Control method of high-precision automatic sole gluing system

A control method and high-precision technology, which is applied in the direction of shoemaking machinery, footwear, and gluing shoe parts, etc., to achieve the effect of automatic, accurate and uniform glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

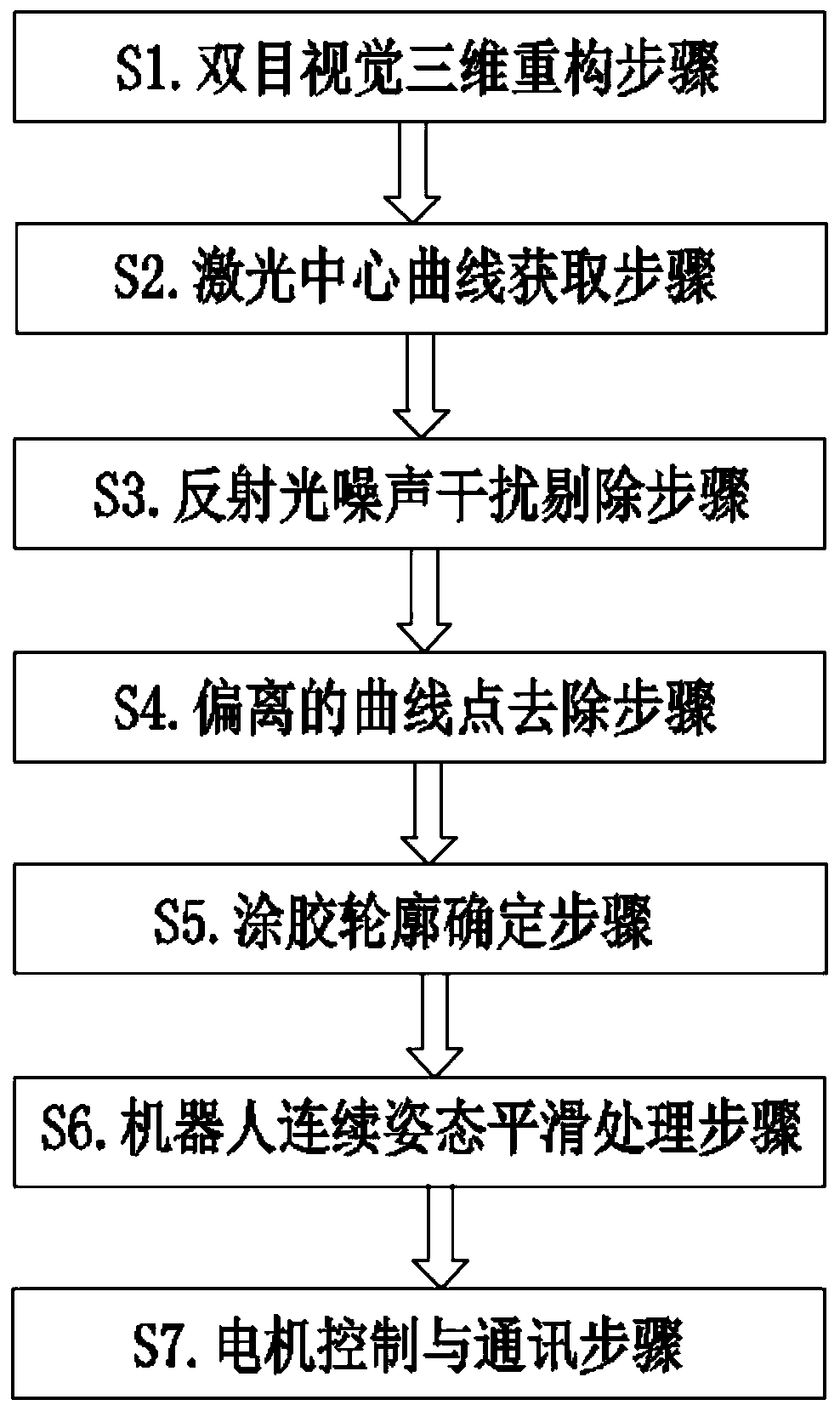

[0030] Such as figure 1 As shown, the present invention provides a control method of a high-precision automatic gluing system for soles, including:

