Paperboard gluing machine with automatic clamping and conveying mechanism

A technology of clamping, conveying and moving mechanisms, which is applied to devices and coatings that apply liquid to the surface. Gluing effect, good effect, uniform gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

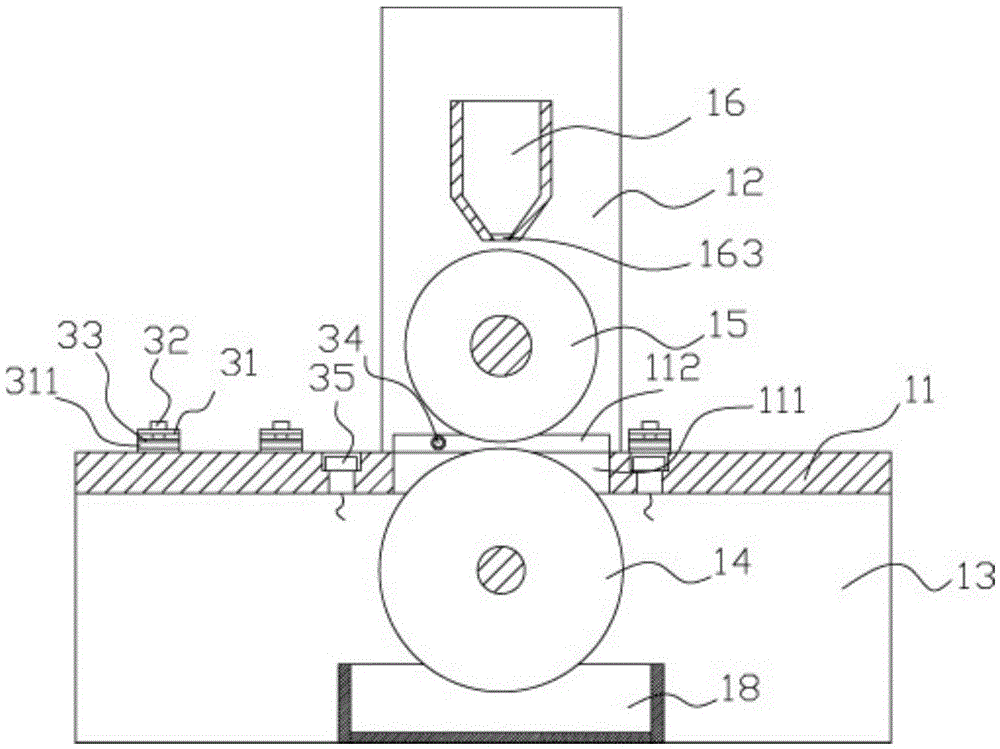

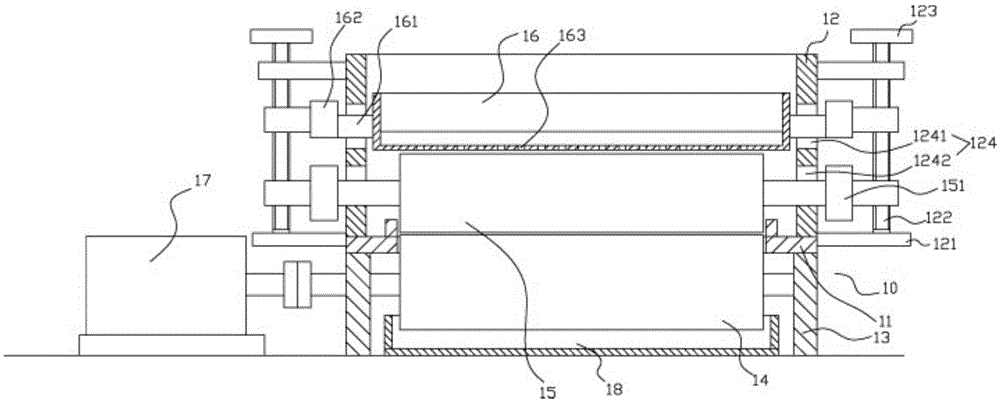

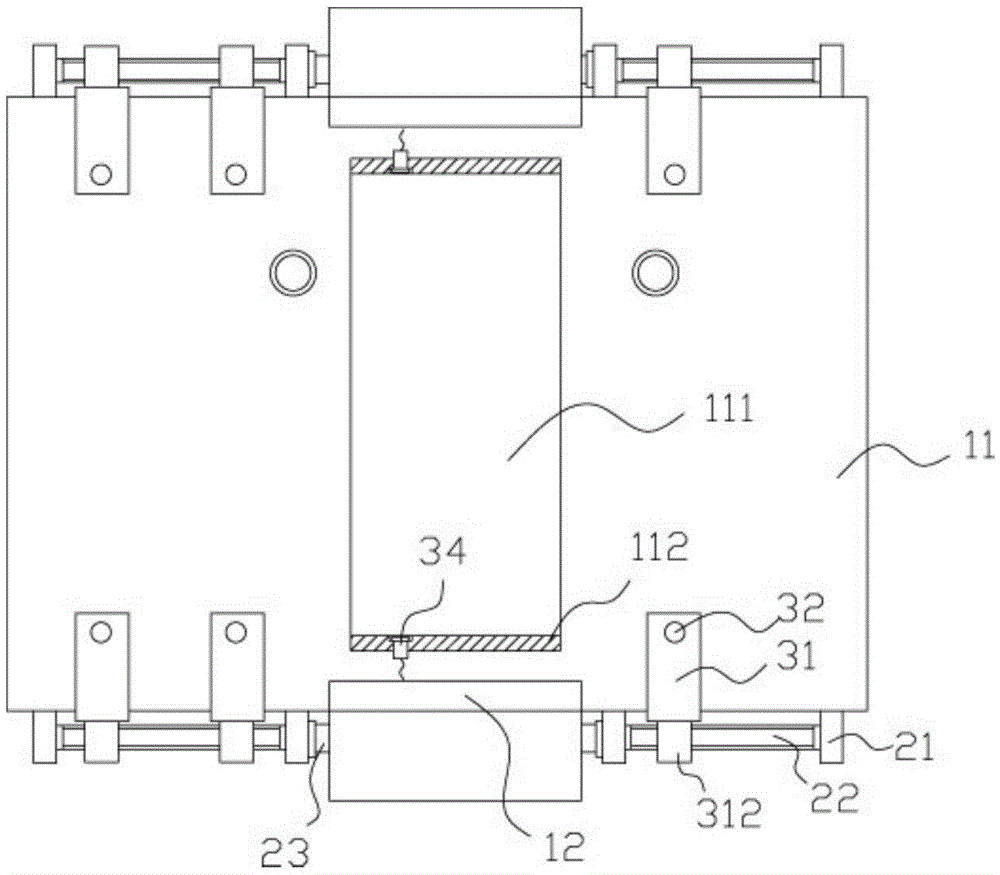

[0023] Example: see Figure 1 to Figure 4 As shown, a gluer on cardboard with an automatic clamping and conveying mechanism includes a frame 10, two vertical plates 12 are fixed on the top surfaces of both sides of the platen 11 of the frame 10, and the two vertical plates 12 of the platen 11 are There are support plates 13 fixed on the side bottom surface, and the two ends of the lower transmission pressure roller 14 are hinged on the two support plates 13, and the lower transmission pressure roller 14 is inserted into the elongated slot 111 provided in the middle of the table 11, the elongated through slot 111 Two limit strips 112 are fixed on the top surface of the platen 11 at the front and rear ends of the groove 111, the top of the lower driving pressure roller 14 stretches out from the top surface of the platen 11, and the two ends of the outer wall of the support plate 13 are A moving mechanism 20 is fixed, and at least two clamping blocks 31 are provided in the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com