Gluing device for filter upper cover sealing ring

A technology of gluing device and sealing ring, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problems of unevenness, slow gluing speed and poor positioning of the sealing ring on the upper cover of the filter, etc. Low cost, simple structure, good effect of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

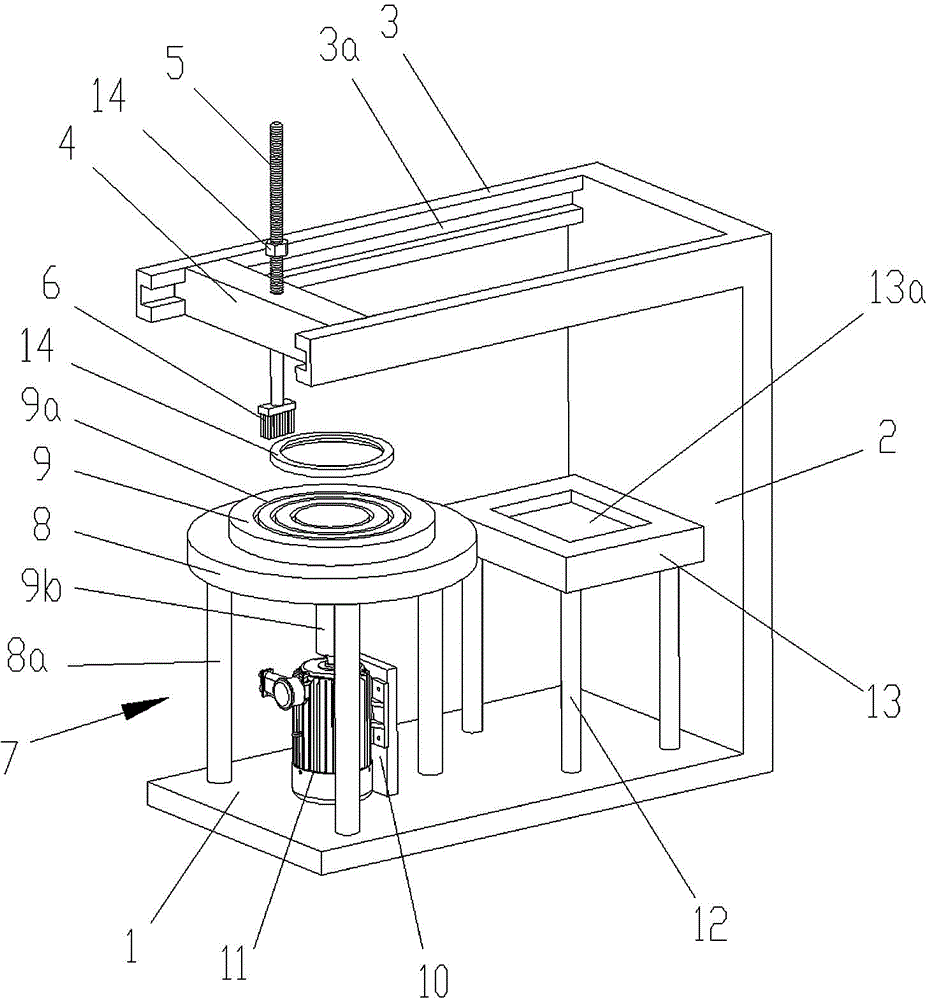

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a gluing device for the sealing ring of the upper cover of the filter, which is characterized in that it includes:

