Patents

Literature

343results about How to "Improve charging safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

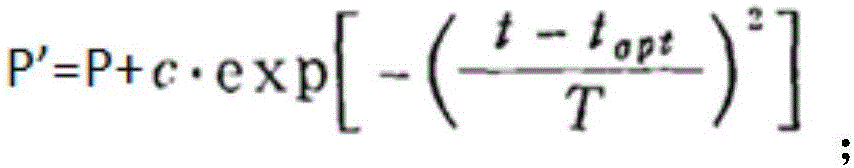

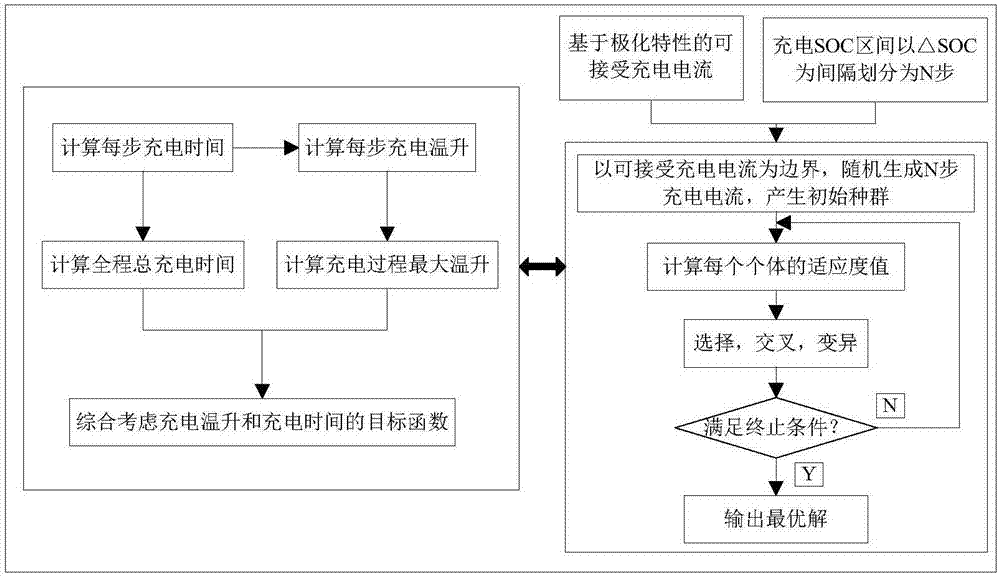

Lithium ion battery optimized charging method based on time and temperature

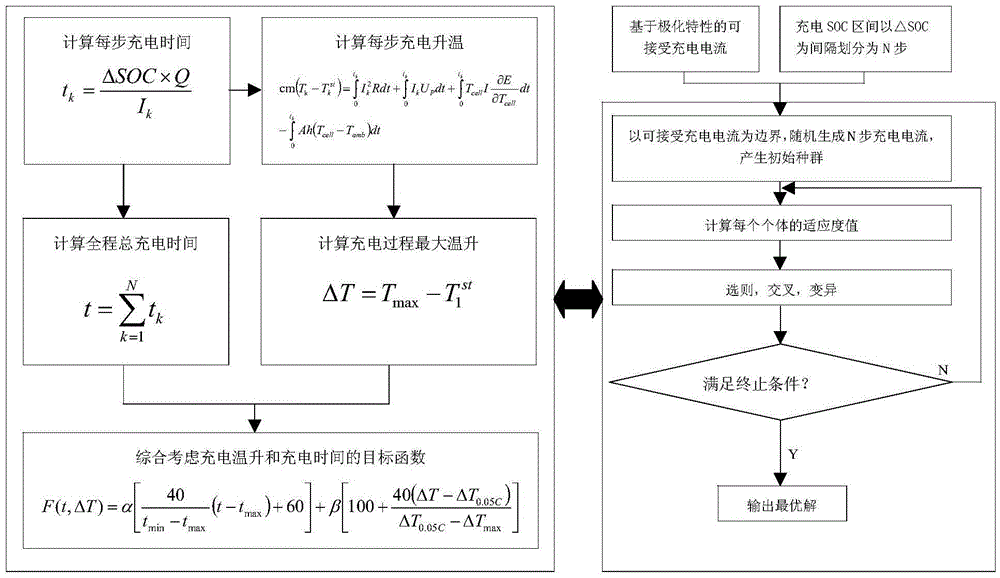

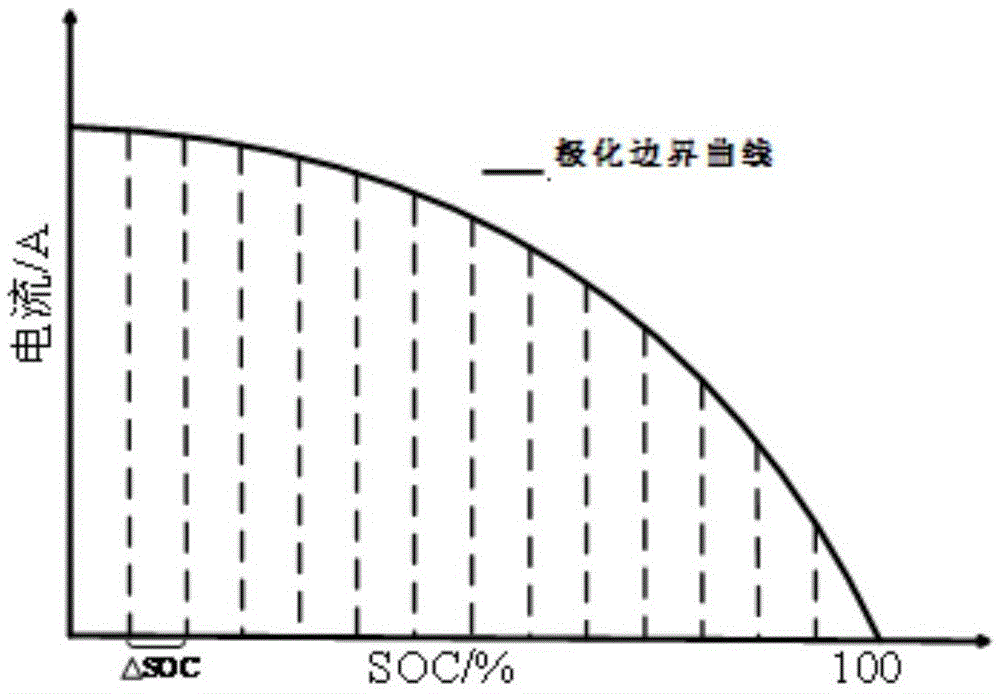

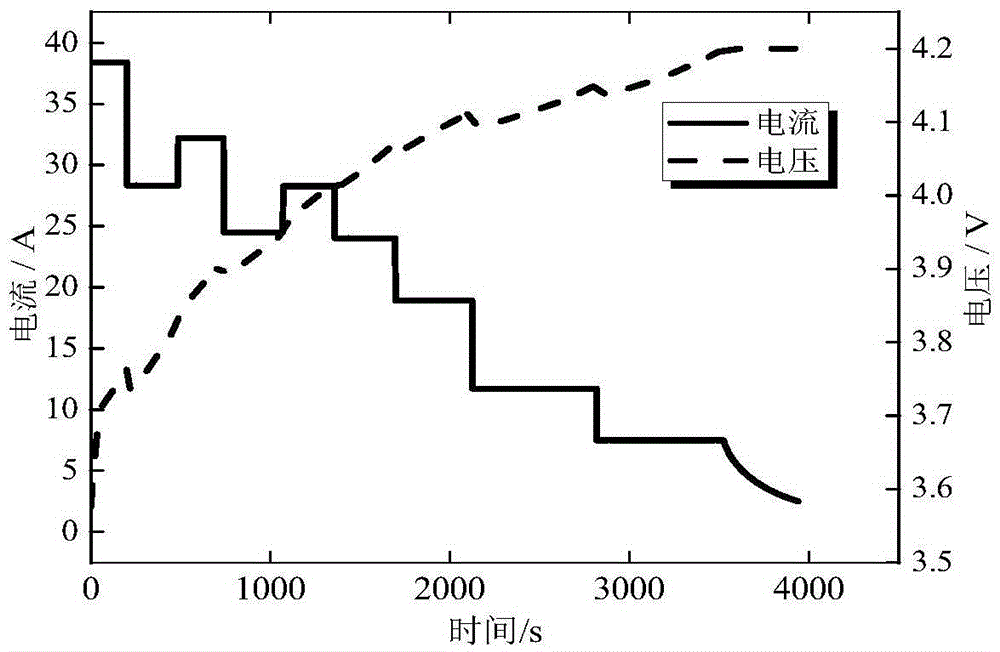

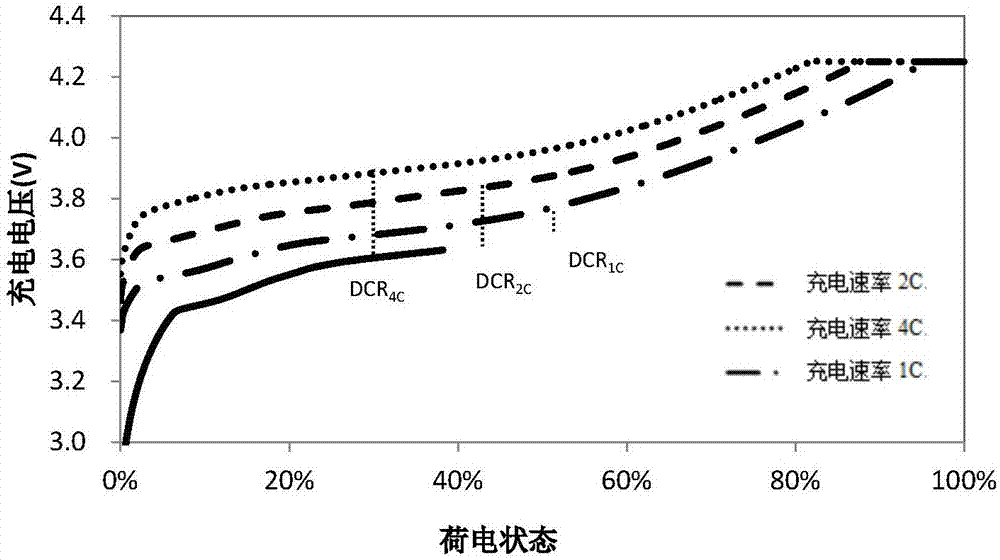

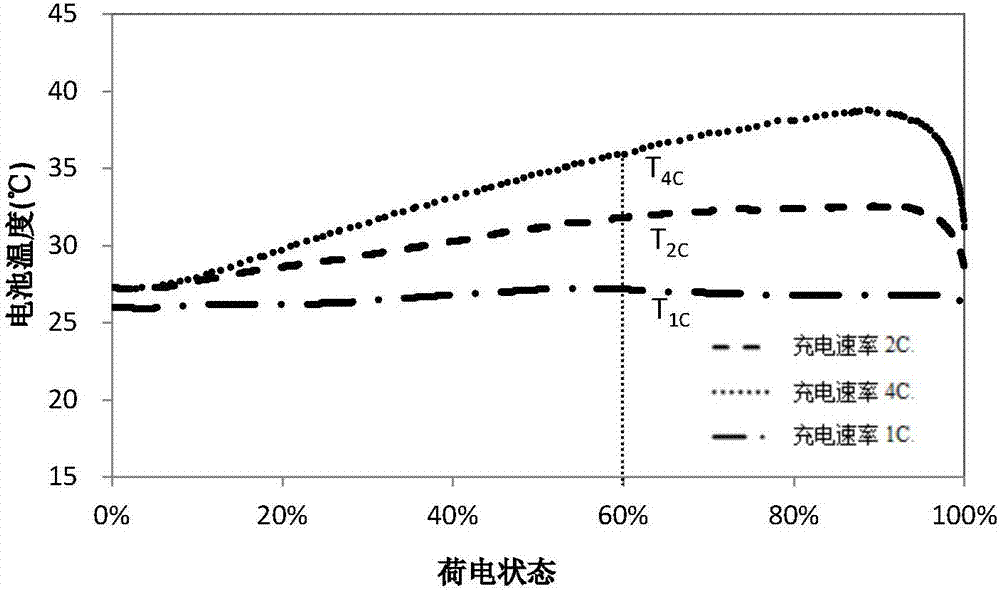

ActiveCN105552465ALimit charging temperature riseAvoid thermal runawayBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentGenetic algorithm

The invention relates to the technical field of battery charging, in particular to a charging method of a lithium ion battery based on time and temperature. Polarization voltage limited maximum charging current is calculated based on lithium ion battery polarization characteristics, and under the constraint of the maximum charging current, charging temperature rise and charging time are considered comprehensively, genetic algorithm is employed to search the optimal charging current so as to balance the mutual contradictory objects of reducing charging time and lowering charging temperature rise. The result shows that the optimal charging current ensures charging rapidity, at the same time controls the polarization voltage and temperature rise of the charging process within an allowable range, and guarantees the charging capacity, charging efficiency and charging safety and battery life.

Owner:BEIJING JIAOTONG UNIV

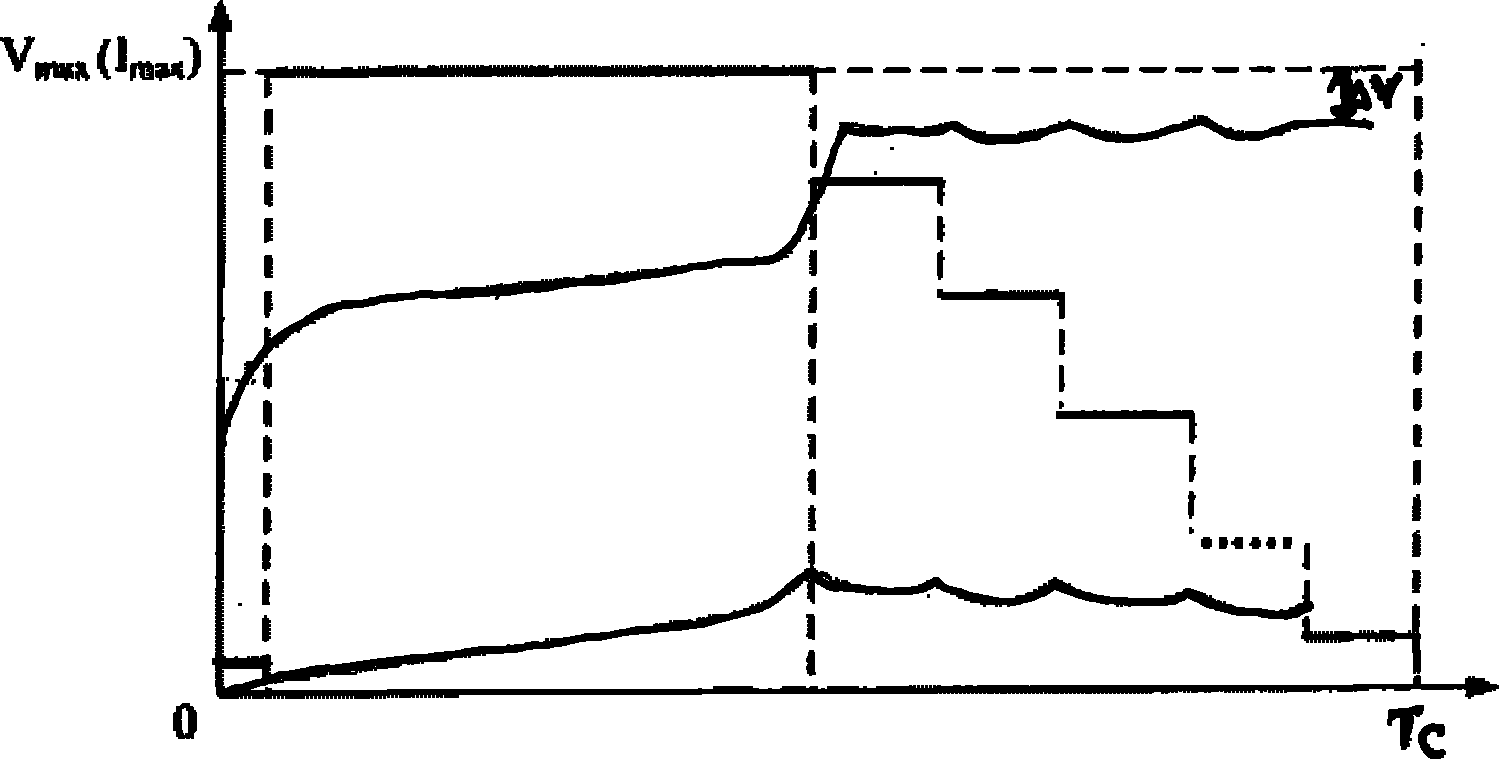

CC-CV charging method for improved power lithium ion battery

ActiveCN101814640AImprove charging efficiencyExtended service lifeSecondary cells charging/dischargingCharge currentPower efficient

The invention relates to the technical field of the lithium ion batteries, in particular to a CC-CV charging method for an improved power lithium ion battery. The charging method comprises the following steps of: firstly, pre-charging the lithium ion battery by adopting 0.1C-0.3C current; enhancing the charging current to the constant charging stage when the charging capacity reaches 5% of the total capacity of the battery; and entering the constant voltage charging stage when the polarization voltage of the battery is abrupt. When the battery is at an environmental temperature of 20-45 DEG C, the charging current formula adopted in the constant current stage is ICC=KC*CA, wherein KC represents the charging and discharging multiplying power efficient at constant temperature of the battery, CA represents the actual capacity of the batter, and Kc is usually 0.5-1. In the method, the external characteristic parameters of the battery are fully taken into consideration, and the charging efficiency and service life of the battery are taken into account.

