Glue-coating device used for folding machine and its glue-coating method

A technology of a gluing device and a folding machine, which is applied in the device, coating, printing and other directions of applying liquid to the surface, and can solve the problems of unusability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

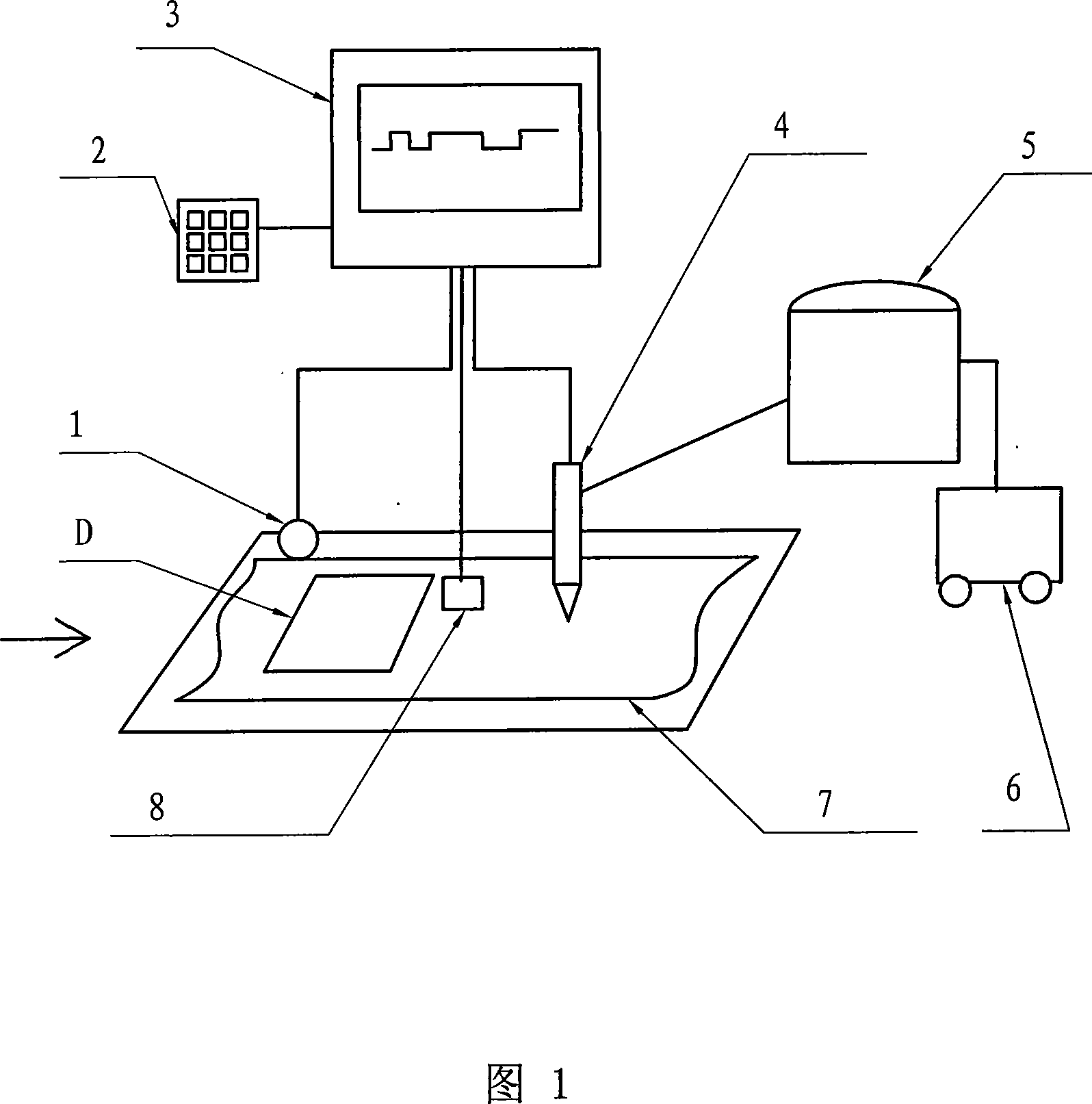

[0027] The present invention will be described in detail below according to the drawings and embodiments.

[0028] Press the command button on the keyboard 2 to control the glue applicator 4 or the screen to control the glue applicator 4, and the corresponding coil of the glue applicator 4 will be energized. If the air pump 6 can supply air pressure normally, the glue in the pressure cooker 5 will be It flows out through the glue applicator 4 along the pipeline. This function is used when the device is debugged and cleaned.

