Lithium ion battery soft package material and aluminum foil layer surface treating liquid thereof

A lithium-ion battery and surface treatment liquid technology, which is applied in the coating process of metal materials, secondary batteries, battery components, etc., can solve the problem of poor adhesion of glue on corrosion resistance, thick trivalent chromium coating, etc. problems, to achieve excellent corrosion resistance and gluing performance, excellent bonding performance and the effect of electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 20g of chromium chloride, 10g of acrylamide-modified acrylic resin, 0.5g of sodium dodecylsulfonate, 3g of boric acid, 1g of sodium tartrate, 0.2g of sodium hydrogen fluoride, and 0.5g of hydroxymethylcellulose in water and set to volume to 1L to obtain a trivalent chromium treatment solution.

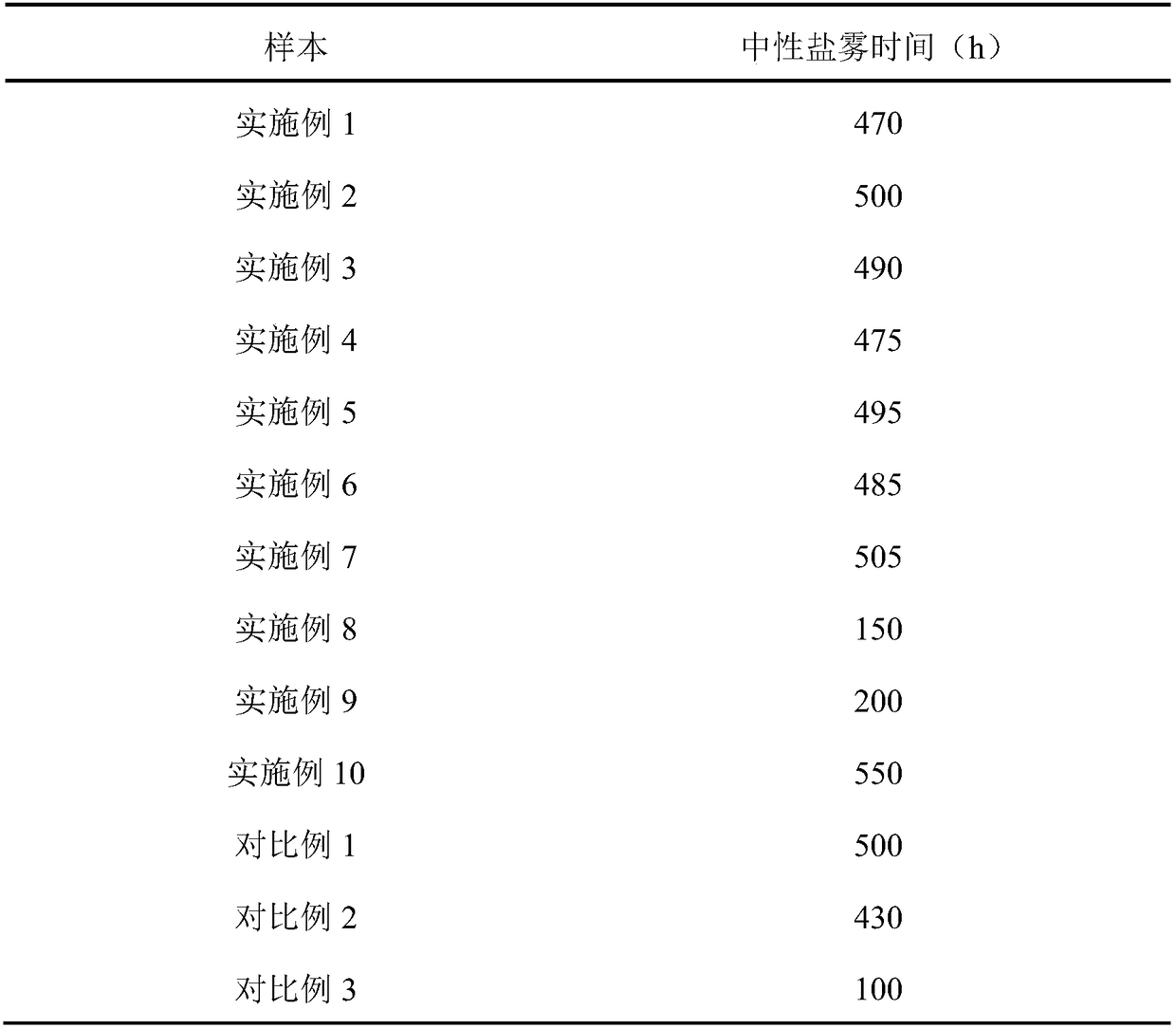

[0025] The aluminum foil was spray-coated with the above-mentioned treatment solution at a treatment temperature of 60° C. and a treatment time of 5 s. Then, the treated aluminum foil was taken out and placed in an oven at 50° C. for drying. Take a small amount of aluminum foil for neutral salt spray test, the specific standard refers to ASTM B117.

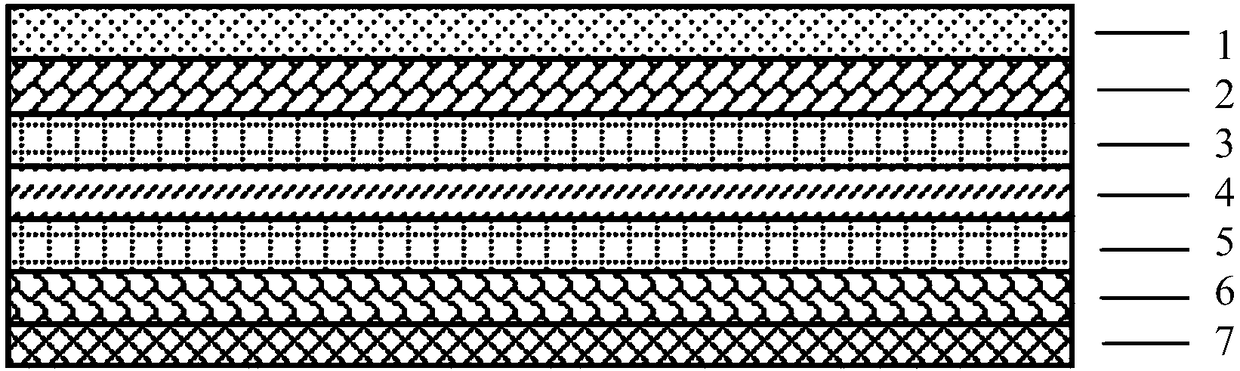

[0026] The treated aluminum foil is thermally laminated with nylon and CPP through the outer layer glue and the inner layer glue to obtain the lithium-ion battery soft package material (aluminum-plastic film).

