Card gluing mechanism

A technology of gluing and carding, which is applied in the direction of coating and liquid coating on the surface, etc., which can solve the problem of poor uniformity of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

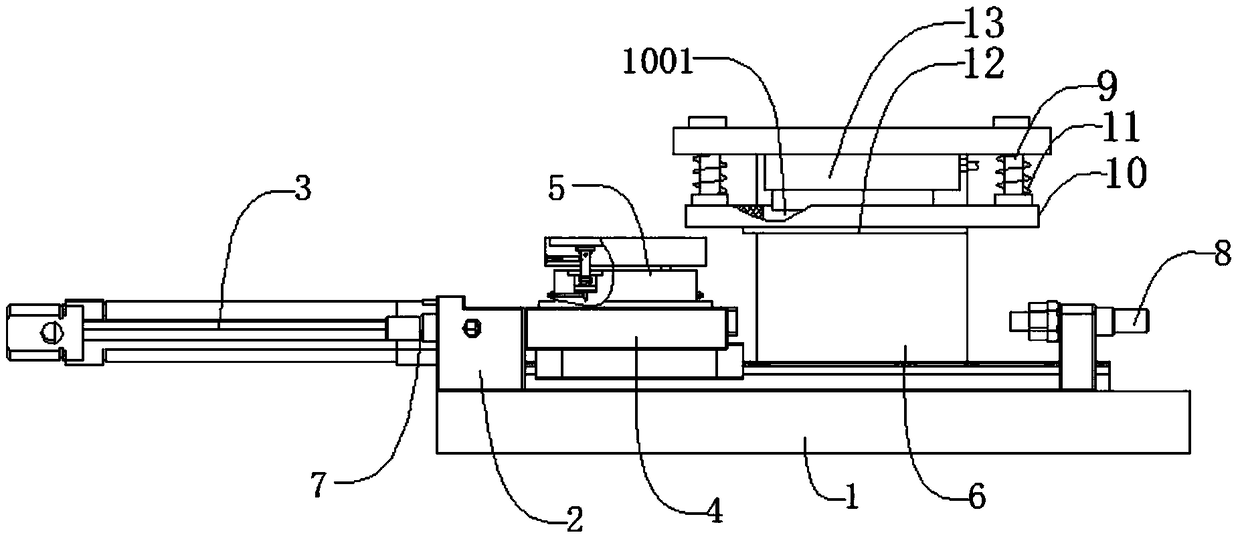

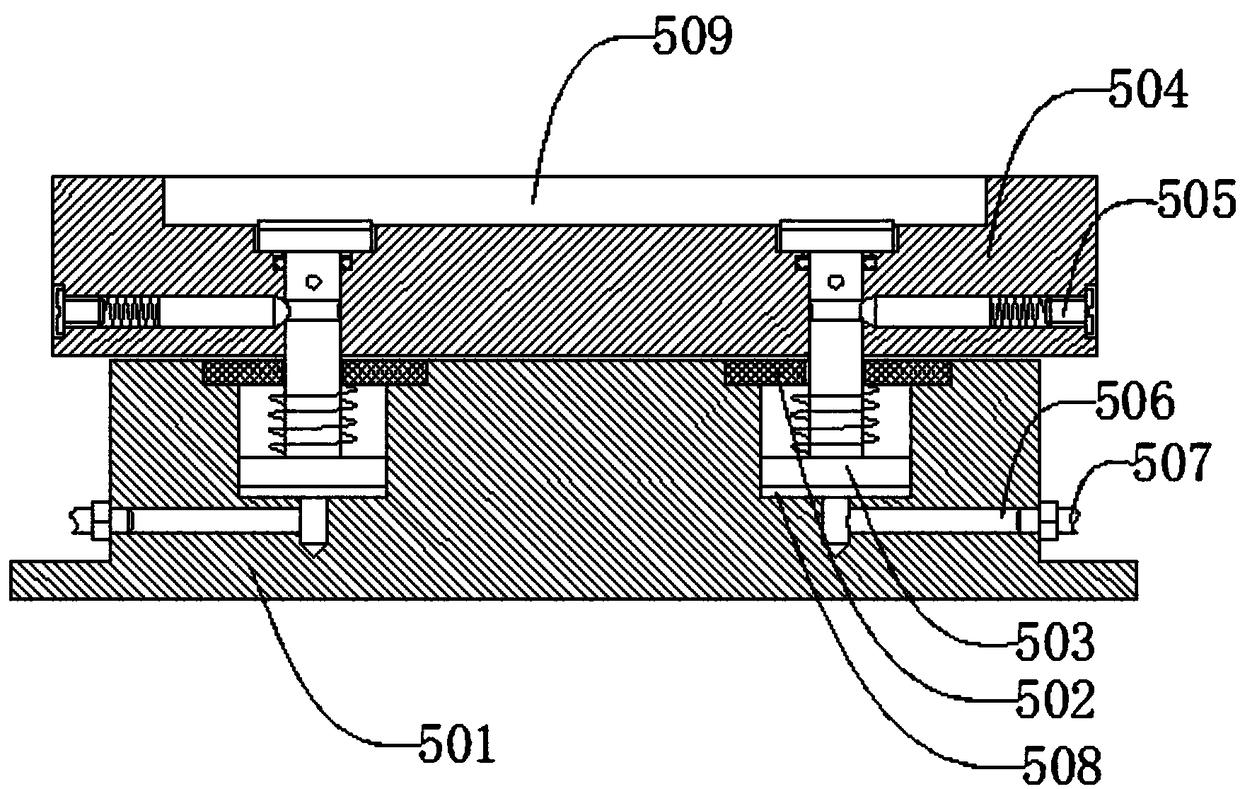

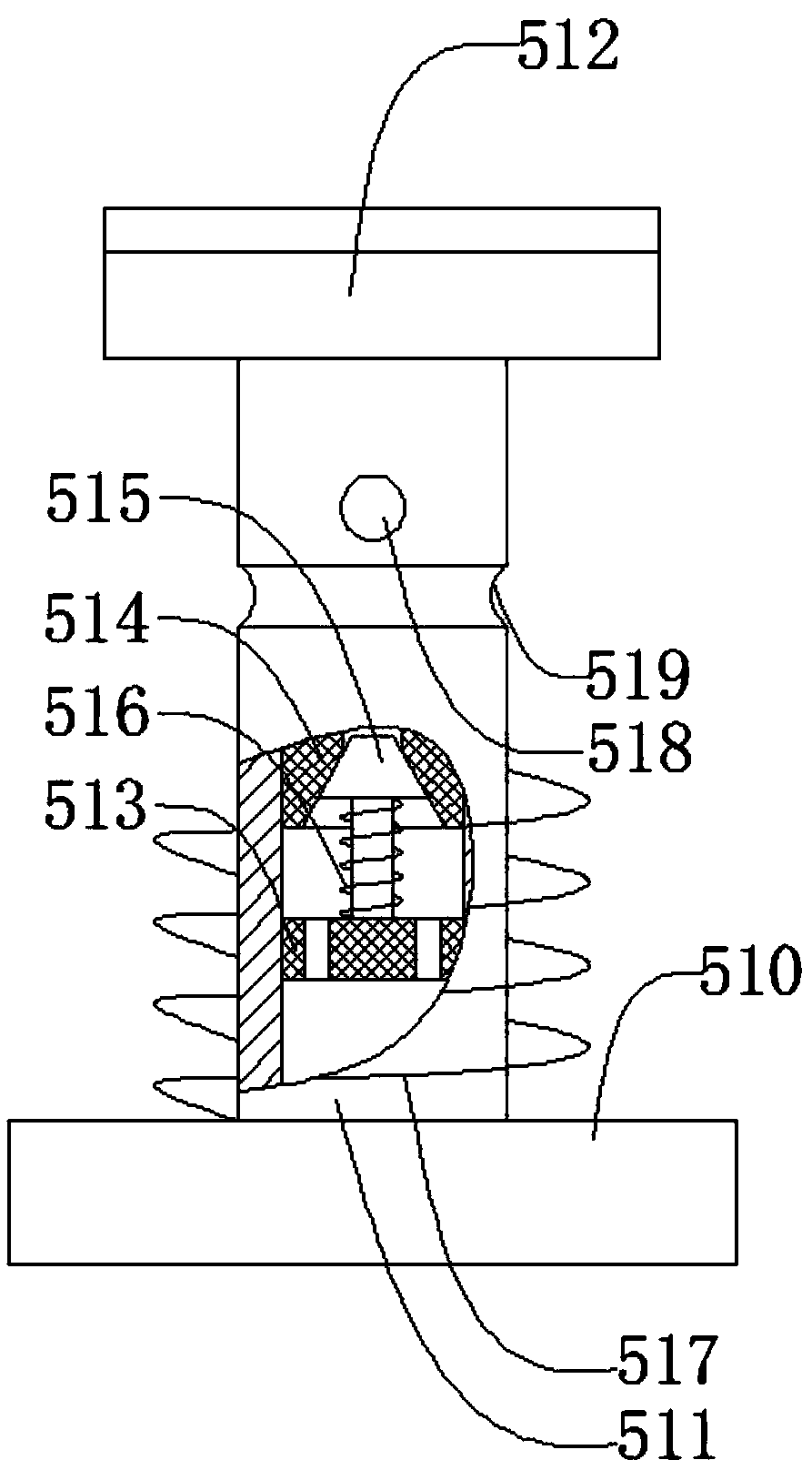

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, a card gluing mechanism includes a base 1, a fixed seat 2, a push cylinder 3, a sliding seat 4, a lifting and placing mechanism 5, a bracket 6, a first proximity switch 7, a second proximity switch 8, a guide Rod 9, pressure frame 10, first spring 11, glue equalizing plate 12 with several glue equalizing holes 1201, glue spreading mechanism 13, said fixing seat 2 is located on the left side of the upper end of base 1, said fixing seat 2 and The base 1 is connected by bolts, the pushing cylinder 3 is located on the left side of the fixed seat 2, the pushing cylinder 3 is connected with the fixed seat 2 by bolts, and the sliding seat 4 is located on the right side of the pushing cylinder 3 and is located The upper end of the base 1, the sliding seat 4 is connected with the pushing cylinder 3 by bolts, the sliding seat 4 can slide left and right along the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com