Owner:HUIZHOU EPOWER ELECTRONICS +1

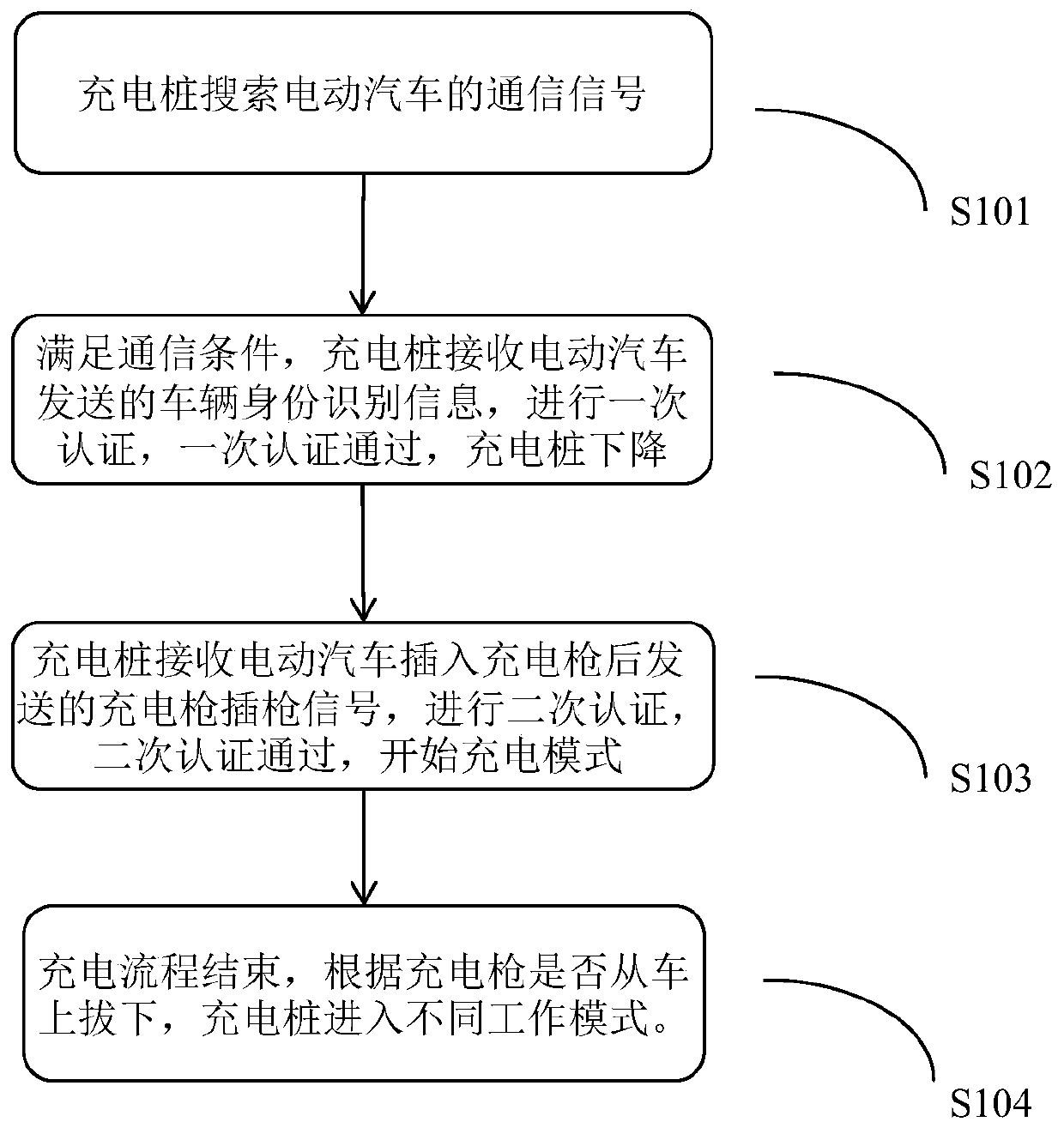

Intelligent charging method and system for electric vehicle

ActiveCN109866648AImprove experienceEasy to checkCharging stationsElectric vehicle charging technologyParking spaceElectric vehicle

The invention relates to the technical field of electric vehicles, in particular to an intelligent charging method and system for an electric vehicle. The intelligent charging method comprises the steps of enabling a charging pile to search for a communication signal of the electric vehicle, enabling the charging pile to receive vehicle identification information sent by the electric vehicle to perform primary authentication if the communication signal satisfies a communication condition, enabling the charging pile to control a parking space blocker to descend if the vehicle identification information received by the charging pile is in accordance with authorized vehicle identification information, enabling the charging pile to receive a charging gun insertion signal sent by the electric vehicle after the charging gun is inserted so as to perform secondary authentication, and enabling the charging pile to start a charging mode to charge the electric vehicle if the vehicle identification information of the electric vehicle included in the charging gun insertion signal is in accordance with the authorized vehicle identification information. The intelligent charging method and systemfor the electric vehicle greatly improve the user experience of charging, and reduce the operation and maintenance time and cost of an enterprise and a user to a certain extent. The charging safety ishigher.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

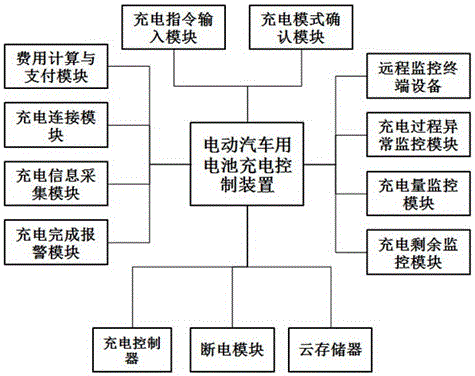

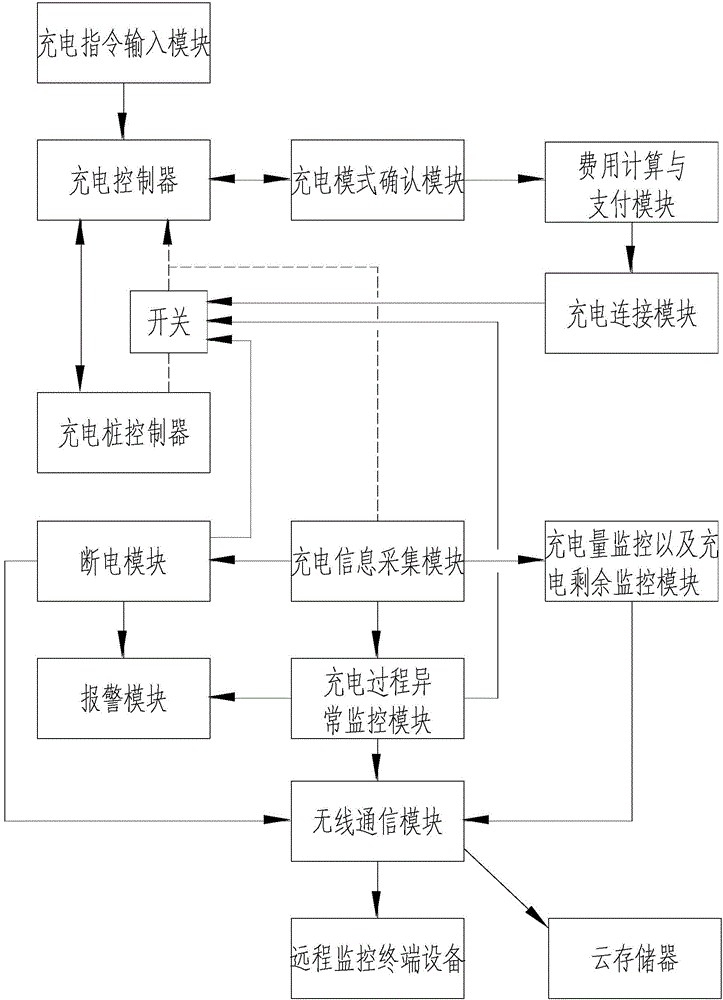

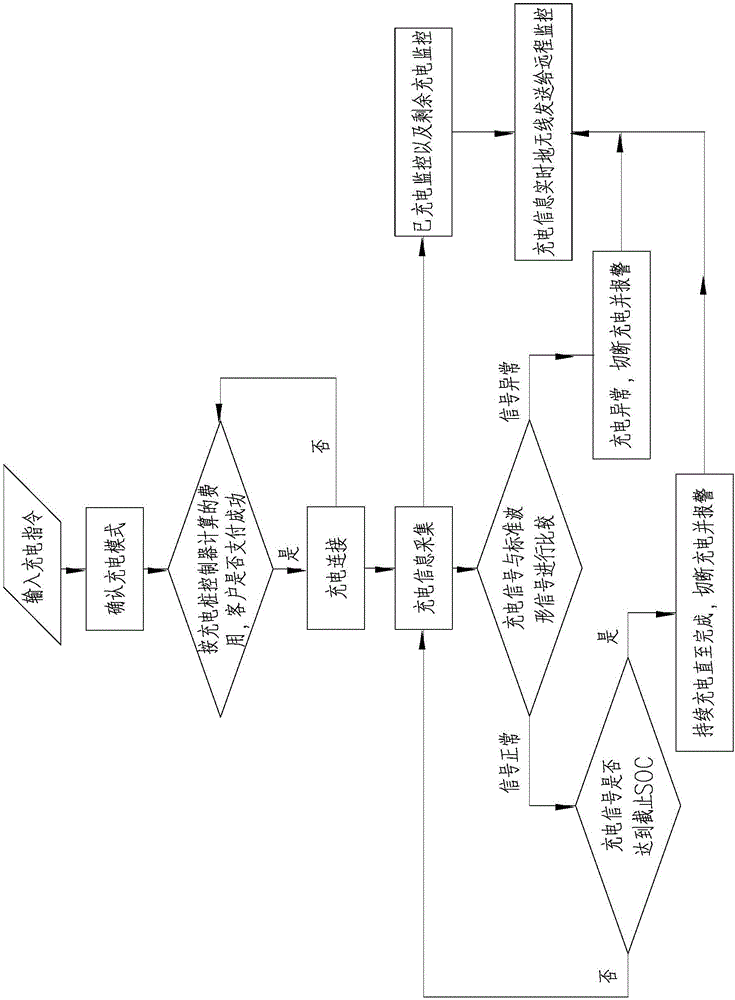

Charging control method and apparatus of battery for electric vehicle

InactiveCN106208220AImprove charging safetyImprove stabilityCircuit monitoring/indicationCharging stationsElectrical batteryEngineering

The invention discloses a charging control method and apparatus of a battery for an electric vehicle. The charging control apparatus comprises a charging controller, a charging instruction input module, a charging mode confirmation module, a cost calculation and payment module, a charging connection module, a charging information acquisition module, a charging process abnormity monitoring module, a charging amount monitoring module. a charging residue monitoring module, remote monitoring terminal equipment, a power-off module, a charging completion warning module and a cloud storage. According to control of the charging control method and apparatus disclosed by the invention, by effectively monitoring charging information in real time, charging safety and stability of the battery for the vehicle are improved; the charging abnormity monitoring module can well carry out real-time monitoring on a charging abnormity; and the remote monitoring terminal equipment is arranged and remote monitoring is carried out in a wireless network mode, so that remote monitoring on the whole charging process of the battery is further improved.

Owner:AGA TECH CO LTD

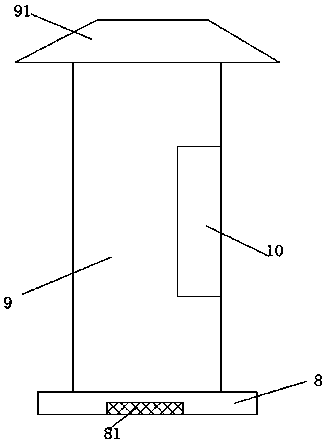

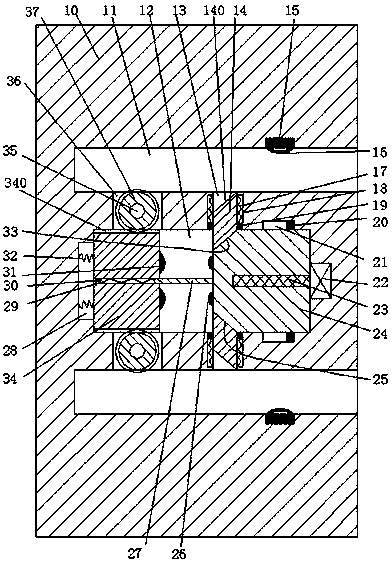

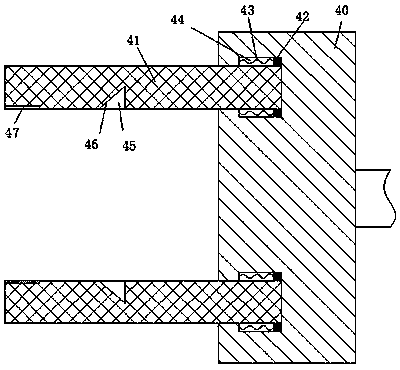

Novel energy charging pile device

InactiveCN108233013AImprove charging safetyRealize chargingVehicle connectorsCharging stationsElectricityAlternative fuel vehicle

The invention discloses a novel energy charging pile device. The novel energy charging pile device comprises a charging pile body, a charging end and a charging terminal, wherein the charging end is arranged on the right side end face of the charging pile body; the charging terminal is connected with a novel energy automobile; a base is fixedly arranged at the bottom of the charging pile body; a counterweight block is arranged on the bottom in the base; a rain-proof cover is fixedly arranged on the top of the charging pile body; insertion holes which have ports facing rightwards and are formedcorresponding in vertical direction are formed in the charging end; a slide cavity capable of extending leftwards and rightwards is formed between the two insertion holes in the charging end; a leftslide block and a right slide block capable of sliding leftwards and rightwards are arranged in the slide cavity; power transmission plugs which are connected with the commercial power are arranged onthe right end face of the left slide block in vertical direction; electric connectors which are matched with the power transmission plugs are arranged on the left end face of the right slide block vertically.

Owner:广州必果贸易有限公司

Charging control device and method of battery used in electric vehicle

InactiveCN106494251AEffective monitoringEfficient managementCharging stationsElectric vehicle charging technologyReal-time chargingElectricity

The invention relates to the technical field of battery charging of electric vehicles, in particular to a charging control device and method of a battery in an electric vehicle. The charging control device comprises a charging controller, a charging instruction input module, a charging pile controller, a charging mode affirming module, a charge calculating and paying module, a charging connecting module, a charging information collecting module, a charging process exception monitoring module, a charging volume monitoring and charging remain monitoring module, a power-off module, an alarming module and a remote monitoring terminal device, wherein the remote monitoring terminal device is used for receiving in real time charging information of the charging process exception monitoring module, the charging volume monitoring and charging remain monitoring module and the power-off module through a wireless communication module. The charging control device and method of the battery in the electric vehicle has the advantages that remote monitoring of the charging process of the battery is achieved, safety and stability of battery charging are improved, integrated managements such as effective monitoring of various kinds, selections of charging modes and storage of charging information are achieved.

Owner:JIANGSU UNIV OF TECH

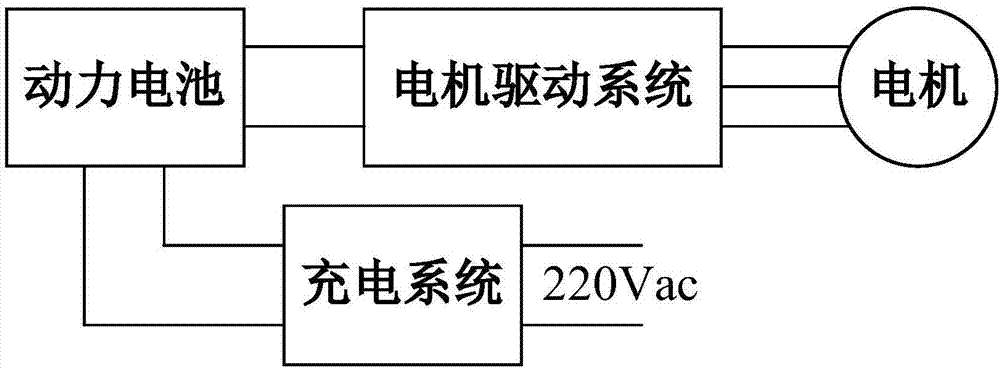

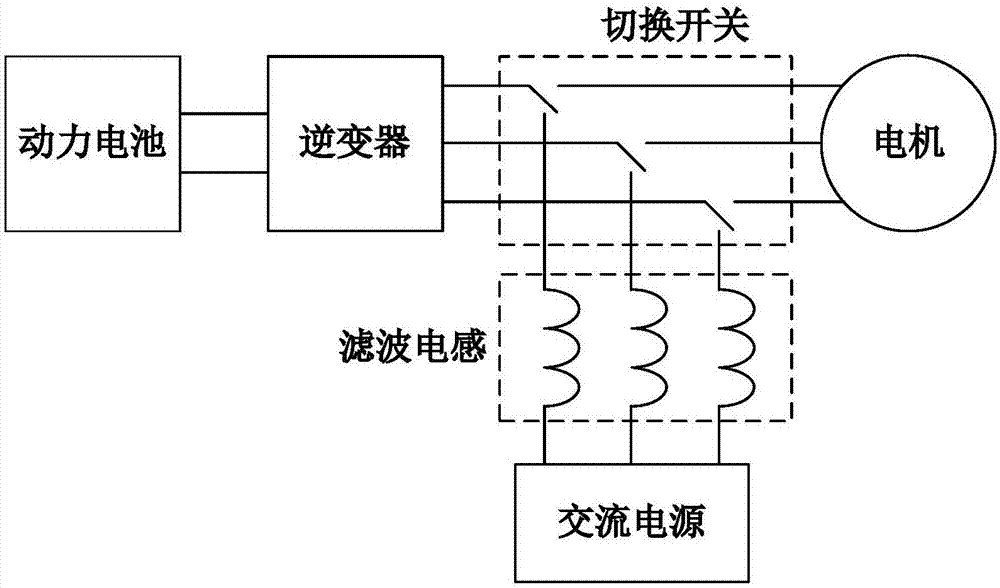

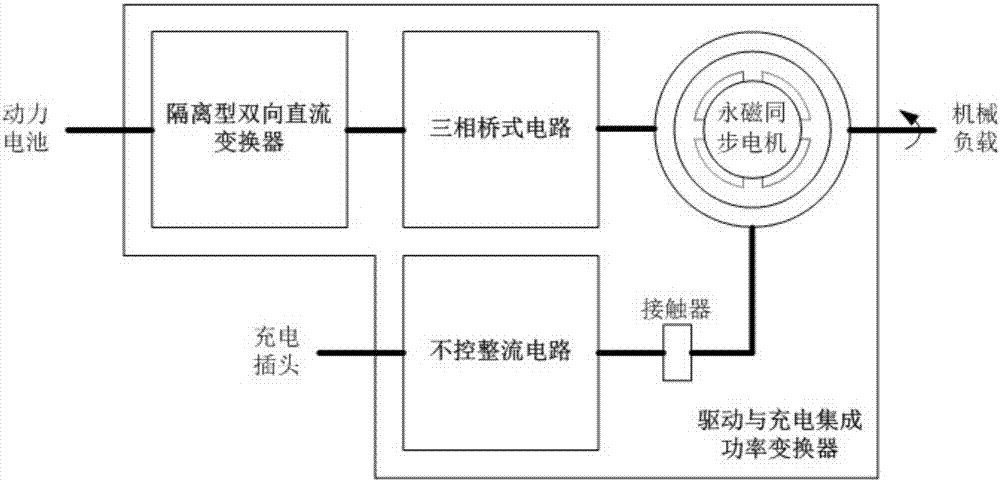

An integrated electric automobile driving and charging power converter

PendingCN107276415AImprove power densityImprove reliabilityAC motor controlCharging stationsElectrical batteryPower factor

The invention discloses an integrated electric automobile driving and charging power converter. The integrated electric automobile driving and charging power converter comprises an isolated bidirectional DC conversion circuit connected with a power cell, a motor three-phase stator winding, a three-phase bridge circuit of which an AC end is connected with the motor three-phase stator winding and a DC end is connected with the isolated bidirectional DC conversion circuit, a single-phase uncontrolled rectification circuit of which an AC end is connected with a charging plug, and a contactor connected between a neutral point of the motor three-phase stator winding and a DC end of the single-phase uncontrolled rectification circuit. The integrated electric automobile driving and charging power converter is advantaged in that the power converter is integrated to make a driving system and a charging system share the same power converter, and high power density, high reliability, unit power factor, electrical isolation and low cost can be realized.

