Patents

Literature

325results about How to "Improve gluing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collagen type I and type III compositions for use as an adhesive and sealant

InactiveUS20030032143A1Reduce riskInherently hemostatic propertiesFibrinogenSurgical adhesivesWound healingCollagen i

Polymerized type I and / or III collagen based compositions for medical use as adhesives and sealants and preparation thereof are described. Prior to polymerization, the collagen monomers are prepared recombinantly whereby chemical modifications of the collagen are not needed to form such monomers. The type I and / or III collagen compositions are useful as medical adhesives for bonding soft tissues or in a sealant film for a variety of medical uses. In a further aspect of the present invention, the polymerized type I and / or III collagen composition includes agents which induce wound healing or provide for additional beneficial characteristics desired in a tissue adhesive and sealant.

Owner:NEFF THOMAS B +1

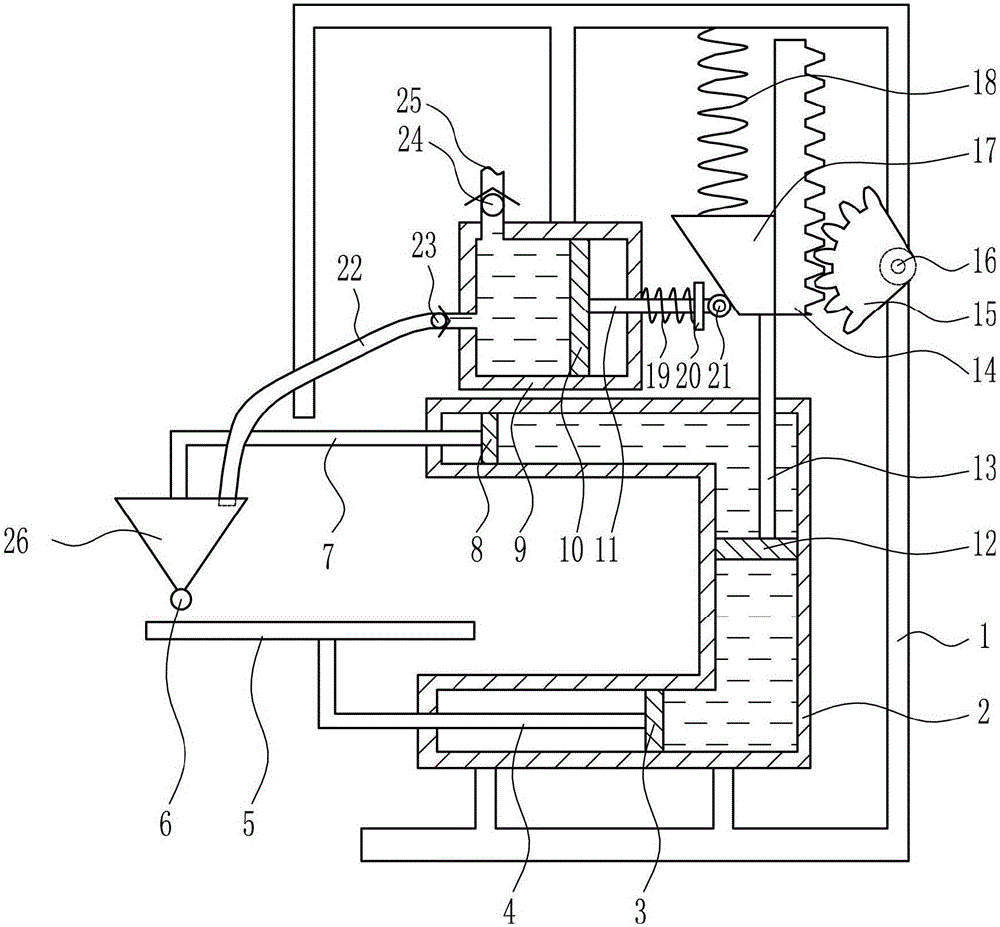

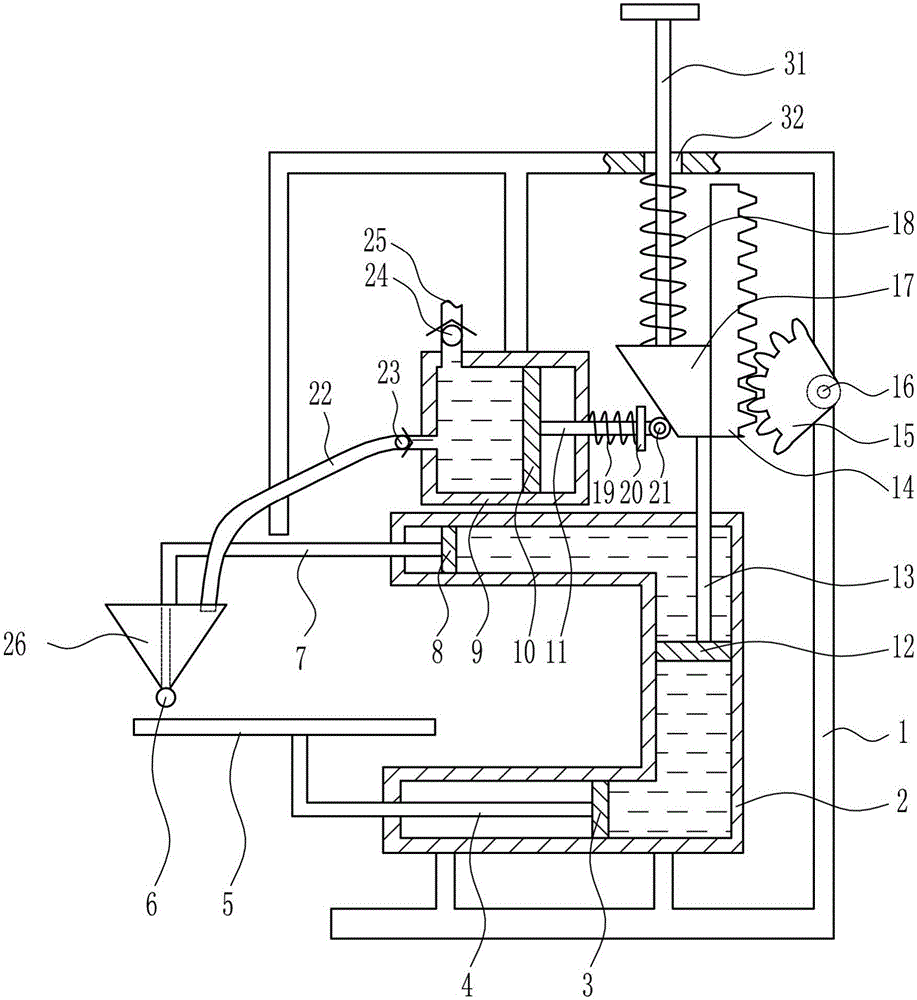

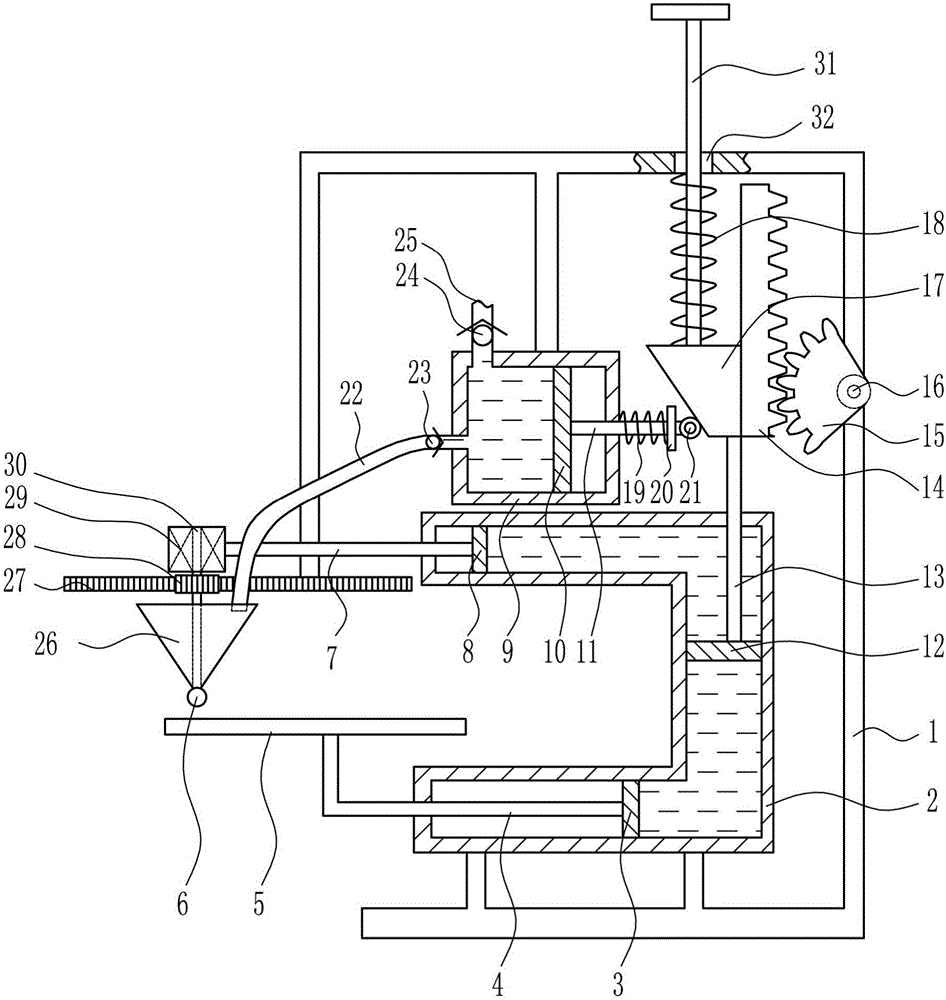

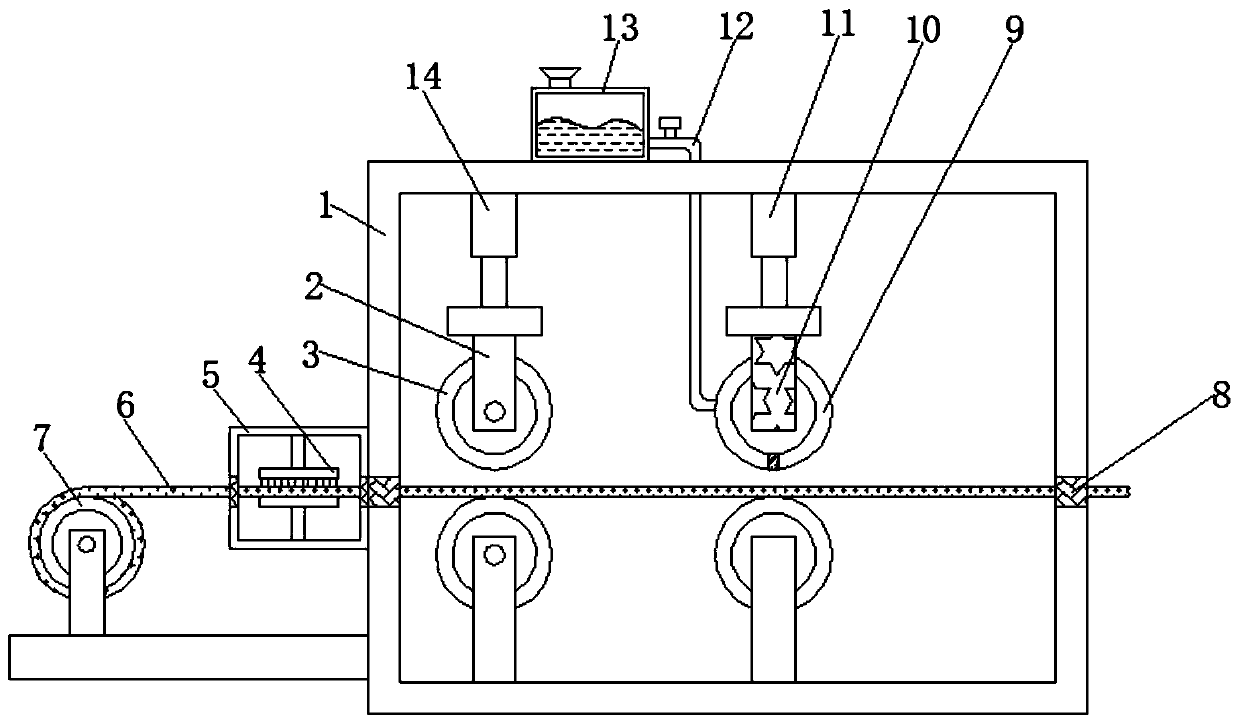

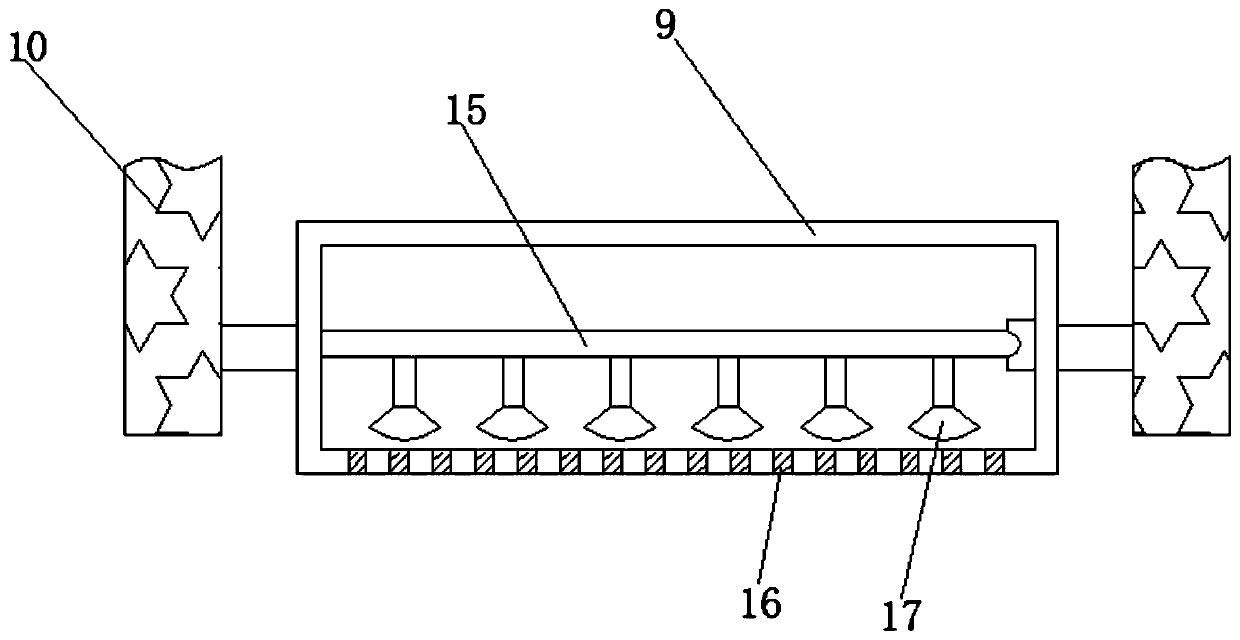

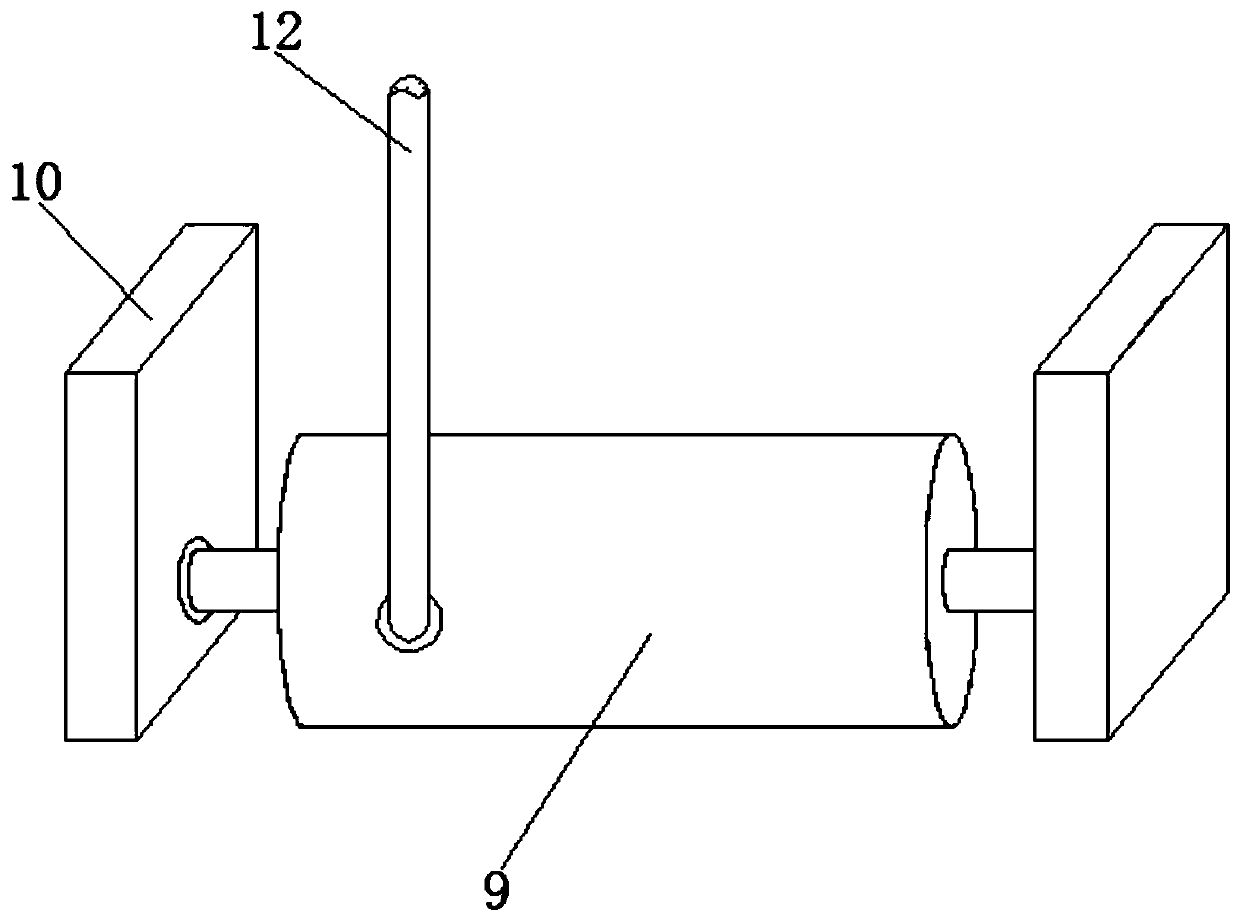

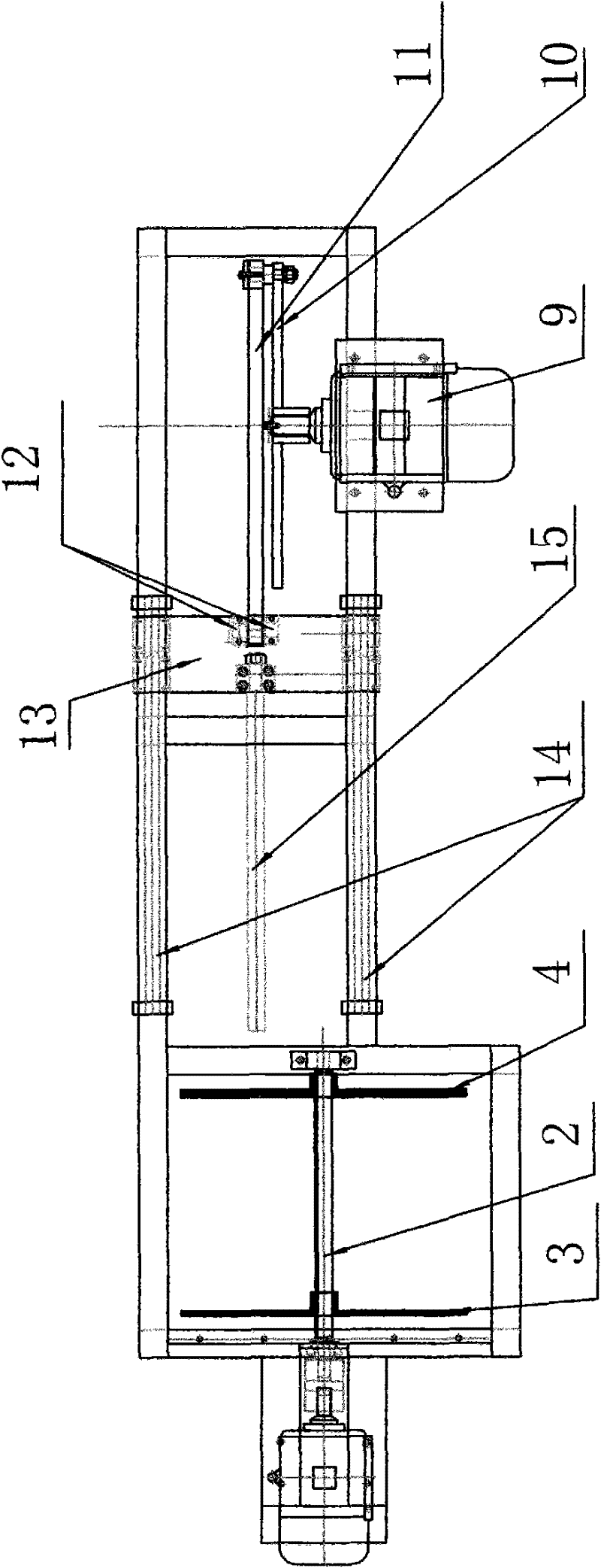

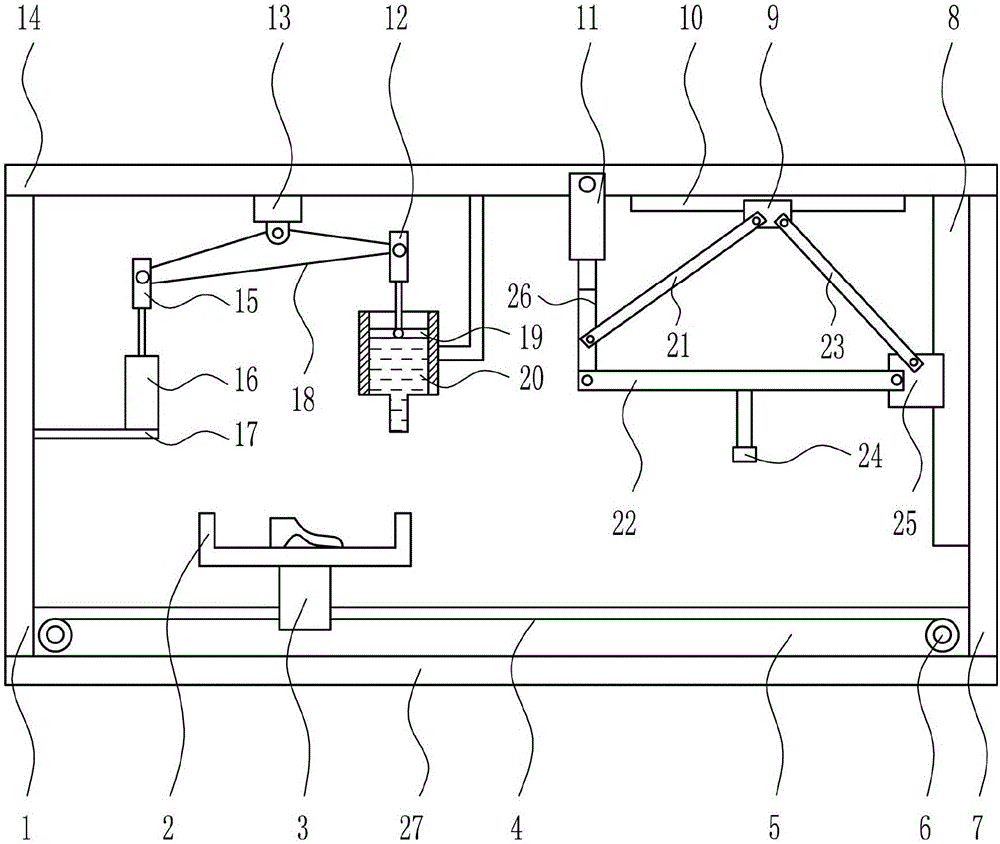

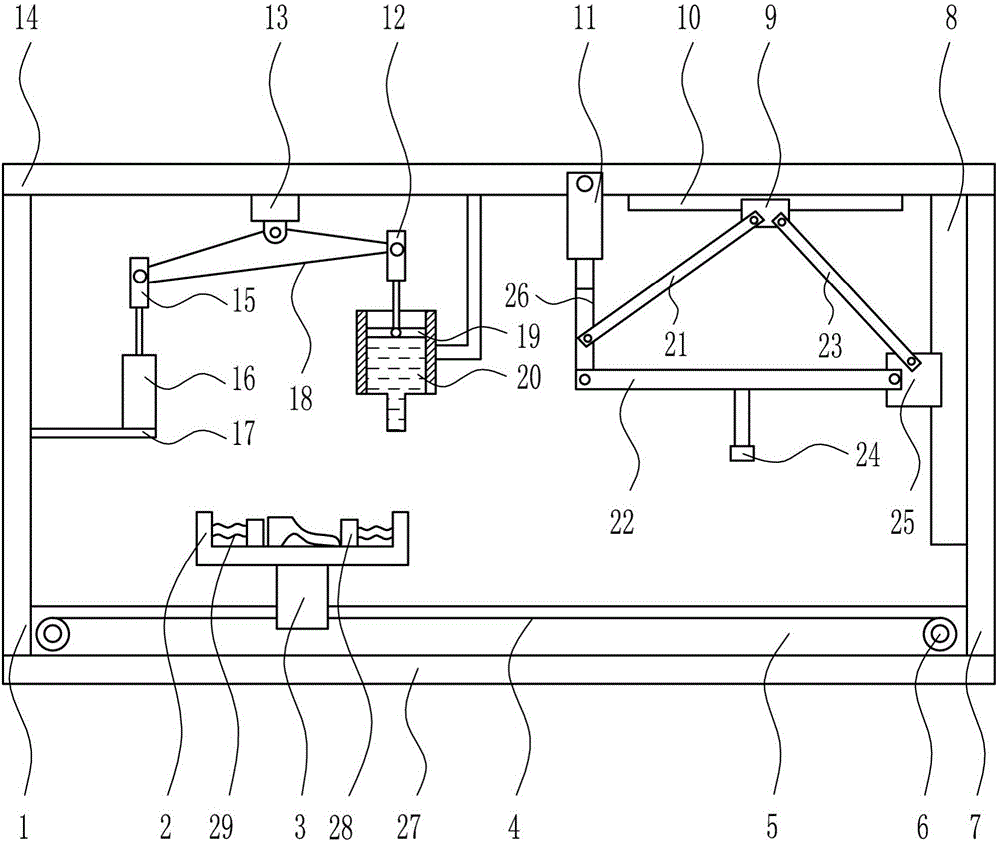

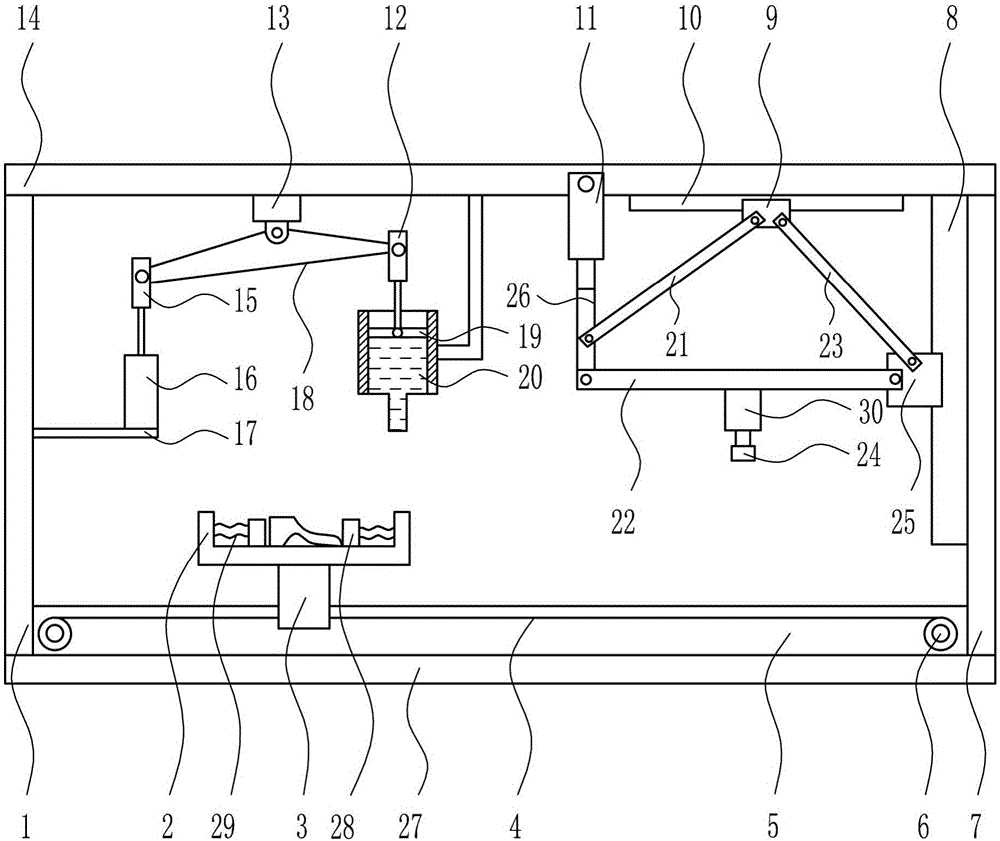

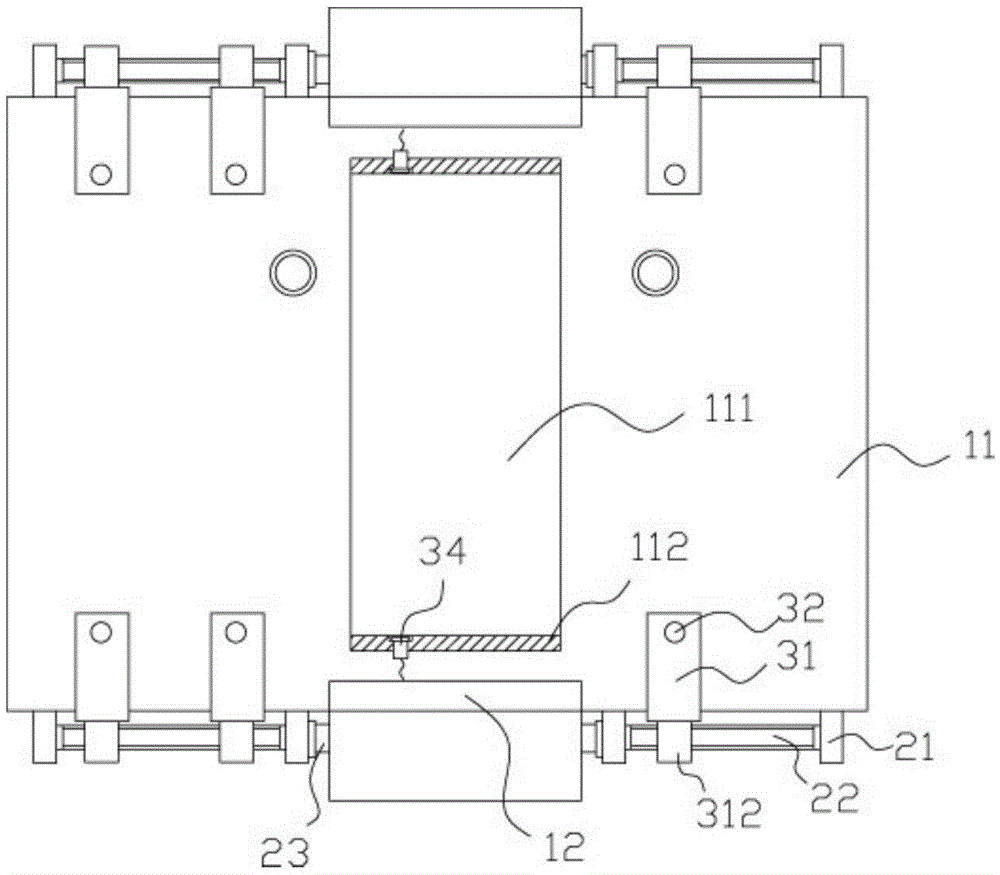

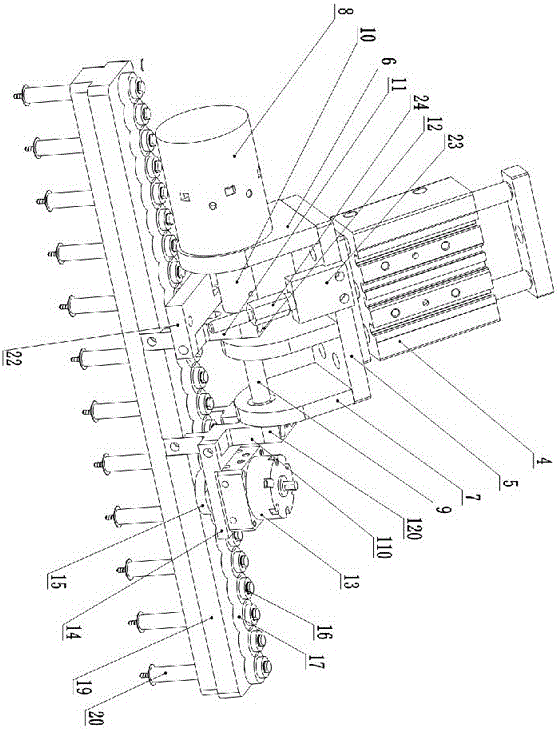

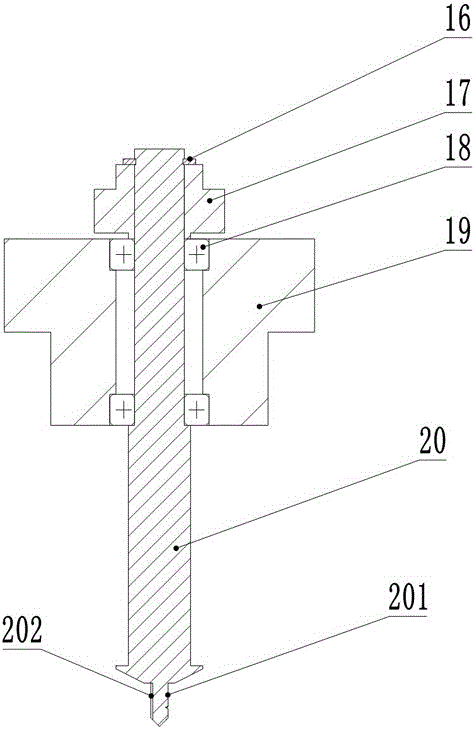

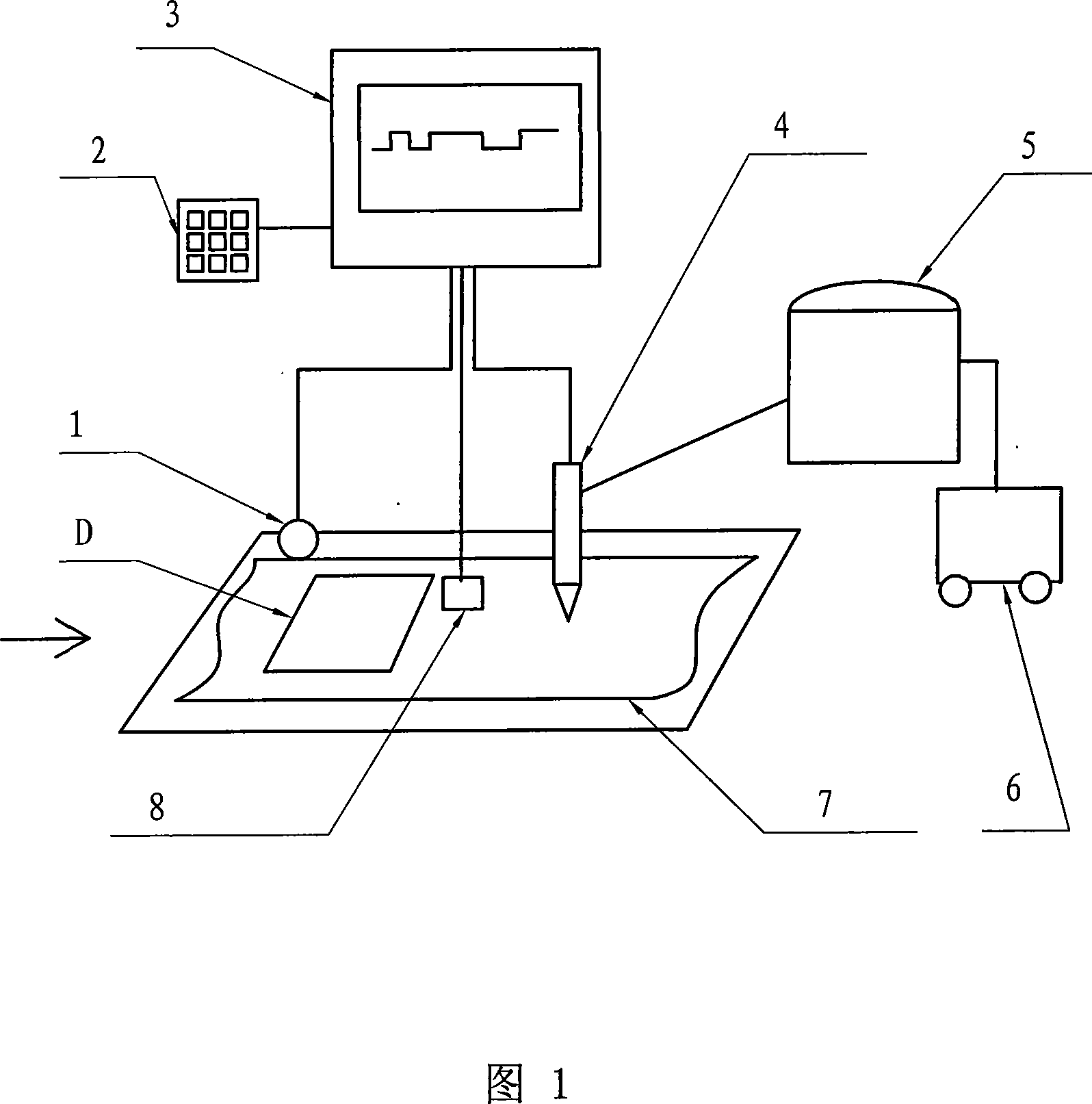

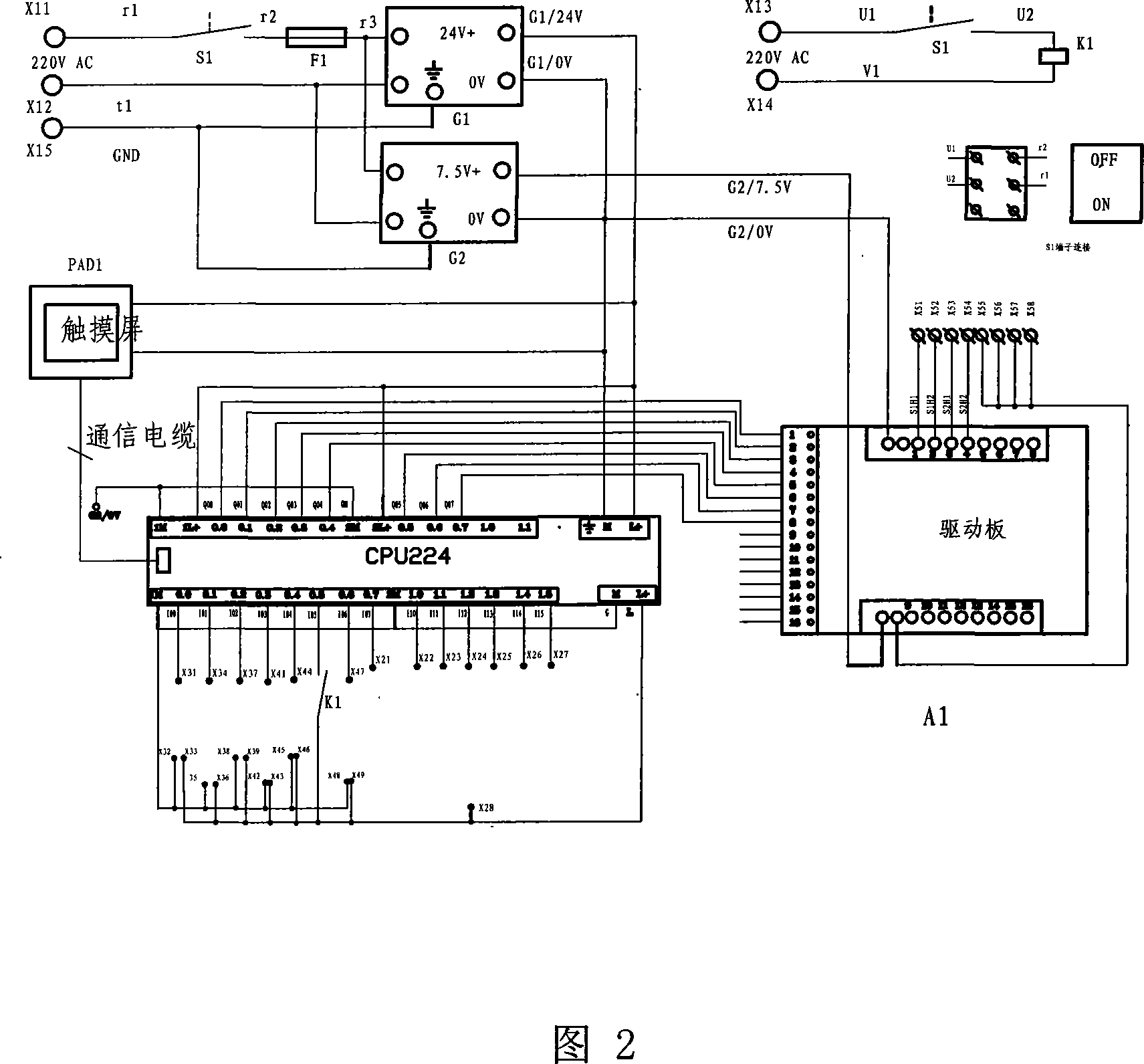

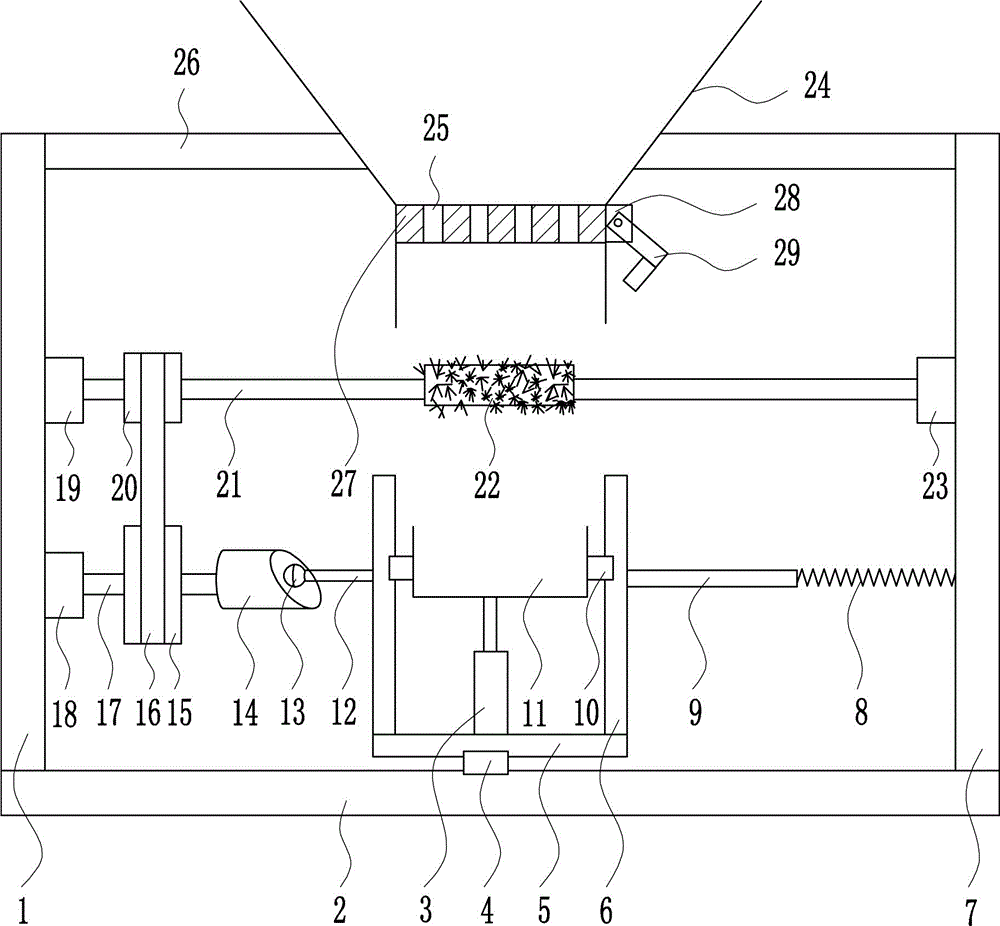

