Gluing device for packaging box production

A technology of gluing device and packaging box, which is applied in the directions of packaging, device for coating liquid on the surface, transportation and packaging, etc., can solve the problems of cardboard sticking to the brush, poor coating effect, and easy shaking of cardboard. , to avoid precipitation, increase friction, and improve the effect of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

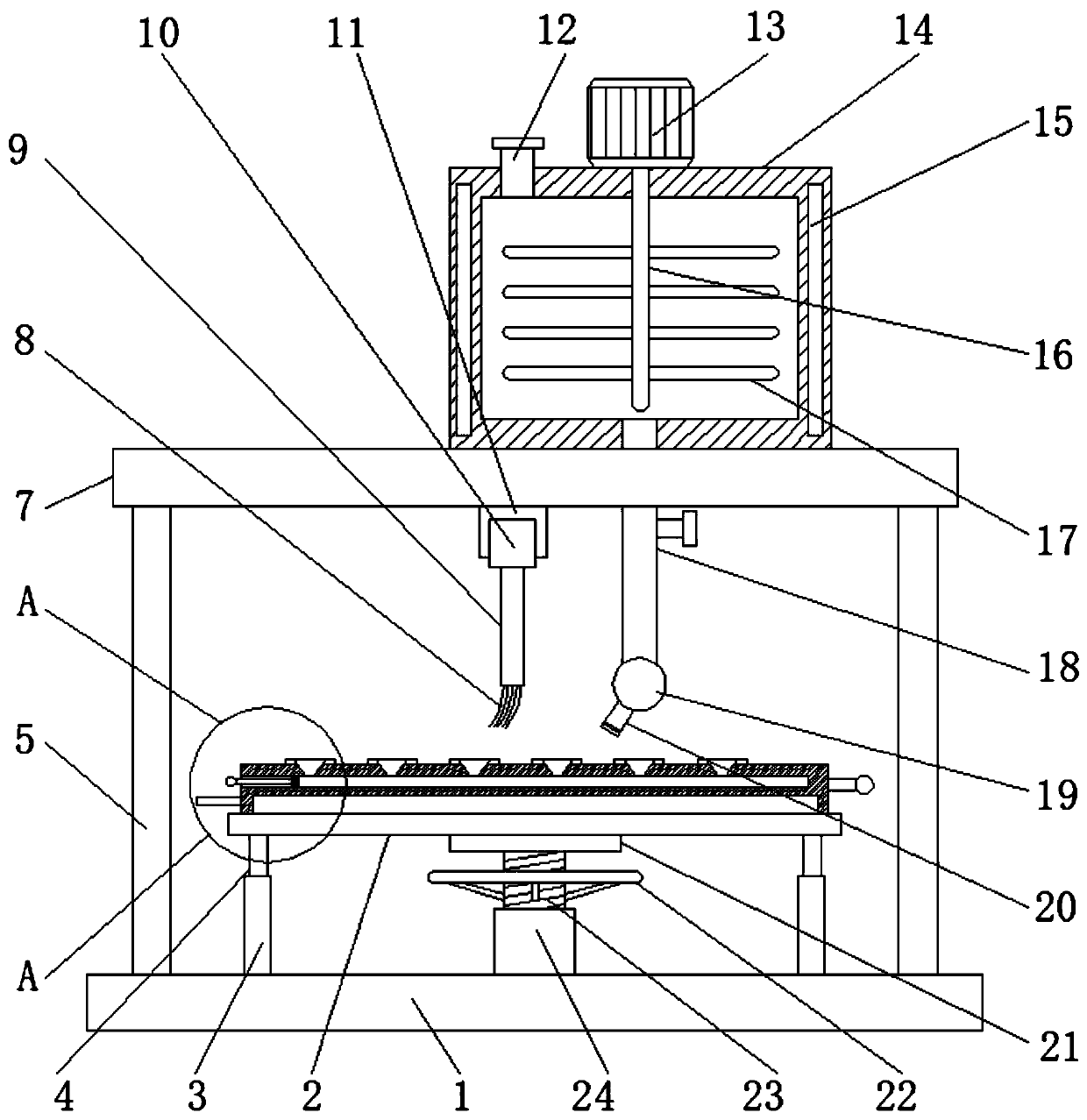

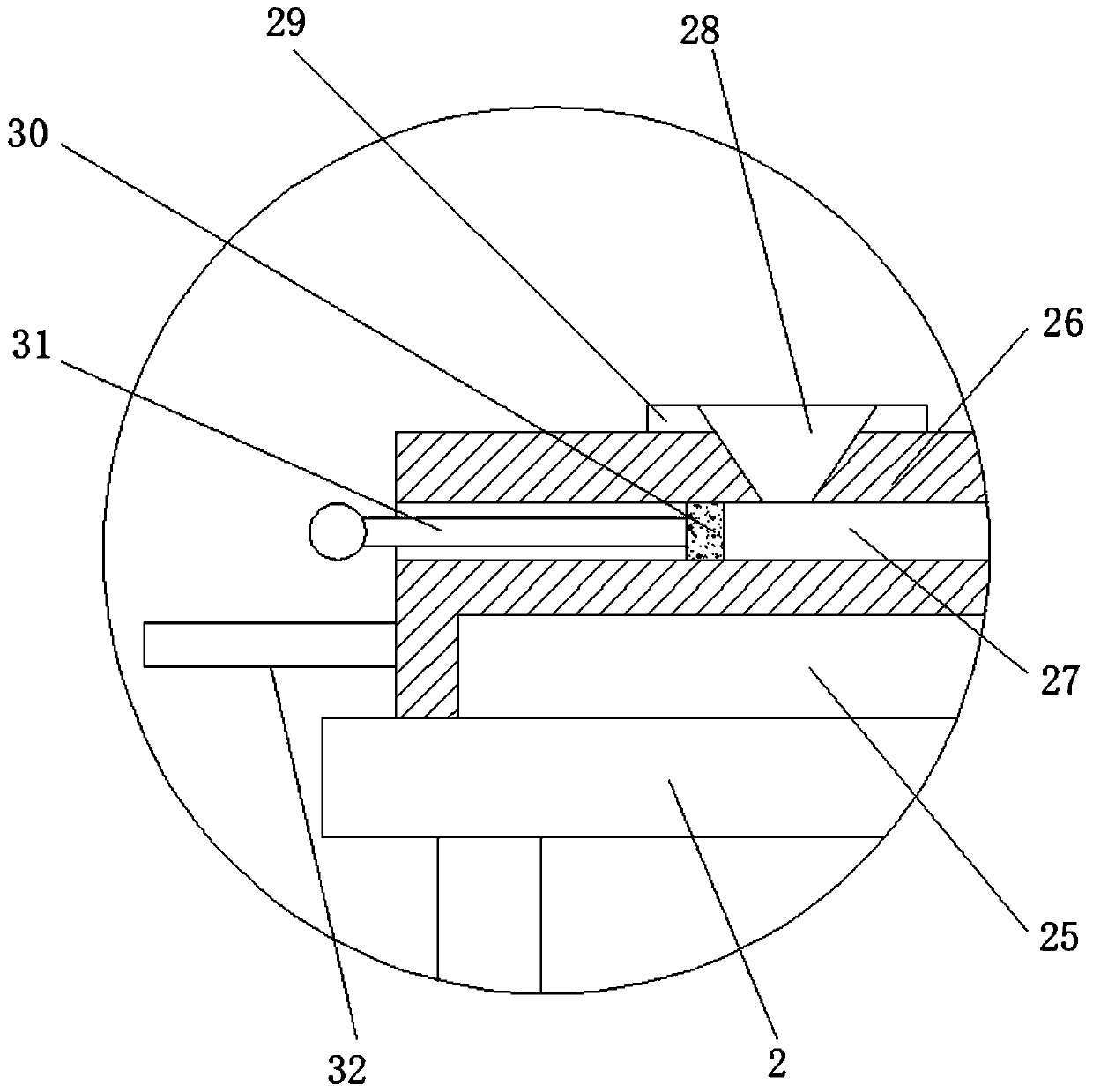

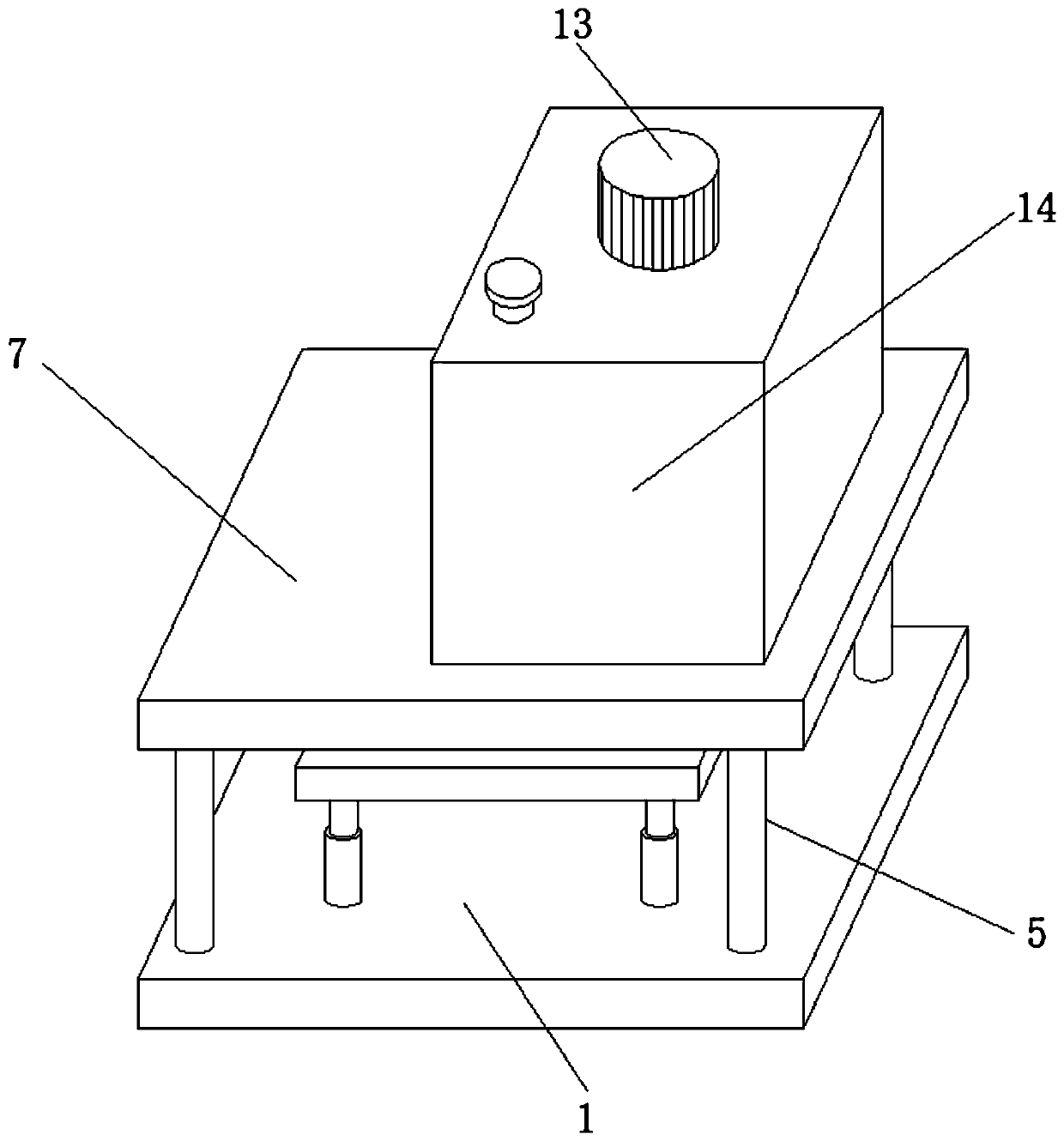

[0032] refer to Figure 1-3 , a kind of gluing device for packaging box production, comprising a bottom plate 1, four corners of the top outer wall of the bottom plate 1 are welded with columns 5, and the top outer