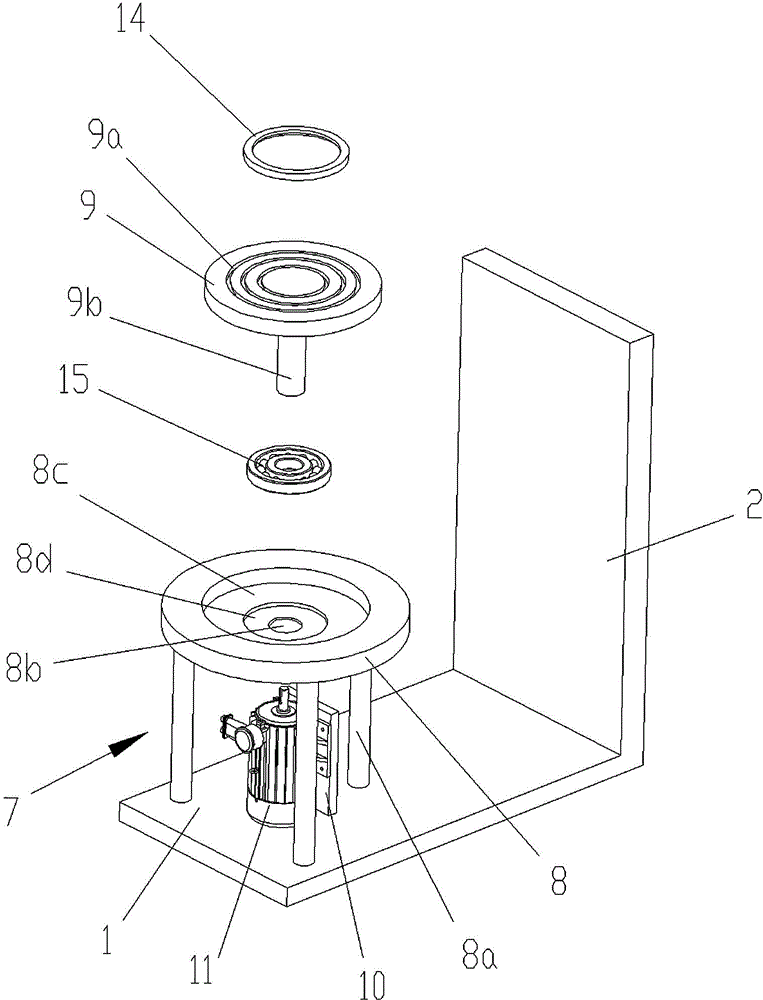

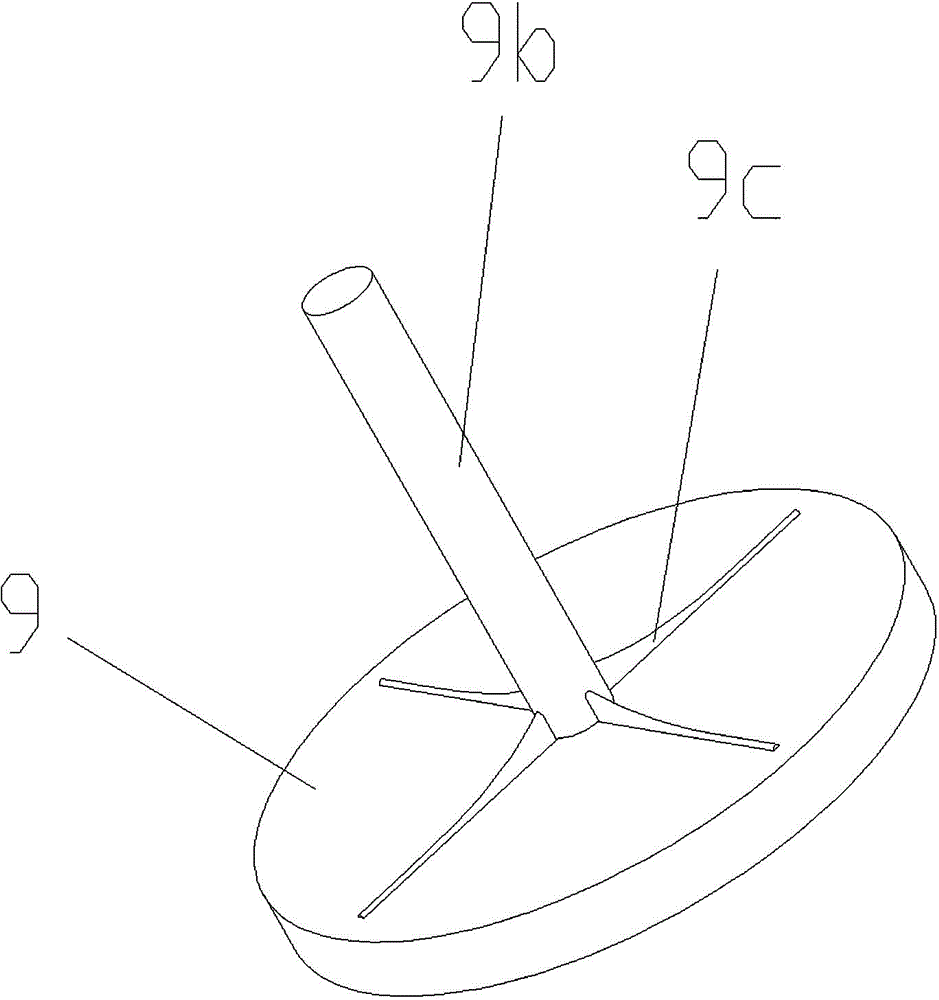

[0021] A base plate 1 for fixing the entire device, on which a bracket 7 is fixedly connected, the bracket 7 includes three uprights 8a connected and fixed on the base plate 1, and a circular round is fixedly connected to the upper ends of the three uprights 8a The support plate 8 is provided with a stepped through hole 8b on the support plate 8, and the stepped through hole 8b includes a turntable fixing groove 8c and a bearing installation groove 8d, and a The bearing 15 is supported and rotated in the stepped through hole 8b to connect a turntable 9, and the upper side of the turntable 9 is provided with a group of concentric annular grooves 9a, and the diameter of the annular groove 9a is the same as that on filters of various specifications. The diameter of the cover sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com