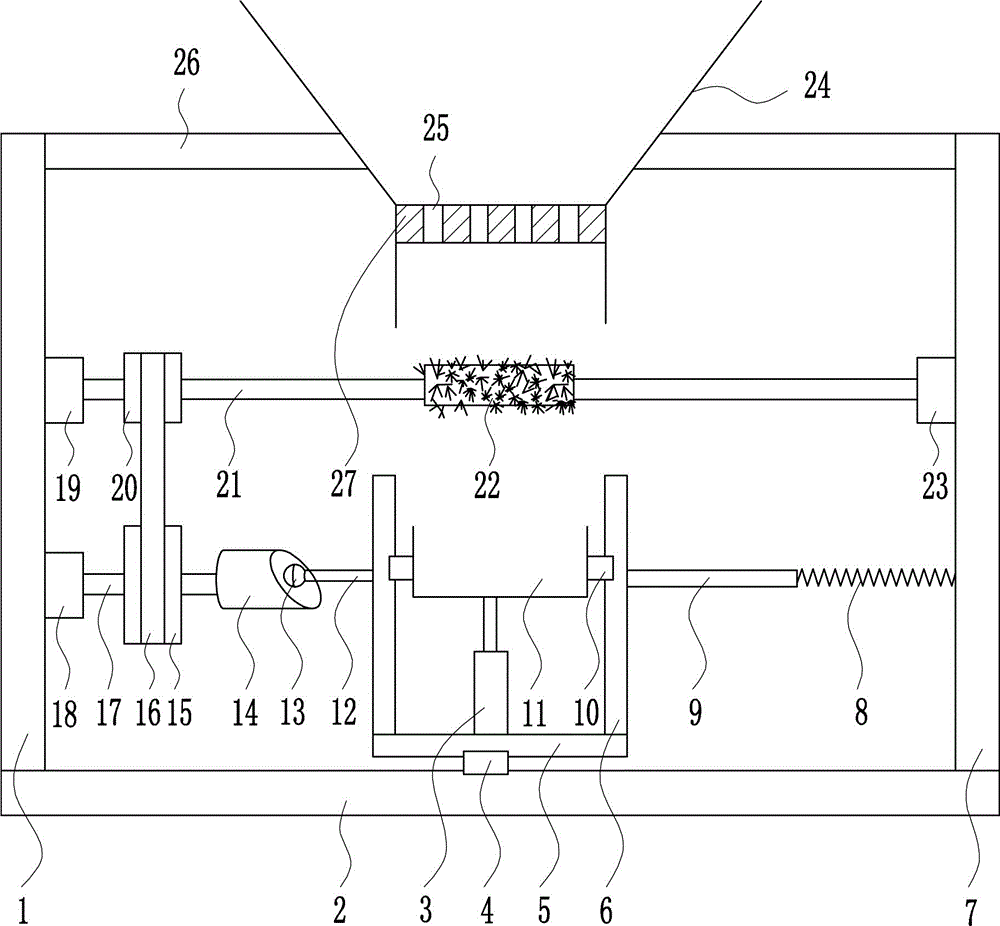

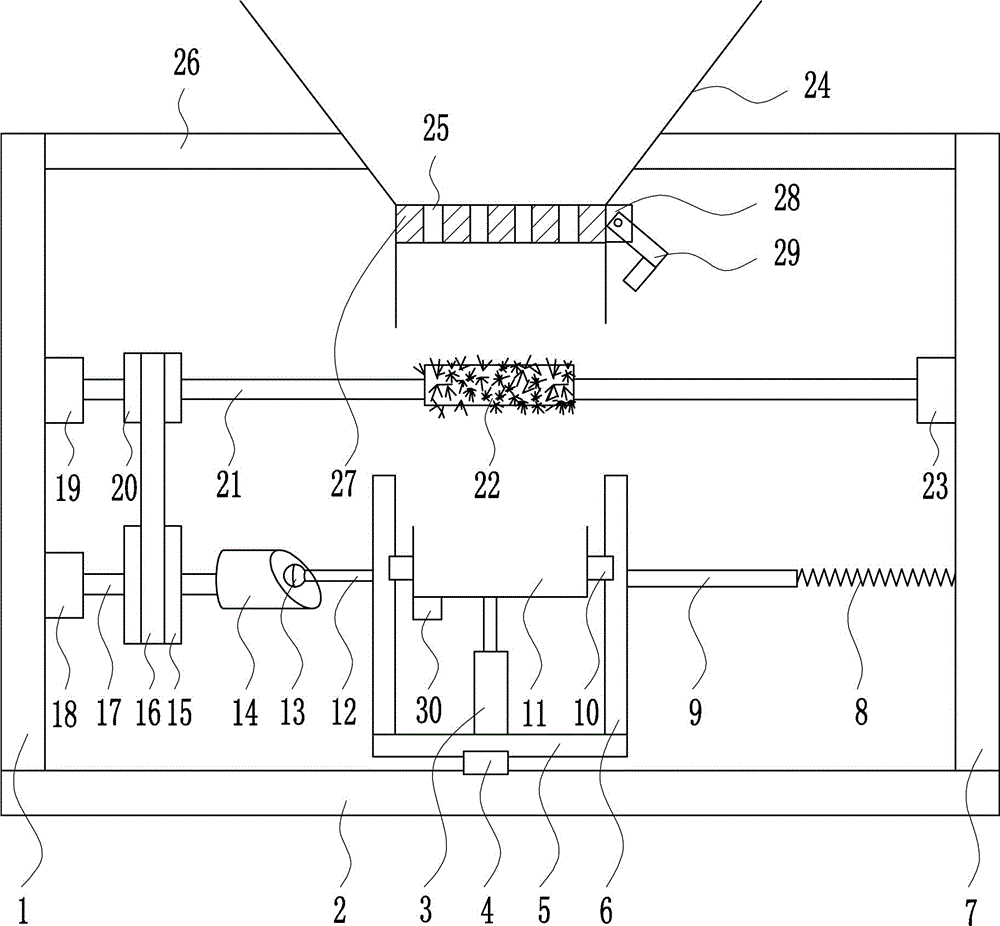

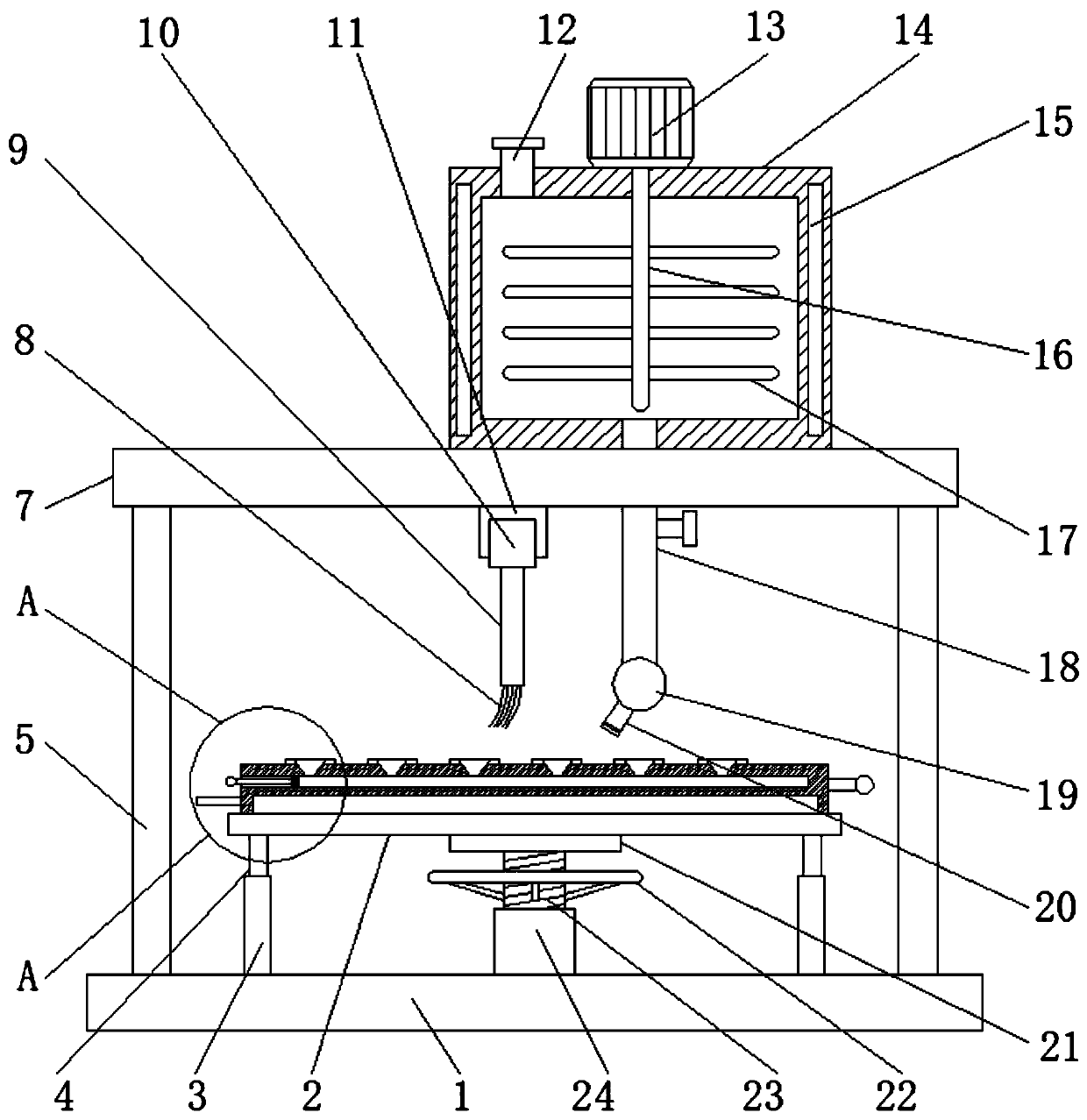

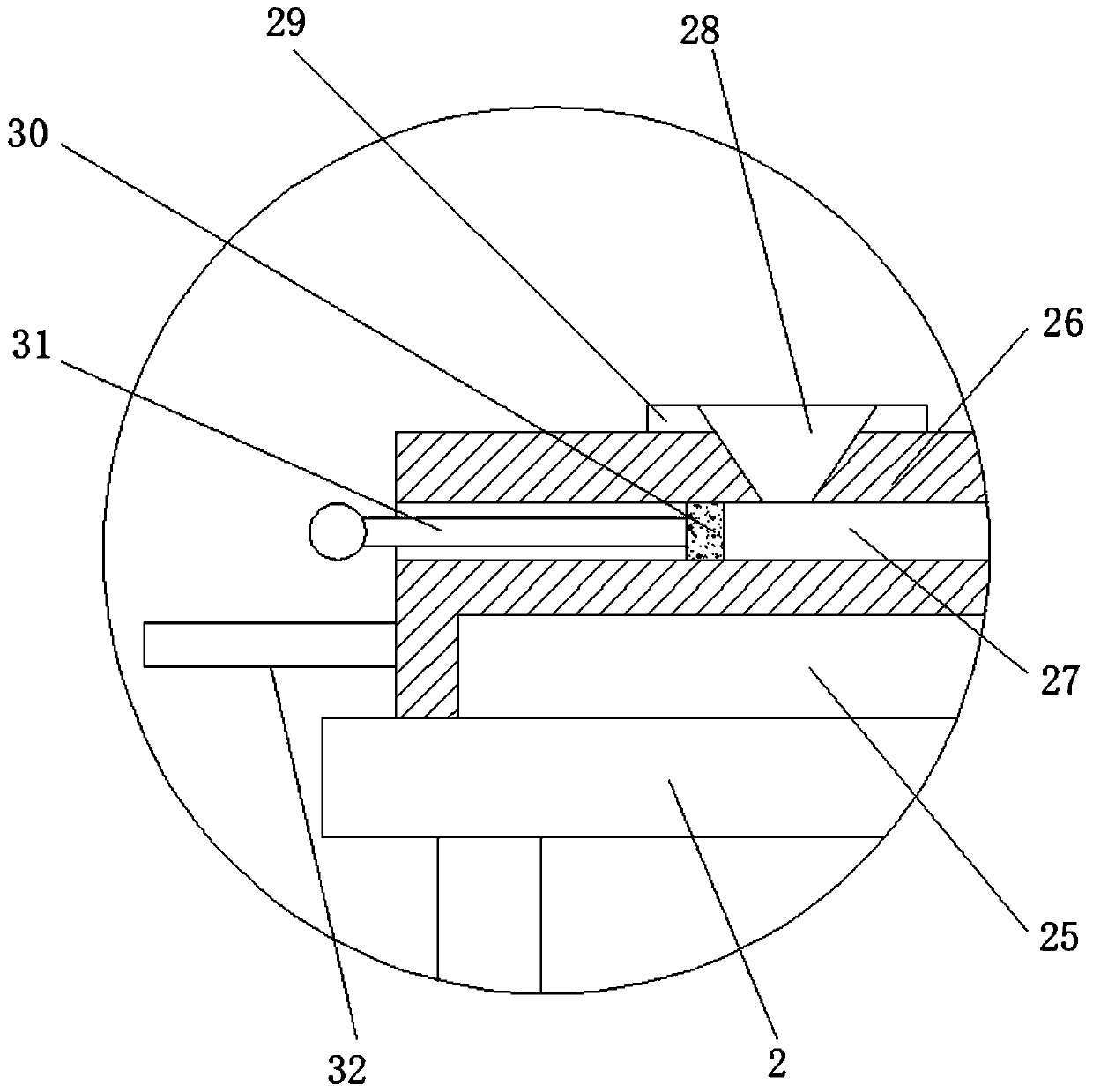

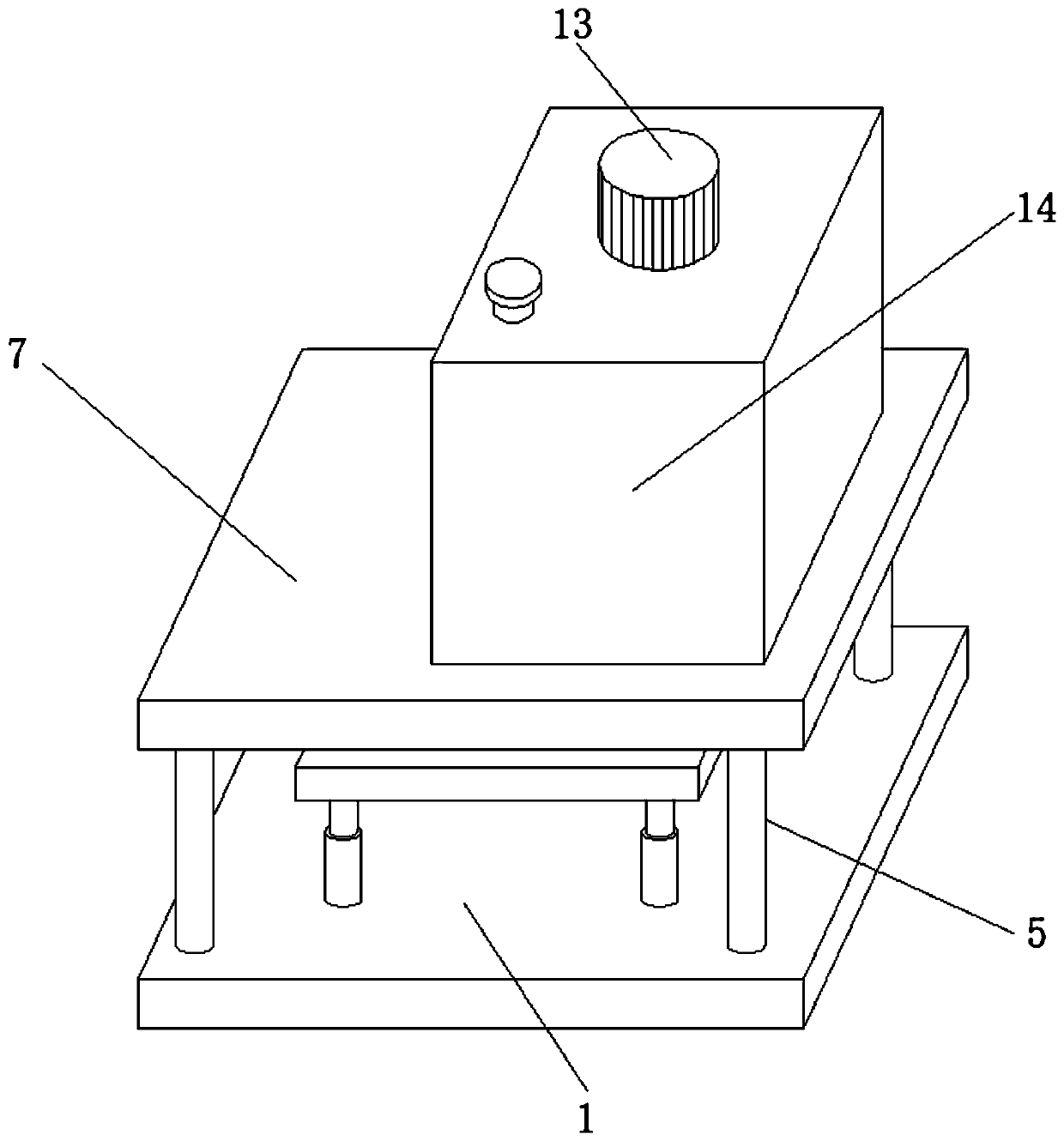

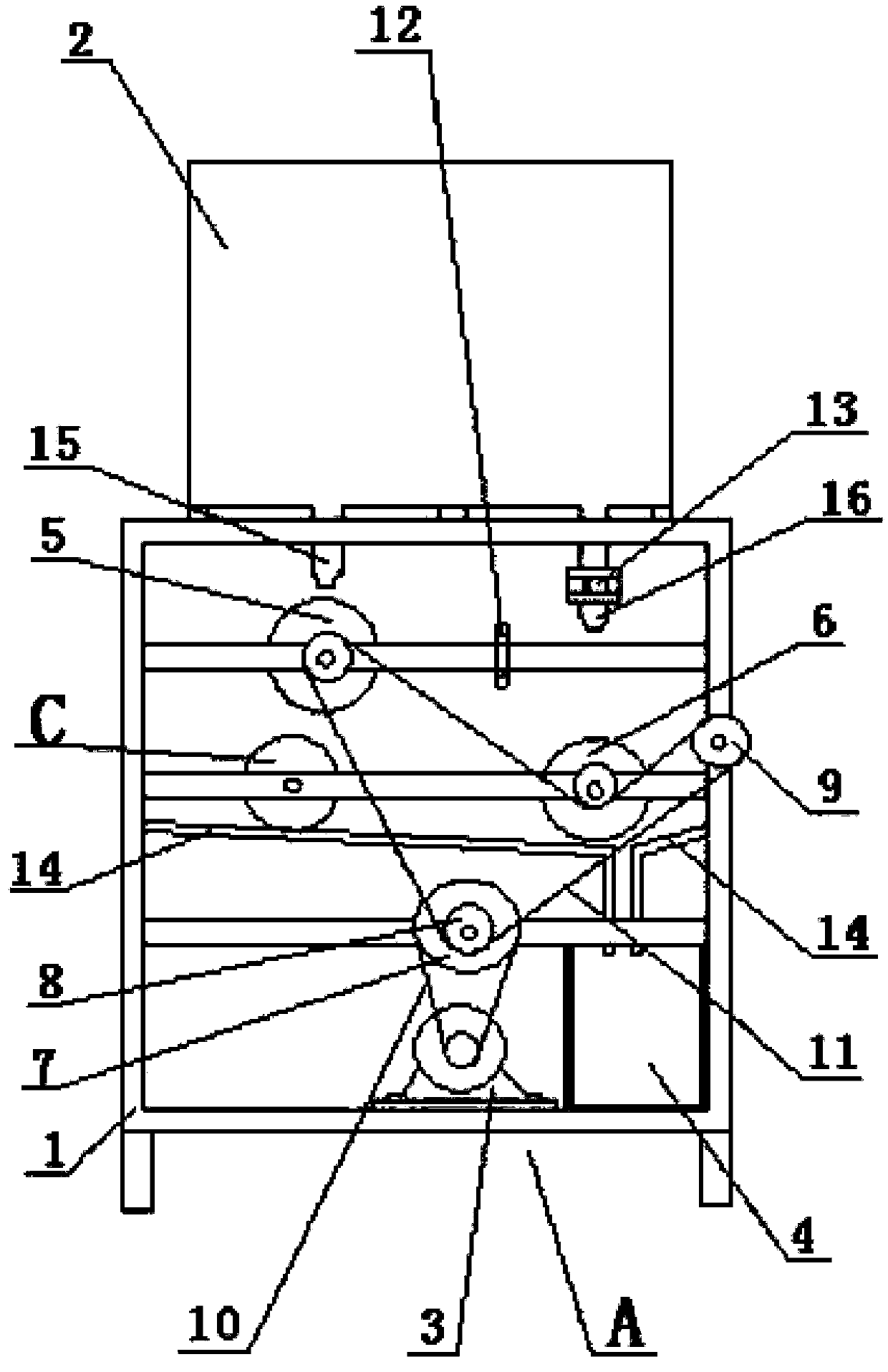

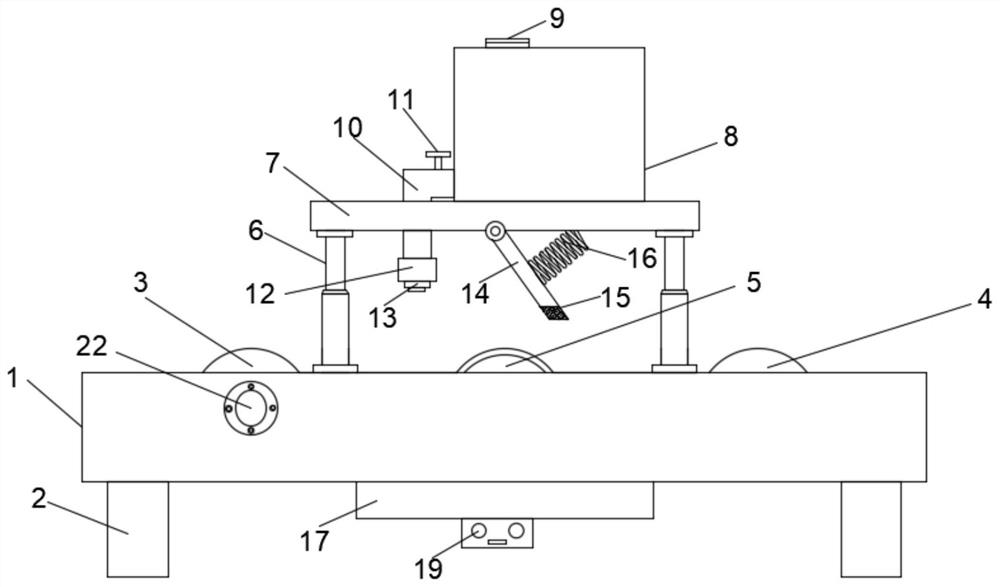

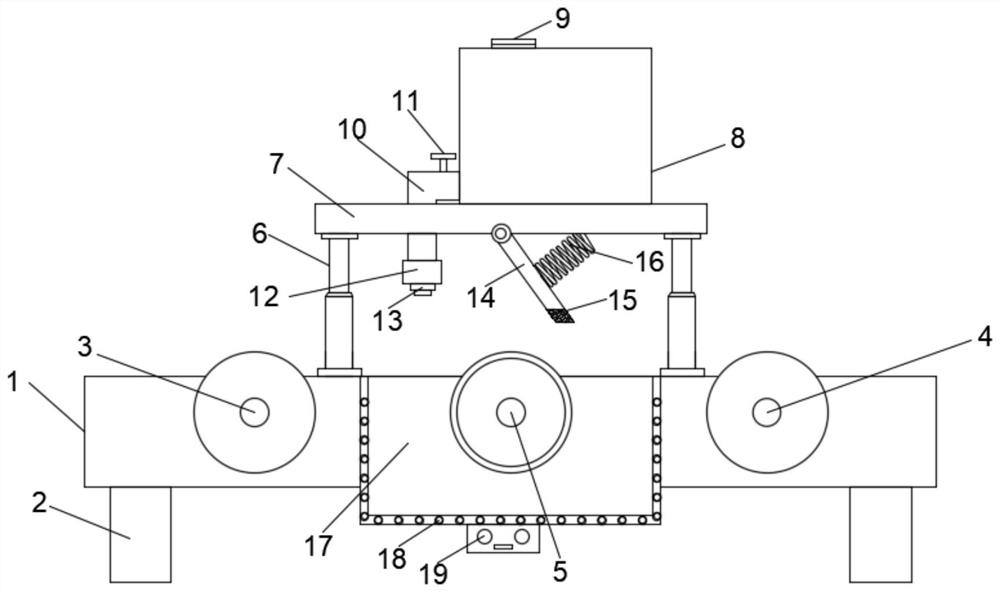

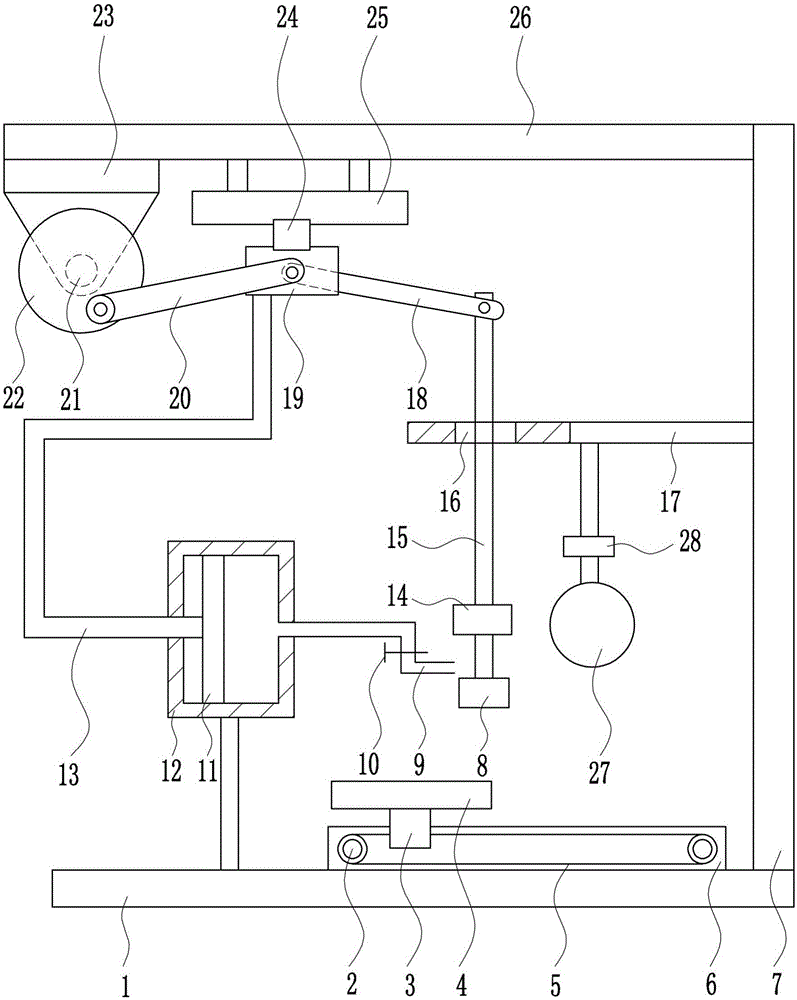

Efficient gluing equipment for shoemaking in shoe factories

InactiveCN106670056AApply glue evenlyDevice stableLiquid surface applicatorsCoatingsPistonFixed frame

The invention relates to gluing equipment, in particular to efficient gluing equipment for shoemaking in shoe factories. According to the efficient gluing equipment for shoemaking in the shoe factories, rapid gluing can be conducted, the gluing effect is good, and the gluing efficiency is high. The efficient gluing equipment for shoemaking in the shoe factories comprises a fixed frame, a U-shaped cylinder body, a first piston, a first left-right movement rod, a placing plate, a gluing head, a second left-right movement rod, a second piston, a small cylinder body and the like. The small cylinder body, a motor and the U-shaped cylinder body are arranged on the fixed frame in sequence from top to bottom. The motor is provided with a fan-shaped gear. The first piston is arranged in the lower portion of the U-shaped cylinder body in a matched mode. The first left-right movement rod is arranged on the left portion of the first piston. The efficient gluing equipment for shoemaking in the shoe factories achieves the effects of being good in gluing effect and high in gluing efficiency; a large number of gluing tasks can be rapidly completed through the efficient gluing equipment; in addition, a large amount of labor force is not needed; and a glued finished product is beautiful.