wall of the column 5 is welded with a top plate 7, and the bottom outer wall of the top plate 7 is connected by bolts. The electric slide rail 11, and the inner wall of the electric slide rail 11 is slidably connected with a slider 10, the bottom outer wall of the slider 10 is welded with equidistant vertical rods 9, and the bottom outer wall of the vertical rod 9 is bonded with a brush 8, the top plate The outer wall of the top of 7 is connected with a glue storage box 14 by bolts, and the top outer wall of the glue storage box 14 is welded with a rubber adding pipe 12, and the bottom outer wall of the glue storage box 14 is welded with a rubber discharge pipe 18, and one side of the outer wall of the rubber discharge pipe 18 is provided with a Control valve, the b...

Embodiment 2

[0036] refer to Figure 4 , a kind of gluing device for packaging box production. Compared with Embodiment 1, this embodiment also includes that the top outer wall of the top plate 7 is connected with a blower 33 by bolts, and one side of the outer wall of the blower 33 is connected with an air guide pipe 34 by bolts. , The outer wall of the bottom of the air guide pipe 34 is welded with an air guide cover 35 .

[0037] Working principle: when in use, the blower 33 is driven to work, and the air can be blown out through the wind guide hood 35, and blown to the surface of the cardboard, which can blow away the dust on the surface of the cardboard, effectively preventing the glue from sticking to dust and affecting the coating effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com