Owner:NANJING NARI GROUP CORP +2

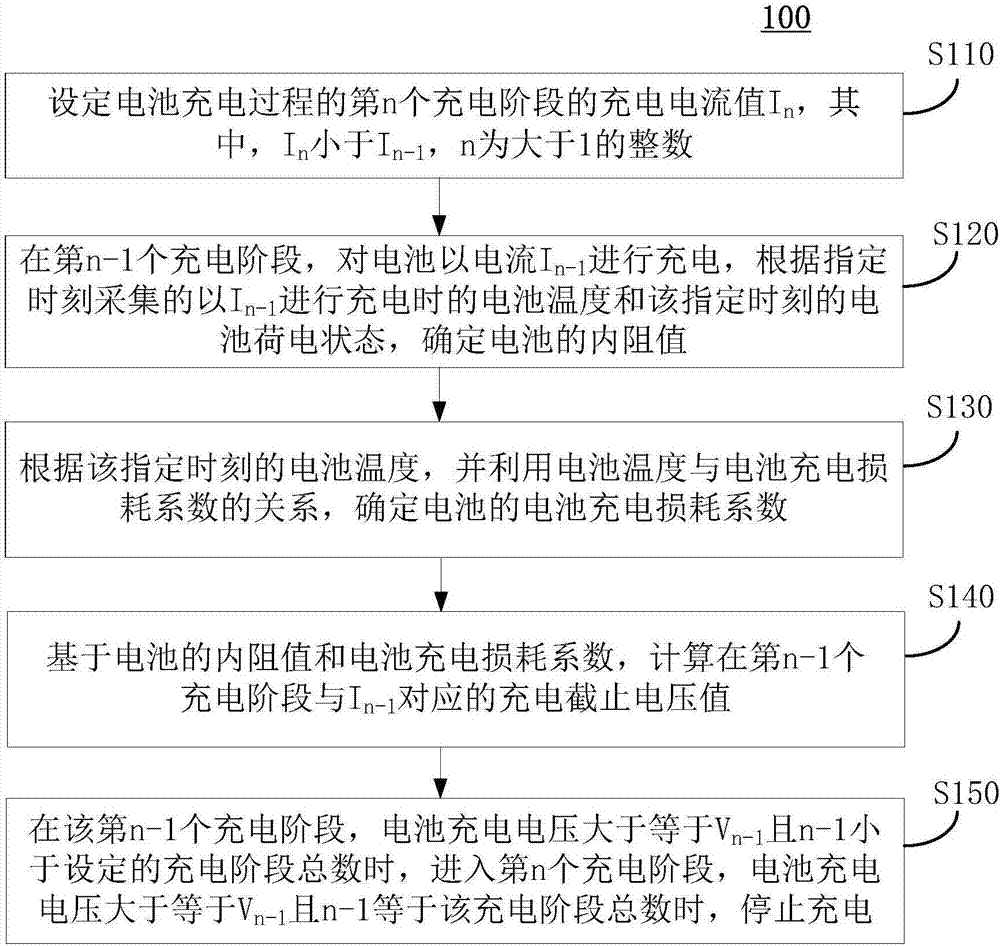

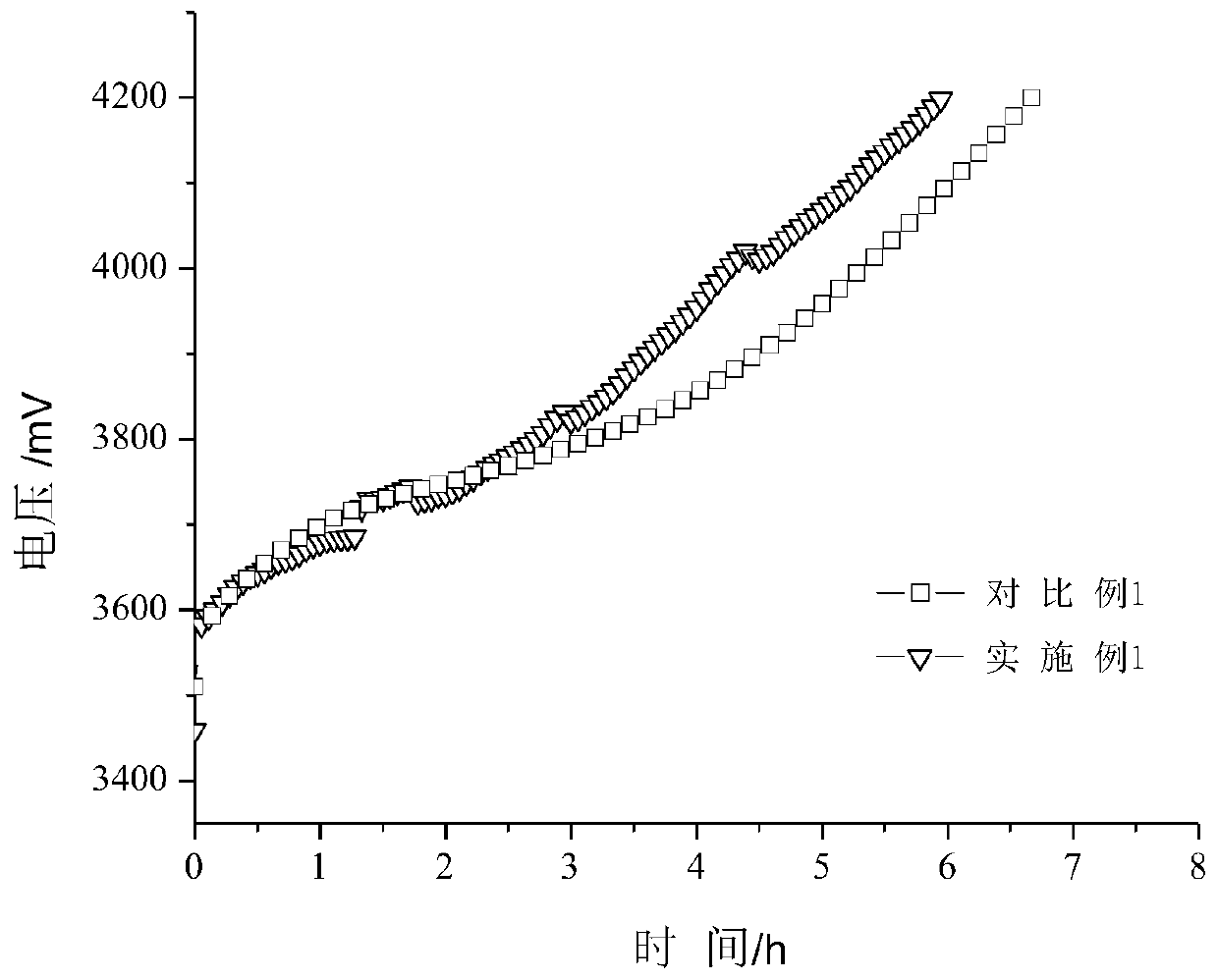

Battery charging method, apparatus and equipment and storage medium

ActiveCN107196371AImprove charging efficiencyReduce the risk of overchargingBatteries circuit arrangementsElectric powerCharge currentBattery charge

The invention discloses a battery charging method, apparatus and equipment and a storage medium. The charging method comprises the steps of setting a charging current value I<n> in the n charging stage in the battery charging process; in the (n-1) charging stage, determining a battery internal resistance value according to a battery temperature and state of charge at an appointed moment charged at I<n-1>; determining a battery charging loss coefficient according to the battery temperature at the appointed moment; correcting a charging cut-off voltage value V<n-1> corresponding to the I<n-1> according to the battery internal resistance value and the battery charging loss coefficient at the appointed moment; in the (n-1) charging stage, if the battery charging voltage is greater than or equal to V<n-1> and n-1 is less than the set charging stage total number, entering the n charging stage; and if the battery charging voltage is greater than or equal to V<n-1> and n-1 is equal to the charging stage total number, stopping charging. By virtue of the battery charging method provided by the embodiments, the charging efficiency can be improved, and risks of over-charging or over-discharging can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO

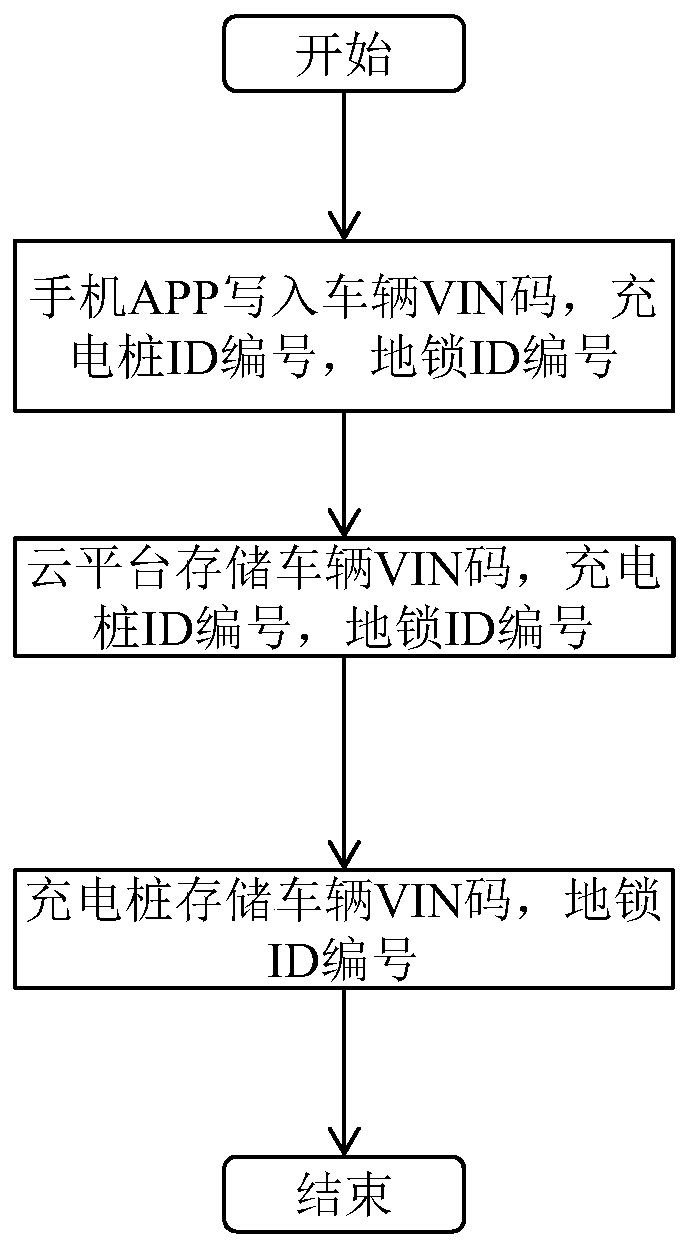

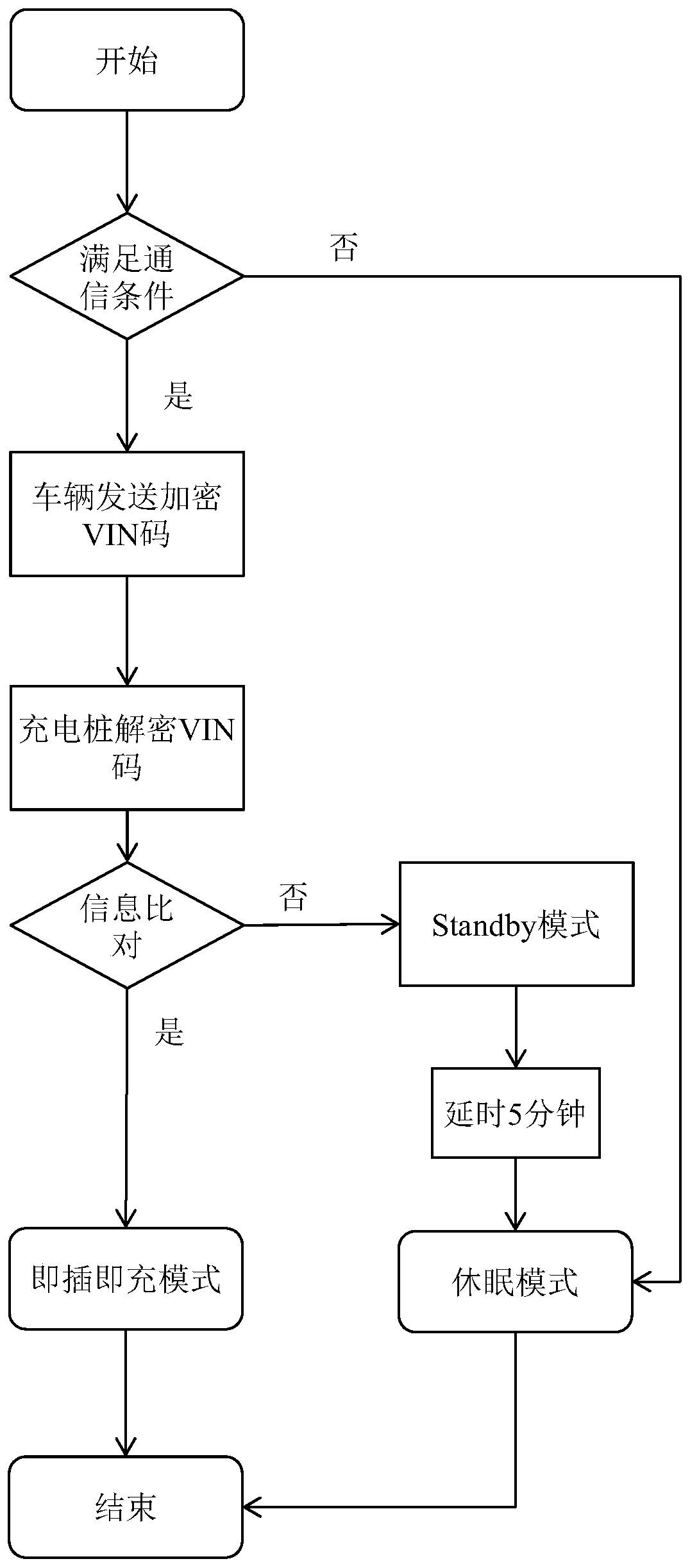

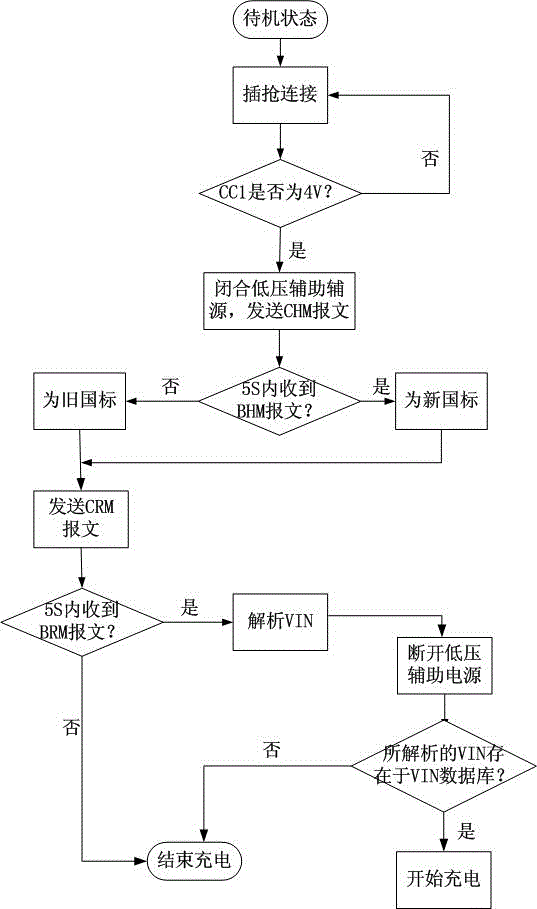

Method for automatically charging by utilizing vehicle identification number (VIN)

PendingCN106627230ASimplify the charging processThe charging process is convenient and fastCharging stationsElectric vehicle charging technologyLow voltageUser charge

The invention relates to a method for automatically charging by utilizing a vehicle identification number (VIN). The method comprises the following steps: detecting a connection state between a charging gun of a charging machine and a charging interface of a to-be-charged vehicle; providing a low-voltage auxiliary power supply for a BMS (battery management system) by the charging machine when the connection state is normal; transmitting a handshake identification message to the BMS by the charging machine and retransmitting a reply identification message to the charging machine by the BMS according to a communication protocol between the charging machine and the BMS, wherein the reply identification message is written into the VIN corresponding to the vehicle in advance; analyzing the VIN when the reply identification message is received by the charging machine in a preset period of time, and controlling to cut off the low-voltage auxiliary power supply; and contrasting the analyzed VIN with a pre-recorded VIN database, and controlling the charging machine to charge or not charge a battery of the vehicle. The method disclosed by the invention is used for solving the problems in the prior art such as complicated charging process, low portability, low reliability and low safety, automatic charging is realized, the charging convenience, reliability and safety are enhanced, and the user charging experience is improved.

Owner:QINGDAO TELD NEW ENERGY CO LTD

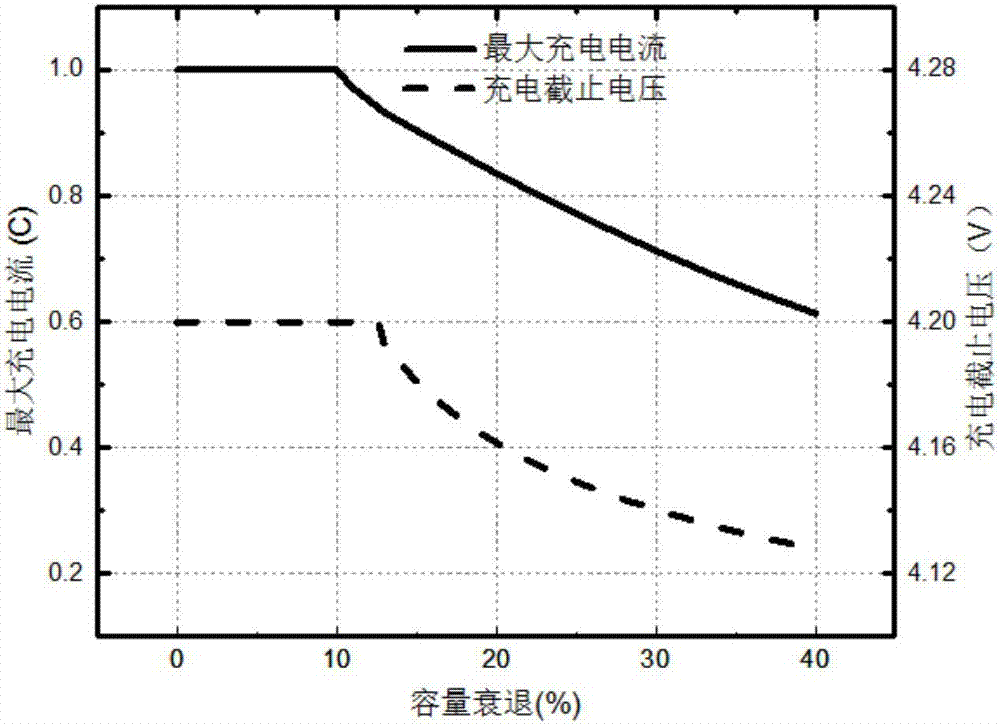

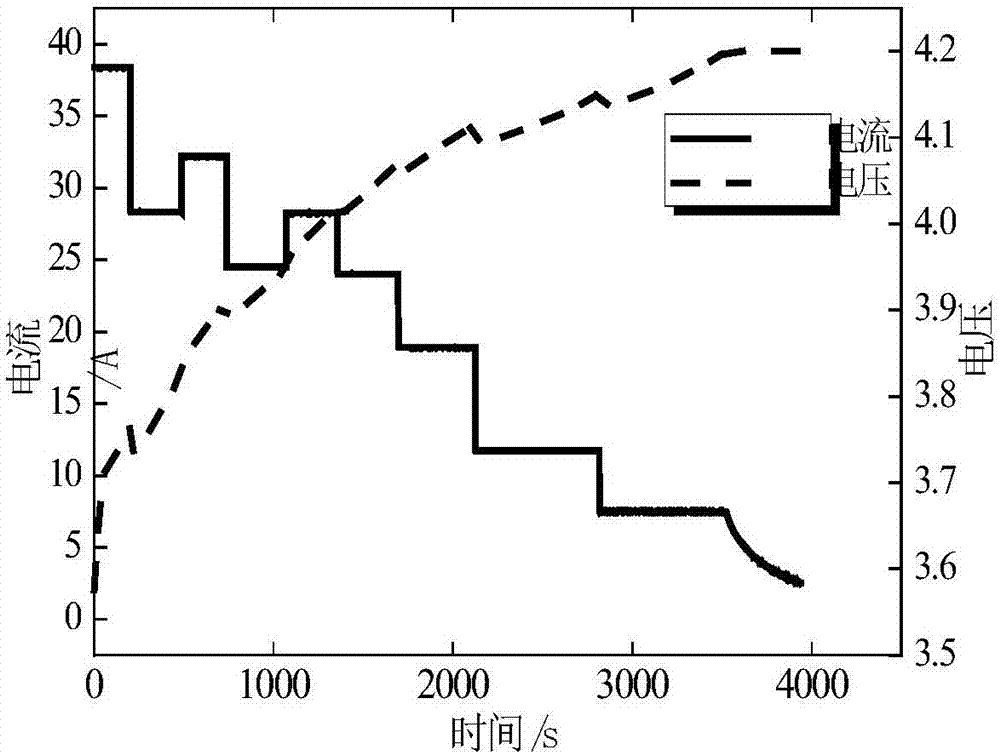

Optimized charging method of vehicle-mounted energy storage lithium ion battery for rail transit

ActiveCN107039696ALimit charging temperature riseAvoid thermal runawayBatteries circuit arrangementsSecondary cells charging/dischargingUltrasound attenuationBattery charge

The invention belongs to the technical field of charging of a lithium ion battery, and particularly relates to an optimized charging method of a vehicle-mounted energy storage lithium ion battery for rail transit. The optimized charging method comprises the steps of calculating maximum charging current and a charging cutoff voltage of a lithium ion battery within a full-life period according to cycle lifetime attenuation characteristic of the lithium ion battery; constructing an optimized charging target function under the constraint of the maximum charging current and the charging cutoff voltage by taking charging time reduction and battery charging temperature rising control as targets; and seeking an optimal charging current by a genetic algorithm so as to balance the two conflict targets of charging time reduction and the charging temperature rising reduction. A result shows that the optimal charging current is used for ensuring charging rapidness and simultaneously controlling a polarization voltage and the temperature rising during the charging process to be within allowable ranges, and the charging capacity, the charging efficiency, the charging safety and the battery lifetime are ensured.

Owner:BEIJING JIAOTONG UNIV +1

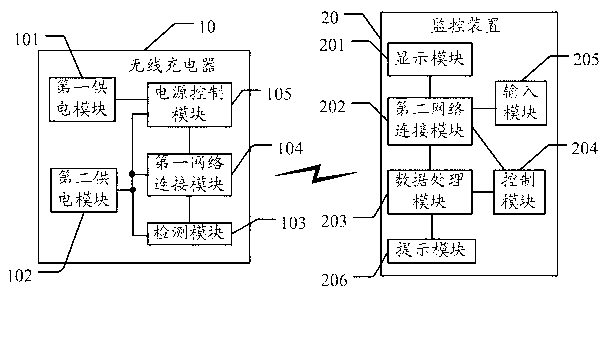

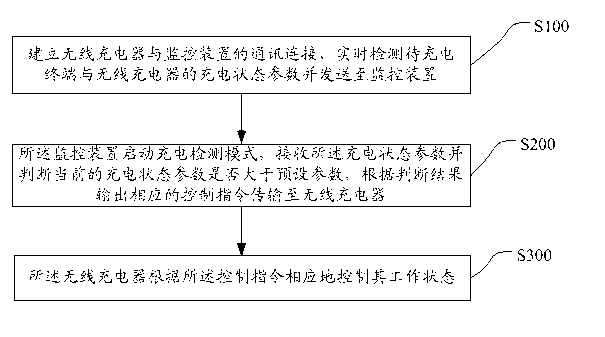

Wireless charging remote control system and remote control method thereof

InactiveCN103217955AOptimize charging control methodImprove charging safetyTotal factory controlProgramme total factory controlWork statusInductive charging

The invention discloses a wireless charging remote control system and a remote control method thereof. The system comprises a wireless charger and a monitoring device, wherein the wireless charger is in communication link with the monitoring device, the wireless charger can be connected with a network to send charging state parameters of a terminal to be charged and charging state parameters of the wireless charger to the monitoring device to be displayed, the monitoring device starts a charging monitoring mode, receives the charging state parameters and judges whether the charging state parameters are larger than preset parameters, and corresponding control orders can be output according to judgment results to remotely control a work state of the wireless charger. Thus, a user can monitor a charging process in real time, and charging abnormal phenomena can be remotely controlled at any place and any time. A charging control method of the wireless charger is optimized, charging safety is improved, and product competitiveness on the market is guaranteed.