Owner:林永远

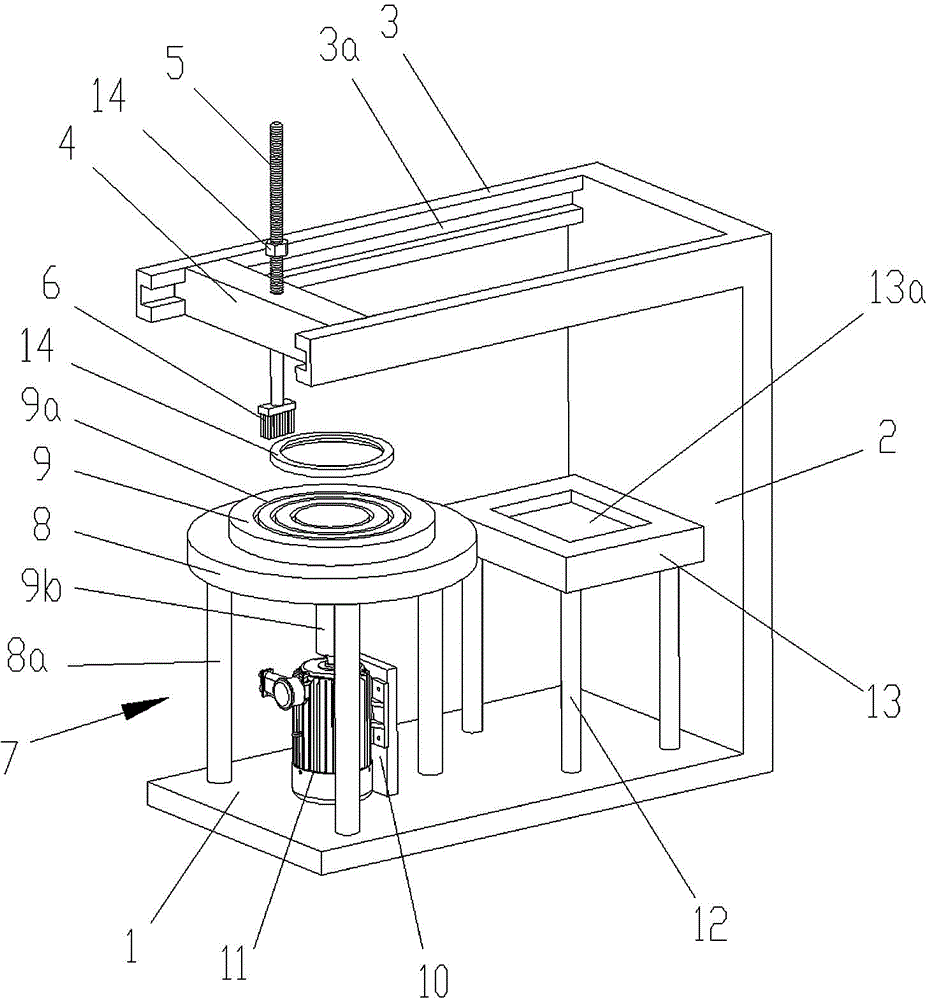

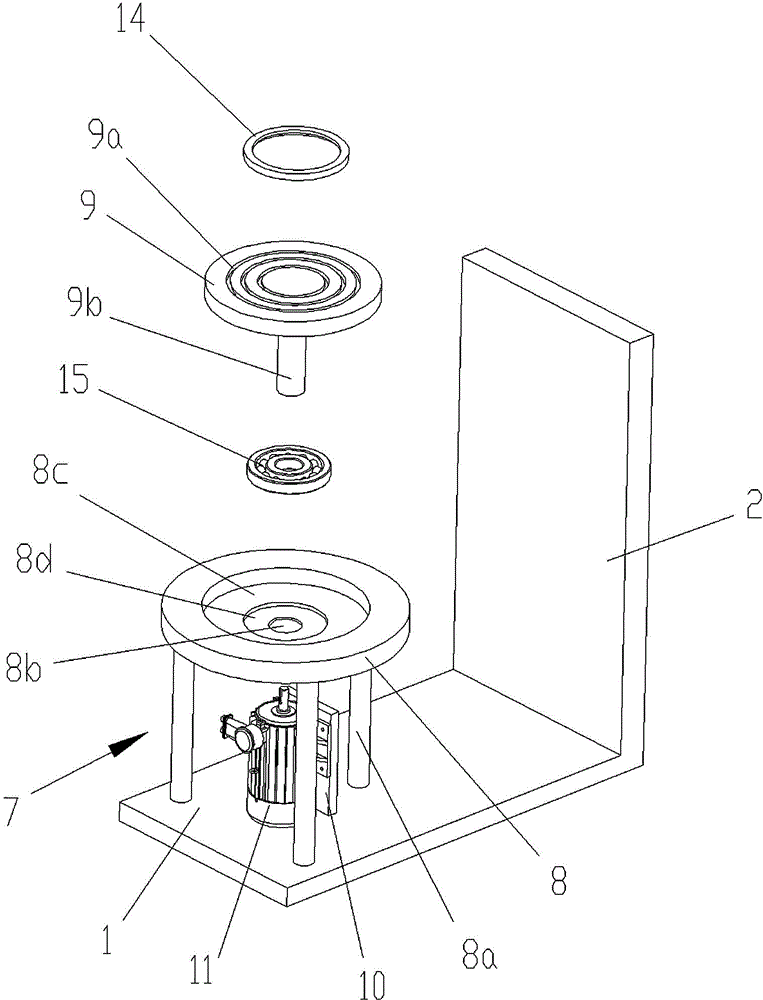

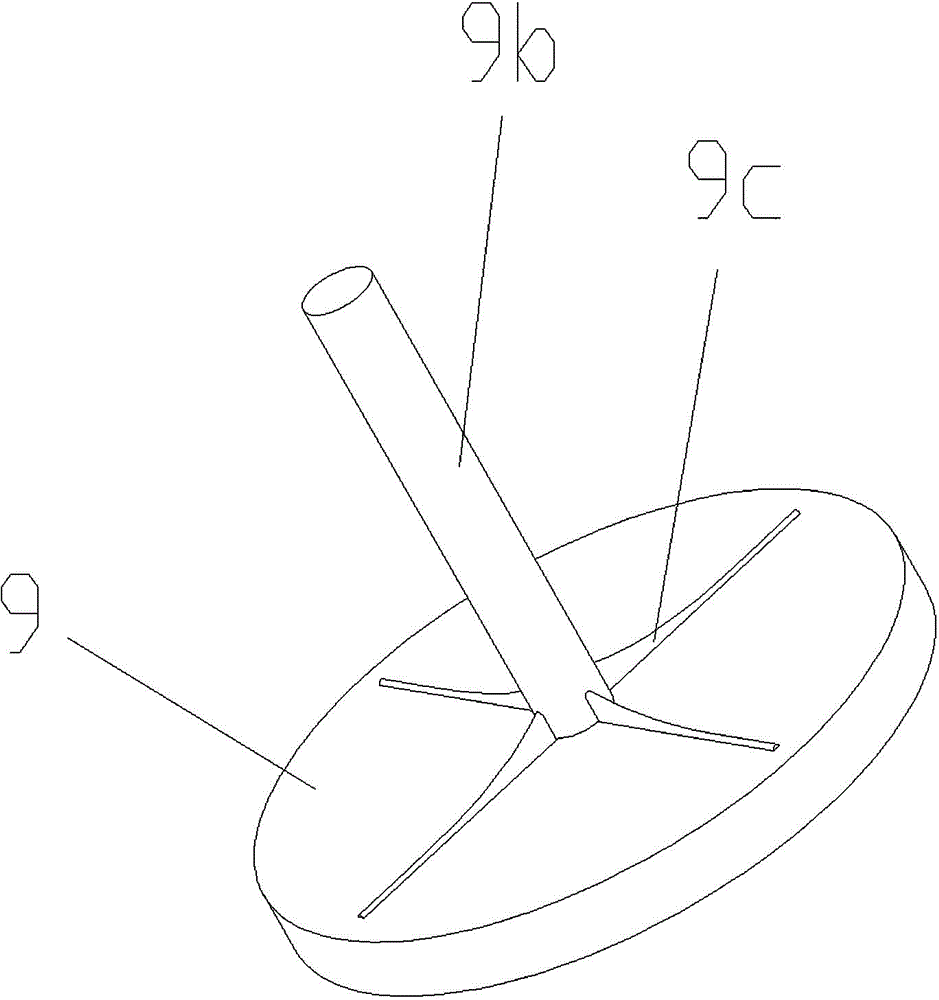

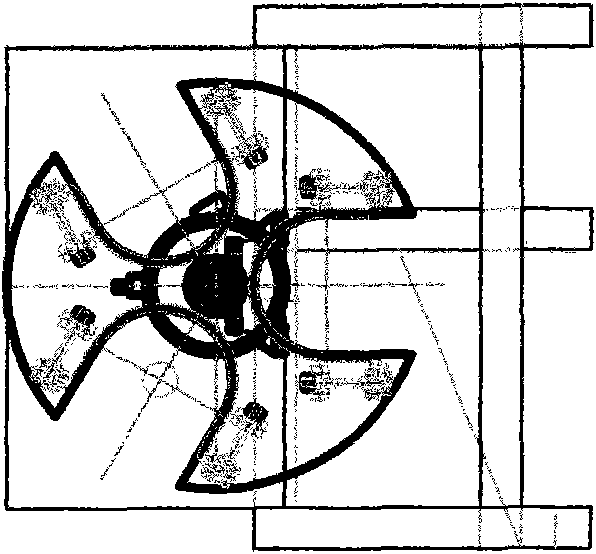

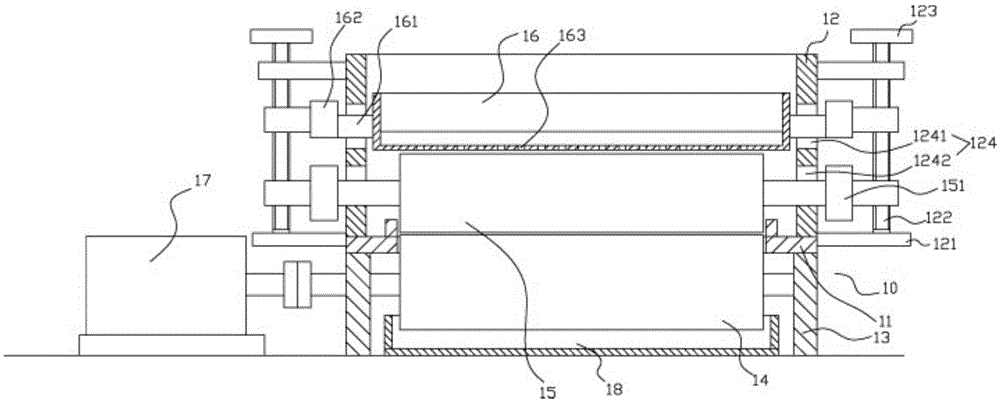

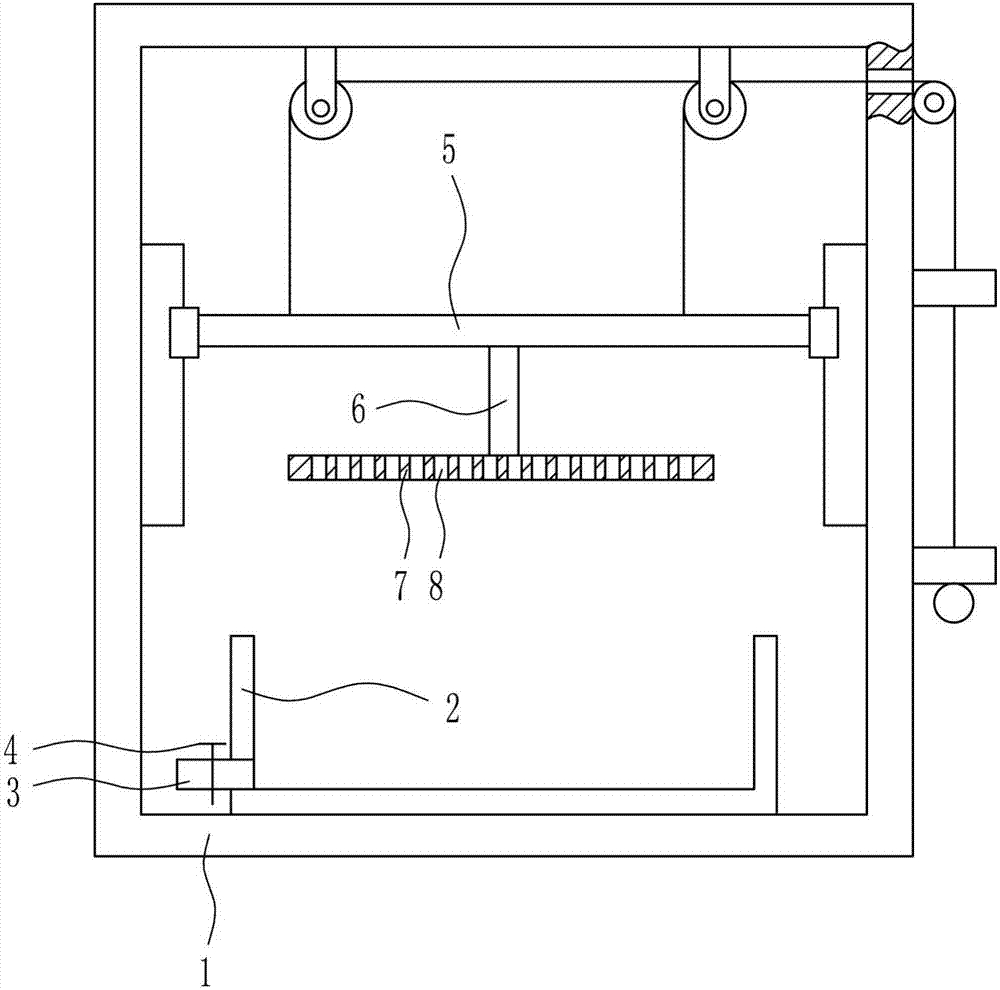

Gluing device for filter upper cover sealing ring

The invention relates to a gluing device for a filter upper cover sealing ring. The gluing device is characterized by comprising a bottom plate (1), wherein a bracket (7) is connected to the bottom plate; a rotating disc (9) is supported and connected to the bracket in running fit; a group of concentric annular grooves (9a) is formed in the rotating disc; a rotating shaft (9b) is arranged on the lower side of the rotating disc; the circle center of the annular grooves is arranged on the axis of the rotating shaft; a motor (11) is arranged below the bracket; an output shaft of the motor is connected with the rotating shaft; a guide seat (3) is fixedly connected to one side of the bottom plate by virtue of an upright plate (2); a sliding plate (4) is slidably connected to the guide seat; and a hairbrush (6) is adjustably connected to the sliding plate by virtue of a connecting piece (5). The gluing device disclosed by the invention has the advantages that the device is simple in structure and low in cost, the filter upper cover sealing ring is clamped in the corresponding annular groove in the rotating disc, the rotating disc is driven to rotate by virtue of the motor, the sealing ring is glued, the gluing speed is high and uniform, and the gluing effect is good.