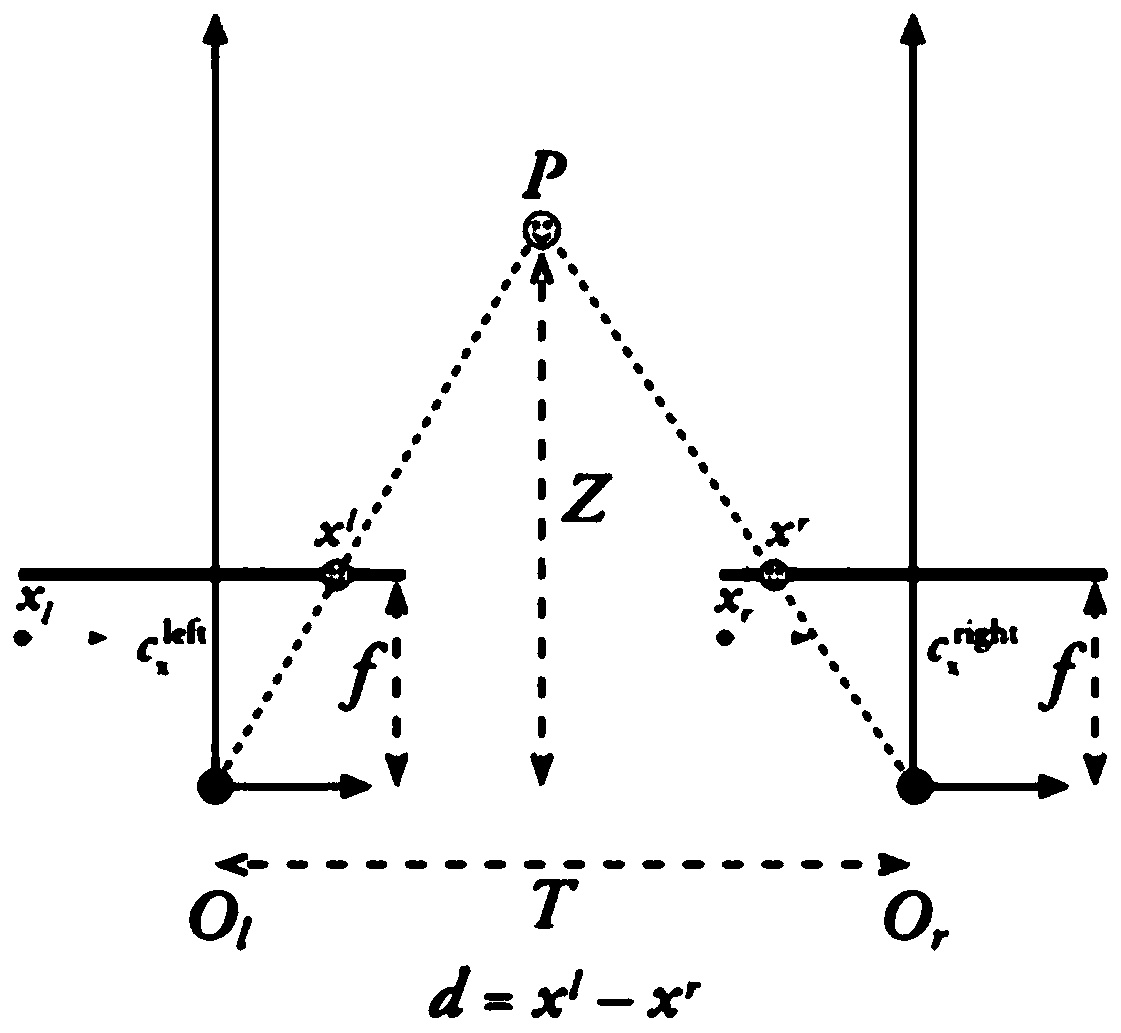

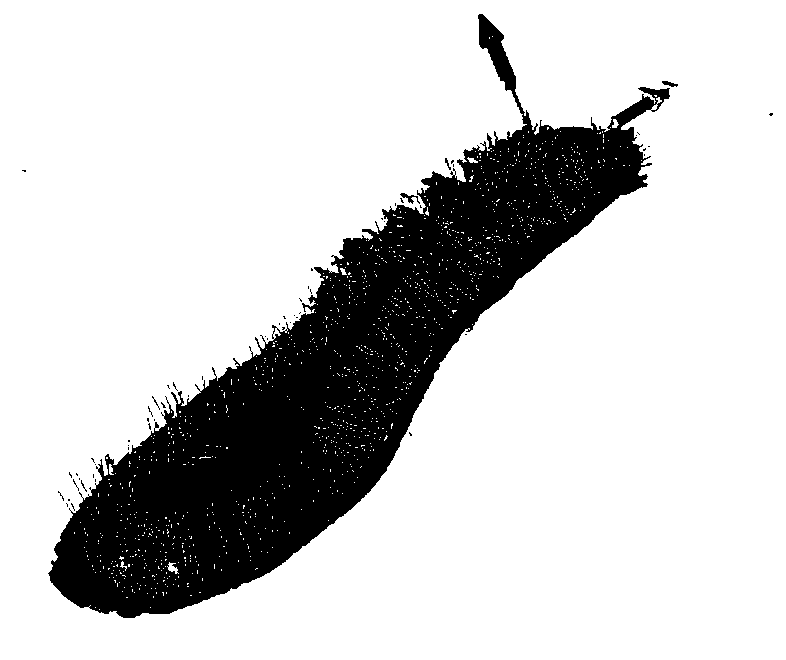

[0031] S1. Binocular vision three-dimensional reconstruction step: determine the three-dimensional reconstruction parameters through binocular vision system calibration;

[0032] S2. Laser center curve acquisition step: through LOG operator analysis, obtain the laser center curve;

[0033] S3. Reflected light noise interference removal step: remove reflected light noise through clustering algorithm and screening principle;

[0034] S4. Deviating curve point removal step: remove the curve point deviating from the straight line through a straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com