Electronic element high-efficiency vacuum gluing equipment

An electronic component, high-efficiency technology, applied in the manufacturing of electrical components, circuits, inductors/transformers/magnets, etc., can solve the problems of many processes, high manufacturing costs, complexity, etc., achieve good baking effect, save equipment costs, work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

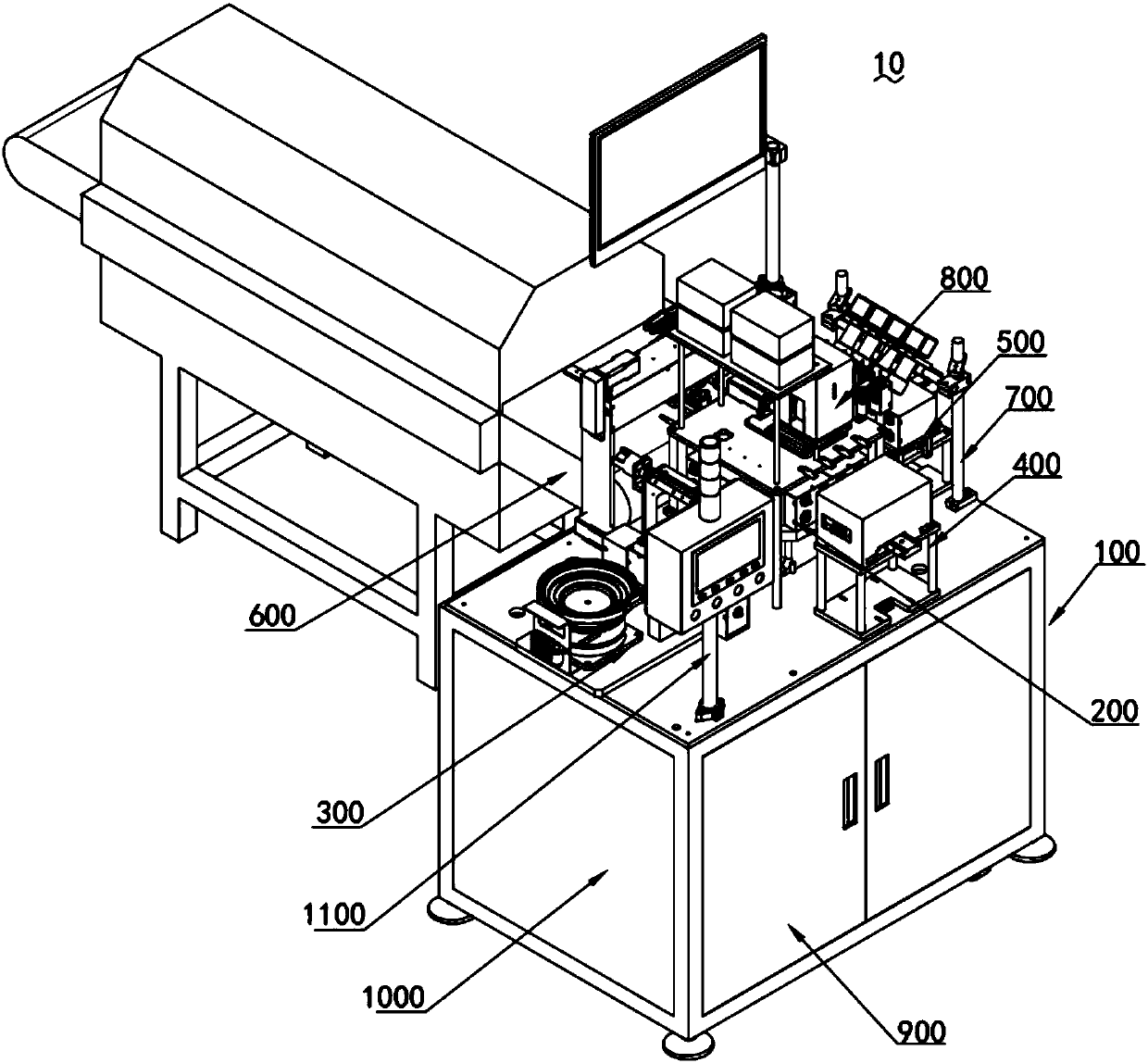

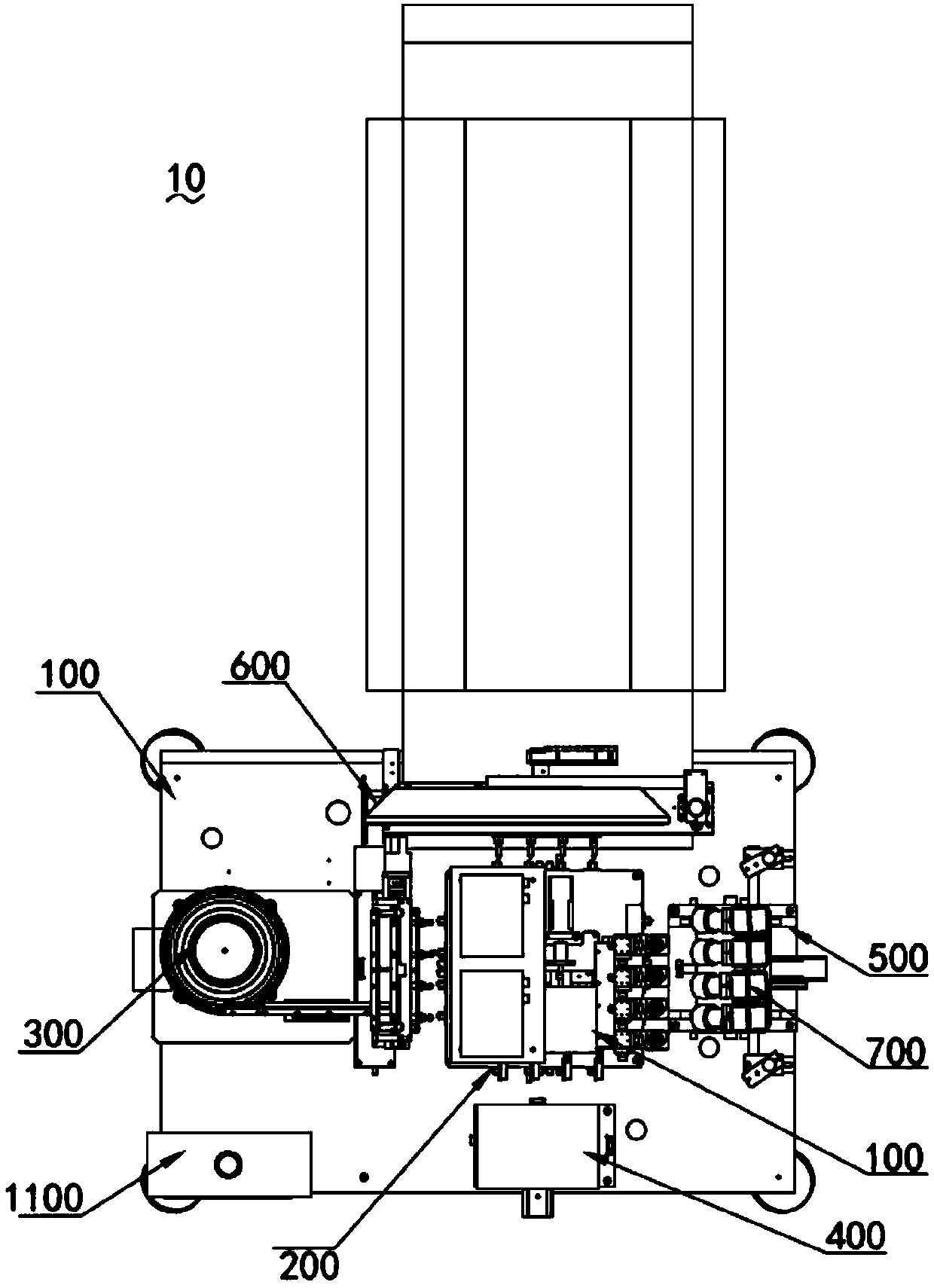

[0046] Such as Figure 1 ~ Figure 2 Shown, are respectively the three-dimensional top view of the present invention.