Owner:DONGGUAN YULONG COMM TECH +1

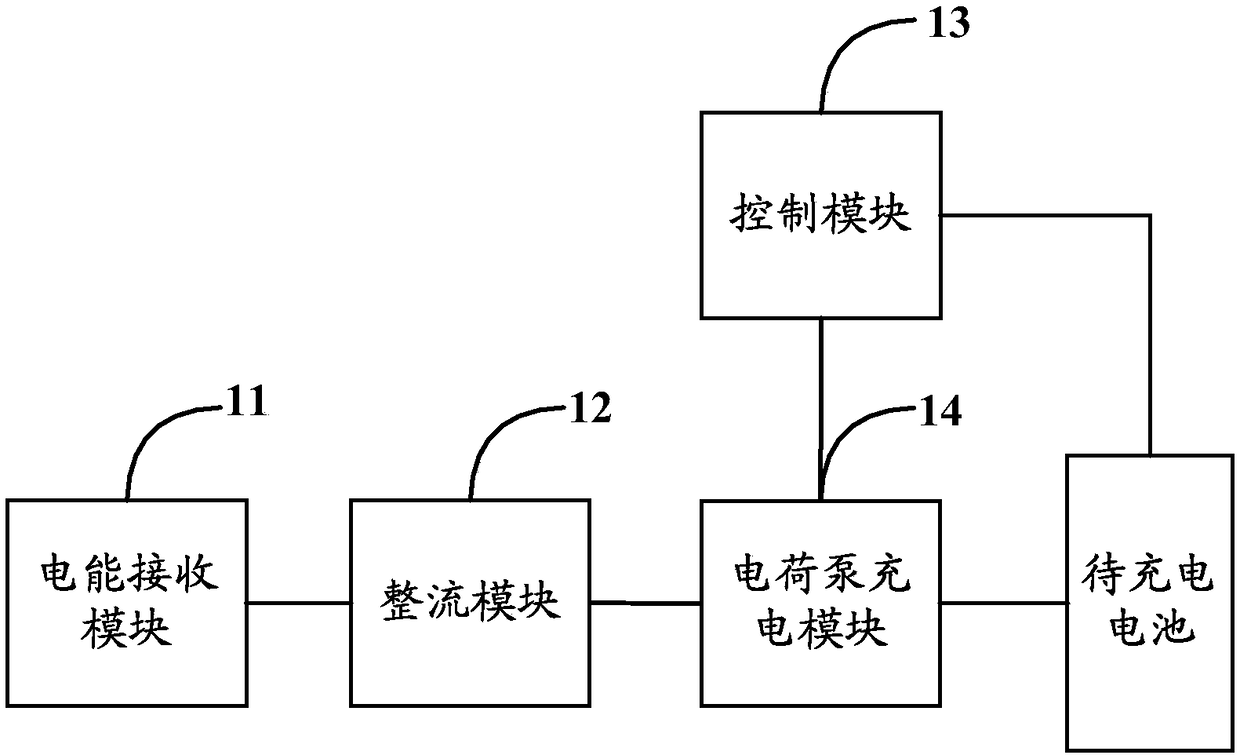

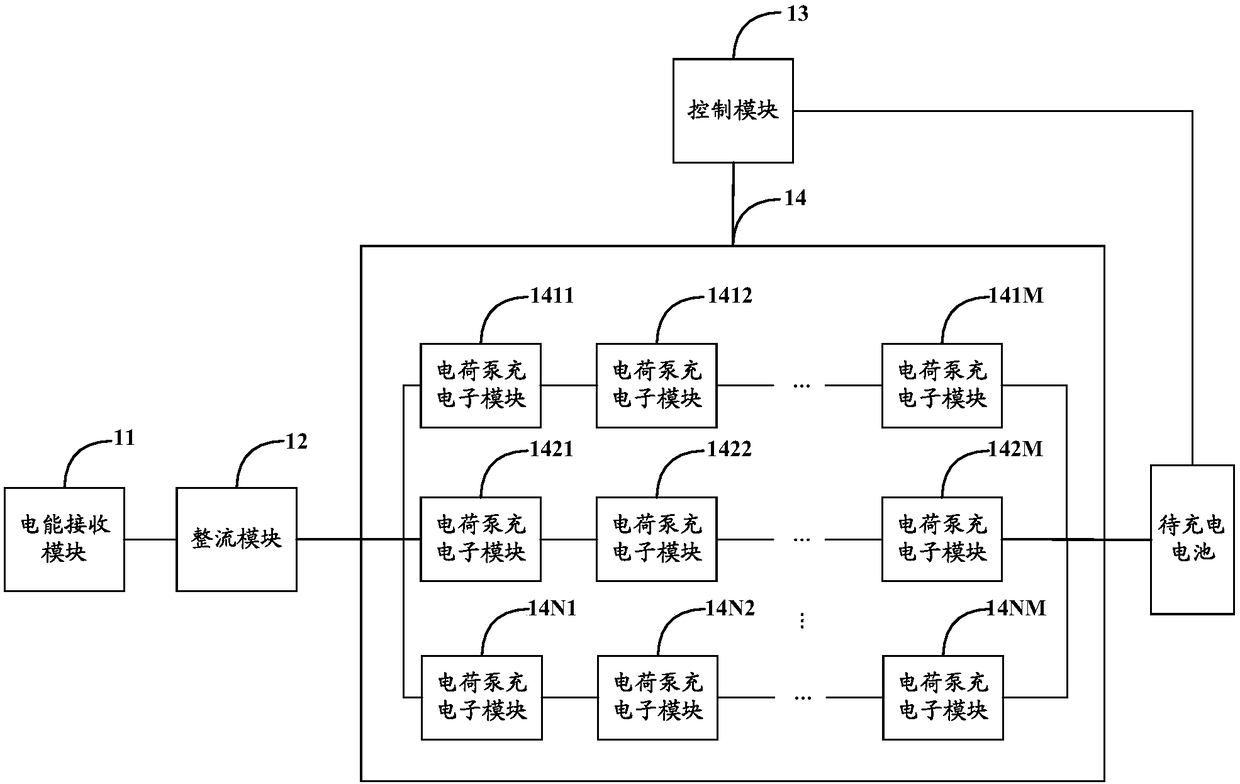

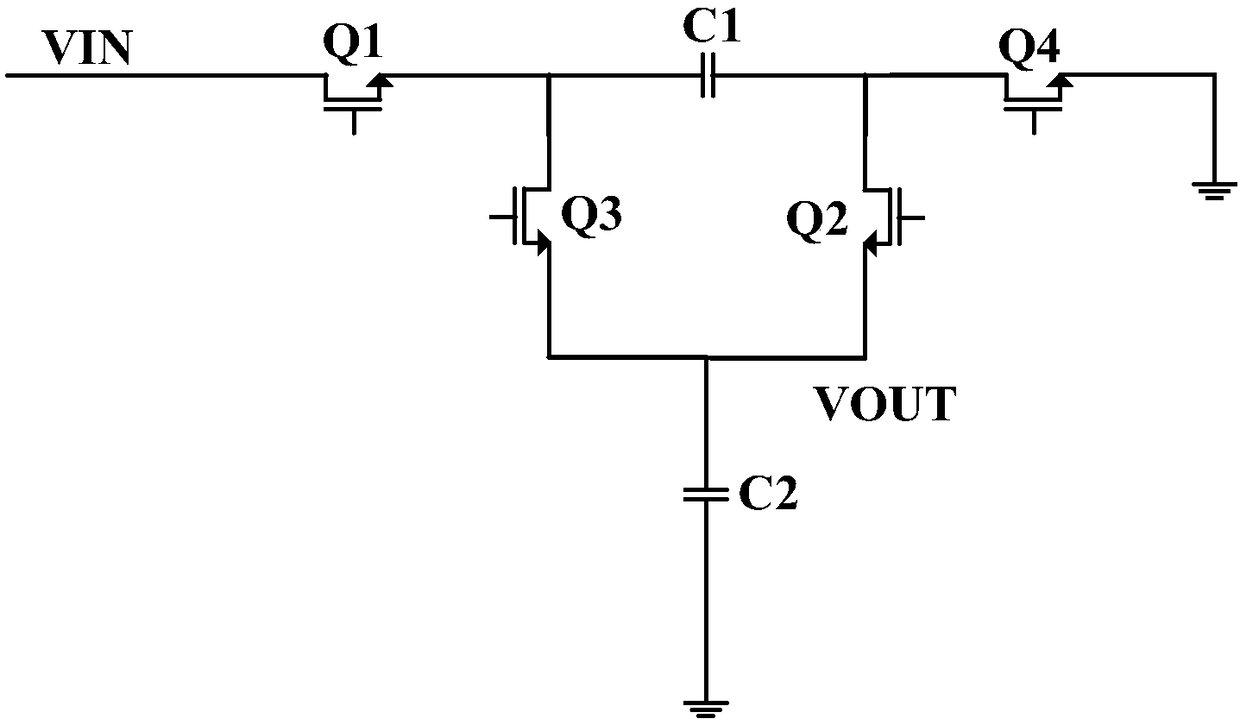

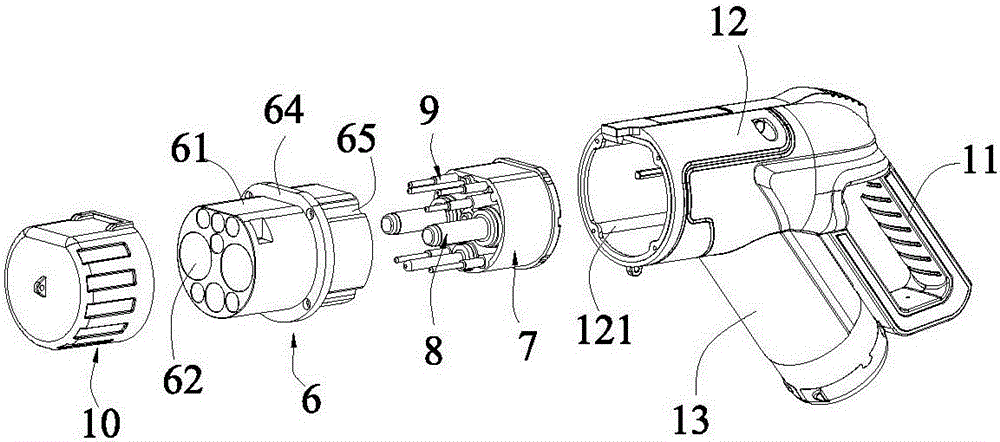

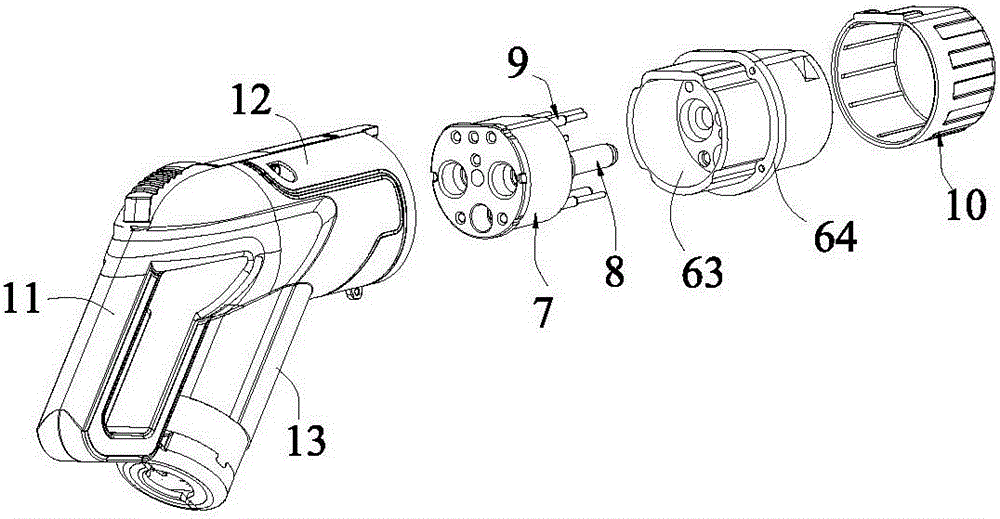

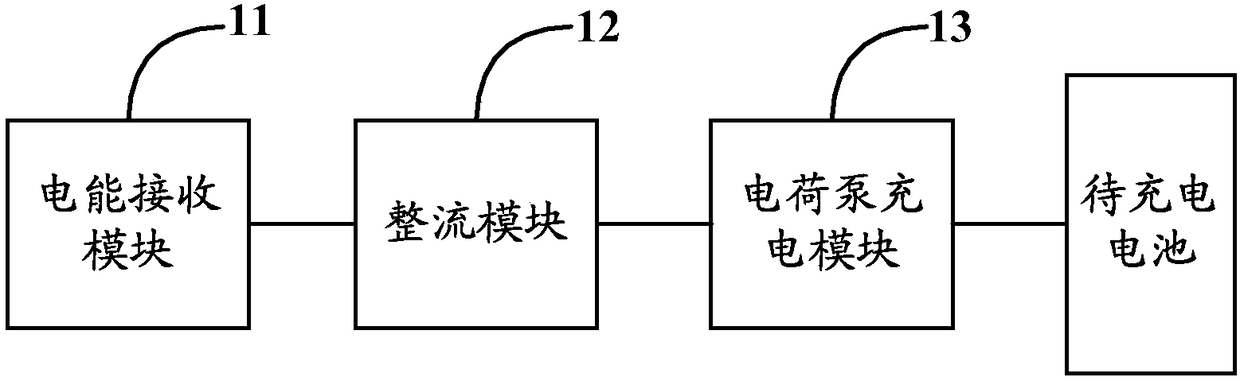

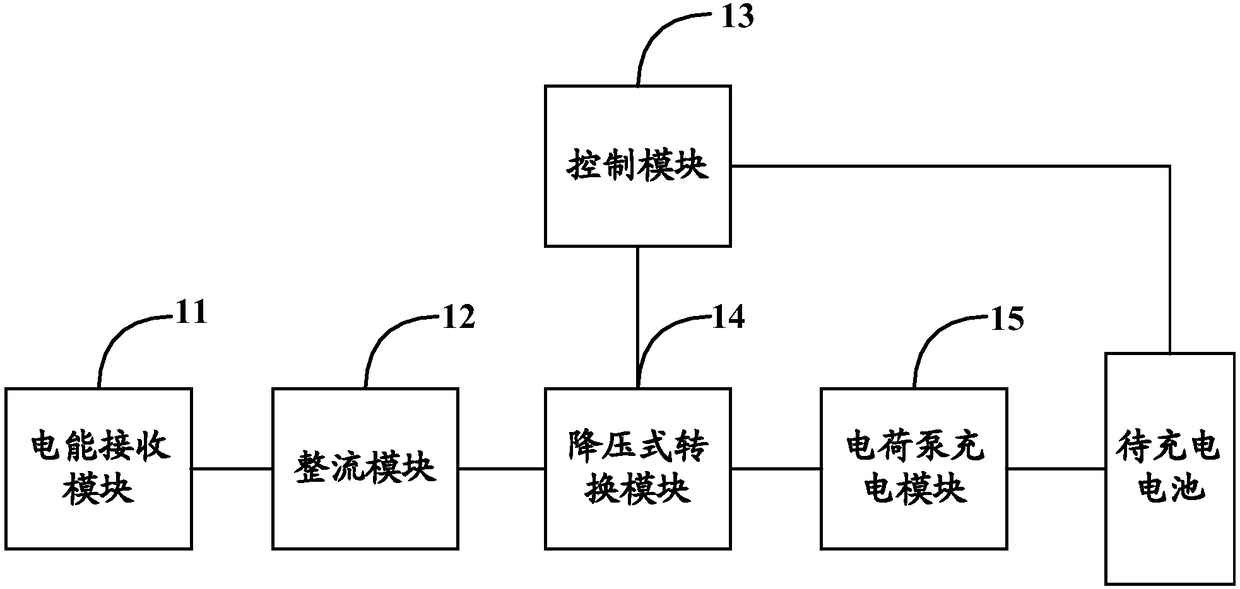

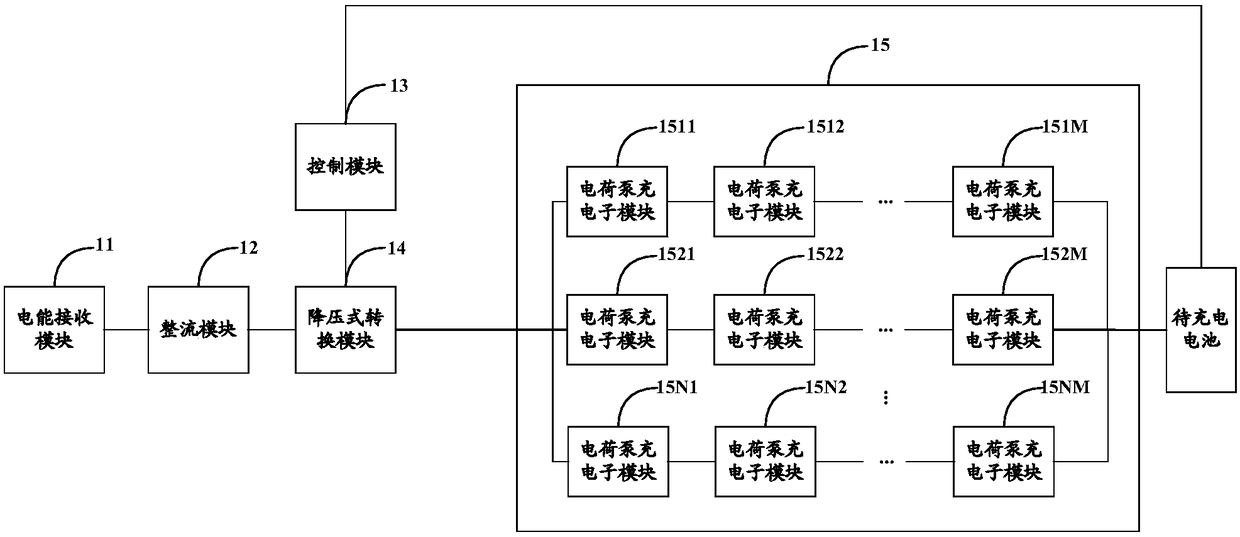

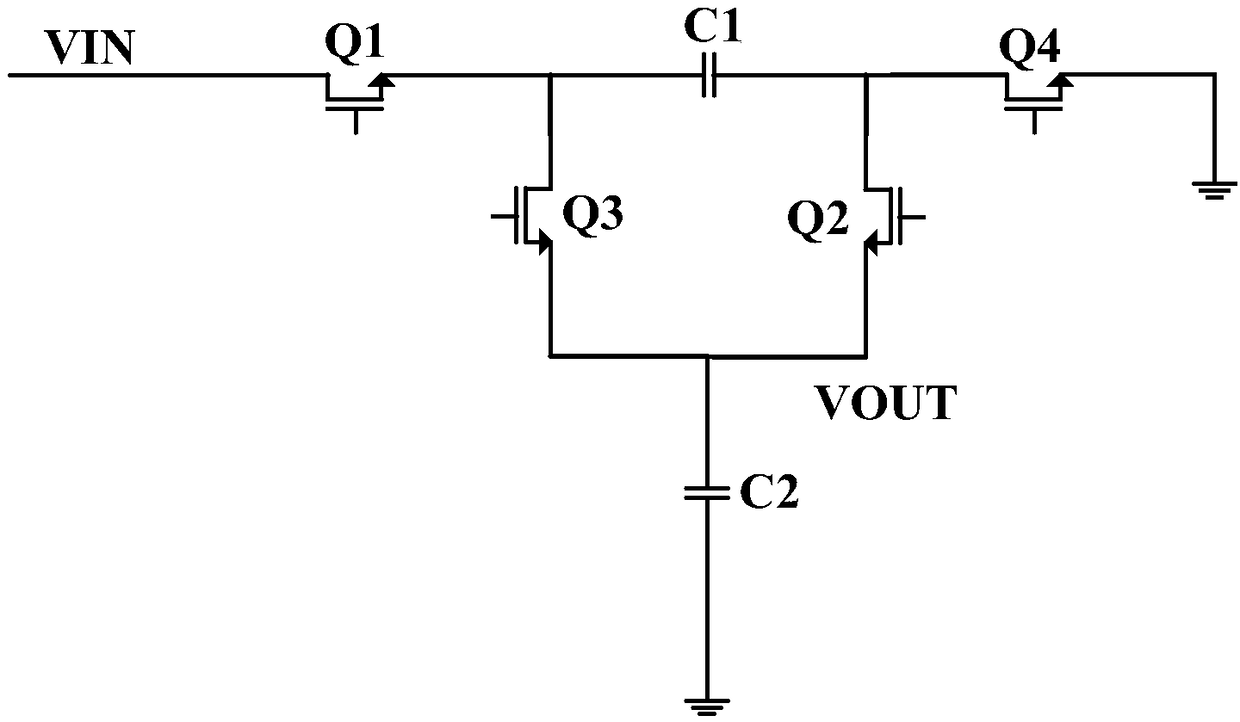

Wireless charging circuit, system and method and electronic equipment

InactiveCN108233454AImprove Buck Conversion EfficiencyReduced Buck Conversion EfficiencyBatteries circuit arrangementsSecondary cells charging/dischargingCoupling lossControl signal

The invention discloses a wireless charging circuit, system and method and electronic equipment. The wireless charging circuit can comprise an electric energy receiving module, a rectifying module, acontrol module and a charge pump charging module. The electric energy receiving module is used for receiving the alternating current transmitted by the electric energy transmitting module of a wireless adapter. The rectifying module is used for converting the alternating current into direct current. The control module is used for generating a first control signal in the constant current stage. Thecharge pump charging module is used for performing voltage reduction and current enhancement on the direct current when receiving the first control signal and transmitting the direct current after voltage reduction and current enhancement to a battery to be charged. Compared with the circuits in the prior art, the wireless charging circuit has no step-down conversion module; the charge pump charging module having no inductance component is used in the constant current stage; and the current of the pre-circuit of the charge pump charging module is low and the coupling loss is low in the constant current stage so that the problems of low charging efficiency and low safety in the prior art can be solved.

