Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

An anti-corrosion coating, ultra-thin technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of poor alkali resistance and weather resistance, insufficient water resistance, anti-corrosion, and anti-rust capabilities, etc., to achieve low production costs. The effect of char residue and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

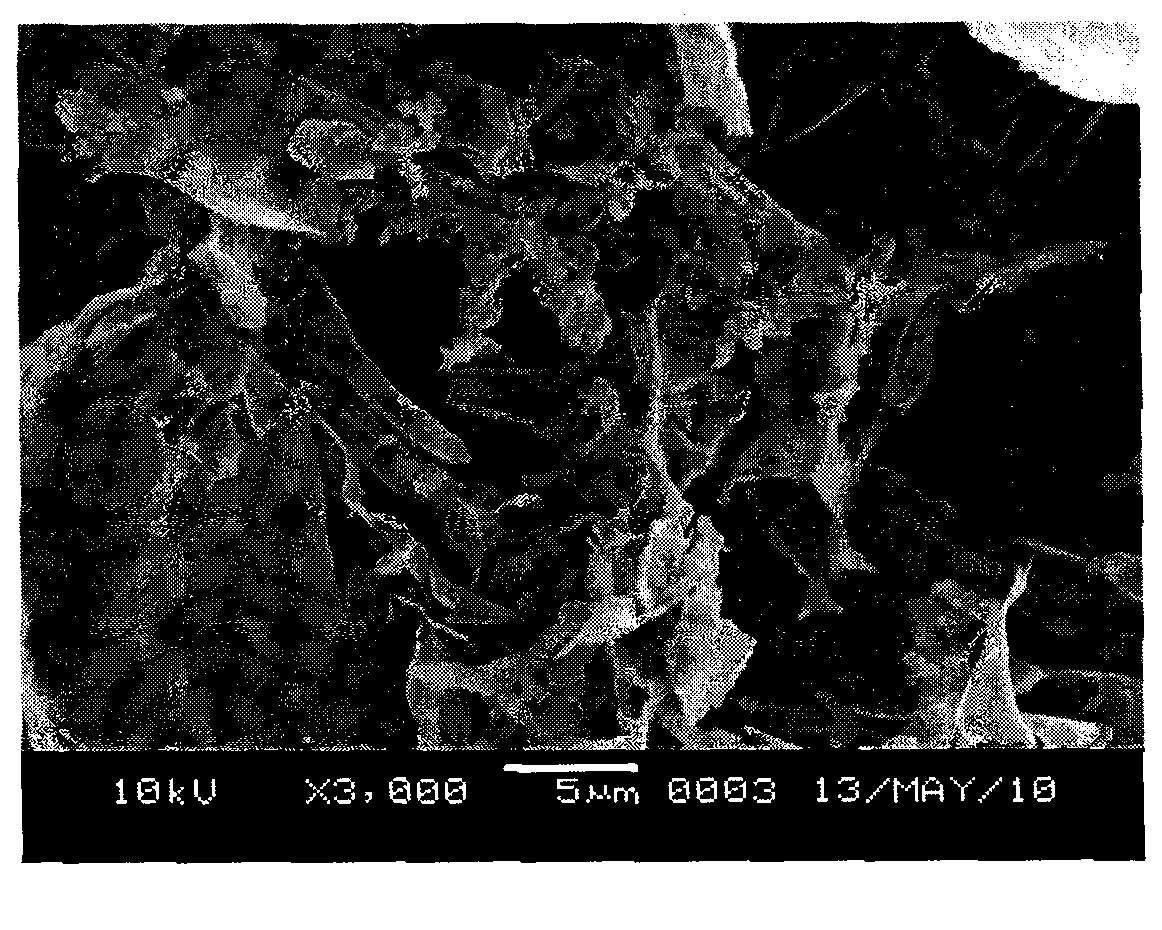

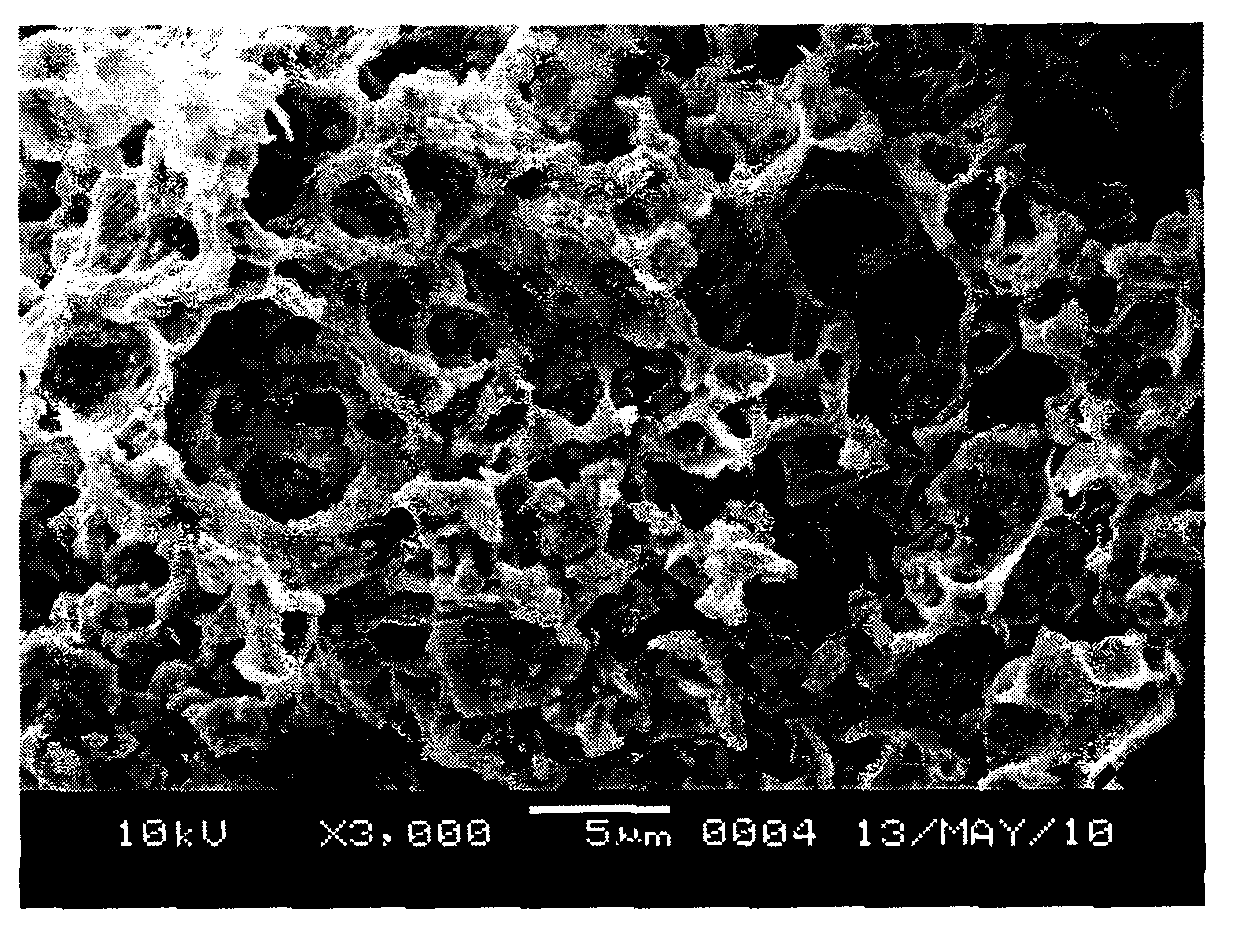

Image

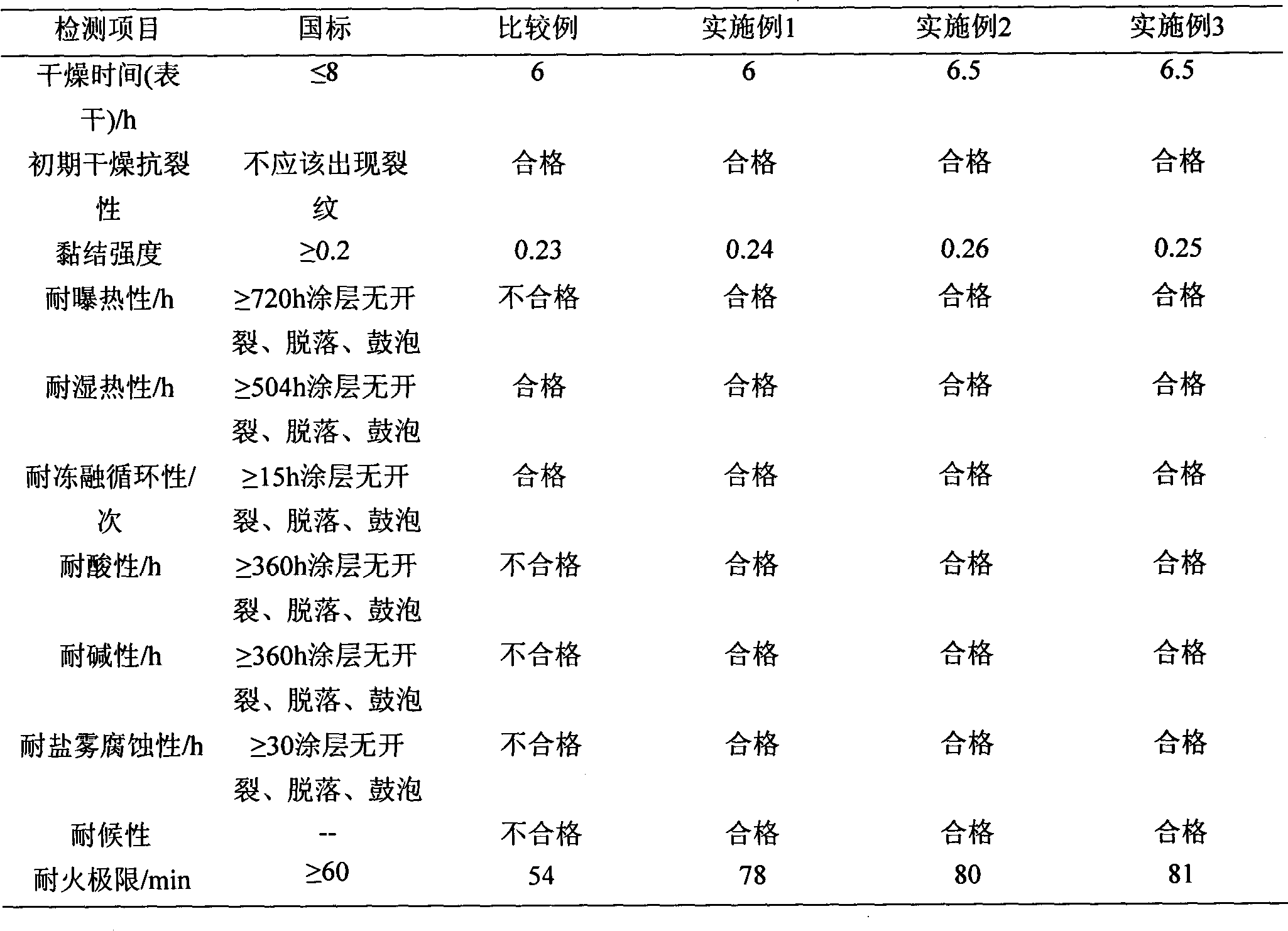

Examples

Embodiment 1

[0064] Silicone modified acrylate emulsion (solid content 42%) 28.0%, ammonium polyphosphate 15.0%, melamine 10.0%, pentaerythritol 6.0%, titanium dioxide 2.0%, expandable graphite 4.0%, zinc phosphate 3.0%, glass fiber 2.0% , defoamer 0.40%, dispersant 0.50%, thickener 3.0%, add deionized water to 100%.

[0065] The concrete implementation method of this recipe:

[0066] (1) Grind powdered materials APP, PER, MEL, zinc phosphate, glass fiber (except expandable graphite) through a grinder, and pass through a 200-mesh sieve.

