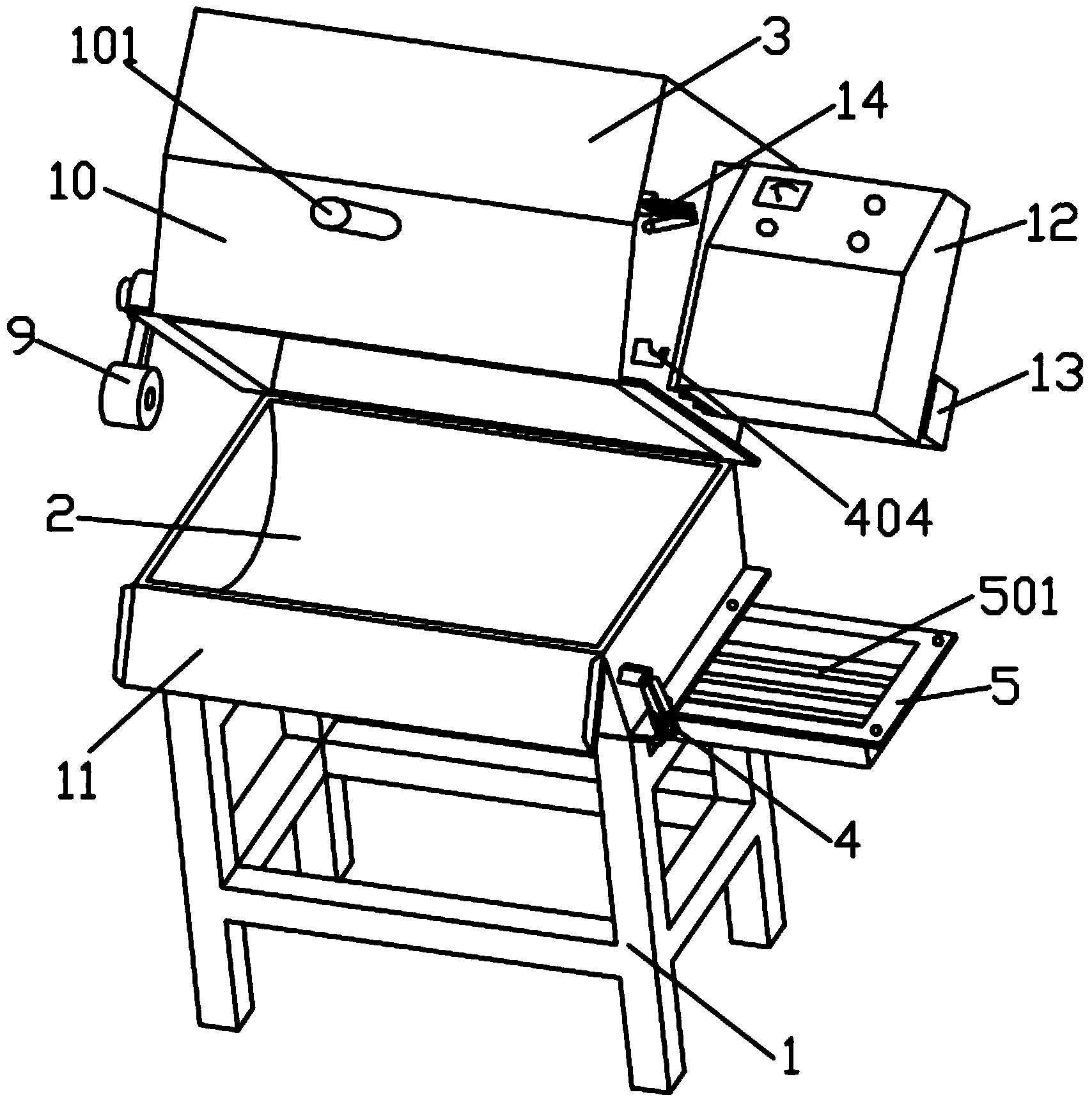

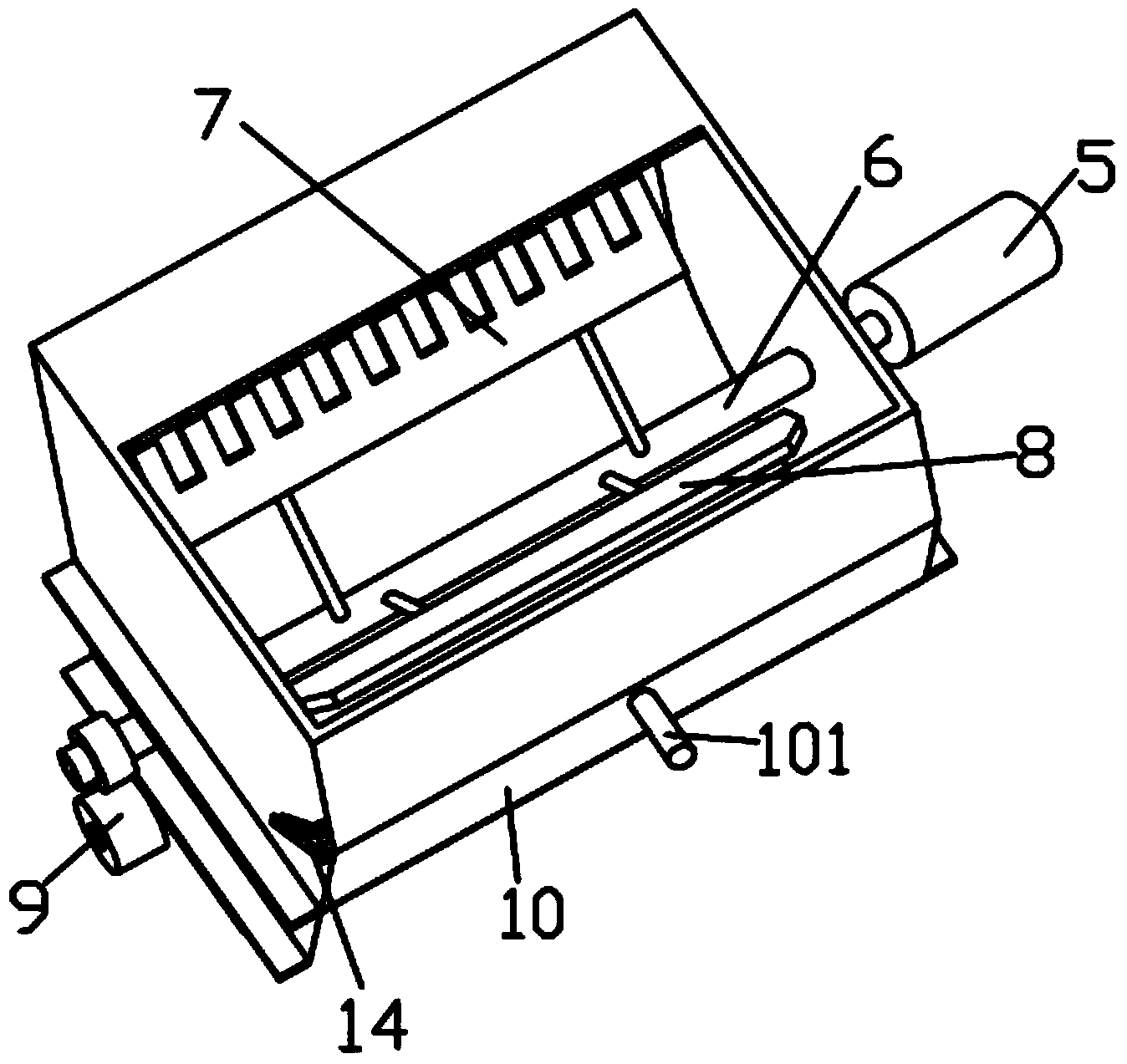

[0025] Tea frying machine of the present invention, as figure 1 Shown, comprise frame 1 and be located at the pot body on it, also comprise heating device, motor and electric control cabinet. like figure 2 As shown in , the pot body is a long groove structure with an arc-shaped bottom surface. The design of the arc-shaped bottom surface is conducive to better stir-frying tea in it and increasing the height of stir-frying. like image 3 As shown in the schematic diagram of the interior of the pot body, there are frying plates 8 and frying rakes 7 moving along the bottom of the pot in the pot body, wherein the front end of the frying rake 7 in contact with the bottom of the pot is provided with a plurality of frying claws arranged at intervals to disperse the tea leaves 71. The frying plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com