Owner:MEIZU TECH CO LTD

DC charging connector and connection method thereof

ActiveCN105896198AIngenious structural designInhibit sheddingVehicle connectorsCharging stationsEngineeringPersonnel safety

The invention discloses a DC charging connector and a connection method thereof. The DC charging connector comprises a shell, a mechanical lock, a safety switch, an electronic lock, a locking feedback switch, a charging interface, an interface inner frame and current terminals, wherein the current terminals are arranged on the interface inner frame. The DC charging connector is ingenious in structural design; the mechanical lock, the safety switch, the electronic lock and the locking feedback switch are reasonably arranged to form multi-protection; energization in the plugging process is avoided, so that sparks are avoided; the potential safety hazard is completely eradicated; the DC charging connector does not easily fall off after being coupled; and the charging stability is good. After the electronic lock works to be locked, a locking confirmation signal is fed back to a charging pile through the locking feedback switch, and then charging is carried out, so that the phenomena of abnormal charging interrupt and the like since the DC charging connector is accidentally unplugged due to a misoperation are avoided; and the charging safety and the personnel safety are greatly improved. Furthermore, the interface temperature in the charging process can be constantly monitored through a temperature sensor and can be fed back to the charging pile, so that the charging safety of the DC charging connector and a vehicle is greatly improved.

Owner:GUANGZHOU ZHICHONG AMPEREX TECH CO LTD

Wireless charging circuit, method and system and electronic equipment

InactiveCN108233455AImprove Buck Conversion EfficiencyBuck Conversion Efficiency GuaranteedBatteries circuit arrangementsApparatus without intermediate ac conversionCoupling lossCapacitance

The invention discloses a wireless charging circuit, method and system and electronic equipment. The wireless charging circuit comprises an electric energy receiving module, a rectifying module and acharge pump charging module. The electric energy receiving module is used for receiving the alternating current transmitted by the electric energy transmitting module of a wireless adapter and transmitting the alternating current to the rectifying module. The rectifying module is used for converting the alternating current into direct current and transmitting the direct current to the charge pumpcharging module. The charge pump charging module is used for performing voltage reduction and current enhancement on the direct current and transmitting the direct current after voltage reduction andcurrent enhancement to a battery to be charged. Compared with the circuits in the prior art, the charge pump charging module is used as the charging module of the wireless charging circuit, and the internal charge and discharge element is the capacitor rather than the inductor; besides, the current of the pre-circuit is enabled to be low and the coupling loss is enabled to be low by the charge pump charging module so that the problems of low charging efficiency and low charging safety can be solved.

Owner:MEIZU TECH CO LTD

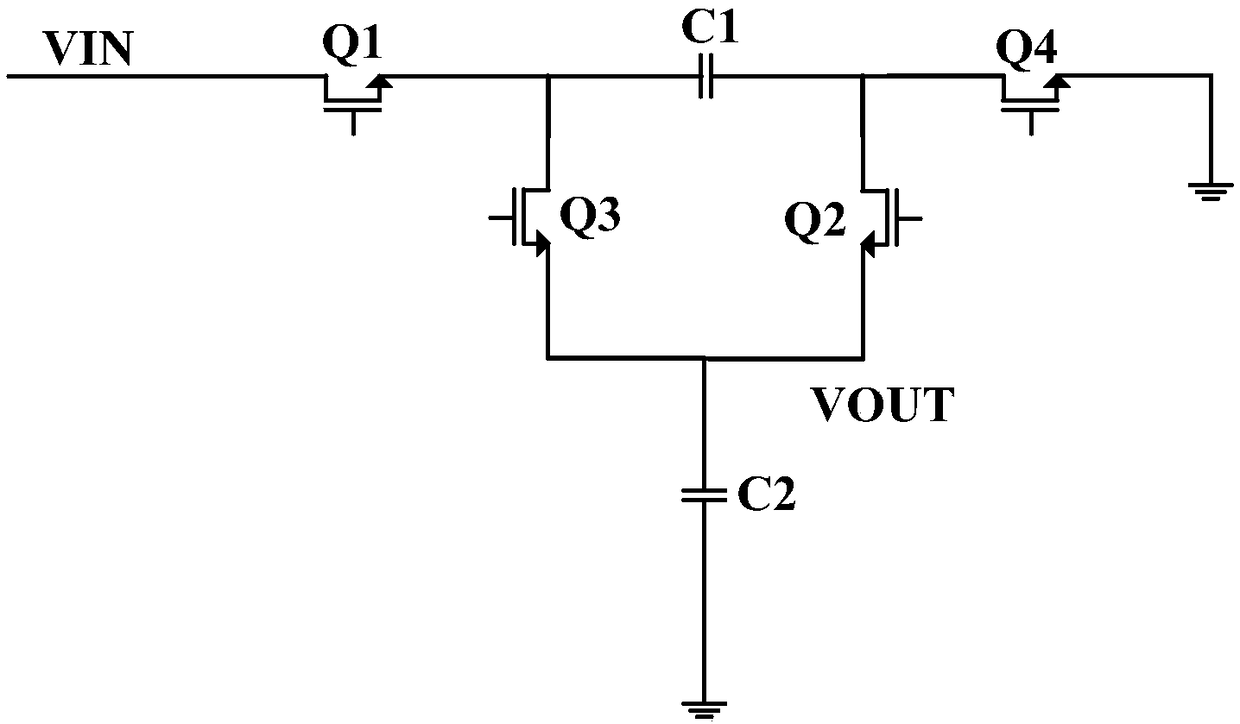

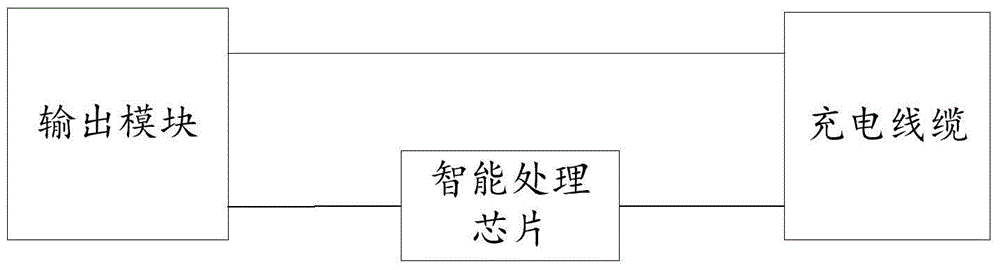

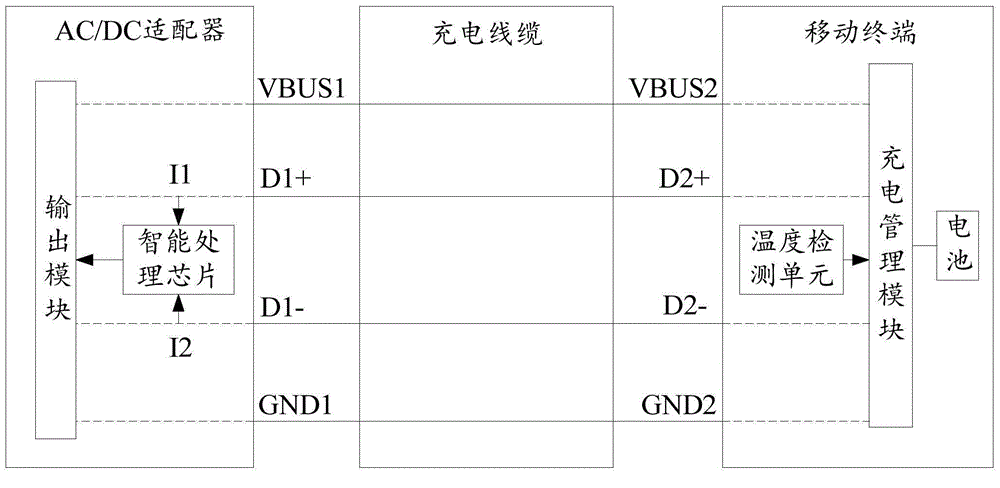

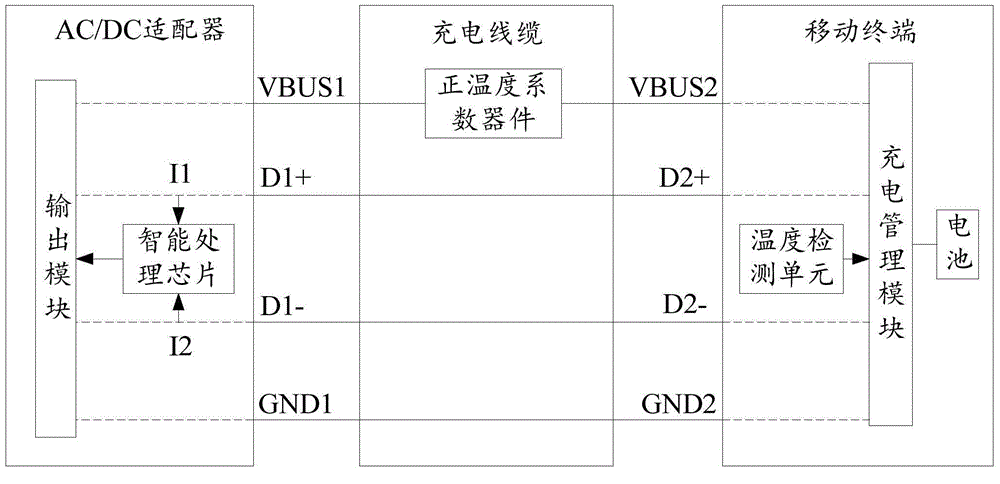

Charging device and charging method for mobile terminal

ActiveCN105098884AAvoid damageImprove charging safetyBatteries circuit arrangementsElectric powerComputer terminalEngineering

The invention discloses a charging device and a charging method for a mobile terminal, and belongs to the technical field of charging. The charging device comprises an output module, an intelligent processing chip and a charging cable, wherein the input end of the output module is connected with the output end of the intelligent processing chip; and the output end of the output module and the input end of the intelligent processing chip are connected with one end of the charging cable. According to the embodiments of the invention, heat accumulation at a charging port of the mobile terminal is effectively avoided and temperature rise at the charging port is avoided, so that the damage of the mobile terminal can be avoided and the charging safety of the mobile terminal is improved.

Owner:XIAOMI INC

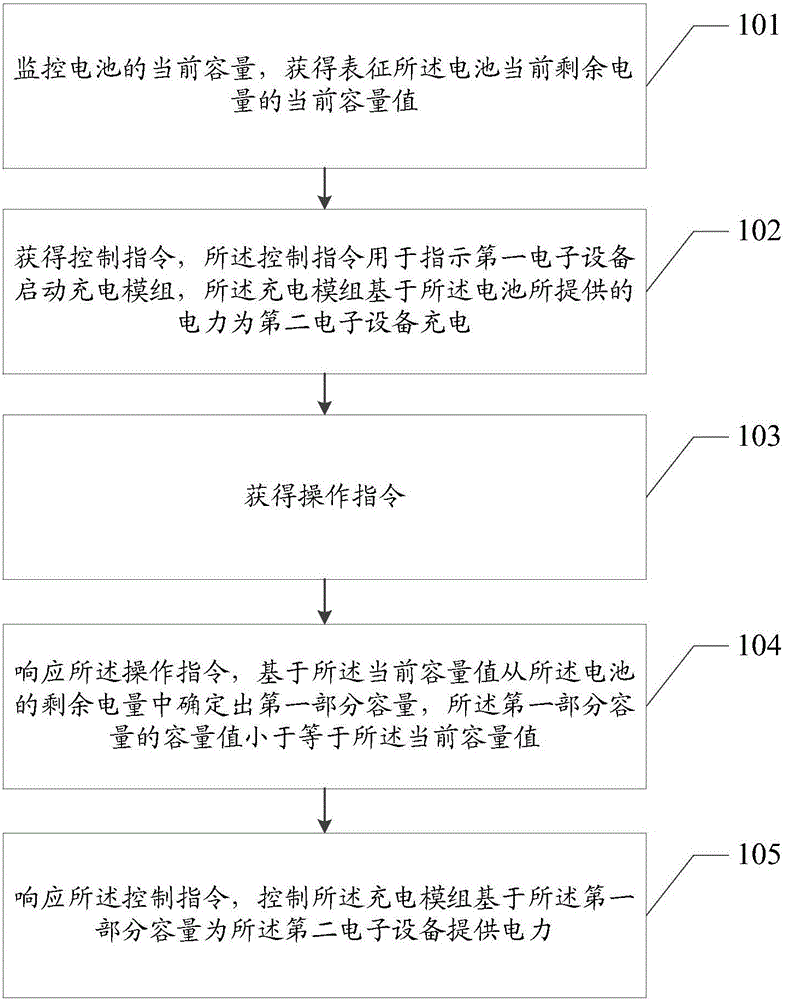

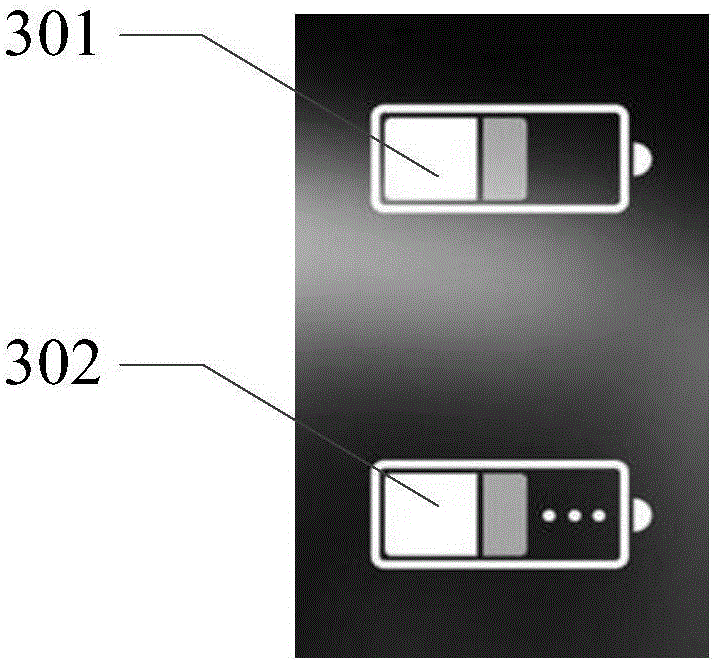

Charging method and electronic device

InactiveCN106125878AGuaranteed battery lifeImprove the efficiency of power resource utilizationProgramme controlCircuit monitoring/indicationCapacity valueElectrical battery

The invention discloses a charging method and an electronic device. The charging method comprises the steps of obtaining a current capacity value that represents current residual battery power of a battery by monitoring current capacity of the battery; when a control instruction of charging a second electronic device is obtained, determining first capacity from the residual battery power of the battery based on the current capacity value; and controlling a first electronic device to charge the second electronic device according to the first capacity. According to the technical scheme in embodiments of the charging method and the electronic device, the power can be output according to a power demand of a user to charge the electronic device, and the technical effects of enhancing power cruising ability of a charging source and improving power resource utilization efficiency are achieved.

Owner:LENOVO (BEIJING) LTD

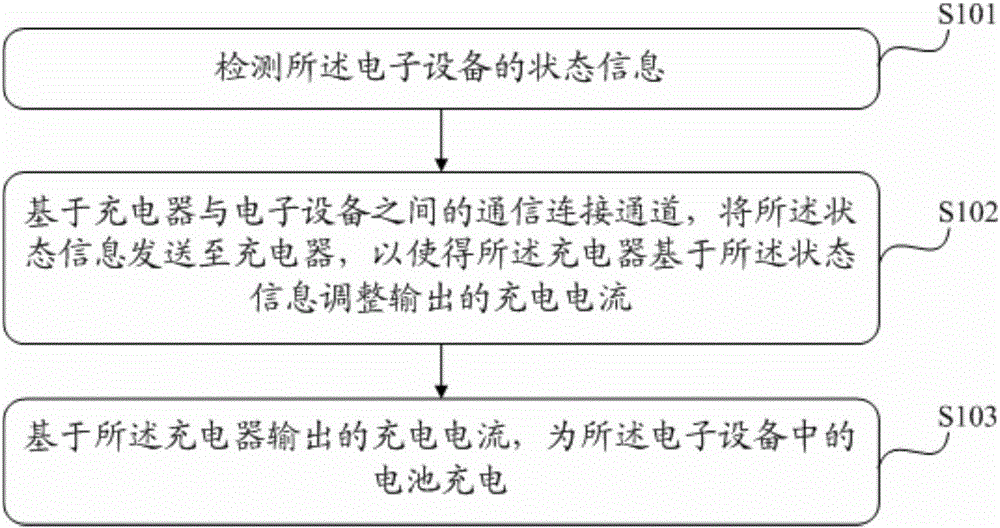

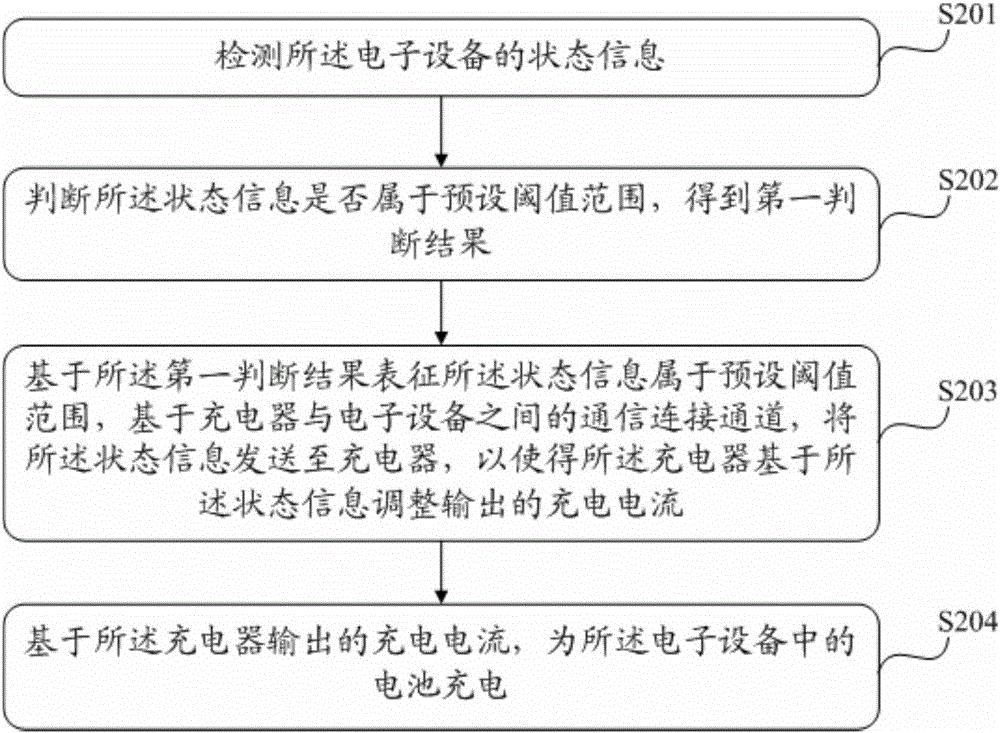

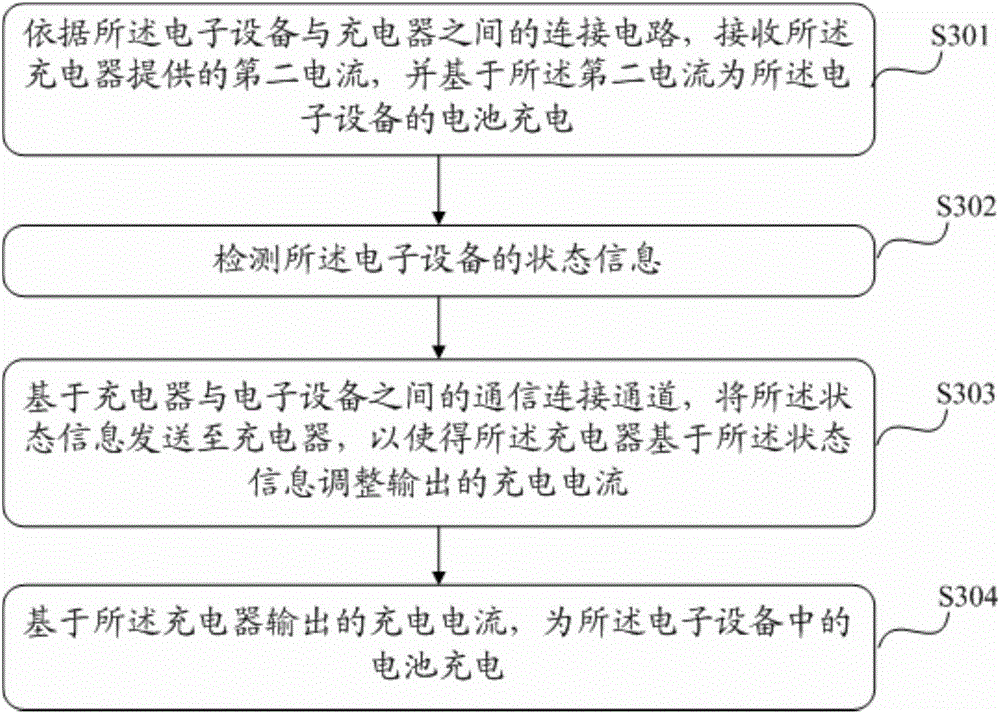

Charging method, charger and electronic device

InactiveCN105226749ADecentralized control capabilityImprove charging safetyBatteries circuit arrangementsElectric powerCharge currentElectrical battery