Owner:来安县永阳知识产权运营有限公司

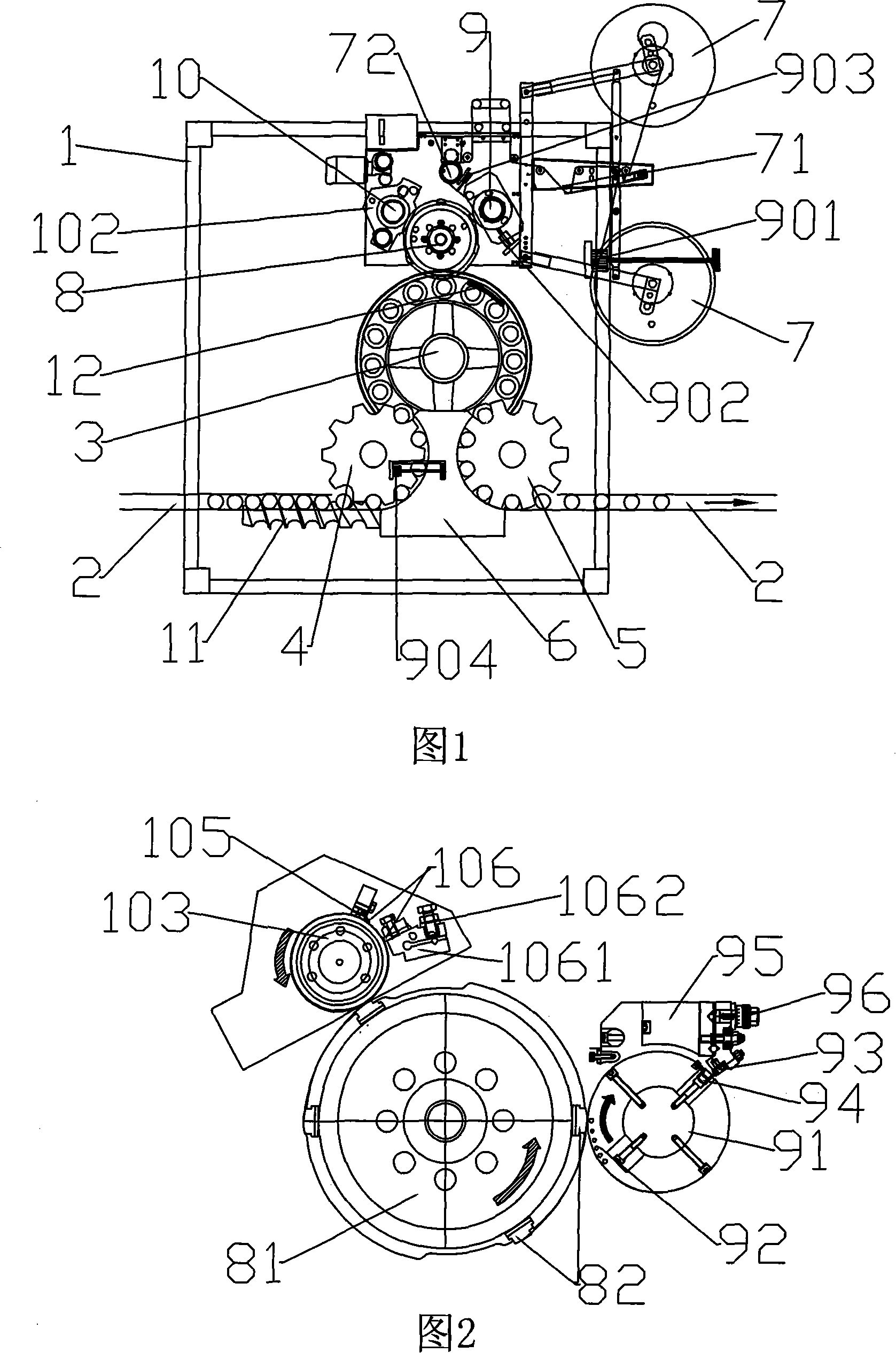

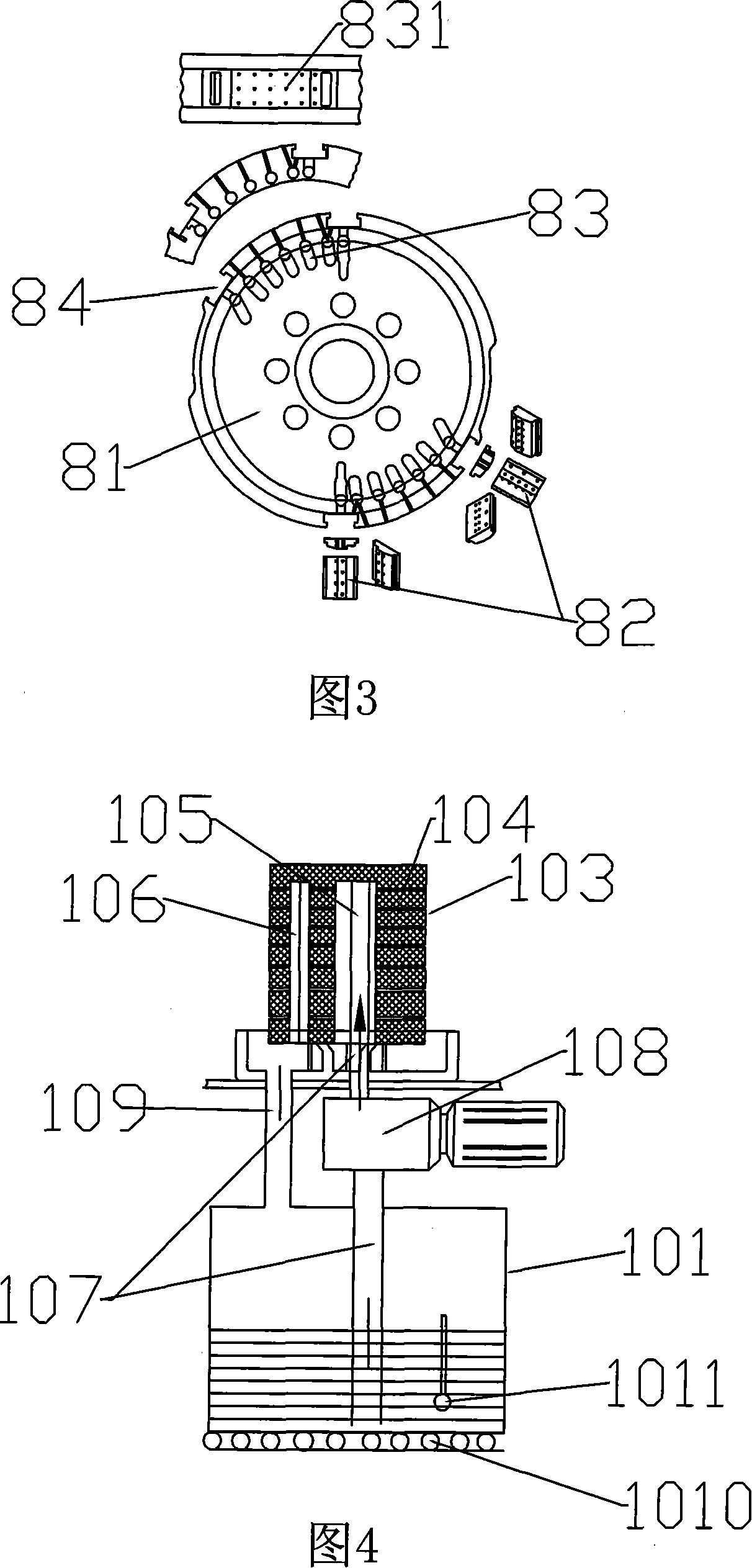

Swinging labeller

InactiveCN101112920ALow costEnsure safetyLabelling machinesLabelling short rigid containersControl systemElectric machinery

The invention discloses a circumgyrate-typed labeling machine which includes a frame, a bottle conveying chain path, a bottle supporting rotary disc device and a label conveying device. The bottle supporting rotary disc device is provided with bottle positions uniformly distributed for package bottle arrangement; the upper part of the bottle supporting rotary disc is provided with a bottle pressing mechanism; the side part of the bottle supporting rotary disc is also provided with a bottle inlet star wheel and a bottle outlet star wheel transmitted with the bottle conveying chain path; a central guide plate is arranged between the bottle inlet star wheel and the bottle outlet star wheel. the invention is characterized in that the label conveying device includes a label disc, a label tightening transmission device, a labeling cam device, a label cutting wheel device arranged at the side part of the labeling cam device and servo motor control systems of powers of all devices. The side part of the labeling cam device is also provided with a hot melting adhesive device. The invention has the advantages of simple operation, convenient maintenance, suitable for all bottle types, fast labeling speed, smooth operation, high production efficiency; the invention can reduce cost and well ensure the safety of the operators when in use.

Owner:广州市万世德智能装备科技有限公司

Honed embossed adhesive tape basilemma and production method thereof

A honed embossed adhesive tape basilemma is made of pure polyolefin resin, the roughness of the front face Ra value is 20-60 mu inch, the roughness of the back face Ra value is 60-200 mu inch, the production method thereof comprises steps of melting and extruding, embossing and finishing. The honed embossed adhesive tape basilemma prepared by the invention has special honed effect, even surface roughness, even thickness stability, good longitudinal and transverse tear resistance, good anti-blocking effect and excellent gluing effect. The method of the invention does not change the inner structure of the basilemma material, thus not influencing the physical performance of the basilemma material, and being applicable to production of honed embossed adhesive tape basilemma and production of honed basilemma for other special uses.

Owner:湖北慧狮塑业股份有限公司

Gluing device for conductive aluminum foil tape processing

InactiveCN110586410AAffecting workAffect the coating effectPretreated surfacesCleaning using toolsEngineeringAluminum foil

The invention discloses a gluing device for conductive aluminum foil tape processing. The device comprises a box body. A supporting plate is arranged on the outer wall of one side of the box body. A winding roller is arranged on the outer wall of the top of the supporting plate. An aluminum foil tape body is wound around the outer wall of the winding roller. A storage box is arranged on the outerwall of the top of the box body. A corrugated pipe is inserted into the outer wall of one side of the storage box. A second electric push rod is arranged on the inner wall of the top of the box body.A second mounting plate is arranged on the outer wall of one end of the second electric push rod. A second fixing plate is arranged on the outer wall of the bottom of the second mounting plate. A gluing roller is arranged on the outer wall of one side of the second fixing plate. According to the gluing device for conductive aluminum foil tape processing, glue in the storage box is sprayed out froma spray head and flows out from a glue outlet hole, meanwhile, the second electric push rod is started, the second electric push rod drives the gluing roller to tightly press the aluminum foil tape body for gluing, and the gluing effect of the device on the aluminum foil tape is improved.

Owner:湖北富和冠电子材料有限公司

Equipment and process for industrially producing containers by using moso bamboo

InactiveCN102126238AImprove the utilization rate of rotary cuttingSmooth feedingPlywood pressesVeneer pressesThermal insulationAgricultural engineering

The invention discloses equipment and a process for industrially producing containers by using moso bamboo. The equipment comprises a moso bamboo cutter, a moso bamboo joint beating machine for beating internal joints of segment bamboo, a high-temperature segment bamboo softening container, a segment bamboo washing device, a segment bamboo thermal insulation device, a precision moso bamboo rotarycutter for rotationally cutting the segment bamboo, a bamboo sheet length control device, a bamboo sheet drying machine for drying bamboo sheets, a double-sided gluing machine for coating glue on thebamboo sheets, and a bamboo sheet hot-press section forming machine. The process comprises the following steps of: cutting the moso bamboo, beating the internal joints of the segment bamboo, softening the segment bamboo at high temperature, washing the segment bamboo, performing thermal insulation on the segment bamboo, rotationally cutting the segment bamboo into the bamboo sheets, drying the bamboo sheets, coating glue on the bamboo sheets, hot-pressing a plurality of bamboo sheets coated with the glue to obtain bamboo sheet sections meeting the requirements on thickness and dimension, and respectively moulding the bamboo sheet sections in a square container moulding mould, a bamboo sheet cylindrical container moudling mould and a once-setting mould for moulding containers to obtain square containers, cylindrical containers, round or square discs and the like without abutted seams.