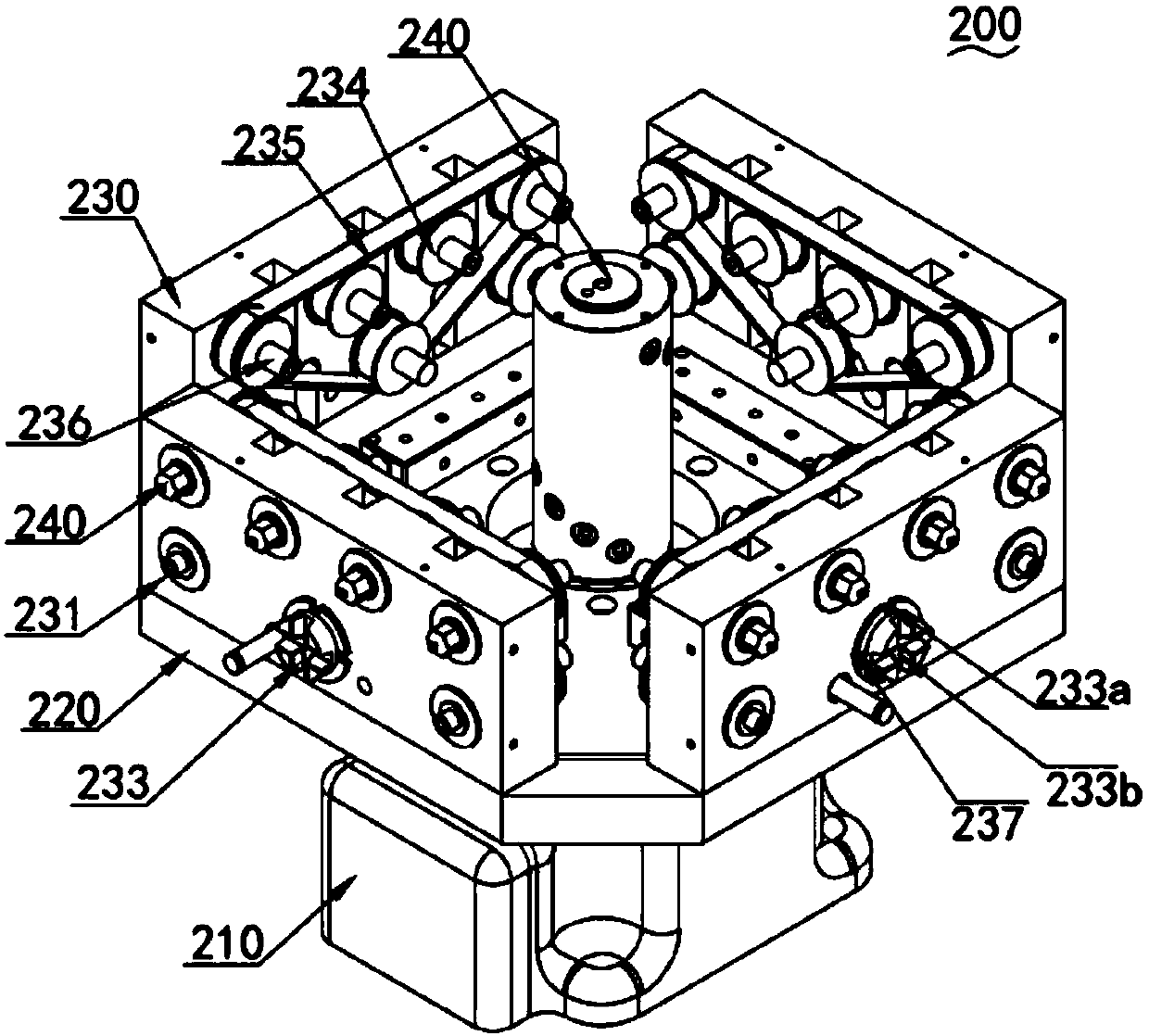

[0047] A high-efficiency vacuum gluing equipment 10 for electronic components, including a frame 100, a turntable mechanism 200 arranged on the frame 100, a feeding mechanism 300, a positioning mechanism 400, and a rotating mechanism arranged on the frame 100 around the turntable mechanism 200 500 and the unloading mechanism 600, the detection mechanism 700 fixed to the frame 100 above the rotating mechanism 500, the gluing mechanism 800 installed on the frame 100 above the turntable mechanism 200; the vacuum mechanism 900 and electric The control mechanism 1000 is connected with the electric control mechanism 1000 and is fixed on the control mechanism 1100 of the frame 100. The vacuum mechanism 900 is connected with the feeding mechanism 300, the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com