The invention provides a charging method, comprising the steps of detecting state information of an electronic device; sending the state information to a charger based on a communication connection channel between the charger and the electronic device to enable the charger to regulate output charging current based on the state information; and charging a battery based on the charging current output by the charger. When the charger provides power for the electronic device, the electronic device sends the state information generated in the charging process to the charger, so that the charger can regulate power of power supply electronic device based on the state information so as to regulate the power for the electronic device in real time according to the related state information in the charging process of the electronic device; the control ability of a charging IC (integrated circuit) in the charging process is scattered; the charging IC can independently judge and regulate the charging process without needing the electronic device; and even if the charging IC is in failure, the charger can regulate the charging power in the charging process for the electronic device based on the state information, so that the charging safety is improved.

Owner:LENOVO (BEIJING) CO LTD

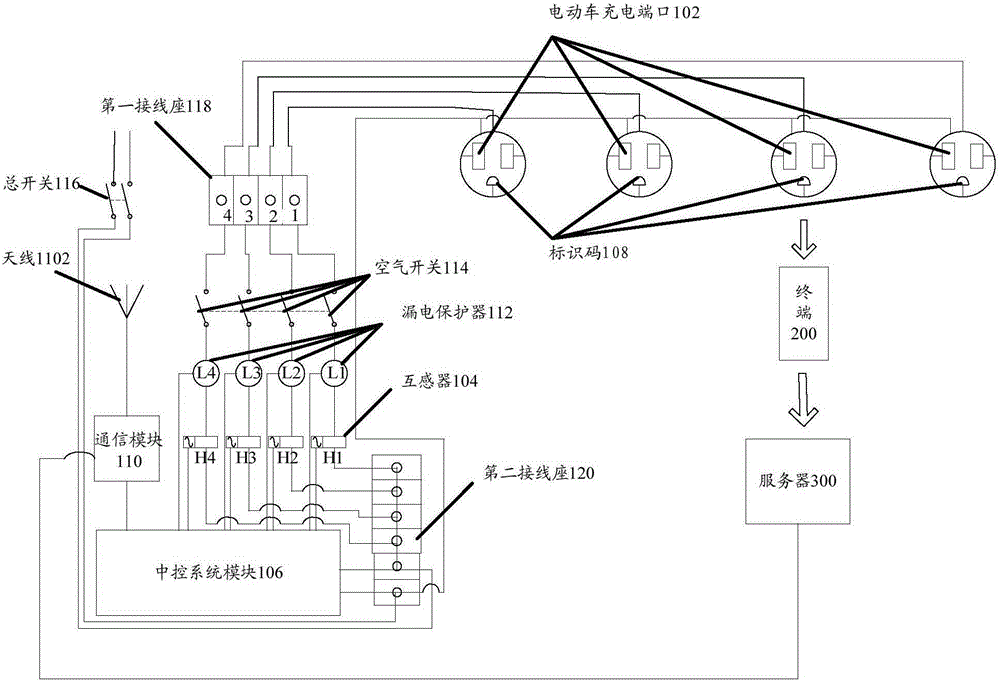

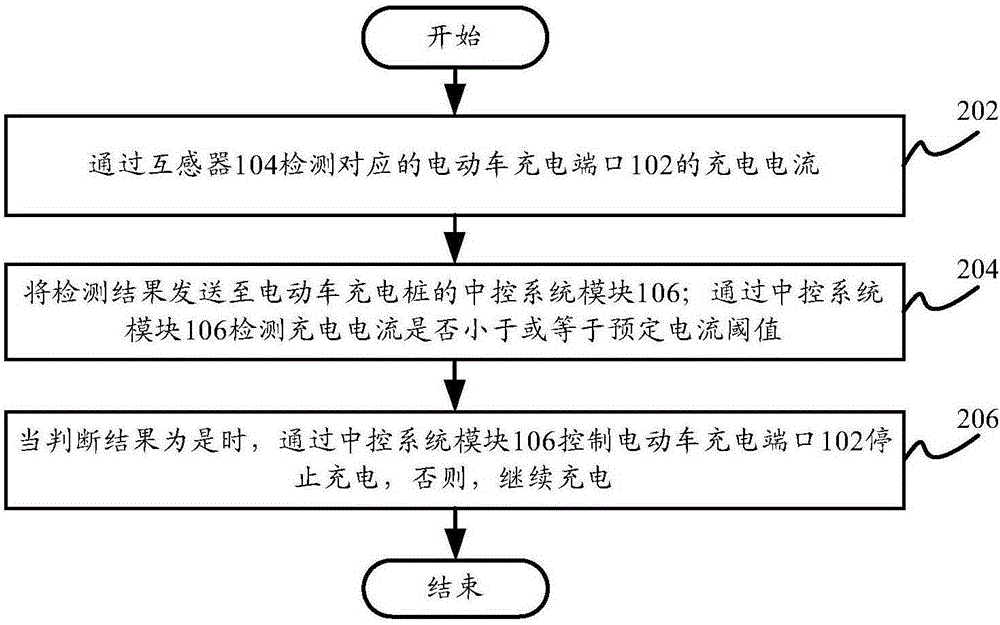

Electric vehicle charging pile and electric vehicle charging method

InactiveCN105226782AAvoid damageExtended service lifeBatteries circuit arrangementsEmergency protective circuit arrangementsCharge currentElectrical battery

The invention proposes an electric vehicle charging pile and an electric vehicle charging method. The electric vehicle charging pile includes: an electric vehicle charging port; a mutual inductor connected to the electric vehicle charging port and used for detecting charging current of the electric vehicle charging port and sending the charging current to a central control system module of the electric vehicle charging pile; and the central control system module connected to the electric vehicle charging port and used for receiving the charging current from the mutual inductor and controlling the electric vehicle charging port to stop charging when the charging current is smaller than or equal to a predetermined current threshold value. Through the technical scheme of the electric vehicle charging pile provided by the invention, charging can be automatically stopped when completed, and a battery is prevented from being damaged due to too long charging, thereby prolonging the service life of the battery, and improving charging safety of the electric vehicle.

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE

Fast charging method for battery

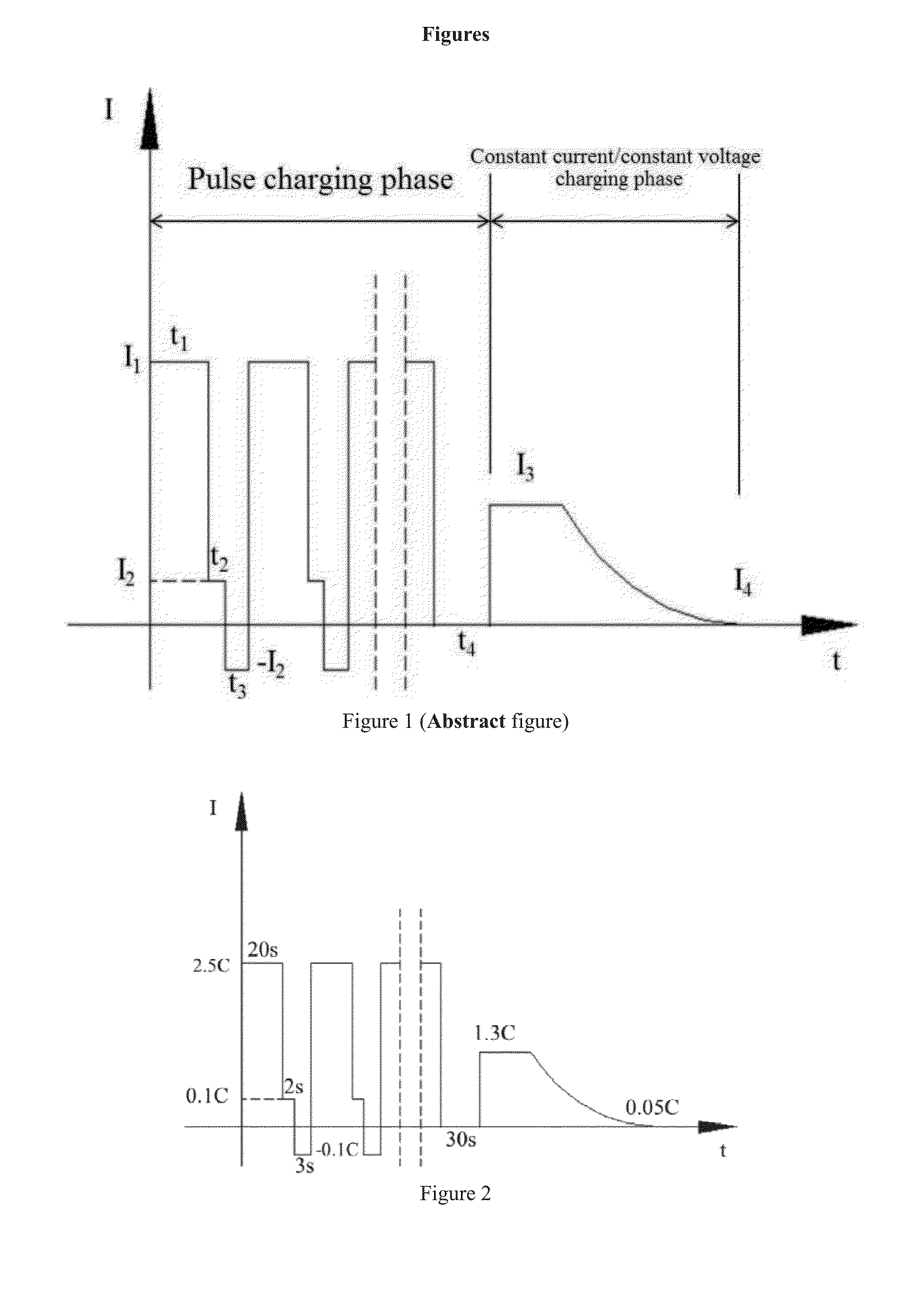

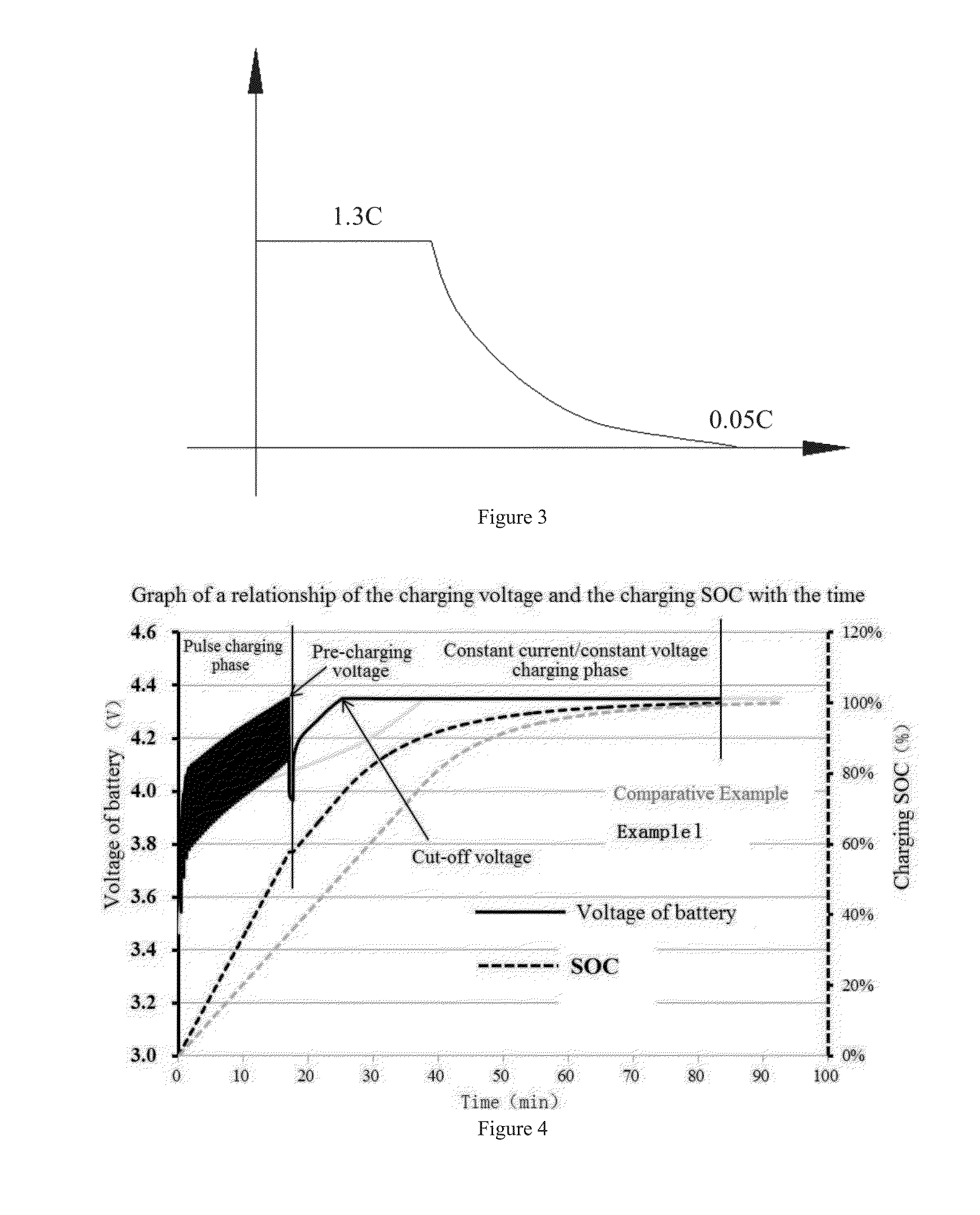

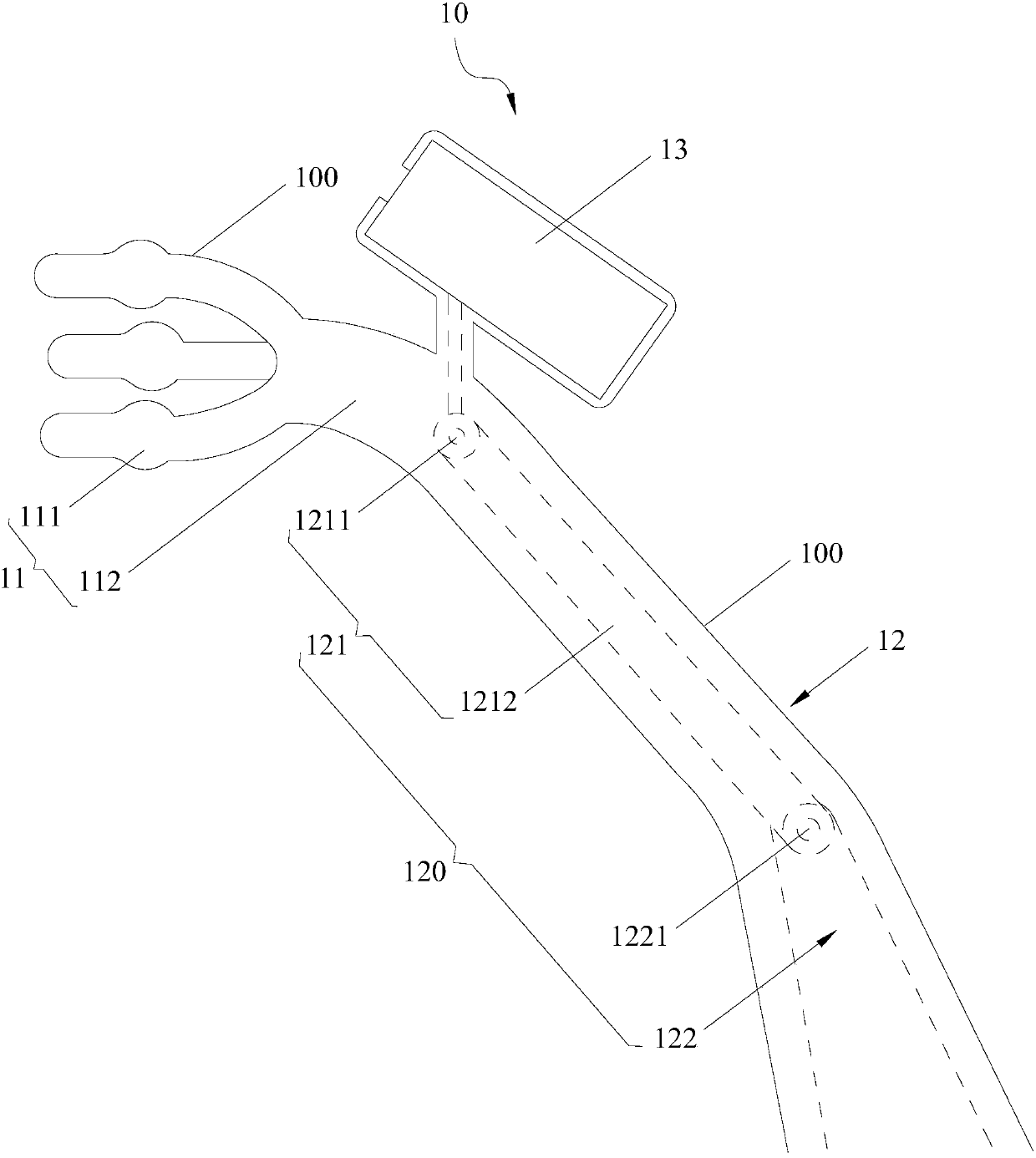

ActiveUS20160111898A1Improve charging safetyIncrease the speed of chargingElectric powerCharging/discharging current/voltage regulationResting timeFast charging

The present invention provides a fast charging method for battery, including the steps as follows: (1) the battery is charged with a constant current I1 and the charging time is t1; (2) the battery is charged with a constant current I2 and the charging time is t2; (3) the battery is discharged with the constant current I2 and the discharging time is t3, recycling until the voltage reaches a pre-charging voltage of battery; (4) the battery is standed after the voltage reaching the pre-charging voltage of battery, and the rest time is t4, and then the battery is charged with a constant current I3 until the voltage reaching a cut-off voltage of battery, and then the battery is charged with a constant voltage until the current reaching a cut-off current I4; wherein, I2<I1, t2<t1, t3<t1, I2<I3≦I1, I4≦I2. The fast charging method provided in present invention can decrease the polarization in pulse charging phase, increase the time of whole pulse charging phase, improve the charging speed in pulse charging phase, and thus shorten the full-charging time.