Owner:三明市柏毅竹业技术开发有限公司

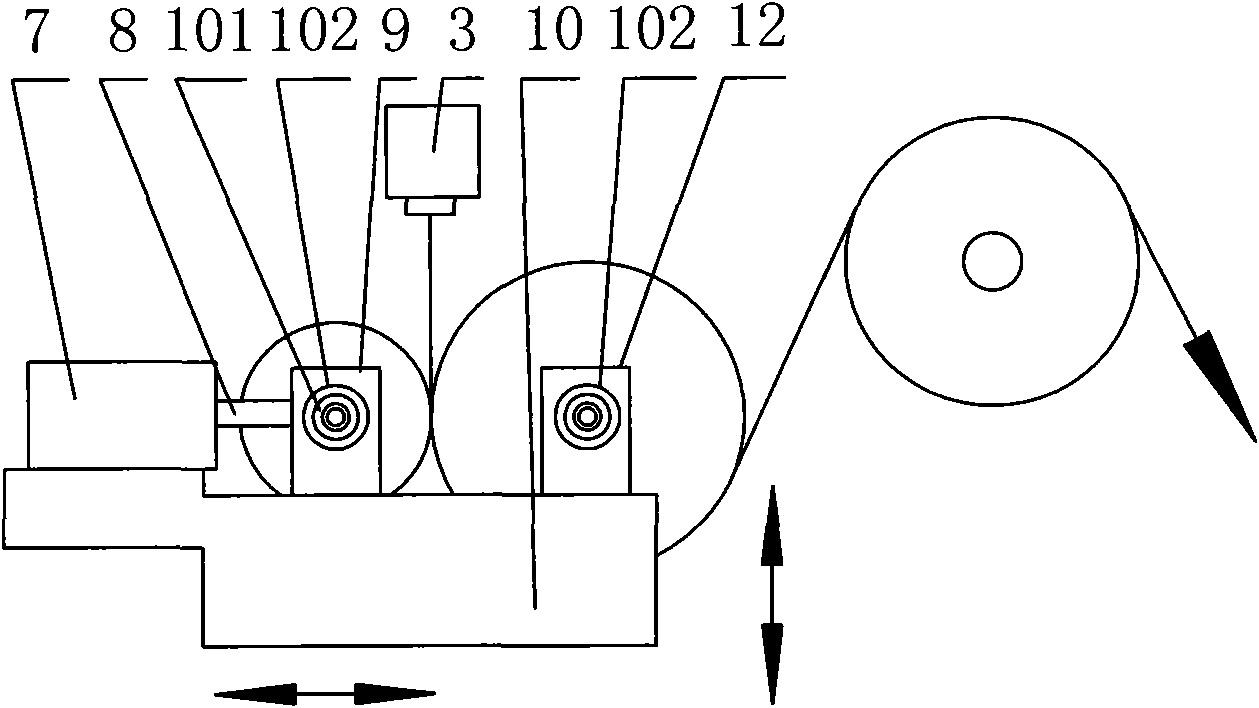

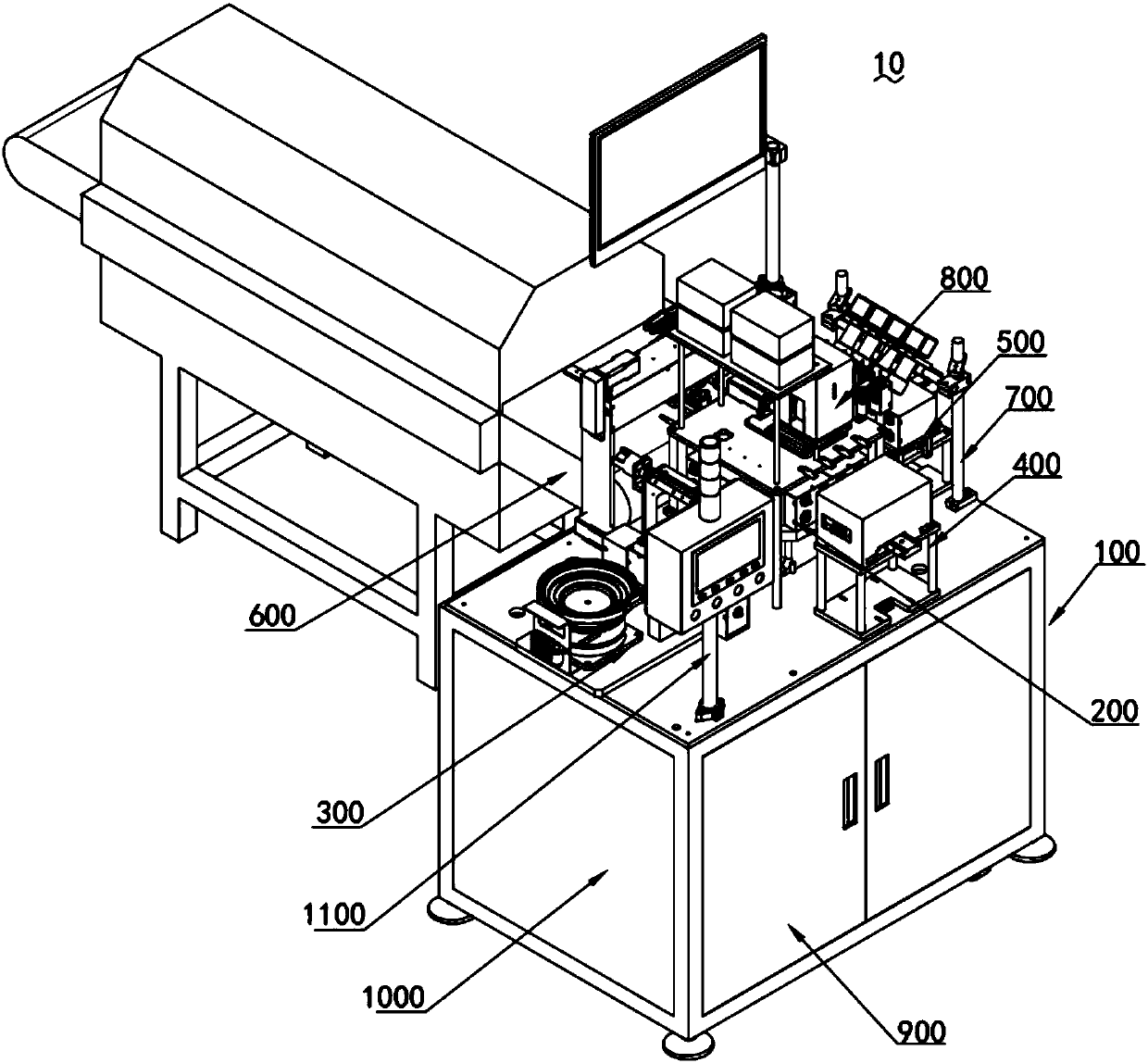

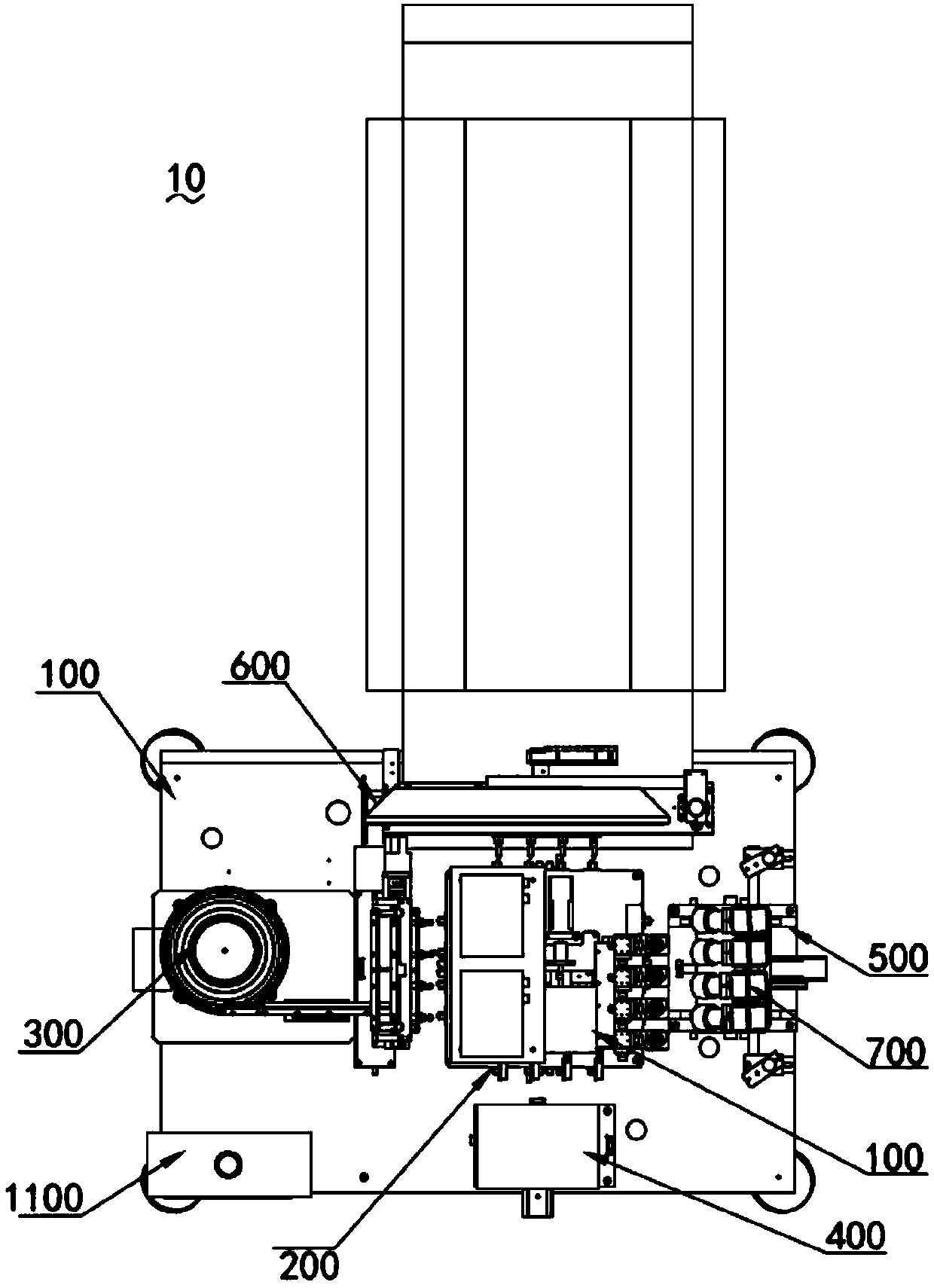

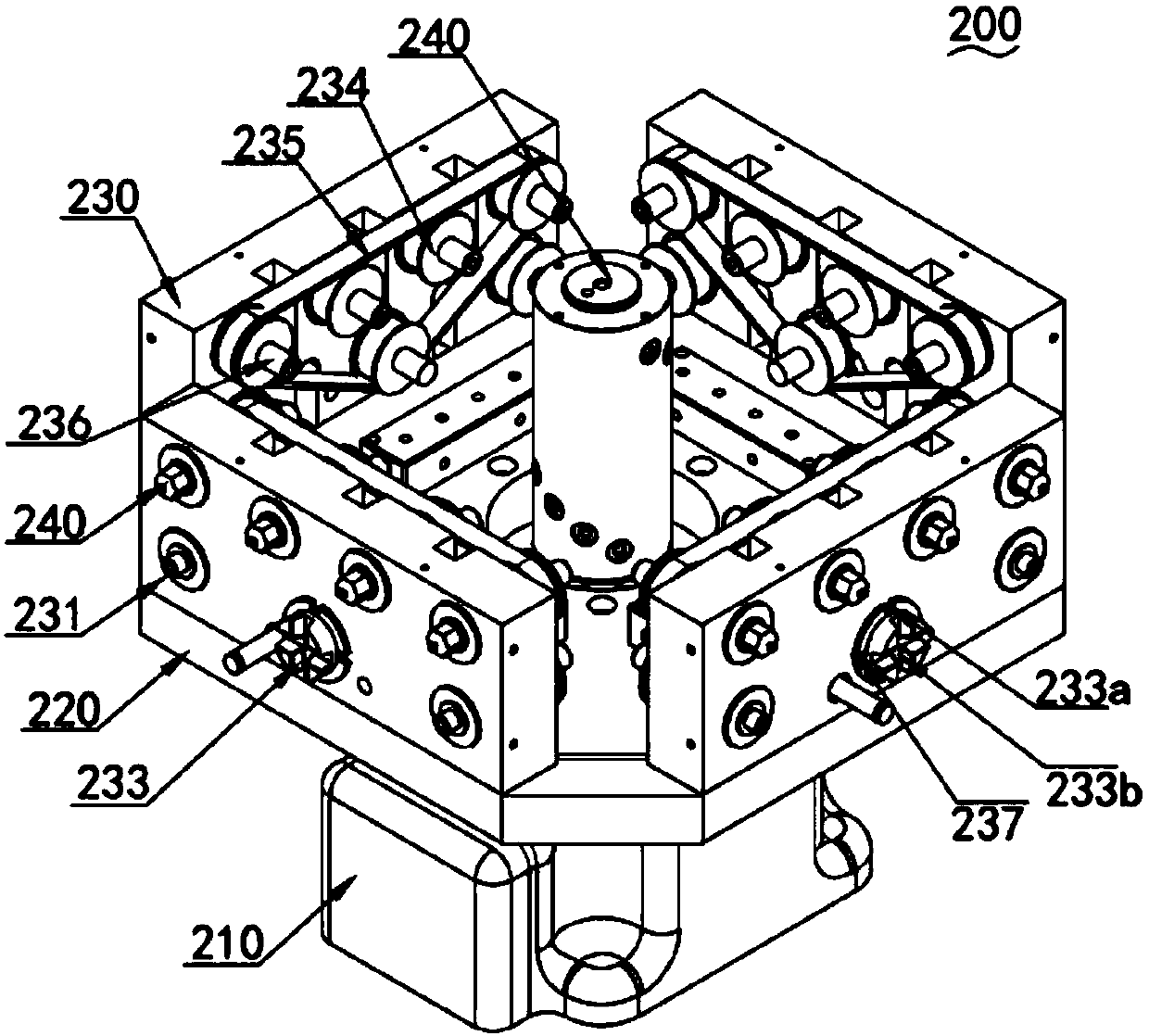

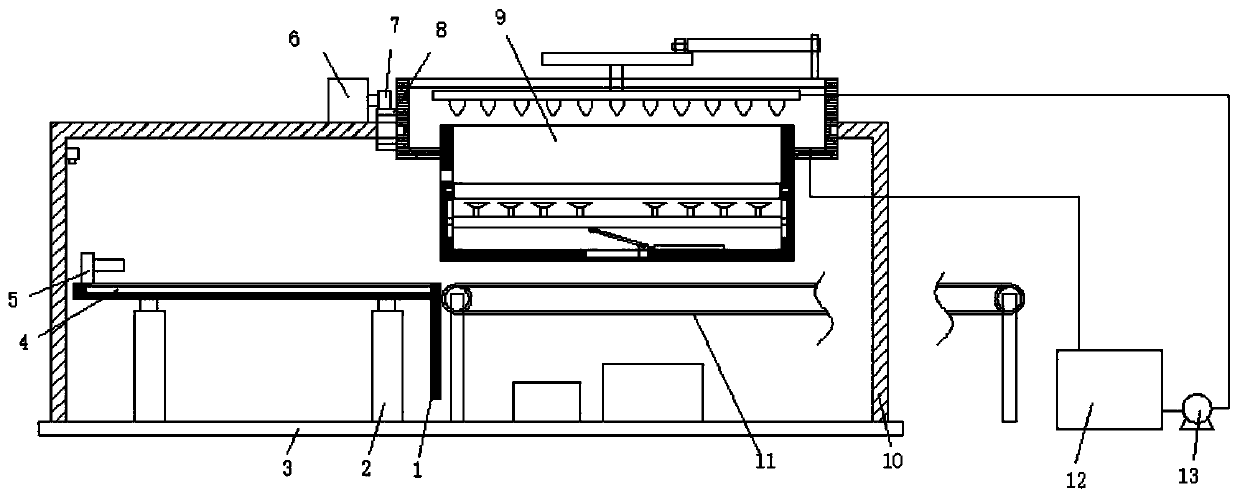

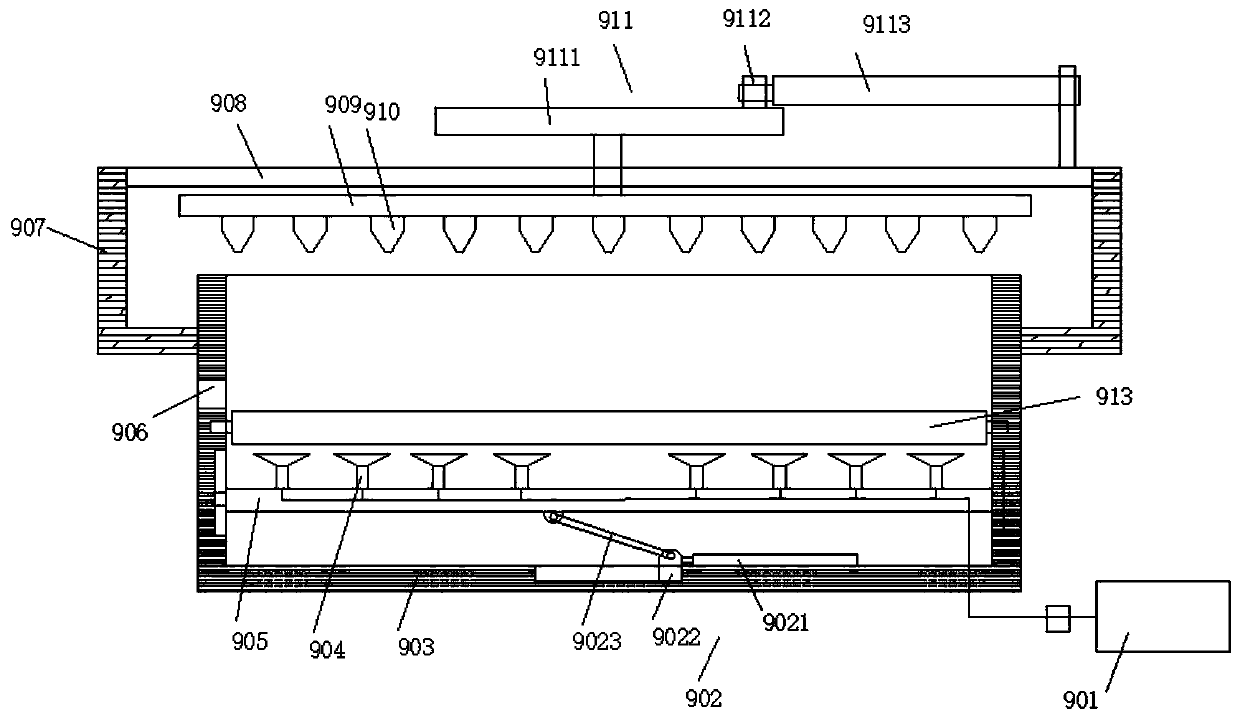

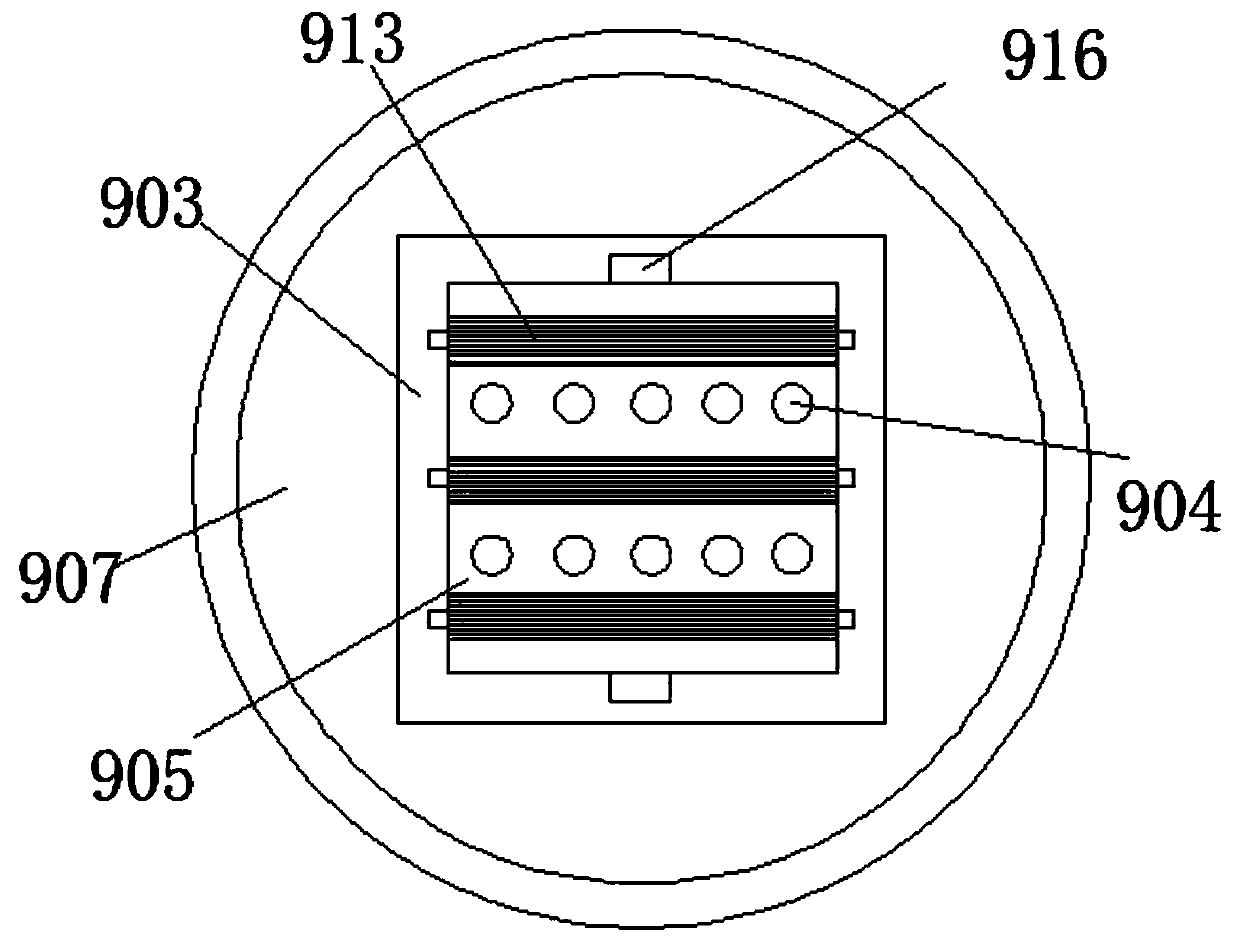

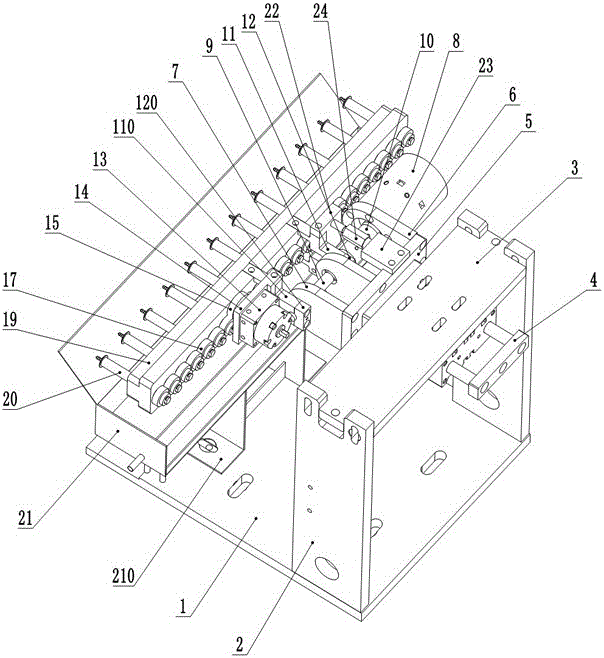

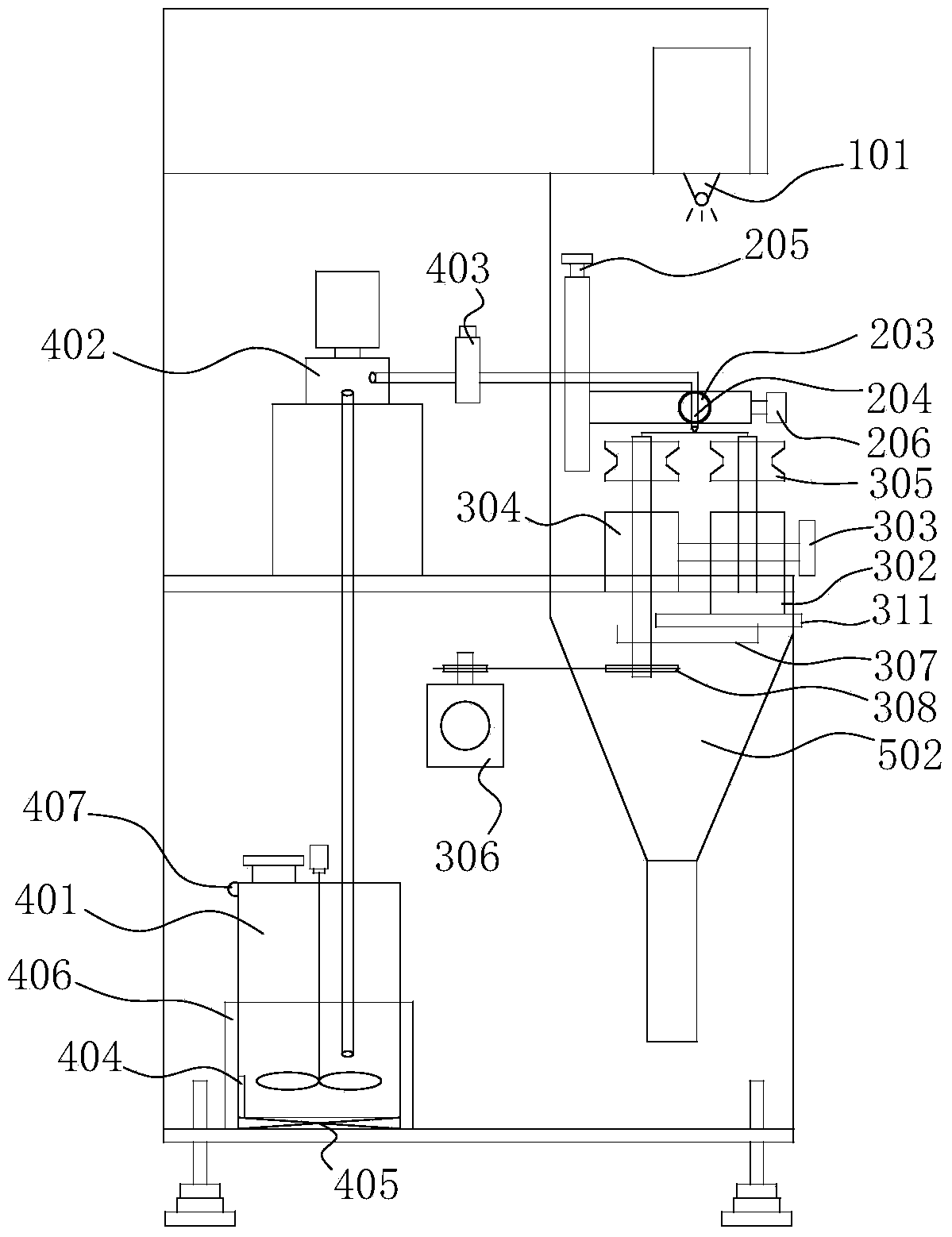

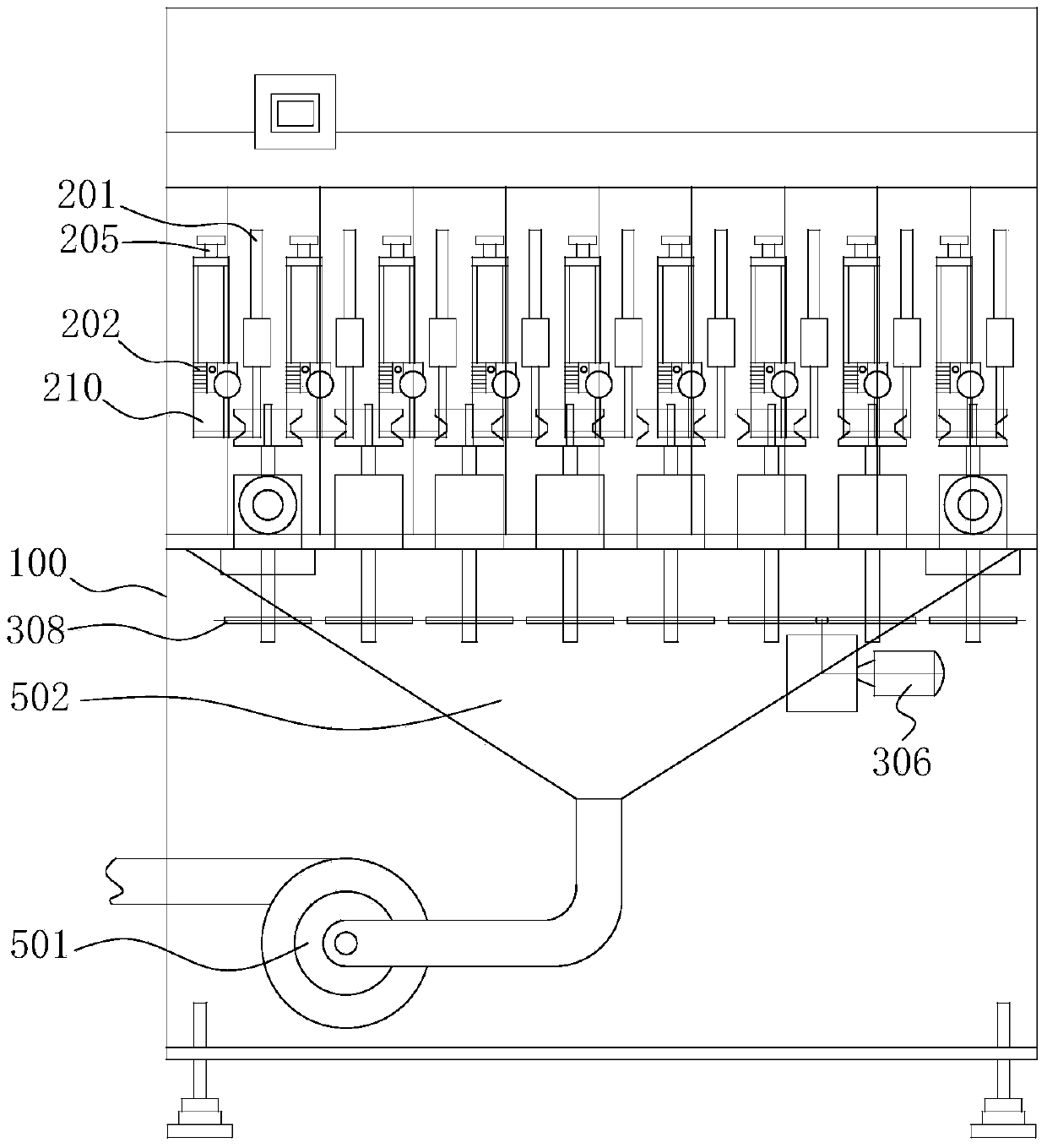

Electronic element high-efficiency vacuum gluing equipment

PendingCN107742573AImprove gluing qualityEasy to absorb and grabEncapsulation/impregnationElectricityEngineering

The invention relates to the technical field of electronic element gluing, and particularly relates to electronic element high-efficiency vacuum gluing equipment, which comprises a rack, a turntable mechanism, a loading mechanism, a positioning mechanism, a rotating mechanism, an unloading mechanism, a detecting mechanism, a gluing mechanism, a vacuum mechanism, an electric control mechanism and acontrol mechanism, wherein the turntable mechanism is arranged on the rack; the loading mechanism, the positioning mechanism, the rotating mechanism and the unloading mechanism are arranged on the rack and around the turntable mechanism; the detecting mechanism is fixed on the rack and above the rotating mechanism; the gluing mechanism is mounted on the rack and above the turntable mechanism; thevacuum mechanism and the electric control mechanism are arranged in the rack; the control mechanism is connected with the electric control mechanism and is fixed on the rack; the vacuum mechanism isconnected with the loading mechanism, the unloading mechanism and the turntable mechanism; the electric control mechanism is electrically connected with the turntable mechanism, the loading mechanism,the positioning mechanism, the rotating mechanism, the unloading mechanism, the vacuum mechanism and the control mechanism. The equipment provided by the invention has the advantages of full-automatic overall operation, high gluing quality of electronic elements, high gluing efficiency and high automation degree.

Owner:DONGGUAN TB ELECTRONICS TECH CO LTD

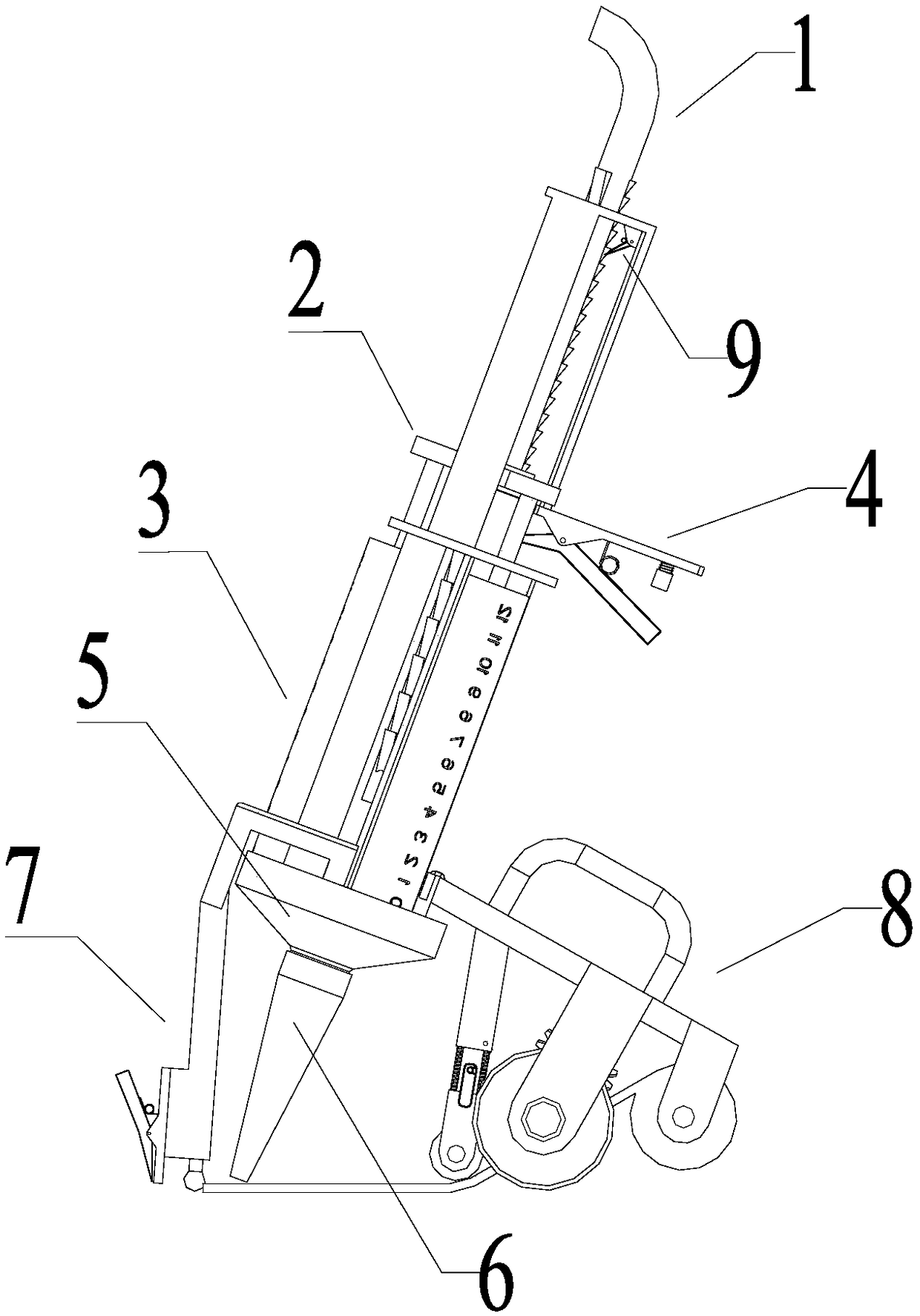

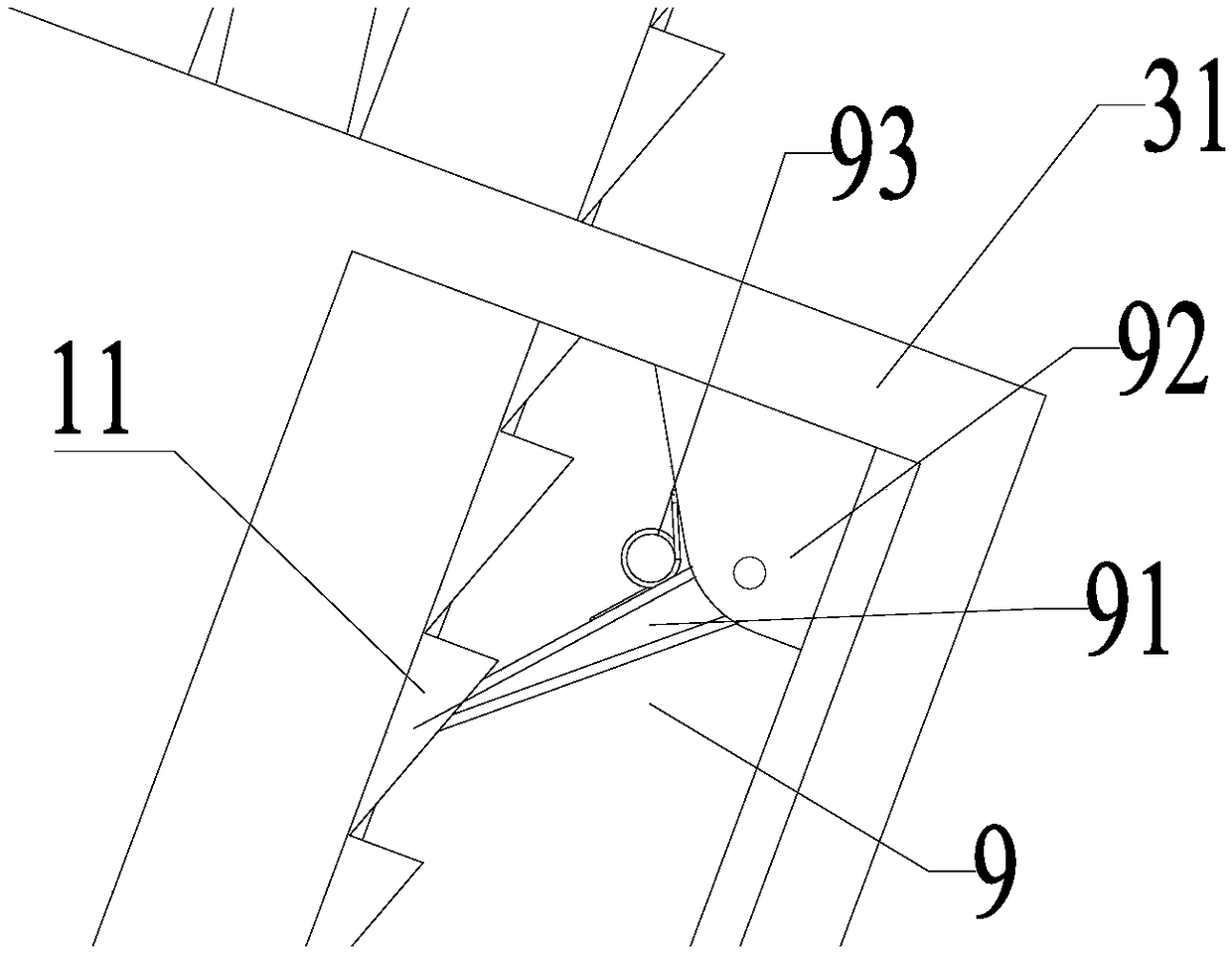

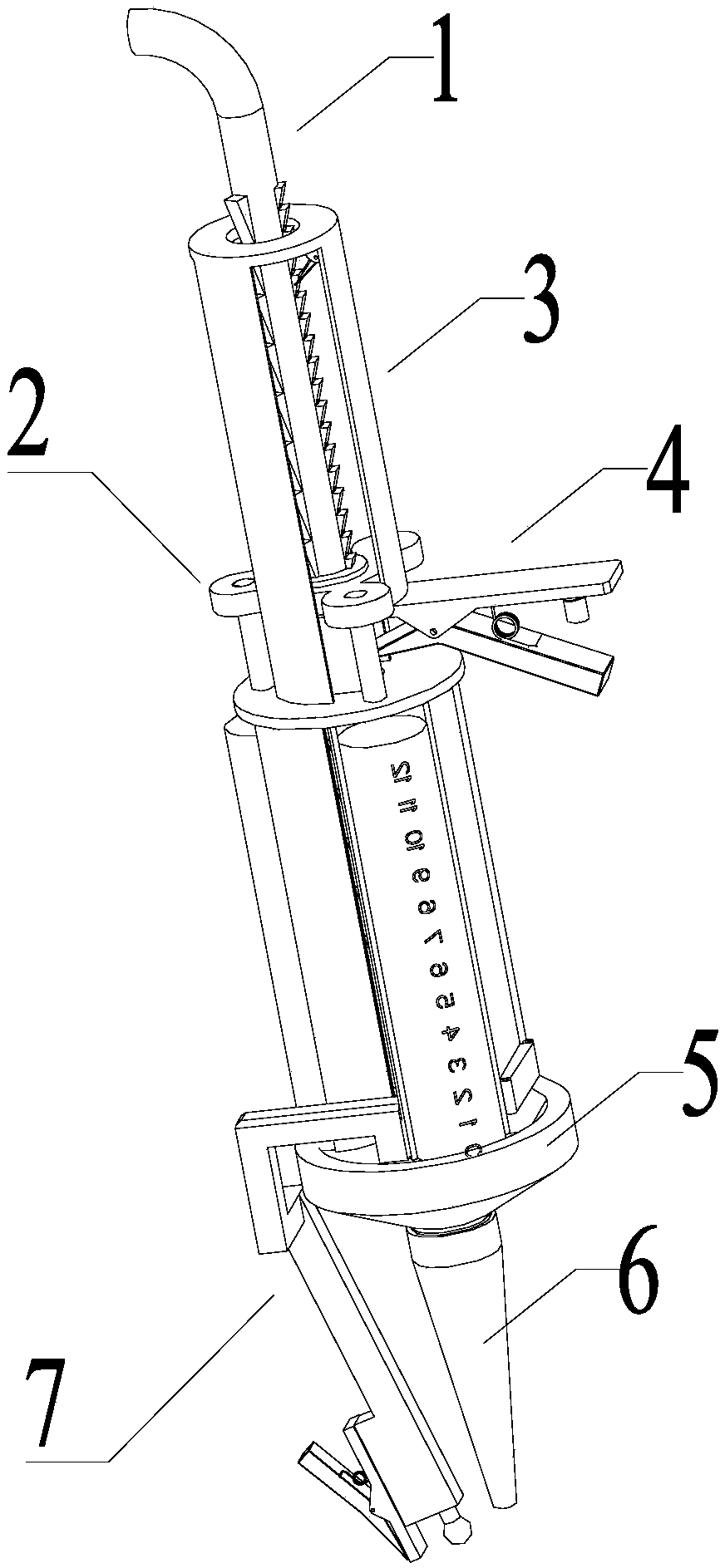

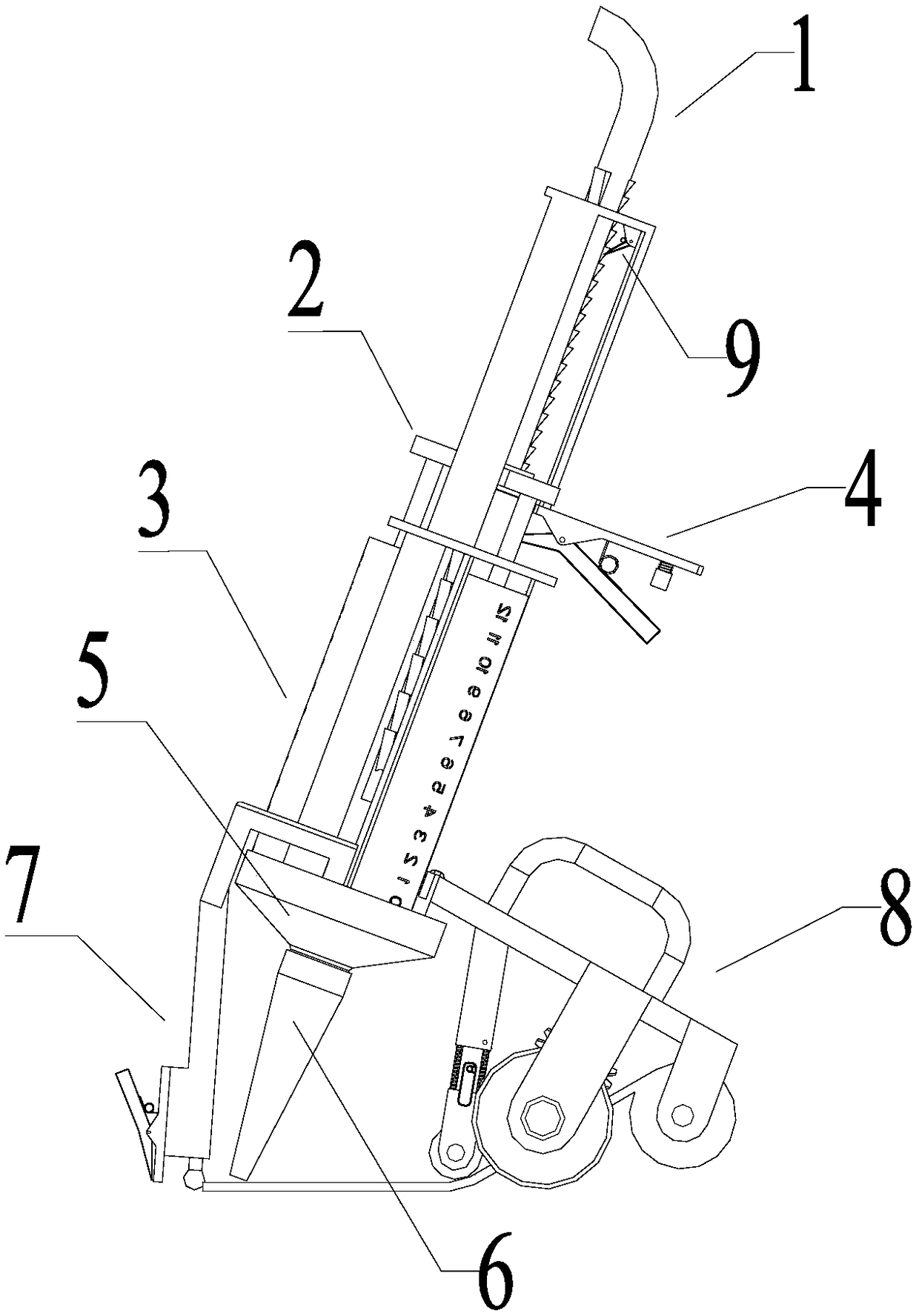

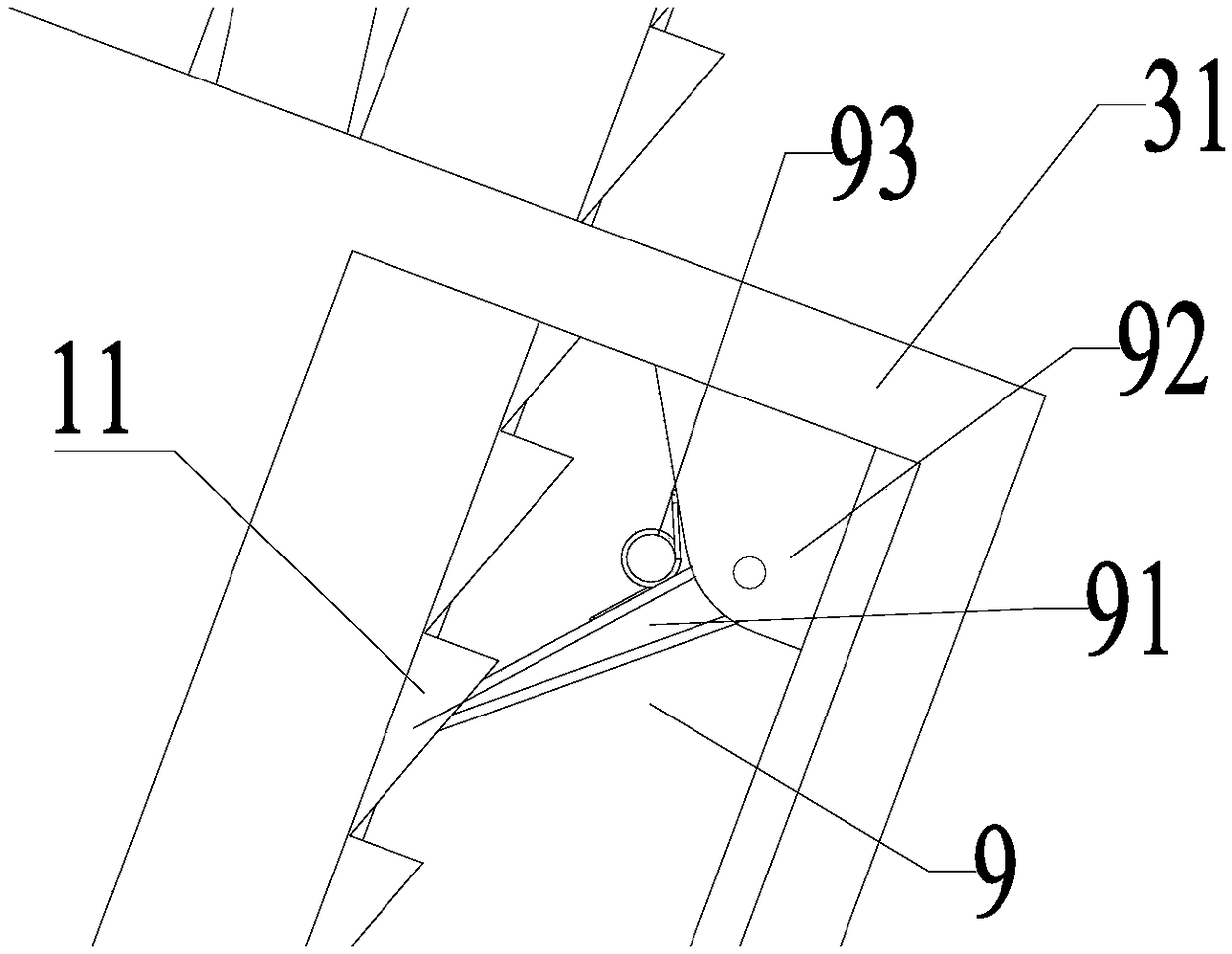

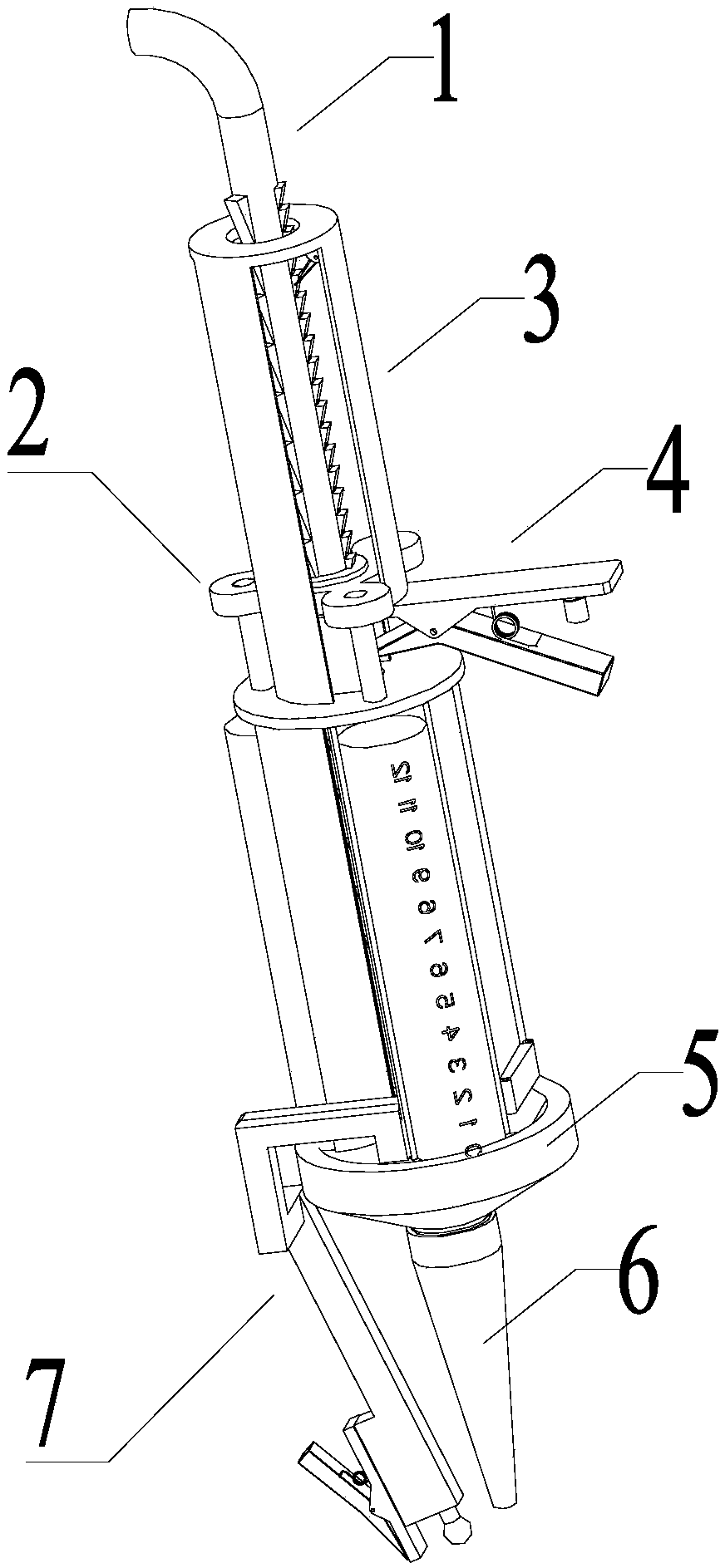

Beautifying seam glue feeding device for building decoration

ActiveCN108930395AReduce the frequency of glue replacementGood gluing effectBuilding constructionsEngineeringNozzle

The invention discloses a beautifying seam glue device for building decoration. The beautifying seam glue device includes a pull rod with teeth (1), a glue pushing device (2), a glue gun frame (3), apressing device (4), a reducing threaded sleeve (5), a glue nozzle (6) and a beautifying seam glue processing device (7). The glue pushing device (2) is arranged on the glue gun frame (3) and can movecorresponding to the glue gun frame (3). The beautifying seam glue processing device (7) is arranged on the glue pushing device (2). The pressing device (4) is fixedly arranged on the glue gun frame(3) and arranged corresponding to the pull rod with teeth (1). The public novel structural glue gun can reduce the change frequency and enable the gluing effect better, construction is performed in the flat surface, a textured paper pasting device can be used, so that the construction quality is improved, the glue gun can install a seam pressing ball, gluing is carried out, at the same time, the seam pressing ball automatically slip off a groove, the seam pressing ball can change the seam pressing ball in different size according to the size of gap of beautifying the seam.

