Efficient gluing device for plywood

A gluing device and plywood technology, applied in the direction of adhesive application device, glue gun, loading/unloading, etc., can solve the problems of uneven gluing, automatic loading and unloading, etc., and achieve uniform gluing, high degree of automation, and coating good glue effect

Inactive Publication Date: 2019-07-19

融安县华荣木业有限公司

View PDF14 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] A high-efficiency gluing device for plywood proposed by the present invention solves the problem that the existing gluing device applies uneven glue and cannot realize automatic loading and unloading

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

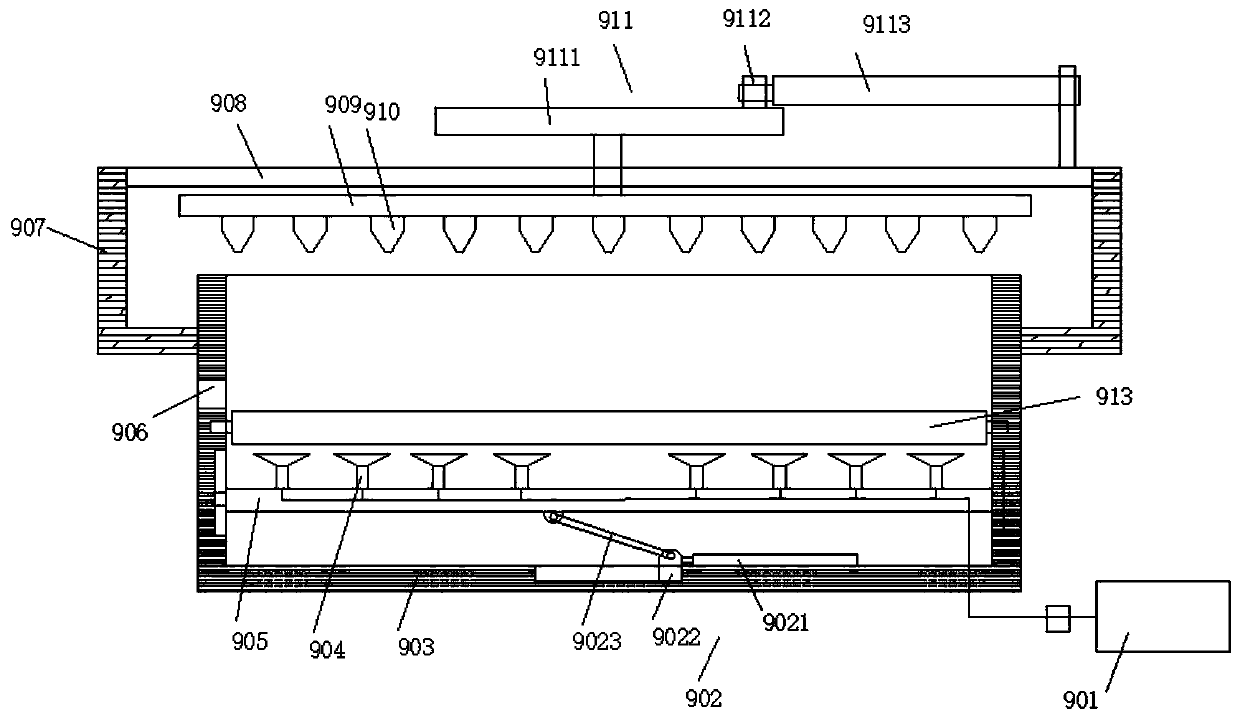

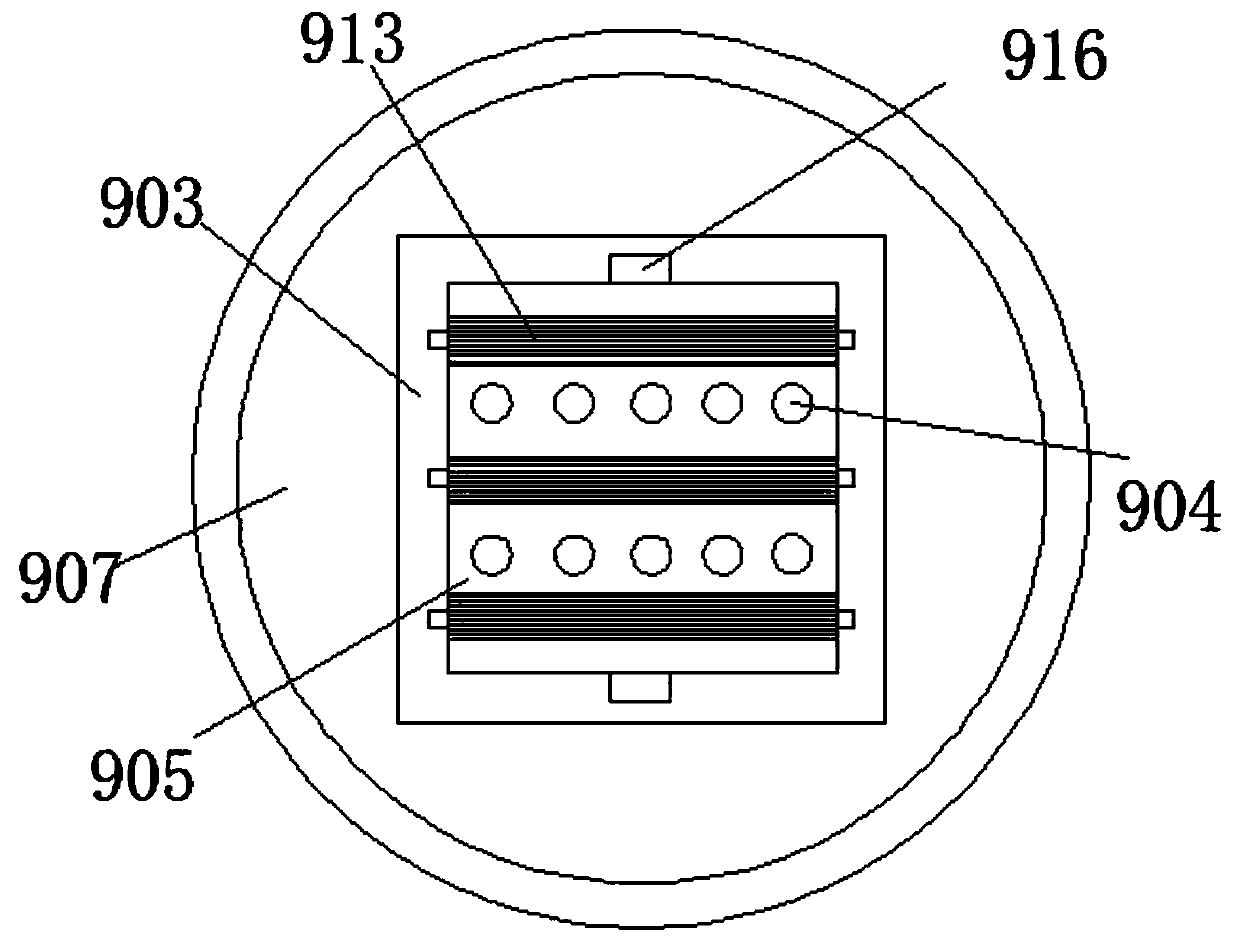

[0033] Embodiment 2: The difference from Embodiment 1 is that the lifting mechanism is the fourth telescopic rod installed on the bottom wall of the gluing box 903, the output shaft of the fourth telescopic rod is connected with the movable plate 913, and the rotating mechanism 911 is installed on the fixed frame 908 On the drive motor, the output shaft of the drive motor is connected with a rubber guide tube 909.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