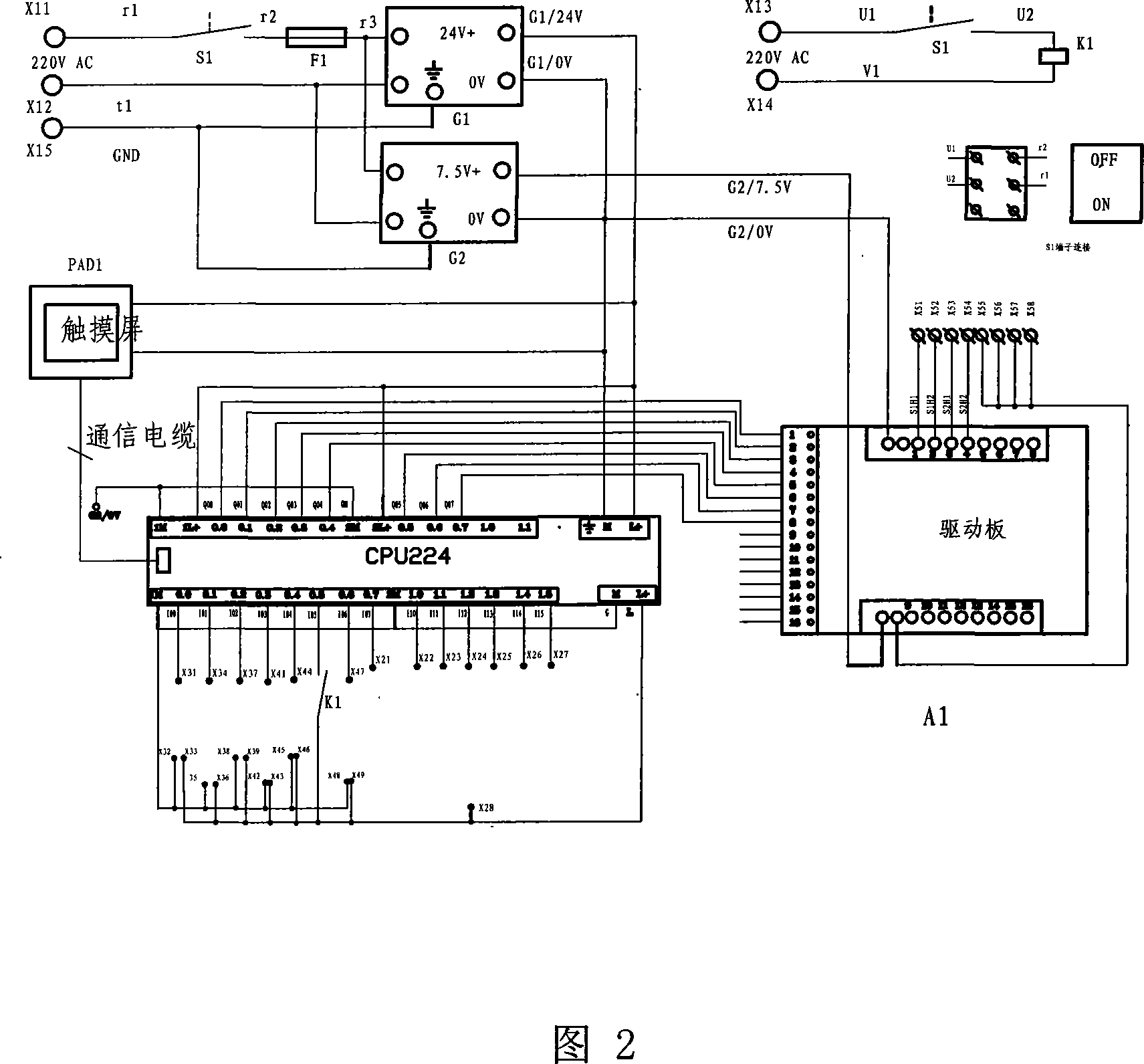

[0029] The rotary encoder 1 is connected to the pulse input end of the high-speed counter of the programmable controller 3, and the output of the photoelectric sensor 8 is connected to the interrupt signal input end of the programmable controller 3. When the workpiece D to be bound moves to the detection position of the photoelectric sensor 8 with the folder, the photoelectric sensor 8 is triggered, and the sensor 8 sends a signal to the interrupt receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com