Owner:梁山鑫航建筑装饰工程有限公司

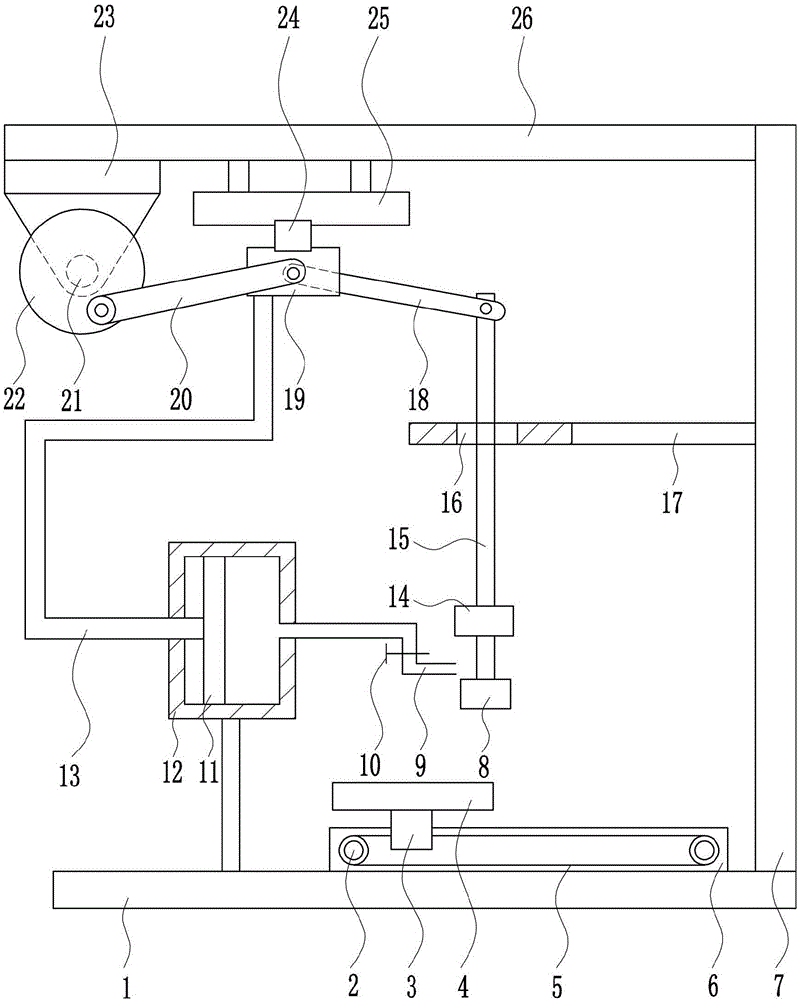

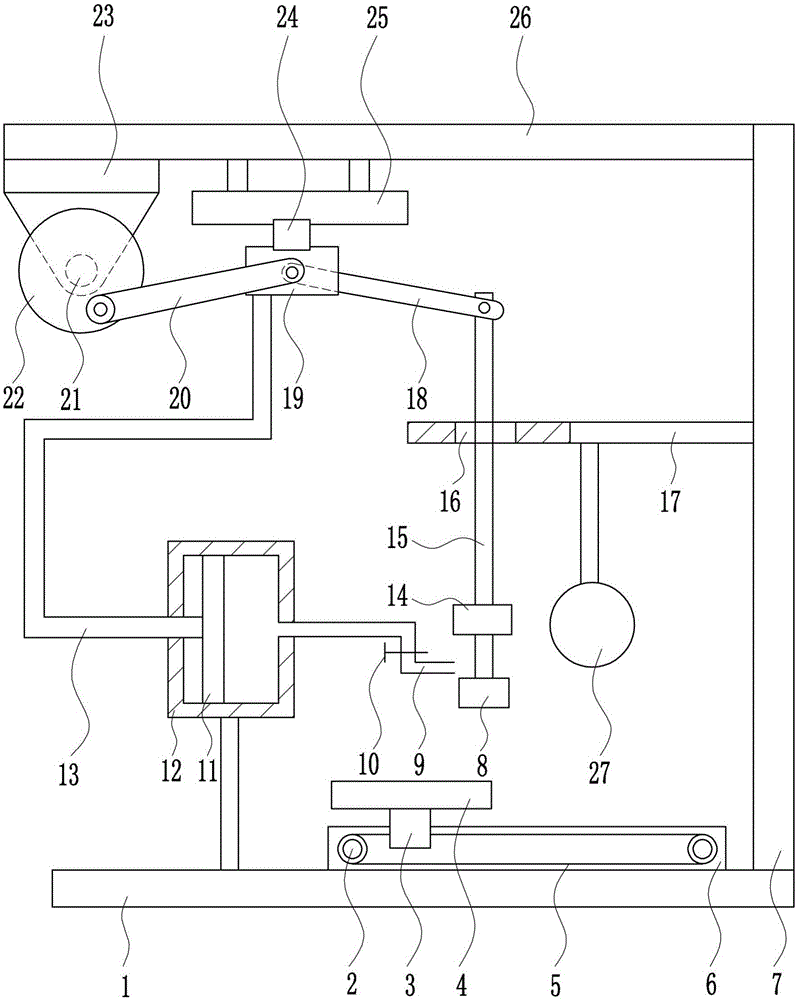

Shoemaking gumming device

InactiveCN106108264APrevent sliding left and rightFully gluedShoe gluingMechanical engineeringPiston

The invention relates to a gumming device, in particular to a shoemaking gumming device, and aims to provide the shoemaking gumming device being accurate in gumming position, comprehensive in gumming, and visual enough for observation. The shoemaking gumming device comprises a left bracket, an accommodating rack, a first slider, a stay wire, a first slide rail, an electric reel, a right bracket, a second slide rail, a third slider, a third slide rail, a first electric push rod, a fifth connecting rod, a supporting seat, a top plate, a fourth connecting rod, a cylinder, a fixing plate, a swing rod, a piston, a cylinder body, a third connecting rod, a second connecting rod, a first connecting rod, a pressing block, a second slider, a lifting rod and a bottom plate. The shoemaking gumming device has the effects of being accurate in gumming position, comprehensive in gumming, and visual enough for observation; being fast in gumming speed, reasonable in design, and convenient to use, the shoemaking gumming device is highly practical.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

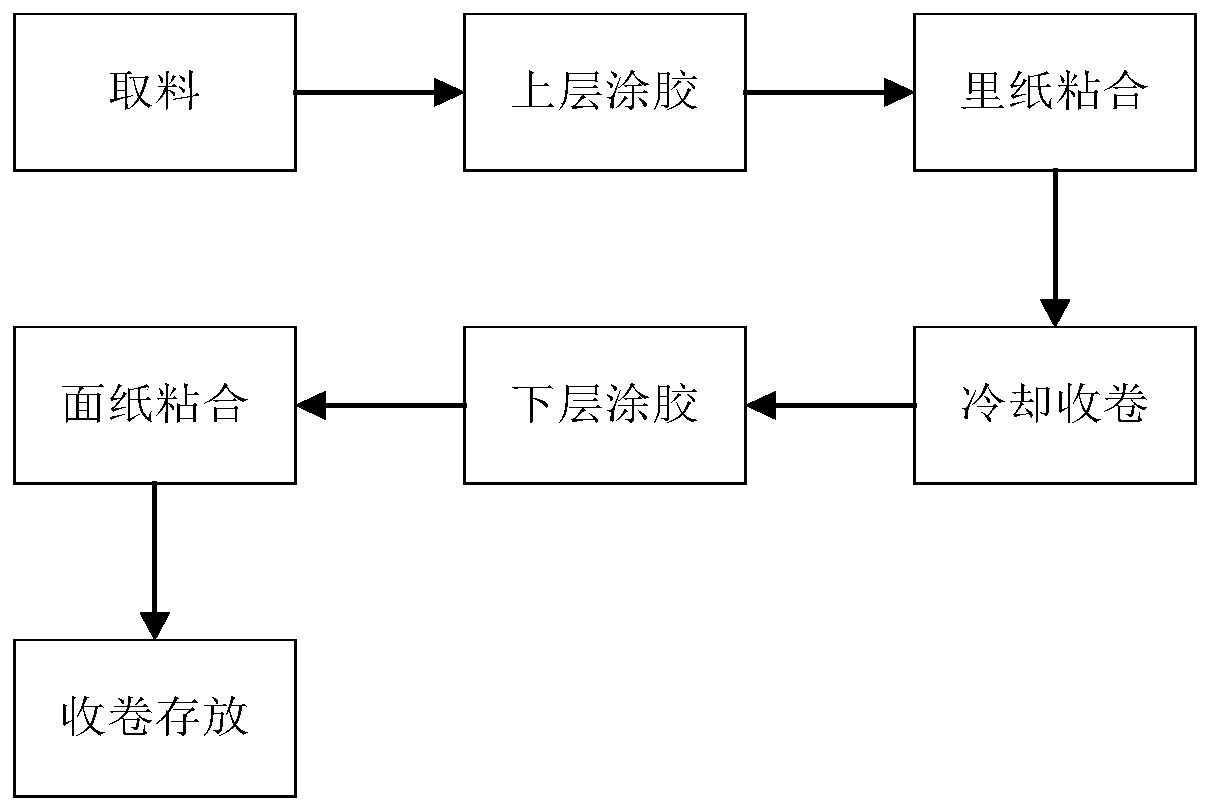

Printing packaging corrugated paper production method

ActiveCN110116519AImprove gluing effectIncrease productivityLiquid surface applicatorsMechanical working/deformationPaper productionPulp and paper industry

The invention relates to a printing packaging corrugated paper production method. A mounting frame, a conveying belt and a gluing device are included, the mounting frame is of a U structure, the conveying belt is arranged on the lower end in the mounting frame, the gluing device is arranged on the upper end in the mounting frame, the gluing device is located in the middle of the upper end of the conveying belt, the problems that when existing corrugated paper is produced, efficiency is low, quality is poor, existing market needs cannot be met, when a corrugated paper core is glued, when the corrugated paper core is stressed, deforming or damage is prone to happening, meanwhile, during gluing, glue coating is not uniform, and glue waste is easily caused are solved, and the advantages of being good in gluing effect, high in production efficiency, and capable of gluing the corrugated paper convex face evenly and effectively reducing the glue waste are achieved.

Owner:汕头市柏瑞纸品包装厂有限公司

Device for panting sewing glue used in building decoration

InactiveCN109057271AReduce the frequency of glue replacementImprove gluing effectBuilding constructionsEngineeringSmooth surface

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

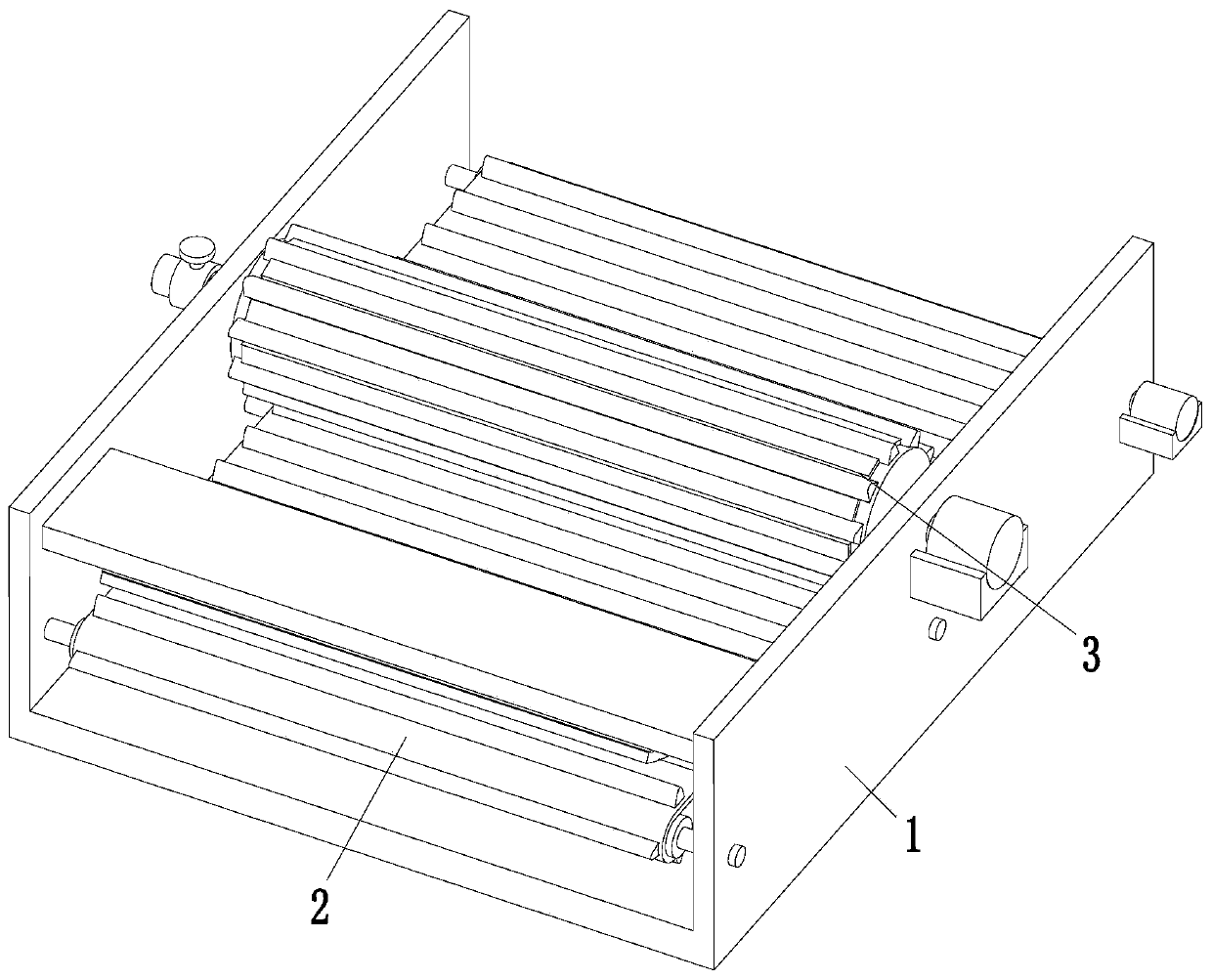

Efficient gluing device for plywood

InactiveCN110027066AApply glue evenlyGood gluing effectGlue gunsLoading/unloadingEngineeringAutomation

The invention belongs to the field of plywood processing, and particularly relates to an efficient gluing device for plywood. The efficient gluing device for the plywood aims to solve the problems that an existing gluing device is not uniform in gluing, and automatic feeding and discharging cannot be realized. The device comprises a base, a feeding conveying belt, a supporting frame and a gluing mechanism, wherein a plurality of first telescopic rods are fixed at one end of the base, and the output shaft of the first telescopic rods are connected with a feeding plate with an L-shaped verticalsection; a mounting groove is formed in the top end of the feeding plate, and a rodless air cylinder is arranged in the mounting groove; the output shaft of the rodless air cylinder is connected witha material pushing plate slidably connected to the top end of the feeding plate, one end of the feeding plate is provided with the feeding conveying belt, and one end of the feeding conveying belt isarranged on the base; the upper end face of the feeding conveying belt and the upper end face of the feeding plate are located on the same plane, and a gluing mechanism positioned on one side of the feeding plate is arranged above the feeding conveying belt; according to the device, the automation degree is high, the automatic feeding and discharging of plates can be realized, the gluing is uniform, and the gluing effect is good.

Owner:融安县华荣木业有限公司

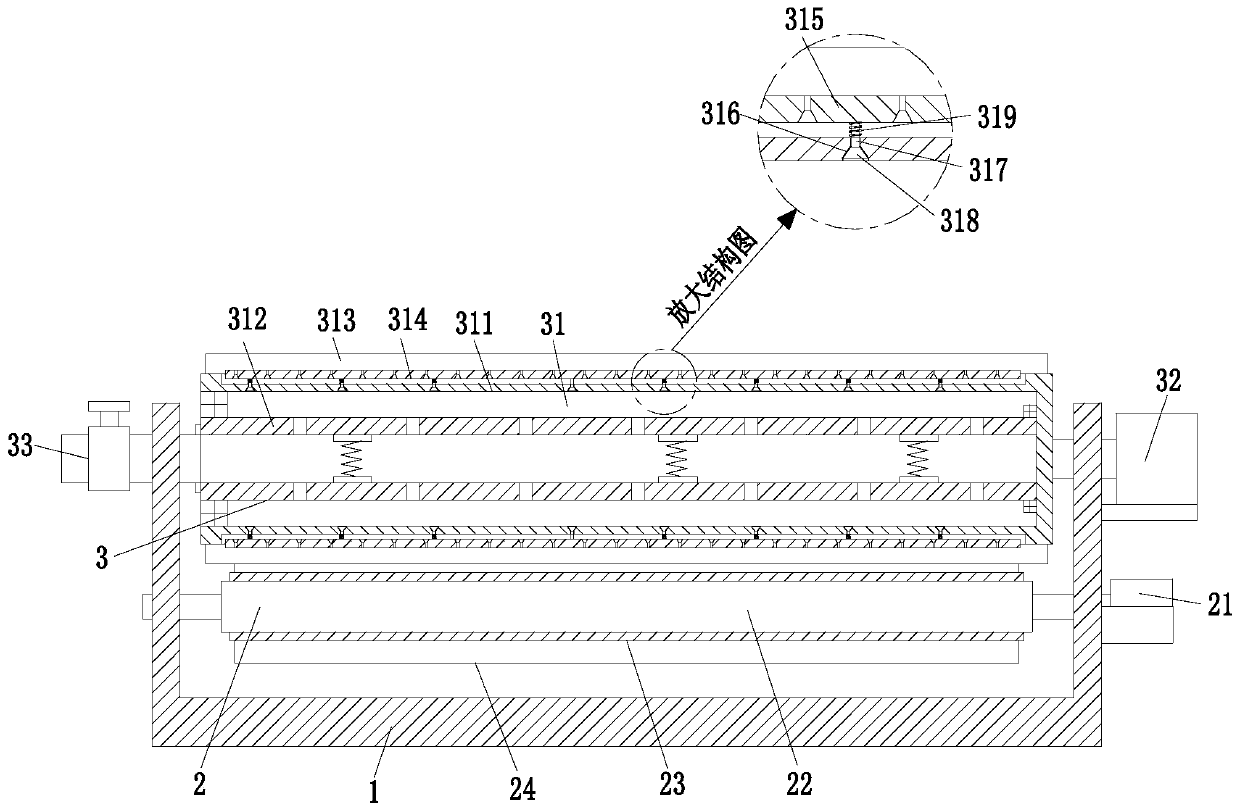

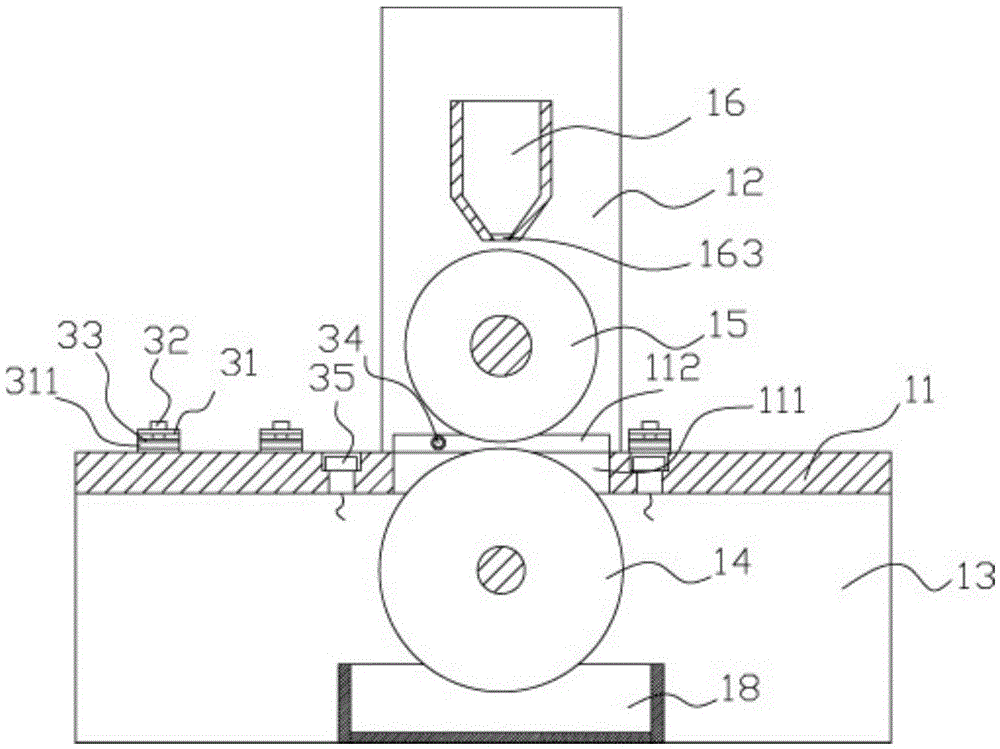

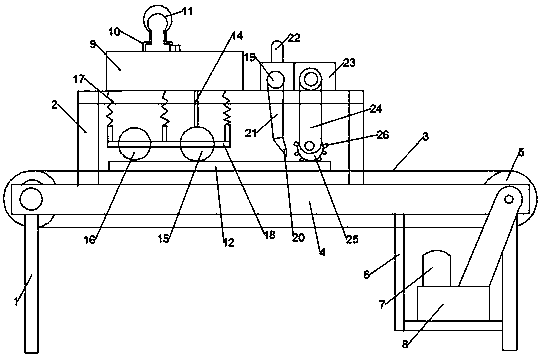

Paperboard gluing machine with automatic clamping and conveying mechanism

ActiveCN105478297AImprove gluing effectImprove efficiencyLiquid surface applicatorsCoatingsPaperboardPulp and paper industry

The invention discloses a paperboard gluing machine with an automatic clamping and conveying mechanism. The paperboard gluing machine comprises a rack. Two vertical plates are fixed to the top faces of the two sides of a platen of the rack. Supporting plates are fixed to the bottom faces of the two sides of the platen. The two ends of a lower transmission press roller are hinged to the two supporting plates. The lower transmission press roller is inserted in a long through hole in a sleeved manner, and the long through hole is formed in the middle portion of the platen. Two limiting strips are fixed to the top faces of the parts, at the front end and the rear end of the long through groove, of the platen. Connecting plates are fixed to the upper portions and the lower portions of the outer side walls of the vertical plates. The two ends of adjusting screws are hinged to the two connecting plates. The upper ends of the adjusting screws stretch out of the connecting plate at the upper portion and are fixedly provided with rotary tables. Synchronous ascending and descending of an upper transmission press roller and a gluing groove can be achieved, even gluing is guaranteed, and the gluing effect is improved. Meanwhile, the paperboard gluing machine can automatically clamp a paperboard and convey the paperboard to the part between two transmission rollers to achieve gluing, automatic pulling out and conveying, and the paperboard gluing machine is high in efficiency and good in effect.

Owner:江苏捷飞环保科技有限公司

Automatic gluing mechanism

ActiveCN105709997AAvoid getting out of controlImprove pass rateLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:YANTAI KAIBO AUTOMATION TECH

Spunlace non-woven fabric composite filter material and manufacturing method thereof

ActiveCN101804274AEasy to fold and shapeEasy to glueSynthetic resin layered productsLaminationWoven fabric compositeComposite filter

The invention discloses a spunlace non-woven fabric composite filter material and a manufacturing method thereof. The manufacturing method of the composite filter material comprises the following steps that: spunlace non-woven fabric which is obtained after the starching treatment is unwound, the surface of the spunlace non-woven fabric is coated, the coat is of oil-based polyurethane with the solid content of 30 to 75 percent, polyfluortetraethylene film is smoothed by a hot ironing roller after being unwound, the spunlace non-woven fabric and the polyfluortetraethylene film are compounded through the compression of pressing rolls, the pressure of the pressing roll is 3 to 10 kg, at the same time the composite material is heated and dried, the drying temperature is 70 to 170 DEG C, and the composite material is rolled to form the finished product after the compounding. Finally the filter material which is formed by compounding the spunlace non-woven fabric and the polyfluortetraethylene film is obtained, the base weight of the composite product is 102 to 258 g / m2, the filter resistant force is 40 to 280 Pa, the filter efficiency is 85 to 99.995 percent, and the stiffness is 1500 to 4500 mg. The filter material has low filter resistant force and high filter efficiency, is easy to fold and for, and can be made into different filters with different shapes.

Owner:杭州路先非织造股份有限公司

Glue-coating device used for folding machine and its glue-coating method

InactiveCN101125322ASimple structureLow costLiquid surface applicatorsCoatingsTransmission beltDrive shaft

The present invention discloses a gluing device for a paper folding machine and the gluing method of spraying glue at the position of paper folding and banding, which belongs to the banding industry. The device comprises: a transmission belt and a transmission shaft of the transmission mechanism of the paper folding machine, and the device further includs: an input unit, a programmable controller(3), a rotating coder(1) contacted with the transmission shaft, and a gluing head(4) and a photoelectrical sensor(8) arranged at the top of the transmission belt. The gluing method comprises: a continuous method of coating a section of glue or glue with different length on the workpiece along a straight line, or a pulsation method of coating a plurality of sections of glue with same length and same discontinuous distance on the workpiece along the straight line. The device has a simple structure, adopts common components mostly with low cost, and eliminates the banding method of steel saddle binding, thus realizing different gluing methods of continuous method and pulsation method, with good gluing effect, high working efficiency, the device is especially suitable for banding the slim booklet with few pages.