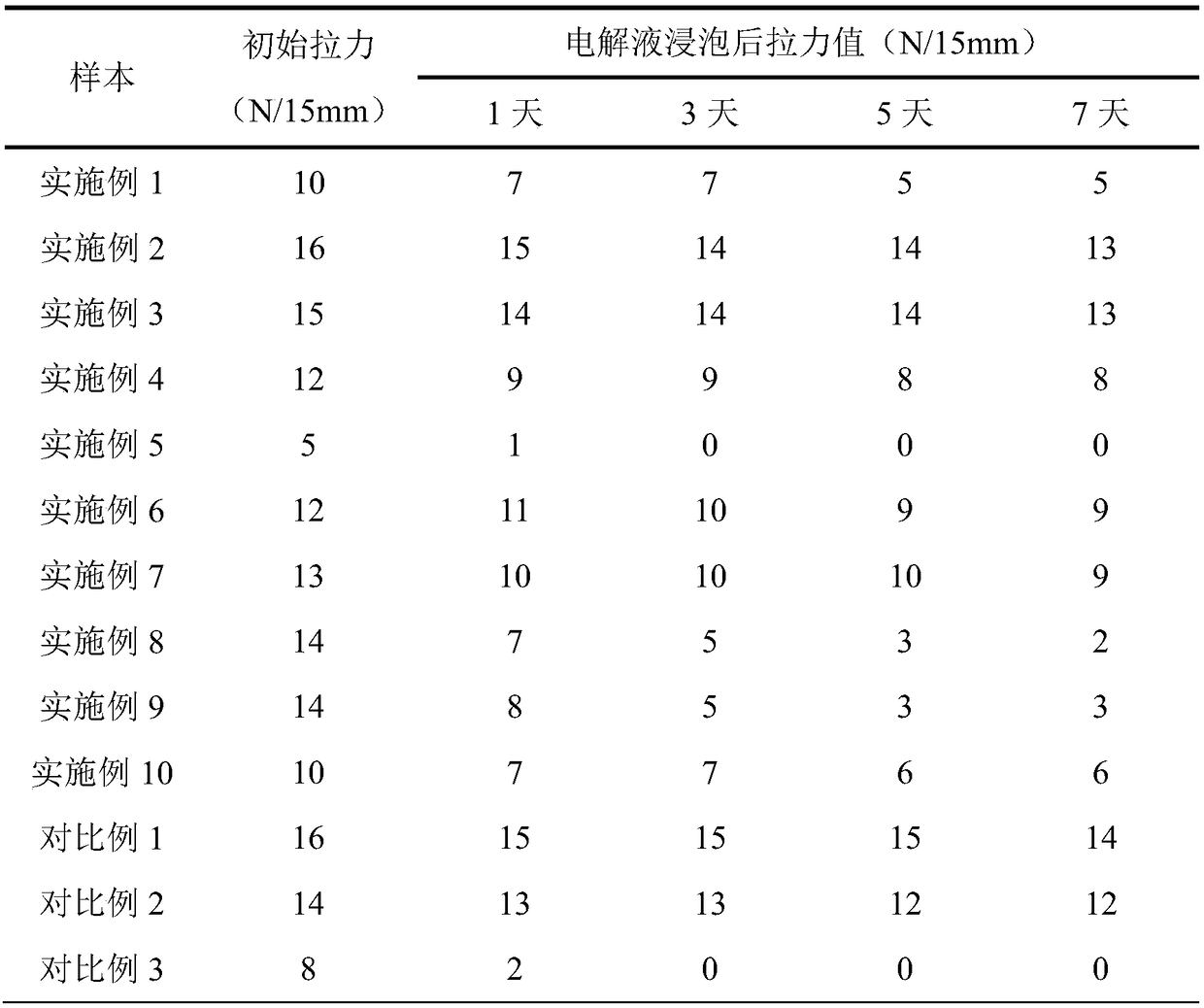

[0027] The obtained aluminum-plastic film was cut into a sample strip with a width of 15 mm, and the mechanical ...

Embodiment 2

[0030] Dissolve 20g of chromium chloride, 10g of acrylamide-modified acrylic resin, 0.5g of sodium dodecylsulfonate, 3g of boric acid, 1g of sodium tartrate, 0.2g of sodium hydrogen fluoride, and 0.5g of hydroxymethylcellulose in water and set to volume to 1L to obtain a trivalent chromium treatment solution.

[0031] The aluminum foil was spray-coated with the above-mentioned treatment solution at a treatment temperature of 80° C. and a treatment time of 5 s. Then, the treated aluminum foil was taken out and placed in an oven at 50° C. for drying. Take a small amount of aluminum foil for neutral salt spray test, the specific standard refers to ASTM B117.

[0032] The treated aluminum foil is thermally laminated with nylon and CPP through the outer layer glue and the inner layer glue to obtain the lithium-ion battery soft package material (aluminum-plastic film).

[0033] The obtained aluminum-plastic film was cut into a sample strip with a width of 15 mm, and the mechanical ...

Embodiment 3

[0036] Dissolve 20g of chromium chloride, 10g of acrylamide-modified acrylic resin, 0.5g of sodium dodecylsulfonate, 3g of boric acid, 1g of sodium tartrate, 0.2g of sodium hydrogen fluoride, and 0.5g of hydroxymethylcellulose in water and set to volume to 1L to obtain a trivalent chromium treatment solution.

[0037] The aluminum foil was spray-coated with the above-mentioned treatment solution at a treatment temperature of 100° C. for 5 s. Then, the treated aluminum foil was taken out and placed in an oven at 50° C. for drying. Take a small amount of aluminum foil for neutral salt spray test, the specific standard refers to ASTM B117.

[0038] The treated aluminum foil is thermally laminated with nylon and CPP through the outer layer glue and the inner layer glue to obtain the lithium-ion battery soft package material (aluminum-plastic film).

[0039] The obtained aluminum-plastic film was cut into a sample strip with a width of 15 mm, and the mechanical properties of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com