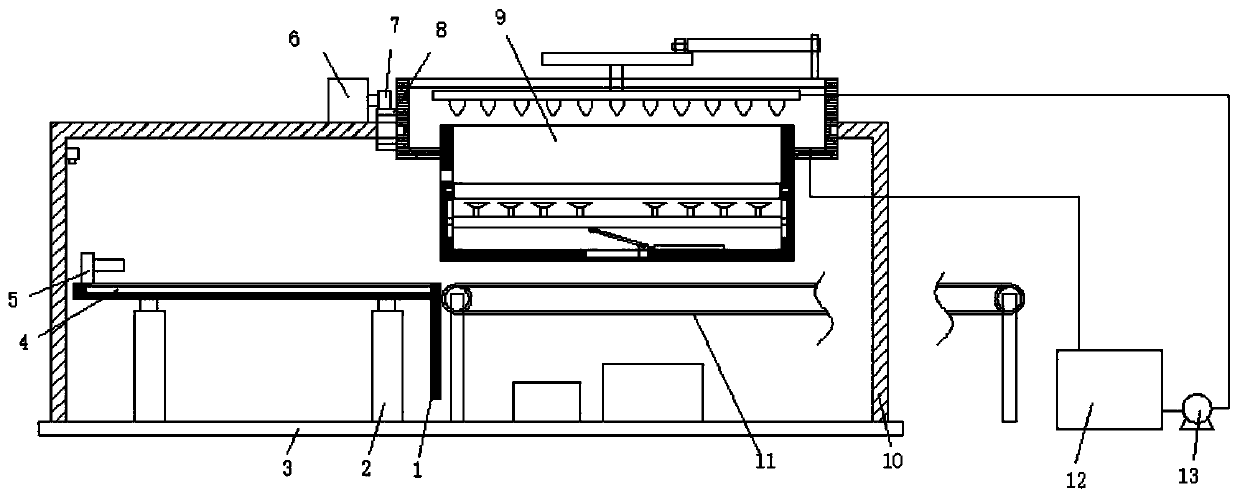

The invention belongs to the field of plywood processing, and particularly relates to an efficient gluing device for plywood. The efficient gluing device for the plywood aims to solve the problems that an existing gluing device is not uniform in gluing, and automatic feeding and discharging cannot be realized. The device comprises a base, a feeding conveying belt, a supporting frame and a gluing mechanism, wherein a plurality of first telescopic rods are fixed at one end of the base, and the output shaft of the first telescopic rods are connected with a feeding plate with an L-shaped verticalsection; a mounting groove is formed in the top end of the feeding plate, and a rodless air cylinder is arranged in the mounting groove; the output shaft of the rodless air cylinder is connected witha material pushing plate slidably connected to the top end of the feeding plate, one end of the feeding plate is provided with the feeding conveying belt, and one end of the feeding conveying belt isarranged on the base; the upper end face of the feeding conveying belt and the upper end face of the feeding plate are located on the same plane, and a gluing mechanism positioned on one side of the feeding plate is arranged above the feeding conveying belt; according to the device, the automation degree is high, the automatic feeding and discharging of plates can be realized, the gluing is uniform, and the gluing effect is good.

Description

technical field [0001] The invention relates to the technical field of plywood processing, in particular to a high-efficiency gluing device for plywood. Background technique [0002] Plywood is one of the commonly used materials for furniture. It is a kind of wood-based panel, usually made of a group of veneers after gluing and pressing. [0003] At present, in the production enterprises of plywood in our country, the glue coating machine is generally used to apply glue to the wood boards. Most of the glue coating machines use glue rollers to apply glue to the boards. There is a lot of waste, and automatic feeding and discharging cannot be realized. Therefore, we propose a high-efficiency gluing device for plywood. Contents of the invention [0004] A high-efficiency gluing device for plywood proposed by the invention solves the problems that the existing gluing device applies uneven glue and cannot realize automatic loading and unloading. [0005] In order to achieve th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B27G11/00B65G65/32B65G65/42

CPCB27G11/00B27G11/005B65G65/32B65G65/42

Inventor 黄恩荣唐胜荣

Owner 融安县华荣木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com