Owner:SHANGHAI UNIV OF ENG SCI

Advertisement newspaper gluing device for use in accounting teaching

InactiveCN106040519AAvoid stickingSpeed up glue applicationLiquid surface applicatorsCoatingsEngineeringPulley

The invention relates to a gluing device, in particular to an advertisement newspaper gluing device for use in accounting teaching. The advertisement newspaper gluing device is convenient to operate, contributes to saving of time and labor, and has a good gluing effect. The advertisement newspaper gluing device for use in accounting teaching comprises a left bracket, a first slide rail, a cylinder, a first slide block, a fixing plate, a second slide rail, a right bracket, a spring, a first moving rod, a second slide block, an accommodating frame, a second moving rod, a contact roller, a wedged column, a big belt pulley, a flat belt, a first revolving shaft, a first bearing base, a first motor, a small belt pulley, a second revolving shaft, a brush roller, a second bearing base, a charging box, a top bracket and a baffle plate, wherein the left bracket, the first slide block and the right bracket are arranged in sequence on the top of the first slide rail from left to right. The advertisement newspaper gluing device is convenient to operate, contributes to saving of time and labor, and has a good gluing effect.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

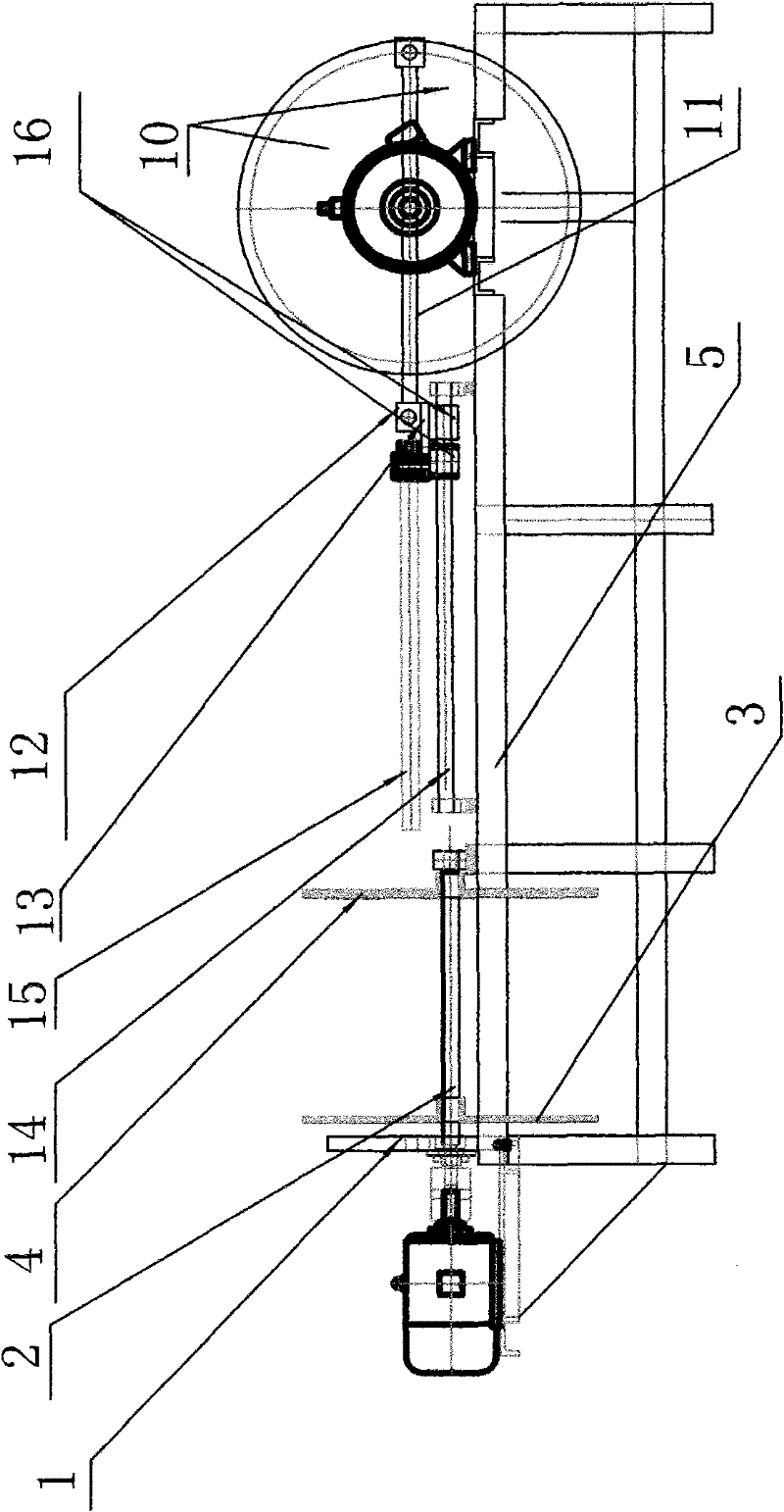

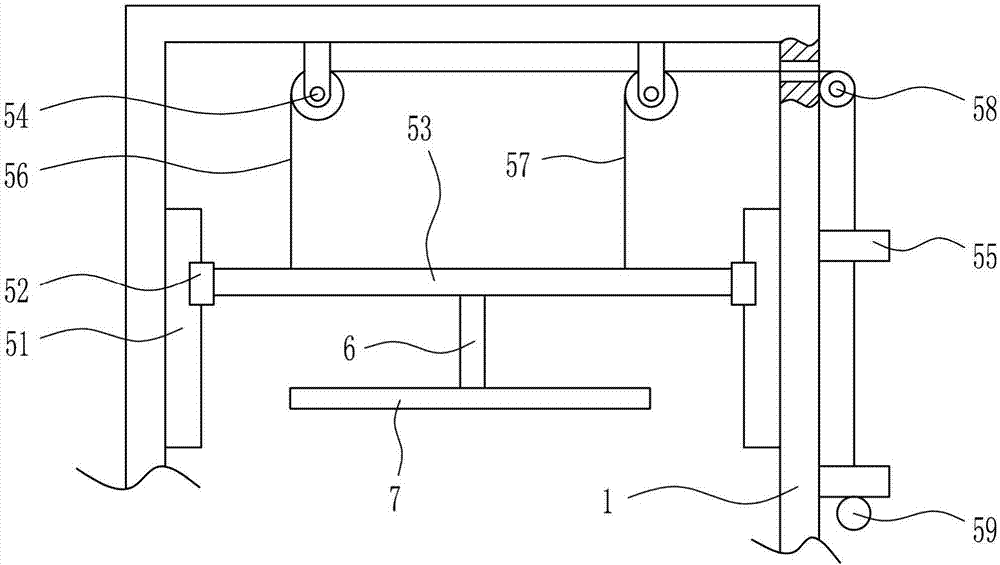

Pen head coating device for making writing brush

PendingCN106944306AImprove gluing effectOptimum gluing positionLiquid surface applicatorsCoatingsEngineeringLeft wall

The invention relates to a coating device, particularly to a pen head coating device for making a writing brush. The invention technically aims to provide a pen head coating device for making the writing brush. According to the above technical scheme, the invention provides a pen head coating device for making a writing brush, comprising a mounting rack, a frame, a water outlet pipe, a valve, a first lifting device, etc.; the inner bottom of the mounting rack is provided with the frame, and the lower part of the left wall of the frame is provided with the water outlet pipe; the water outlet pipe is provided with the valve, and the inner middle part of the mounting rack is provided with the first lifting device provided with a connecting rod of which the bottom is connected to an emplacement plate provided with emplacement holes. In the invention, the emplacement plate is provided with a plurality of emplacement holes so that a plurality of writing brushes can be placed on the emplacement plate, and the emplacement plate is lifted through the first lifting device so as to fit to the lifting device mutually.

Owner:HUZHOU SHANLIAN YONGHEFENG PEN HOUSE

Efficient surface sizing agent

InactiveCN101481890AImprove performanceGood gluing effectWater-repelling agents additionSlurrySizing

A high-efficiency surface sizing agent is mainly made from the following components by mass percent: 10-18% of an alkyl ketene dimmer, 10-18% of a graft copolymer of starch and acrylamide, 8-16% of polyamine resin, 3-10% of quaternary ammonium salt of trimethyl ammonium chloride and 45-65% of water. The surface sizing agent has the advantages of excellent sizing effect, good film forming property, wide application range and environmental protection. Using the surface sizing agent, the surface sizing agent is easily kept on a surface of a paper sheet, which obviously improves indexes of the paper sheet after sizing, such as surface strength, smoothness, Cobb value, printability and the like, and eliminates phenomena such as linting, dusting, pasting and the like during a finished paper printing process. And, the surface sizing agent can greatly reduce sizing procedures of paper making and requirement for a slurry clarifying system, thus the surface sizing agent can completely replace internal sizing to reduce sizing cost on the paper sheet.

Owner:HUBEI JIAYUN CHEM TECH

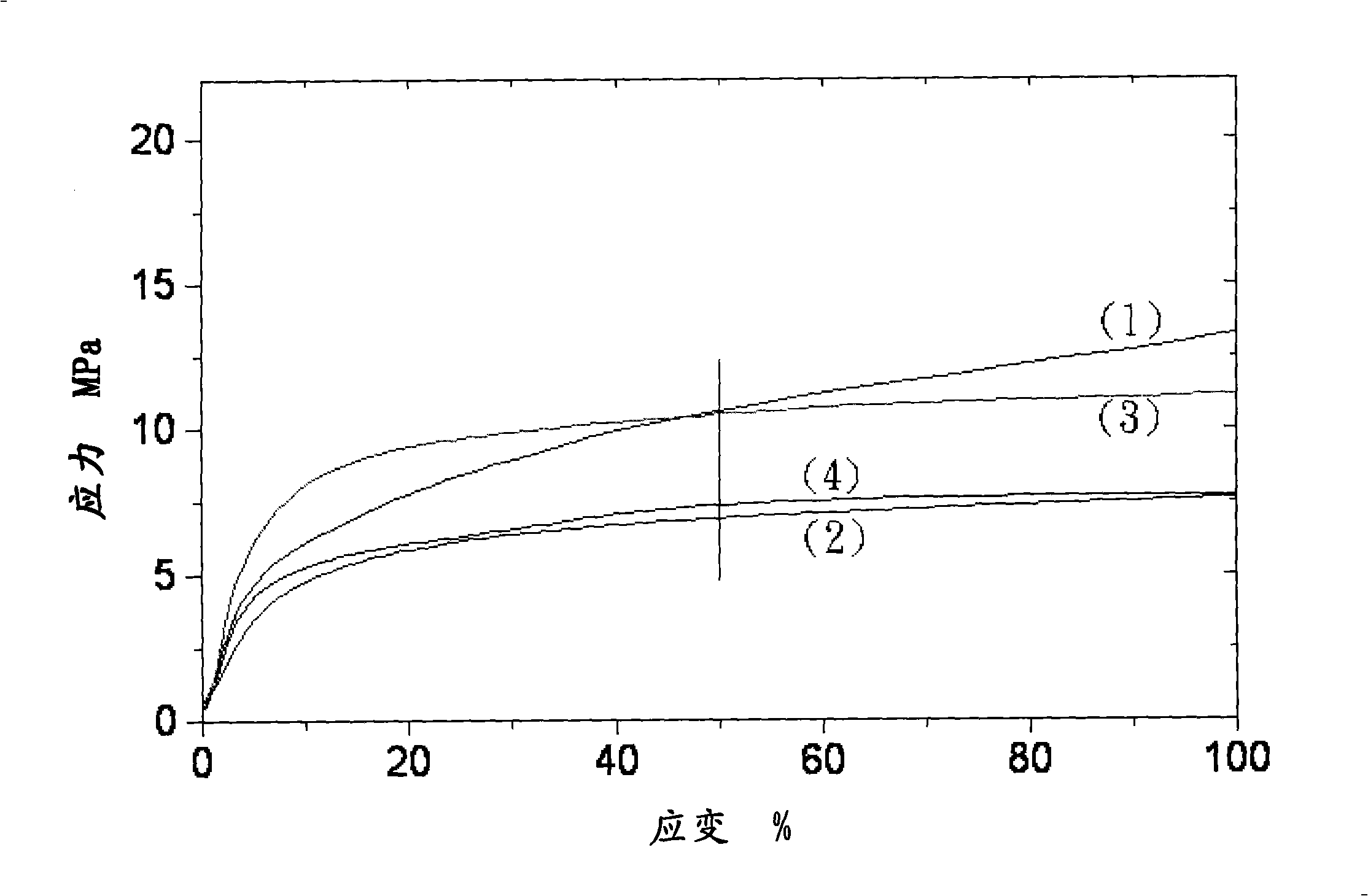

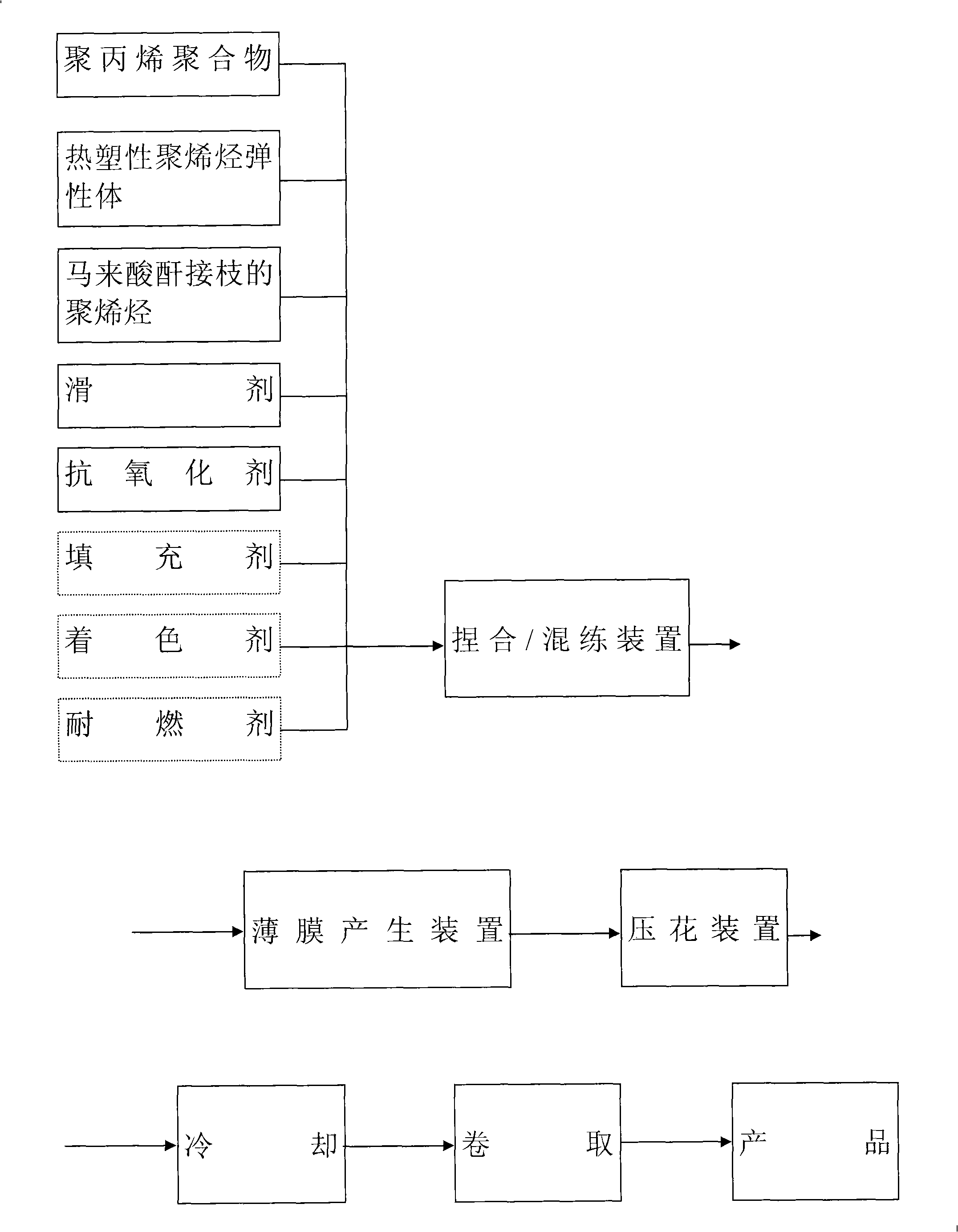

Non-halide thin film for rubber belt and preparation

InactiveCN101293977AGood tensile modulus strengthExcellent destruction voltageFilm/foil adhesivesElastomerPolyolefin

The invention provides a non-halogen film used for adhesive tapes and the preparation thereof. The film is made from 10-80 phr (parts per hundred of resin) of polypropylene polymer, 90-20 phr of thermoplastic polyolefine elastomer, 3-20 phr of maleic anhydride-grafted polyolefine, 0.1-5 phr of lubricant, 0.1-5 phr of antioxidant, 0-200 phr of bulking agent, 0-15 phr of pigment and 0-20 phr of flame retardant. The preparation of the non-halogen is as follows: subjecting a batch mixture to a mixing / mulling device, a film forming device, and manufacturing the film with a thickness of 0.05-0.30 mm. The film is a recoverable and environment-friendly material free of halogen elements, has similar property to the polyvinyl chloride (PVC) film, and is used as substitute for the conventional film for PVC adhesive tapes.

Owner:CHINA GENERAL PLASTICS

Gluing device for packaging box production

ActiveCN110918396AApply evenlyEasy to useLiquid surface applicatorsBox making operationsPaperboardRubber mat

The invention discloses a gluing device for packaging box production. The gluing device comprises a bottom plate, wherein stand columns are welded at the four corners of the outer wall of the top of the bottom plate, and a top plate is welded to the outer wall of the top of the stand columns; an electric sliding rail is connected to the outer wall of the bottom of the top plate through bolts, a sliding block is slidably connected to the inner wall of the electric sliding rail, vertical rods which are distributed equidistantly are welded to the outer wall of the bottom of the sliding block, andbrushes are connected to the outer walls of the bottoms of the vertical rods in a bonding mode; and a glue storage box is connected to the outer wall of the top of the top plate through bolts, and aglue adding pipe is welded to the outer wall of the top of the glue storage box. According to the gluing device for the packaging box production, the brushes on the vertical rods can continuously moveleft and right, and glue body flowing to a paperboard is evenly spread, so that the using effect is better, and the paperboard can be firmly adsorbed on a sucker; and meanwhile, a rubber pad on the sucker can increase the friction force with the paperboard, so that the fixing is stabler, it is guaranteed that the paperboard does not shake during coating, and the gluing effect of the device is further improved.

Owner:株洲蓝海包装有限公司

Gelatinizing device for bamboo and wood processing

InactiveCN108080207AReasonable designSimple structureLiquid surface applicatorsCleaning using toolsWater pipeEngineering

The invention discloses a gelatinizing device for bamboo and wood processing. The gelatinizing device comprises support legs, a fixed rack, a conveying device, a gelatinizing part and a cleaning part,wherein the conveying device comprises a conveyor belt, a conveying support, conveying wheels, a mounting rack, a first motor and a driving device; the fixed rack is mounted on the conveying support;the gelatinizing part comprises a glue box, a handhold handle, a grip-pressure ball, a glue spraying pipe, a gelatinizing wheel and a glue dividing wheel; the lower end of the fixed rack is connectedwith a wheel rack through springs; the gelatinizing wheel and the glue dividing wheel are respectively arranged at the two ends of the wheel rack through a rotating rod; the gelatinizing wheel is communicated with the glue spraying pipe; the cleaning part comprises an air box, an air nozzle, a second motor, a water tank and a cleaning wheel; the air box is communicated with the air nozzle throughan air pipe; the water tank is communicated with the cleaning wheel; a plurality of water spraying holes and hair brushes are arranged at the circumference of the cleaning wheel. The gelatinizing device disclosed by the invention has the advantages that existing manual cleaning and gelatinizing operations are changed, so that the labor strength is reduced, the production efficiency is improved, the gelatinizing is carried out uniformly, and a gelatinizing effect is good.

Owner:安吉森虎机械有限公司

Degumming process of natural colorful silk

The invention discloses a degumming process of natural colorful silk and belongs to the technical field of silk. The process comprises the following concrete steps: preprocessing natural colorful raw silk, swelling and steaming silk gum on the surface of the raw silk, curing by an acidic curing agent and a grafting agent, grafting pigment in the silk gum, and fully degumming in alkali liquid to obtain the natural colorful silk. According to the process, a very large hole is formed between the swelled silk gum, the pigment is transferred to fibroin from the silk gum by steaming, and the curing agent and the grafting agent enter the silk gum and the fibroin, so that the water solubility of the silk gum is reduced; the processed natural colorful silk is improved in mechanical strength, good in gumming effect and high in color retention rate, and retains the performances of the natural colorful silk, such as moisture retention, ultraviolet resistance, bacterial resistance and oxidation resistance.

Owner:SUZHOU INSILK CO LTD

Gluing machine

InactiveCN103464331AReduce adverse effectsProtect healthLiquid surface applicatorsCoatingsToxic gasGear pump

The invention discloses a gluing machine. The gluing machine comprises a stander, wherein a two-dimensional guide rail device is arrange above the stander and comprises a plurality of glue headstocks, and strokes and pivot angles of needle heads of the glue headstocks are adjustable; a conveying device is arranged below the two-dimensional guide rail device and is used for conveying a to-be-glued workpiece; a glue supply system is used for conveying glue in a glue storage tank to the needle head of each glue headstock through a connecting pipe via a gear pump; an air suction system is further arranged on the stander below the conveying device and is used for sucking out and intensively processing toxic gas released by the glue during a gluing process so as to guarantee the operation safety of a worker. The gluing machine disclosed by the invention is high in automation degree and gluing efficiency, is ideal in gluing effect and good in stability.

Owner:JIANGSU ZHENGDELI MECHANICAL TECH

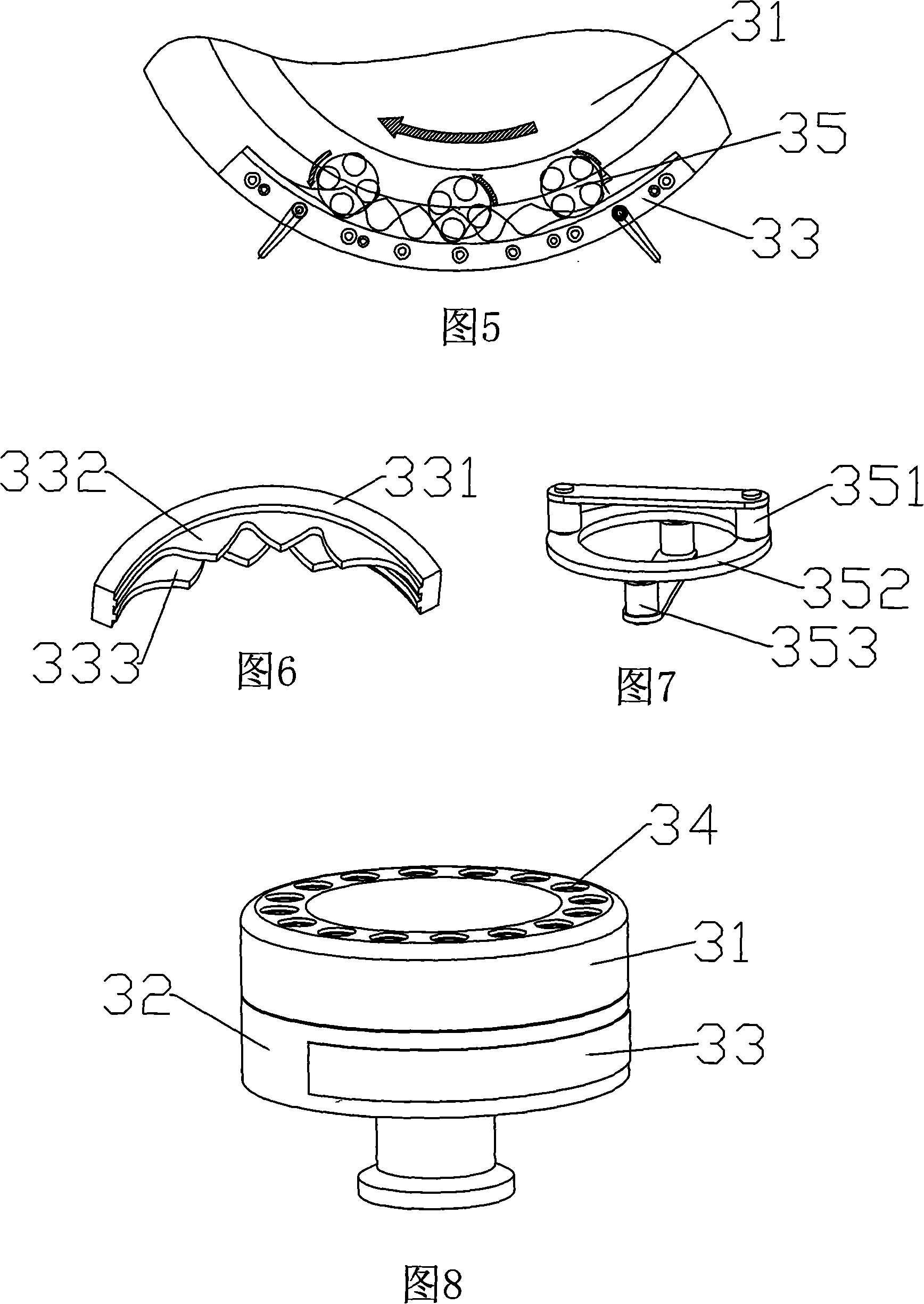

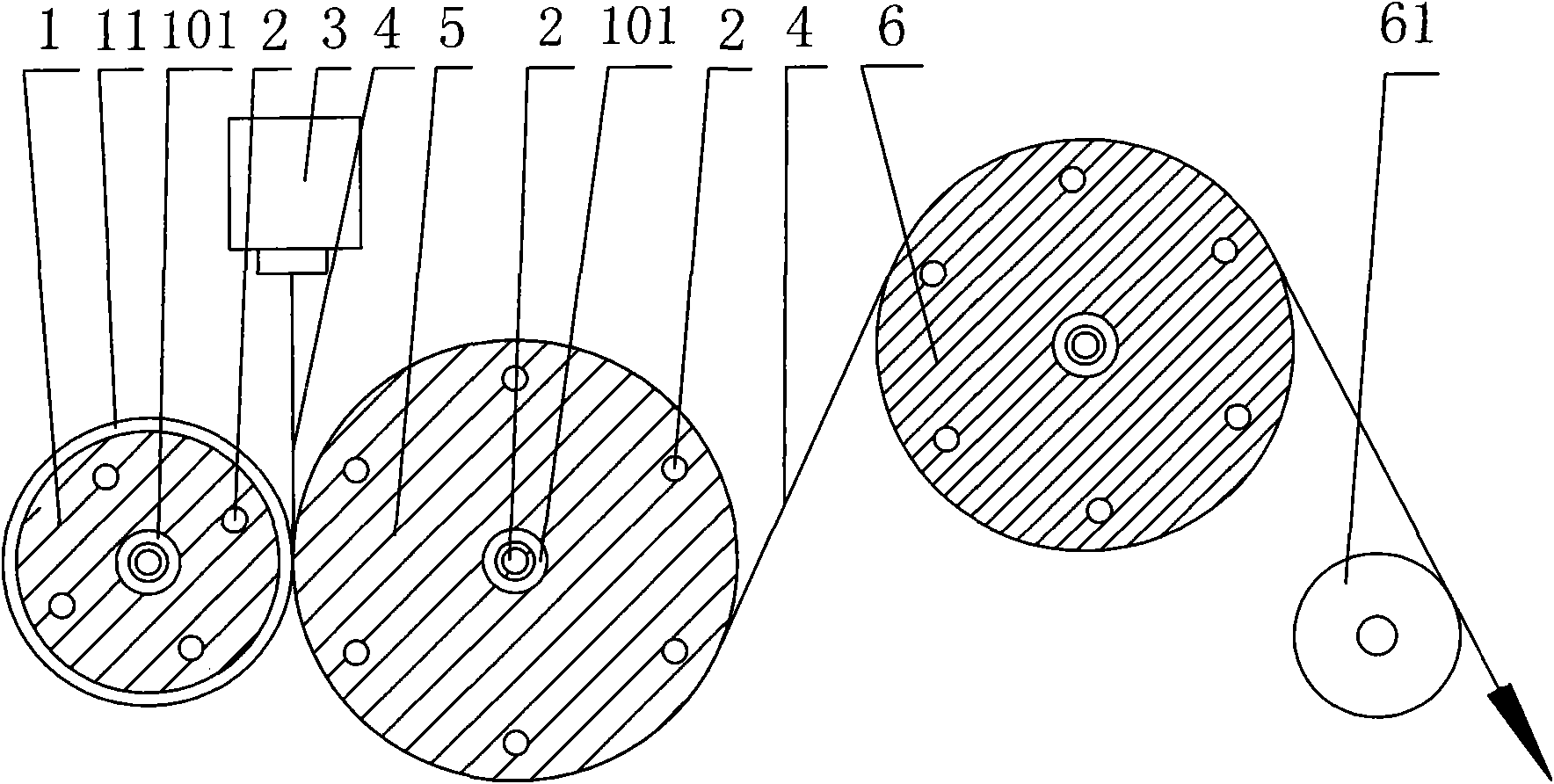

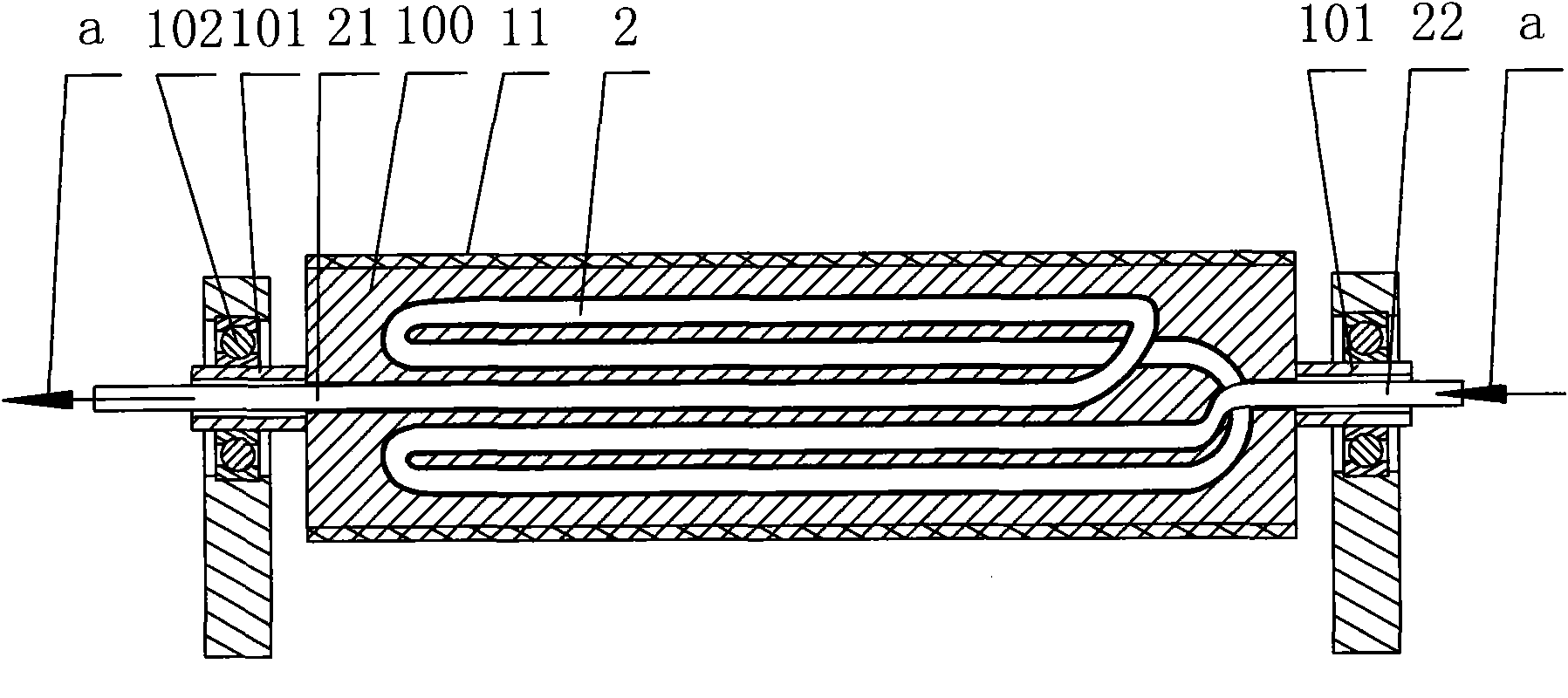

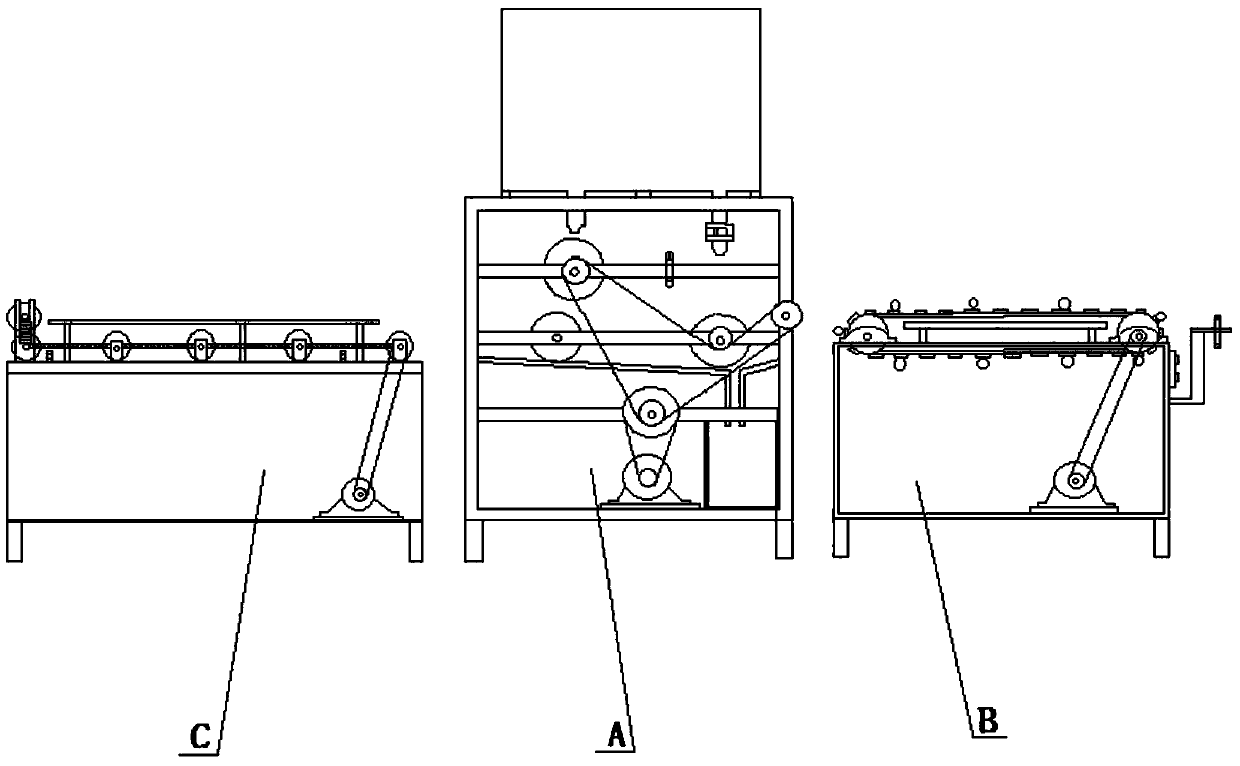

Automatic plate conveying, glue coating and plate feeding system

InactiveCN108043654AImprove bindingQuality improvementLiquid surface applicatorsCoatingsSteel ballEngineering