[0067] (2) Weigh each component in turn according to the formula dosage, first add silicone-modified acrylate emulsion, then add ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide, zinc phosphate, glass fiber, then add expandable graphite, and then Add additives such as dispersant, thickener and defoamer, and add deionized water to reduce the viscosity of the components so that each component can be fully ground and dispersed.

[0068] ...

Embodiment 2

[0072] Silicone modified acrylate emulsion (solid content 42%) 32.0%, ammonium polyphosphate 16.0%, melamine 9.0%, pentaerythritol 7.0%, titanium dioxide 3.0%, expandable graphite 5.0%, aluminum phosphate 4.0%, zinc borate 2.0% , defoamer 0.30%, dispersant 0.20%, thickener 2.0%, add deionized water to 100%.

[0073] The concrete implementation method of this recipe:

[0074] (1) Grind powdery materials APP, PER, MEL, aluminum phosphate, zinc borate (except expandable graphite) through a grinder, and pass through a 200-mesh sieve.

[0075] (2) Weigh each component in turn according to the formula dosage, first add silicone-modified acrylate emulsion, then add ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide, expandable graphite, aluminum phosphate, zinc borate, and then add Expanded graphite, then add additives such as dispersant, thickener and defoamer, and then add some water to reduce the viscosity of the components so that each component can be fully gro...

Embodiment 3

[0080] Silicone modified acrylate emulsion (solid content 42%) 29.0%, ammonium polyphosphate 15.0%, melamine 8.0%, pentaerythritol 6.0%, titanium dioxide 2.0%, expandable graphite 4.0%, aluminum phosphate 3.0%, boric acid 2.0%, Defoamer 0.50%, dispersant 0.40%, thickener 2.0%, add deionized water to 100%.

[0081] The concrete implementation method of this recipe:

[0082] (1) Grind powdered materials APP, PER, MEL, aluminum phosphate, boric acid (except expandable graphite) through a grinder, and pass through a 200-mesh sieve.

[0083] (2) Weigh each component in turn according to the formula dosage, first add silicone-modified acrylate emulsion, then add ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide, expandable graphite, aluminum phosphate, boric acid, and then add expandable Graphite, then add additives such as dispersant, plasticizer and defoamer, and then add some water to reduce the viscosity of the components so that each component can be fully gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com