Owner:DONGGUAN AMPEREX TECH

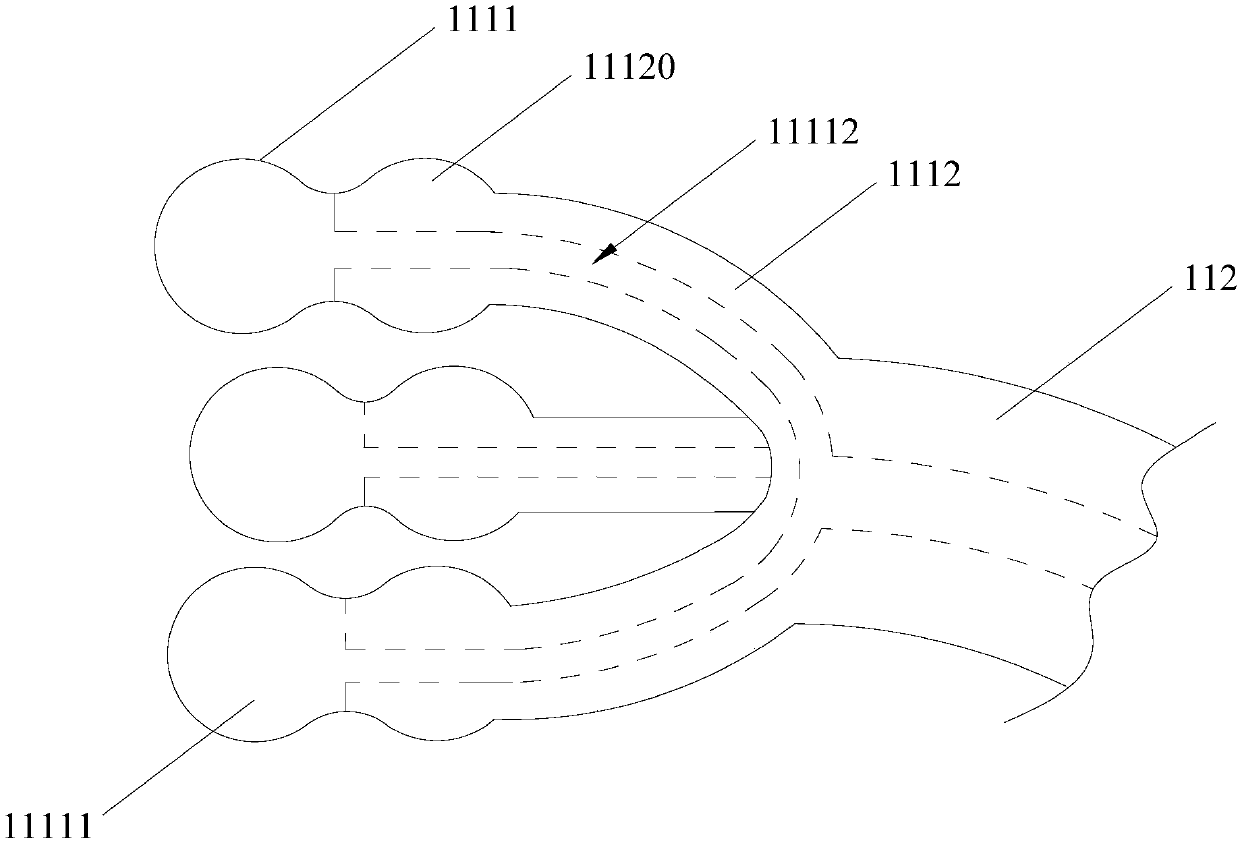

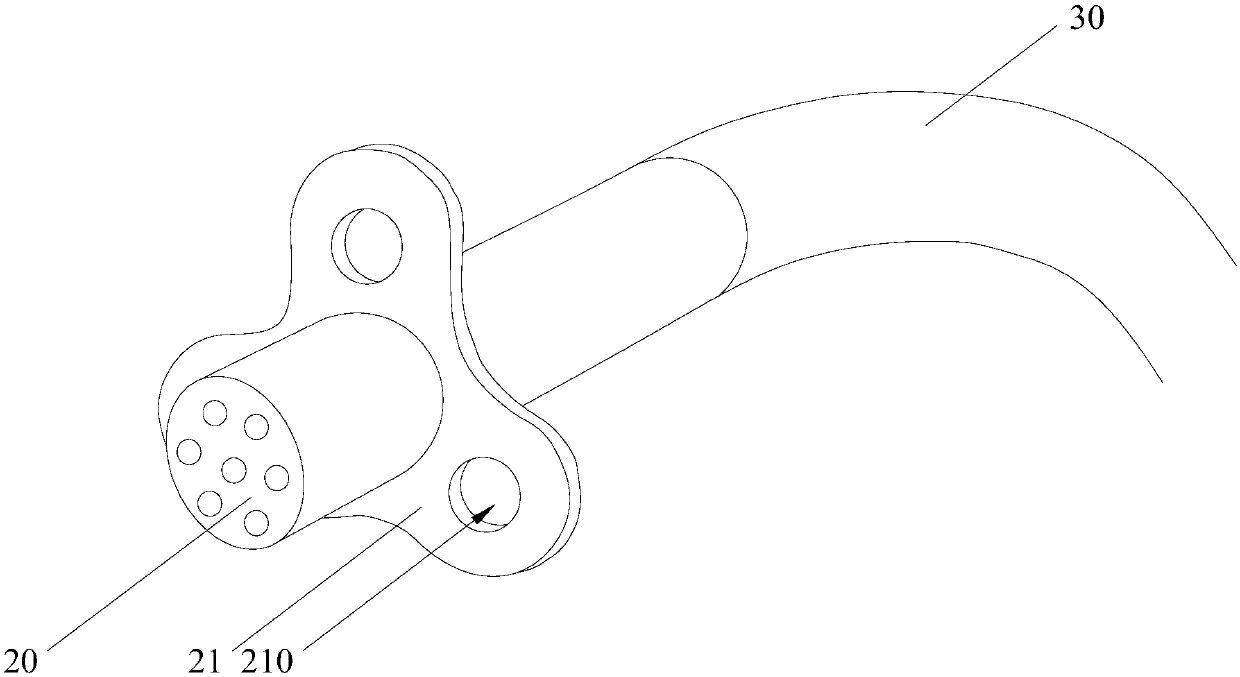

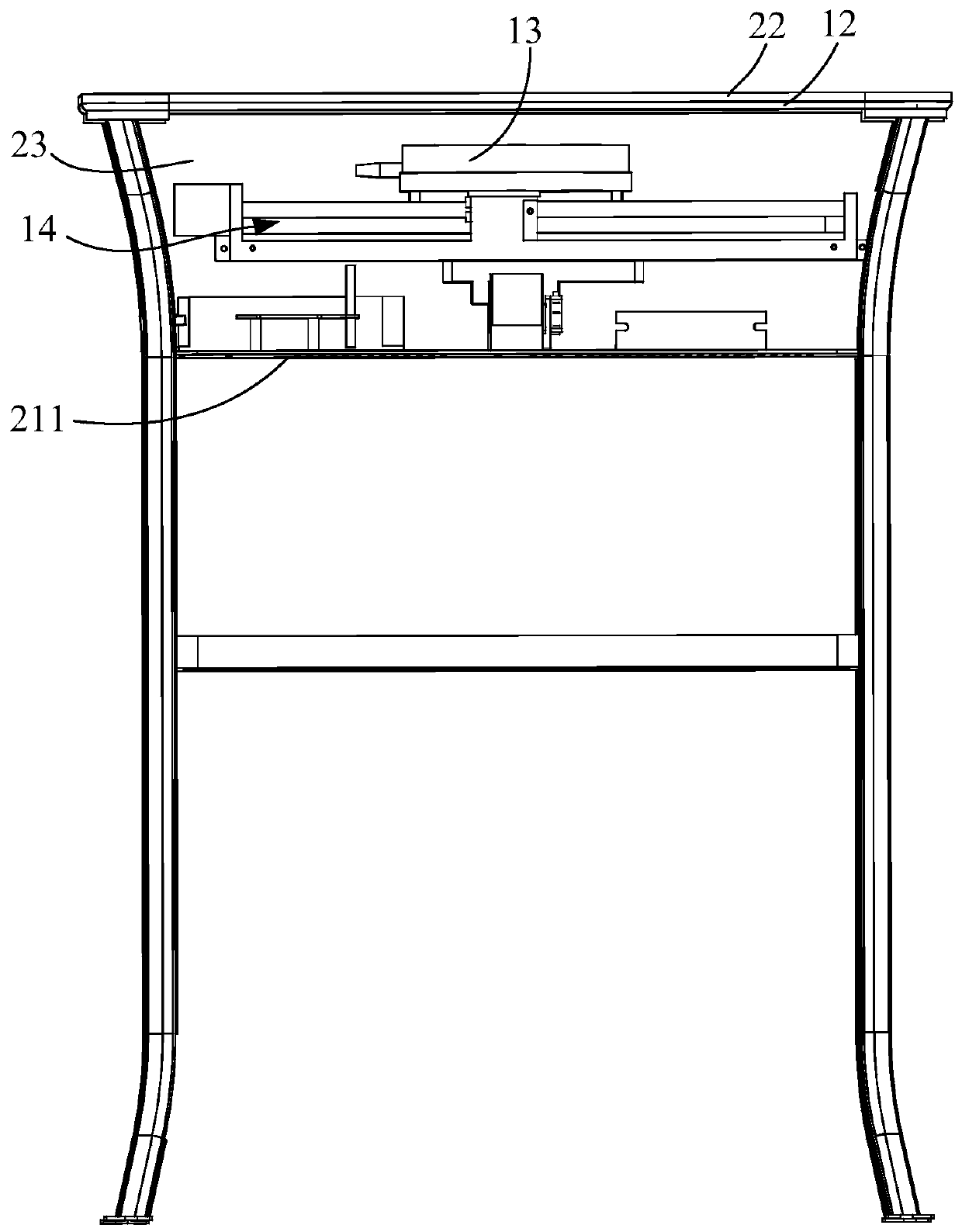

Robot arm and electric vehicle charging device

PendingCN107813297ARealize automatic chargingSolve technical problems of manual operationProgramme-controlled manipulatorCharging stationsElectric vehicleHand operations

The invention provides a robot arm. The robot arm comprises a machine hand for grabbing a charging plug of an electric vehicle charging device, an identifying mechanism for identifying the charging plug and an electric vehicle charging socket, and a machine arm for urging the identifying mechanism and the machine hand to move; the machine hand comprises a wrist, and at least three fingers connected to the wrist at intervals; and the machine arm comprises a driving module movably connected with the wrist and the identifying mechanism. In addition, the invention further provides the electric vehicle charging device, which comprises a chassis, a cable, the charging plug and the robot arm. Through cooperation of the machine hand, the machine arm and the identifying mechanism, the accurate positions of the charging plug and the electric vehicle charging socket of the electric vehicle charging device are identified through the identifying mechanism, and the machine arm urges the machine handto grab the charging plug and to accurately insert the charging plug in the charging socket to realize automatic charging of an electric vehicle, so that the technical problem of need of hand operation in the charging process of the electric vehicle is effectively solved.

Owner:SHENZHEN HAYLION TECH CO LTD

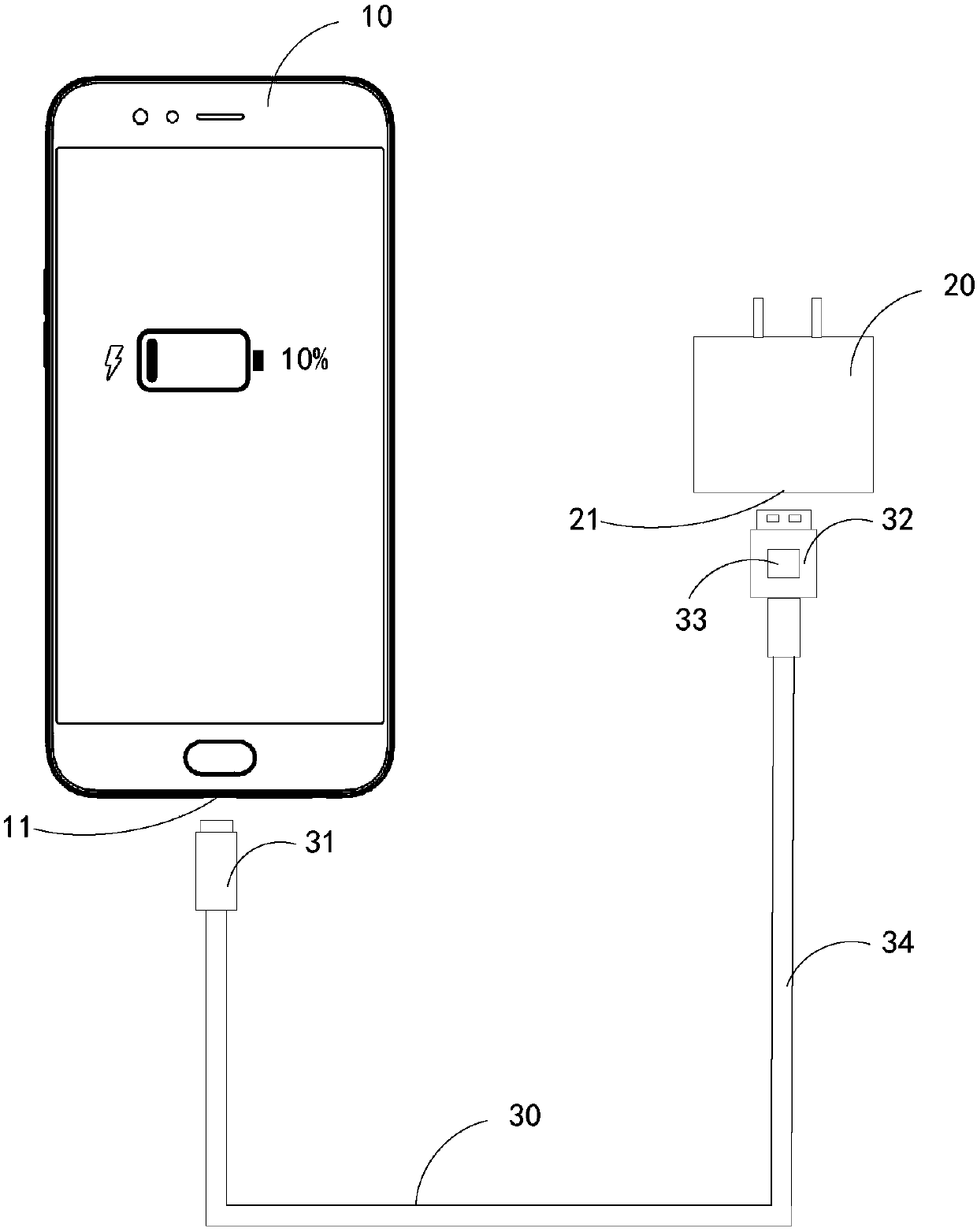

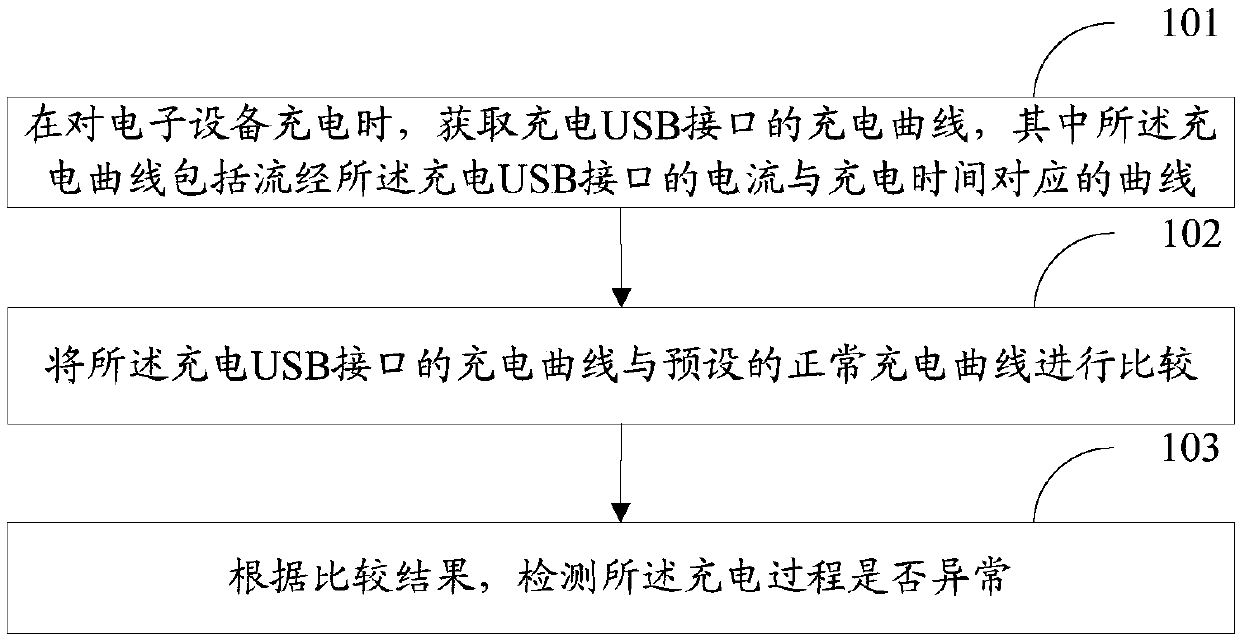

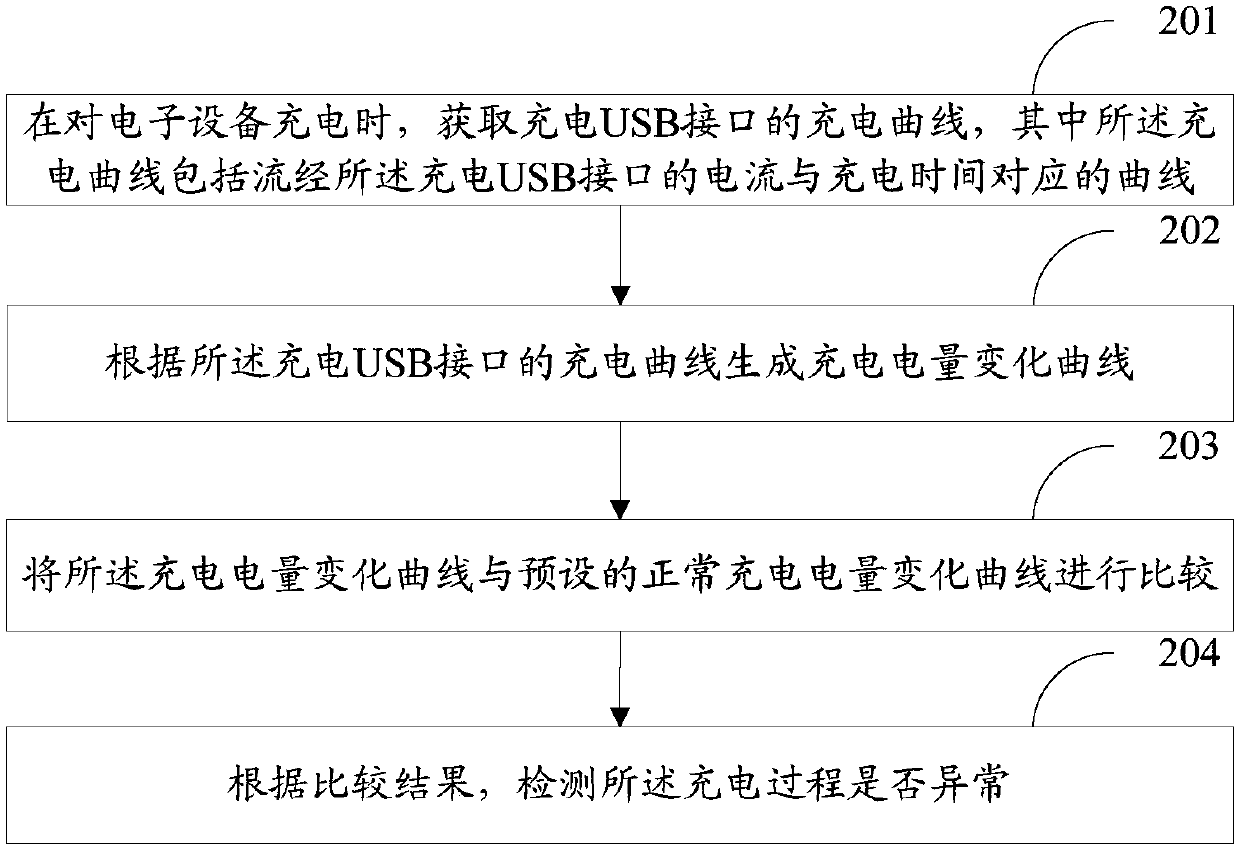

Charging abnormality detection method, charging data line and charging system

InactiveCN107706969AImprove charging safetyCircuit monitoring/indicationIndicating/monitoring circuitsEngineeringData lines

