Automatic gluing mechanism

A gluing, automatic technology, applied in the direction of coating, the device for applying liquid to the surface, etc., can solve the problems of the gluing rod inserted outside the catheter or the end face of the catheter, the work efficiency is low, and the gluing cannot be normally applied. The effect of better gluing effect, rapid response, and higher qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

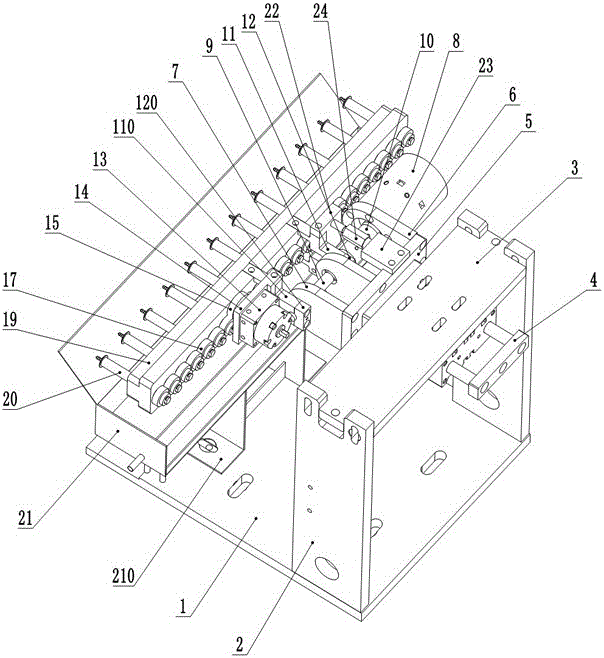

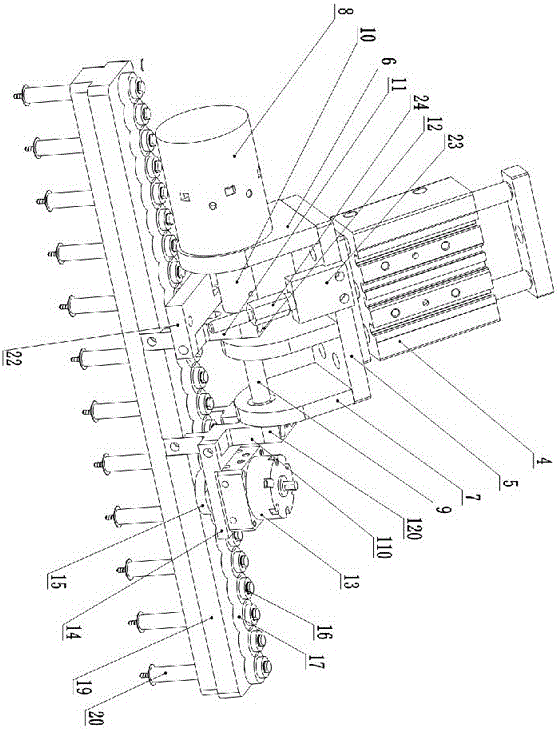

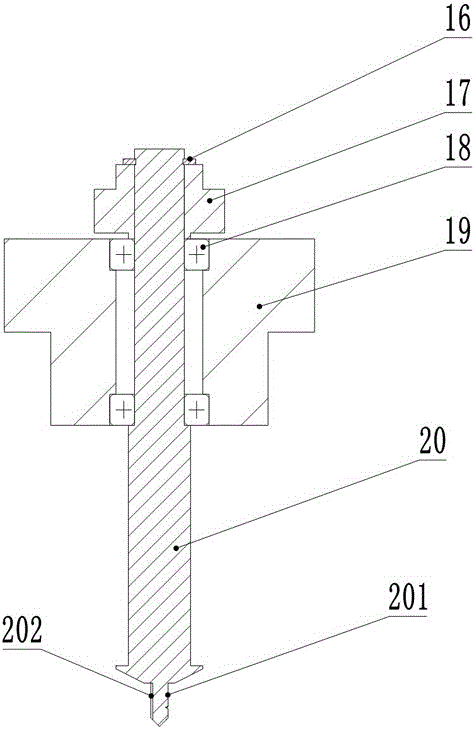

[0017] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing: Figure 1-4 As shown, the automatic gluing mechanism includes a gluing bottom plate 1, a gluing vertical plate 2 and a reciprocating cylinder seat 3. There are positioning grooves on both sides of the gluing bottom plate 1, and at the same time, there are positioning long grooves and two screw holes on the large surface. and four installation holes, the glued vertical plate 2 is vertically arranged on both sides of the rubberized bottom plate 1, the upper end of the glued vertical plate 2 is provided with grooves and long slotted holes, the reciprocating cylinder seat 3 is a steel plate, and both ends are provided with convex holes. The table is erected in the groove of the glue-coated vertical board 2, and fixed with screws in the long slot hole on the side of the glue-coated vertical board 2 after adjusting the height of the recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com