The invention discloses an automatic plate conveying, glue coating and plate feeding system. The system consists of an automatic glue coating device, an automatic plate feeding device and an automaticplate conveying device. The automatic plate conveying device can realize firm combination of plates, secondary shaping of the plates and automatic conveying of the plates; a motor of the automatic glue coating device can synchronously drive a front surface glue coating roller and a reverse surface glue coating roller to operate, so that the front and reverse surfaces of the plates can be uniformly coated with glue, and automatic forward pushing is realized. A rotating system of the automatic plate feeding device enables two point contact conveying chains of the automatic plate feeding deviceto synchronize with the plate feeding speed of a glue coating machine through the rotating speed adjustment; the glue-coated plates are received and sent only by synchronous walking of several round points consisting of steel balls of the point contact conveying chains; and as plate contacted surfaces are smaller, the glue on the plates is not taken away, the phenomenon of glue loss or glue shortage on the uniformly glued plates cannot be caused, manual loss and glue loss do no exist, and the bonding effect of bound surfaces is not influenced.

Owner:GUANGXI NANNING QIAOSHENG WOOD

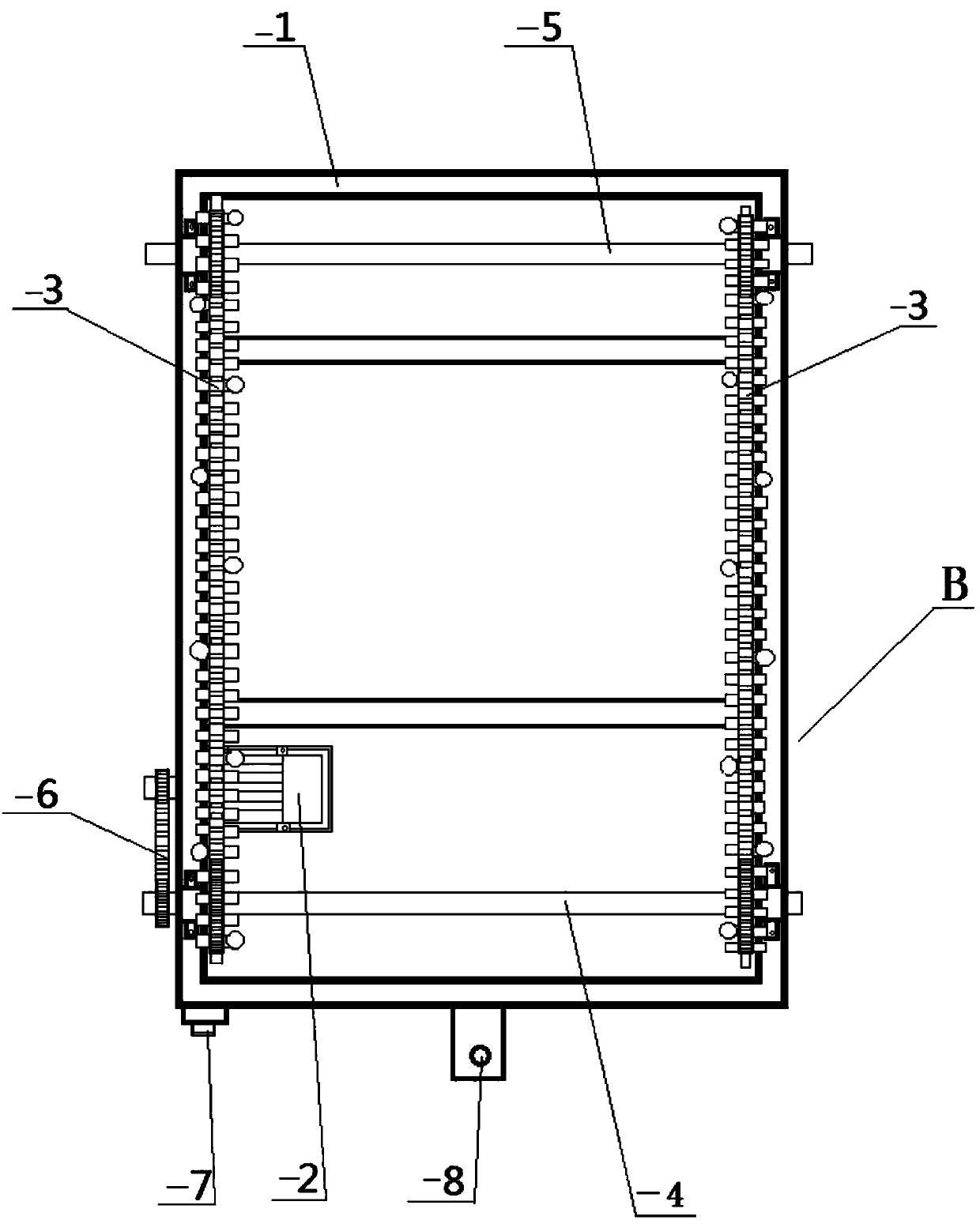

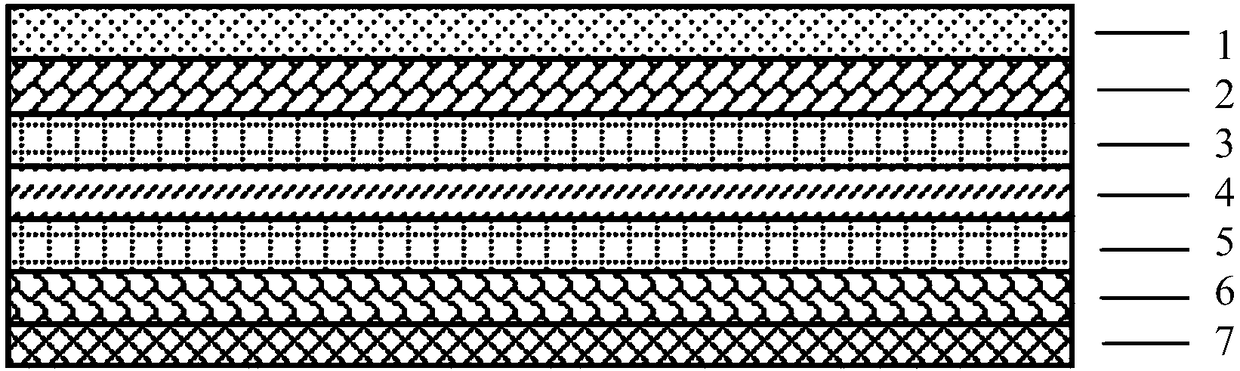

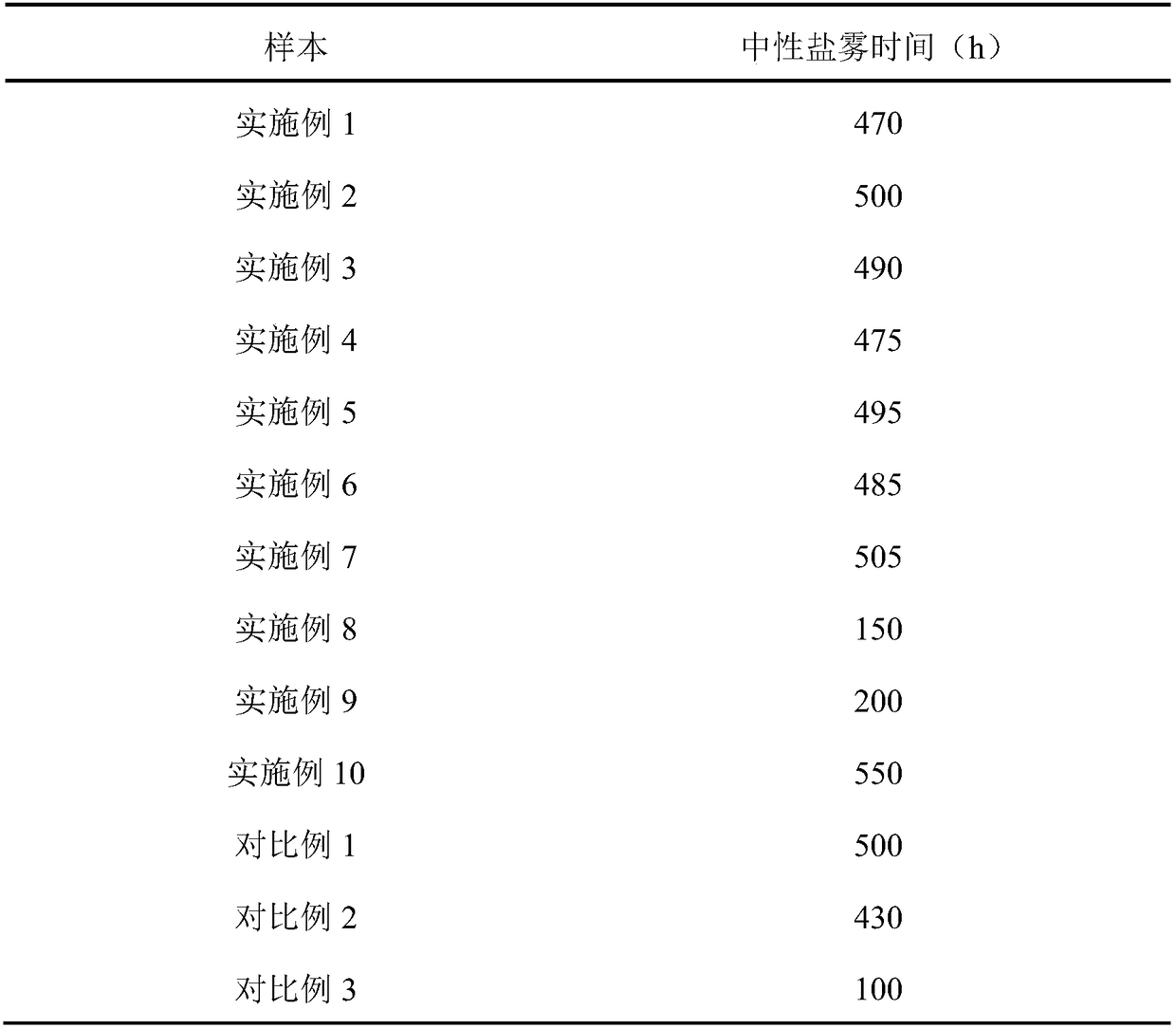

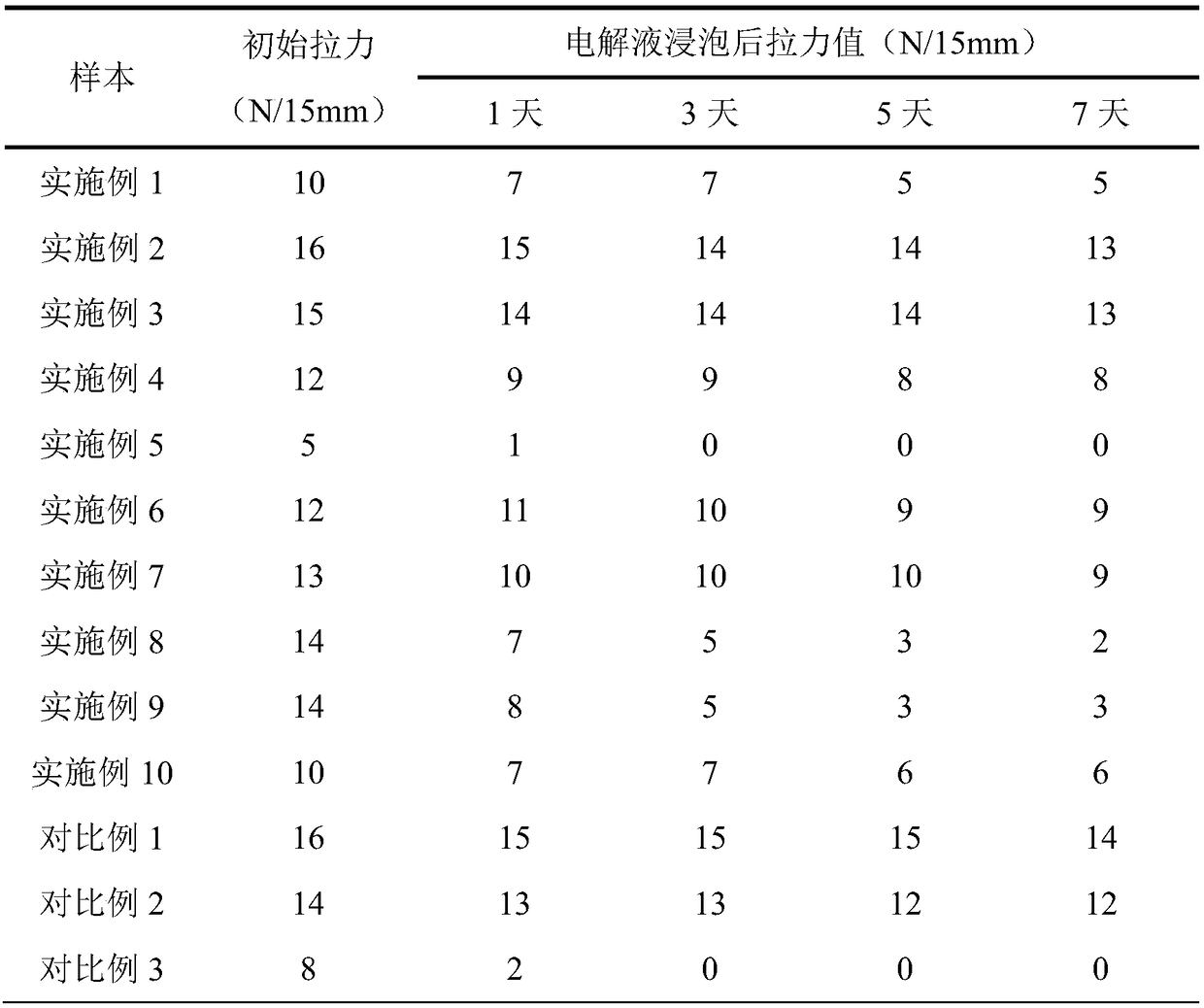

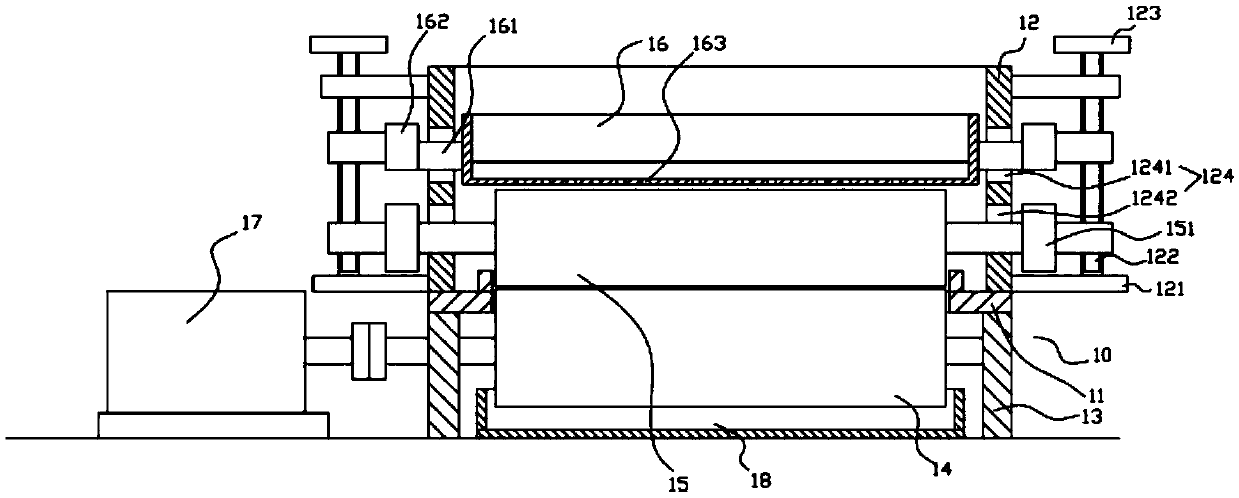

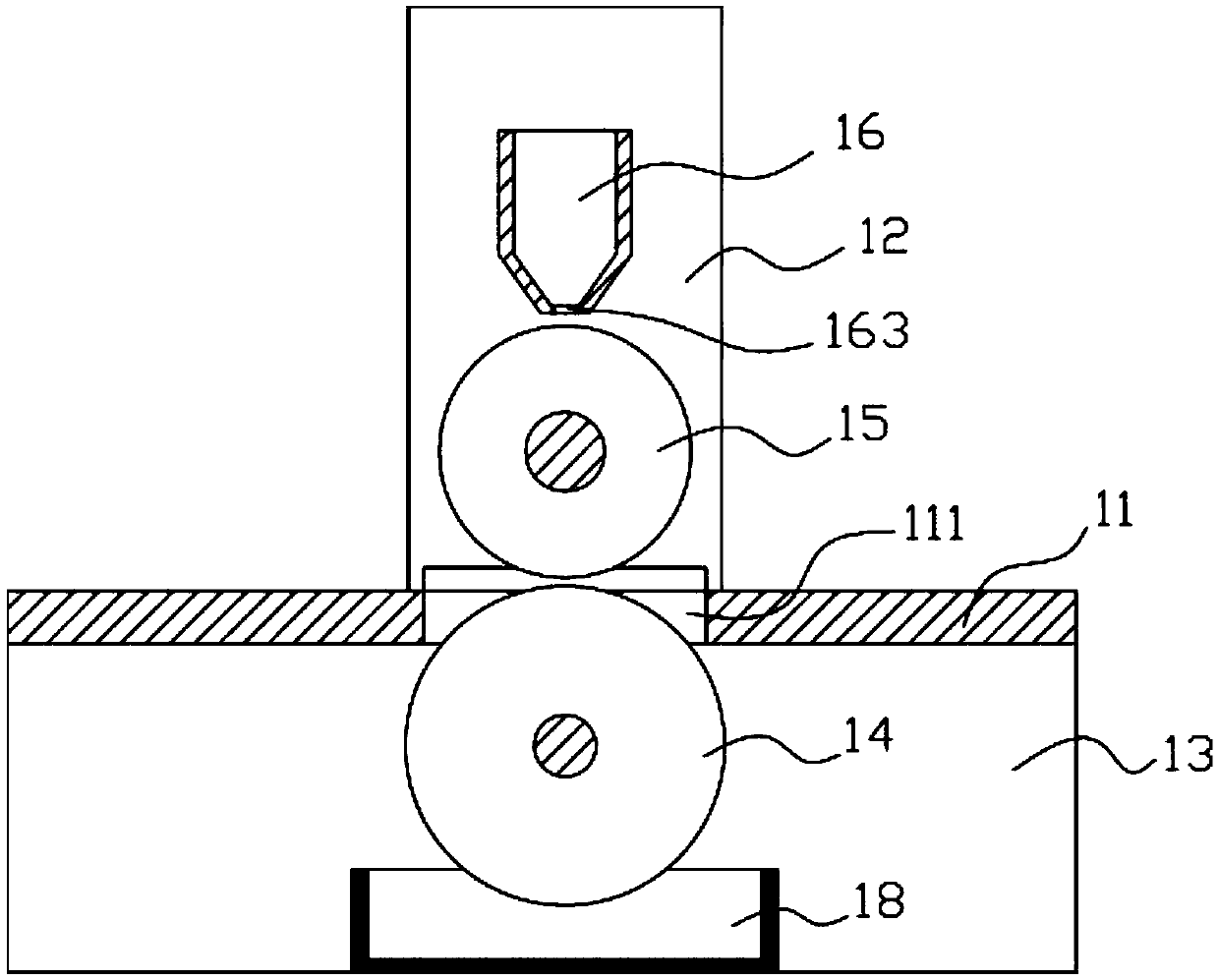

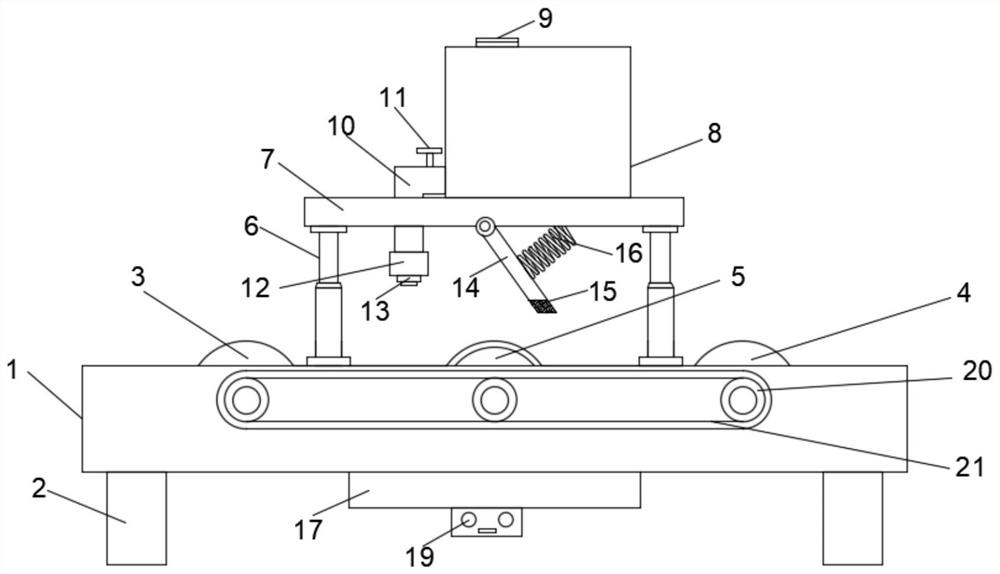

Lithium ion battery soft package material and aluminum foil layer surface treating liquid thereof

InactiveCN109440092AExcellent corrosion resistance and gluing performanceExcellent bonding performance and electrolyte resistanceSecondary cellsMetallic material coating processesCorrosion resistantHexavalent chromium

The invention discloses a lithium ion battery soft package material and aluminum foil layer surface treating liquid thereof. The lithium ion battery soft package composite material structurally comprises an outer layer, an outer layer bonding layer, a first trivalent chromium treating layer, an aluminum foil layer, a second trivalent chromium treating layer, an inner layer bonding layer and a CPPlayer in sequence; and a trivalent chromium reagent of the surface treating liquid is a compounded system of trivalent chromium and acrylic resin, and a layer of transparent trivalent chromium treating film can be formed on the aluminum foil surface. The aluminum foil layer surface treating liquid uses the environment-friendly trivalent chromium for replacing traditional hexavalent chromium and isparticularly suitable for surface treatment of an aluminum package material in a lithium battery soft package, the good electrolyte-corrosion-resistant property and adherence are provided, and the bonding property of the aluminum foil layer and the CPP layer is improved; and film forming can be quickly conducted through a spraying process under the normal temperature, and energy conservation andenvironmental friendliness are achieved.

Owner:浙江华正能源材料有限公司

Paperboard gluing machine

InactiveCN105499061AGlue evenlyImprove gluing effectLiquid surface applicatorsCoatingsArchitectural engineeringPaperboard

The invention discloses a paperboard gluing machine which comprises a rack. The top faces of the two sides of a table plate of the rack are fixedly provided with two vertical plates, the bottom faces of the two sides of the table plate are fixedly provided with two support plates, the two ends of a lower transmission press roll are hinged to the two support plates, the lower transmission press roll is inserted into a long through groove formed in the middle of the table plate in a sleeved mode, and the upper portion of the lower transmission press roll stretches out the top face of the table plate; the upper portions and the lower portions of the outer side walls of the vertical plates are fixedly provided with connecting plates, the two ends of an adjusting screw rod are hinged to every two connecting plates, and the upper ends of the adjusting screw rods stretch out of the connecting plates located on the upper portions and are fixedly provided with rotary plates; the middles of the vertical plates are provided with vertical adjusting through grooves, the two ends of an upper transmission press roll penetrate through the vertical adjusting through grooves and are hinged to two adjusting blocks, and the two adjusting blocks are connected to the interiors of the corresponding adjusting screw rods in a screwed mode. According to the paperboard gluing machine, synchronous lifting and falling of the upper transmission press roll and a gluing tank can be achieved, therefore, the gluing uniformity is guaranteed, and the gluing effect is improved.

Owner:福建三利达环保科技有限公司

Gluing device for insulation board processing

InactiveCN111921742AApply glue evenlyImprove stabilityLiquid surface applicatorsSpraying apparatusElectric machineTransmission belt

The invention discloses a gluing device for insulation board processing. The gluing device comprises a mounting rack and a mounting plate. Supporting legs are fixedly mounted at four corners of the bottom of the mounting rack, an input roller, an output roller and a gluing roller are rotatably connected in the mounting rack, transmission wheels are fixedly mounted at the ends, extending out of themounting rack, of the input roller, the output roller and the gluing roller, transmission belts are in transmission connection to the transmission wheels, a driving motor is fixedly mounted on one side of the mounting rack, the driving end of the driving motor is fixedly connected to one end of the input roller, electrical telescopic rods are fixedly mounted at four corners of the bottom of the mounting plate, the bottoms of the electrical telescopic rods are fixedly connected to the top of the mounting rack, and a glue storage box is fixedly mounted on the mounting plate. The invention relates to the technical field of insulation board processing. The gluing device is simple in structure and convenient to operate, improves the gluing uniformity, is good in gluing effect and improves theprocessing quality of the insulation board advantageously.

Owner:安徽春江保温建材科技有限公司

Shoemaking glue applicator

The invention relates to a glue applicator, in particular to a shoemaking glue applicator and aims to provide the shoemaking glue applicator having good shoemaking quality and good glue application effect and facilitating shoemaking. The shoemaking glue applicator comprises a base, electric wheels, a first sliding block, a placing plate, a stay line, a first sliding rail, a right support, a brush, a hard tube, an electronic control valve, a pushing plate, a glue cylinder, a first support, a second motor, a supporting rod, a supporting plate, a connecting rod, a connecting block, a rotating rod, a first motor, a rotating disc, a stand, a second sliding block, a second sliding rail and a top support, wherein the glue cylinder, the first sliding rail and the right support are arranged at the top of the base from left to right sequentially. The shoemaking glue applicator achieves the effects of good shoemaking quality, good glue application effect and easiness in shoemaking, so that people can better perform shoemaking glue application, time is saved, and convenience is brought.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com