The application discloses a charging abnormality detection method, a charging data line and a charging system. The charging abnormality detection method includes: when an electronic device is charged,a charging curve of a charging USB interface is obtained, wherein the charging curve includes a curve of correspondence between a current flowing through the charging USB interface and charging time;the charging curve of the charging USB interface is compared with a preset normal charging curve; and according to the comparison result, whether the charging process is abnormal is detected. According to the embodiment of the application, current monitoring is carried out on the charging USB interface and whether abnormality occurs during the charging process is monitored, so that charging safety is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

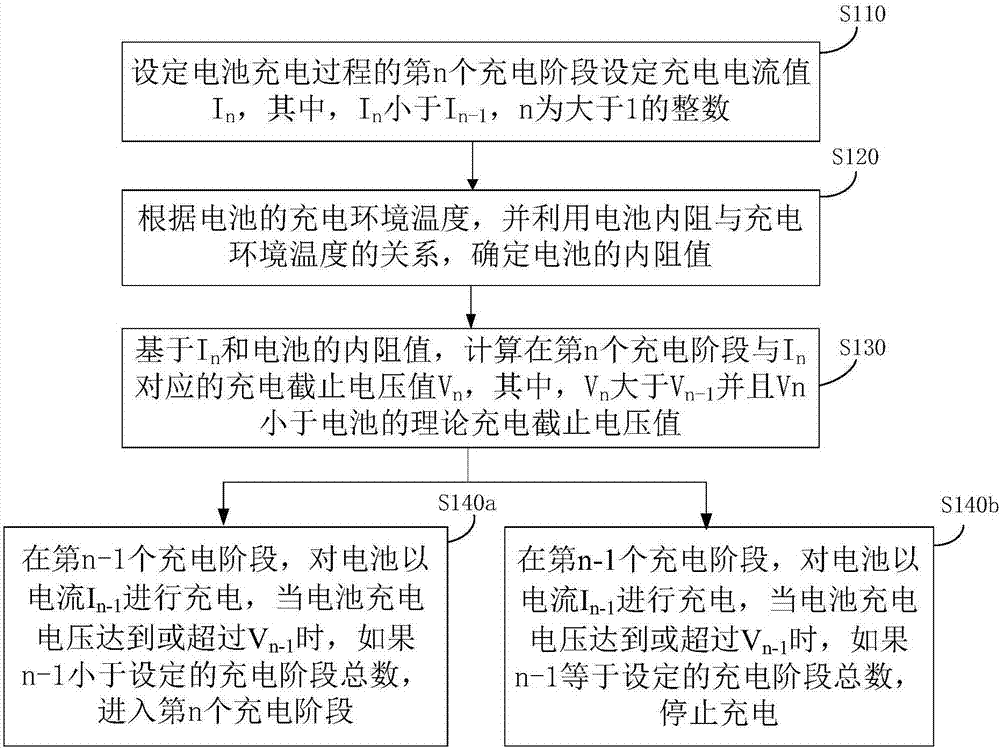

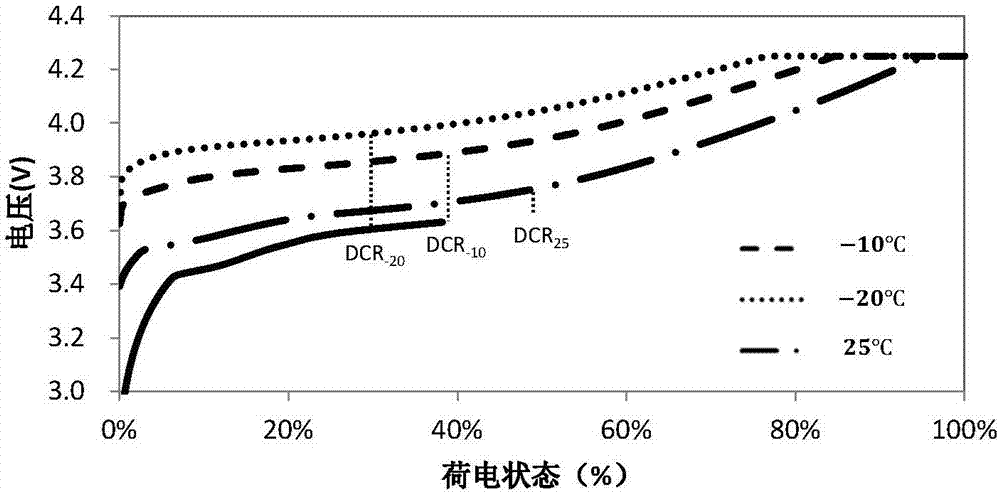

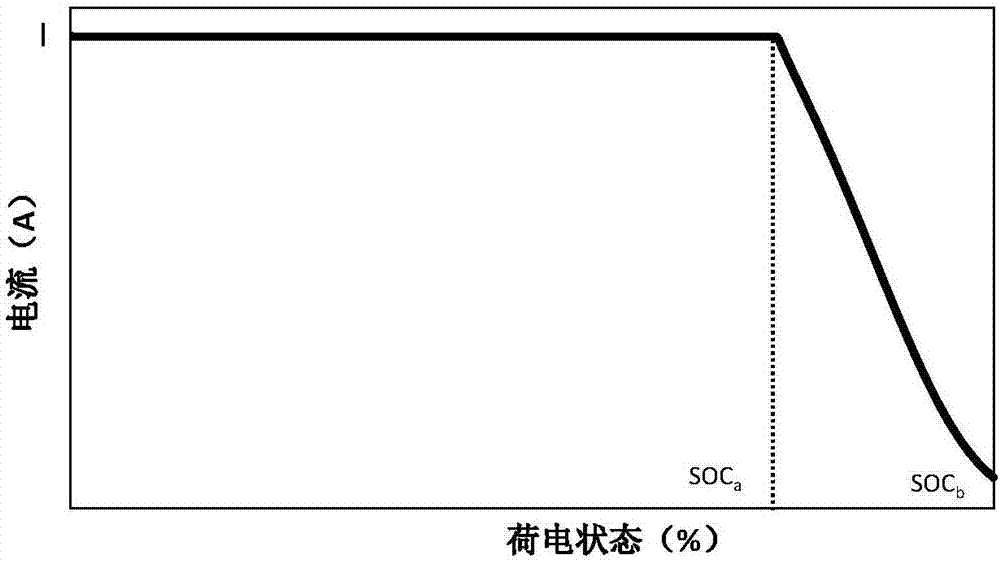

Battery charging method, device, equipment and storage medium

ActiveCN107342608AImprove charging efficiencyReduce the risk of overchargingSecondary cells charging/dischargingElectric powerCharge currentBattery charge

The invention discloses a battery charging method, device and equipment and a storage medium. The battery charging method comprises the following steps: setting the charging current value In in the n-th charging stage of the battery charging process, wherein In is smaller than In-1; according to the charging environment temperature of a battery, using the relationship between the internal resistance of the battery and the charging environment temperature of the battery to determine the internal resistance value of the battery; based on In and the internal resistance value of the battery, calculating a charging cut-off voltage value Vn, corresponding to In, in the n-the charging stage; in the (n-1)-th charging stage, charging the battery by using In-1, and when the battery charging voltage reaches Vn-1, if n-1 is smaller than a charging stage sum, entering the n-th charging stage; in the (n-1)-th charging stage, charging the battery by using In-1, and when the battery charging voltage reaches Vn-1, if n-1 is equal to the charging stage sum, stopping charging. According to the battery charging method provided by the embodiment of the invention, the charging efficiency of the battery can be improved, and the risk of battery cell overcharging is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

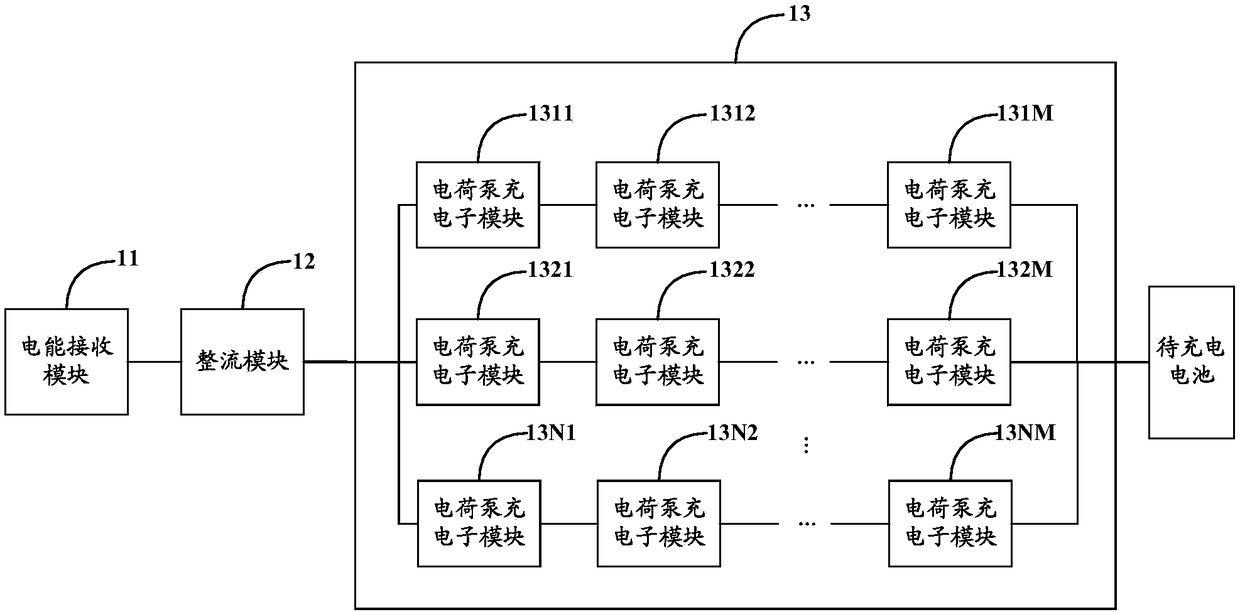

Wireless charging circuit, system and method and electronic equipment

InactiveCN108233456AImprove Buck Conversion EfficiencyImprove charging efficiencyBatteries circuit arrangementsApparatus without intermediate ac conversionCoupling lossControl signal

The invention discloses a wireless charging circuit, system and method and electronic equipment. The wireless charging circuit comprises an electric energy receiving module, a rectifying module, a control module, a step-down conversion module and a charge pump charging module. The electric energy receiving module is used for receiving the alternating current transmitted by the electric energy transmitting module of a wireless adapter. The rectifying module is used for converting the alternating current into direct current. The control module is used for generating a first control signal in theconstant current stage. The step-down conversion module is used for adjusting the direct current according to the first control signal. The charge pump charging module is used for reducing the voltage of the adjusted direct current to the charging voltage and enhancing the current of the adjusted direct current to the charging current. Compared with the circuits in the prior art, the charge pumpcharging module having no inductance component is used as the charging module in the constant current stage so that the charging efficiency can be enhanced; besides, the current of the pre-circuit ofthe charge pump charging module is low and the coupling loss is low so that the charging efficiency can be further enhanced.

Owner:MEIZU TECH CO LTD

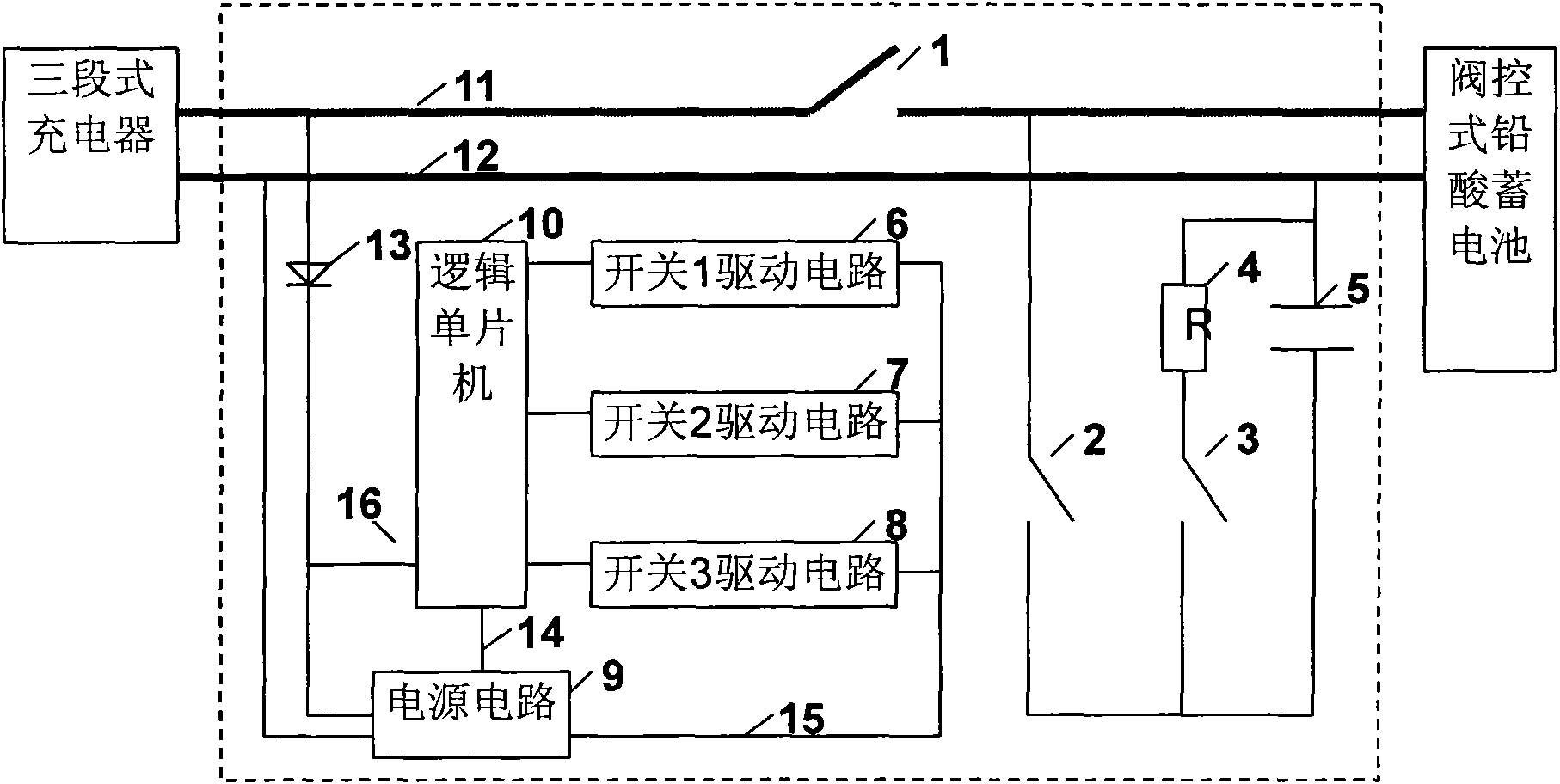

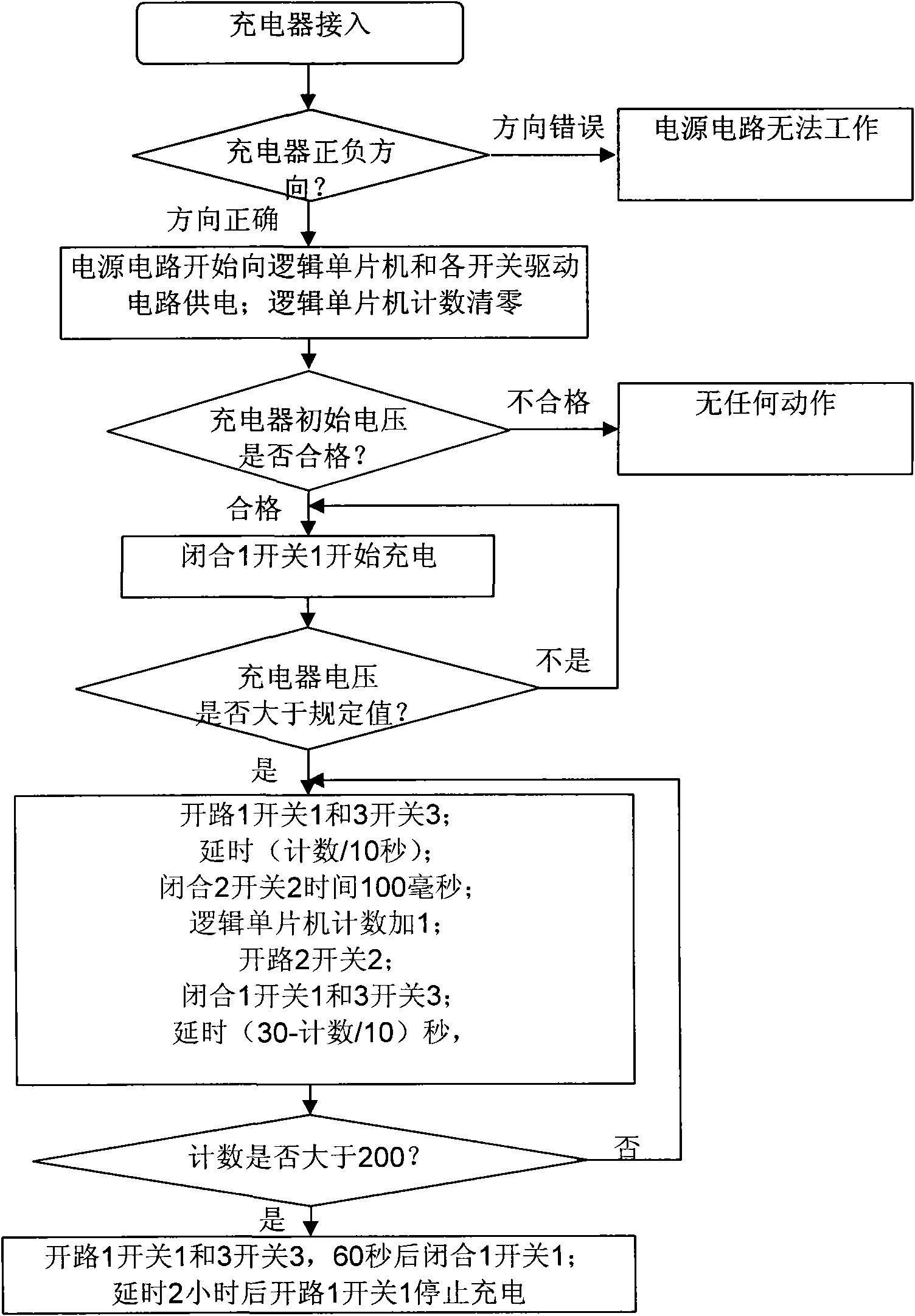

Lead acid battery charge protection and optimization technology

InactiveCN101577421AImprove charging safetyReduce water loss during chargingBatteries circuit arrangementsEmergency protective circuit arrangementsElectrochemical responseElectric vehicle

A lead acid battery for an electric vehicle has to face more use requirements of big capacity, long cycle life, big discharge current, short charging time and the like because the lead acid battery powers the vehicle, particularly a higher requirement on the charging technology. For the conventional three-stage charging technology, on the one hand, if the set breakover voltage from the first stage to the second stage is lower, the battery is insufficiently charged, which causes the quick reduction of the capacity of the battery, and if the set breakover voltage is higher, the loss of electrolyte and heating of the battery are caused due to positive overcharge; on the other hand, because different batteries are different in additive formulas, the ideal breakover voltage and breakover current are different; and the lead acid battery is passively charged by a charger, if the charger and the battery require different rated voltage or anode-cathode directions, the damage of the battery or charger can be caused. Because a charging inference function module lowers the charging potential of the battery by continuously using negative pulse to discharge at the later stage of charging, the polarization potential difference between the charger and the battery is ensured, and the battery can be charged more fully; pole plate active materials of the battery are electrochemically reacted at a low potential, so that the gassing amount generated is greatly reduced; simultaneously, due to enough charging break time, the oxygen separated from the anode is ensured to undergo reaction with hydrogen to obtain water when reaching the cathode, and the enough time for heat dissipation is also ensured; and the service life of the lead acid battery is prolonged.

Owner:王宏图 +2

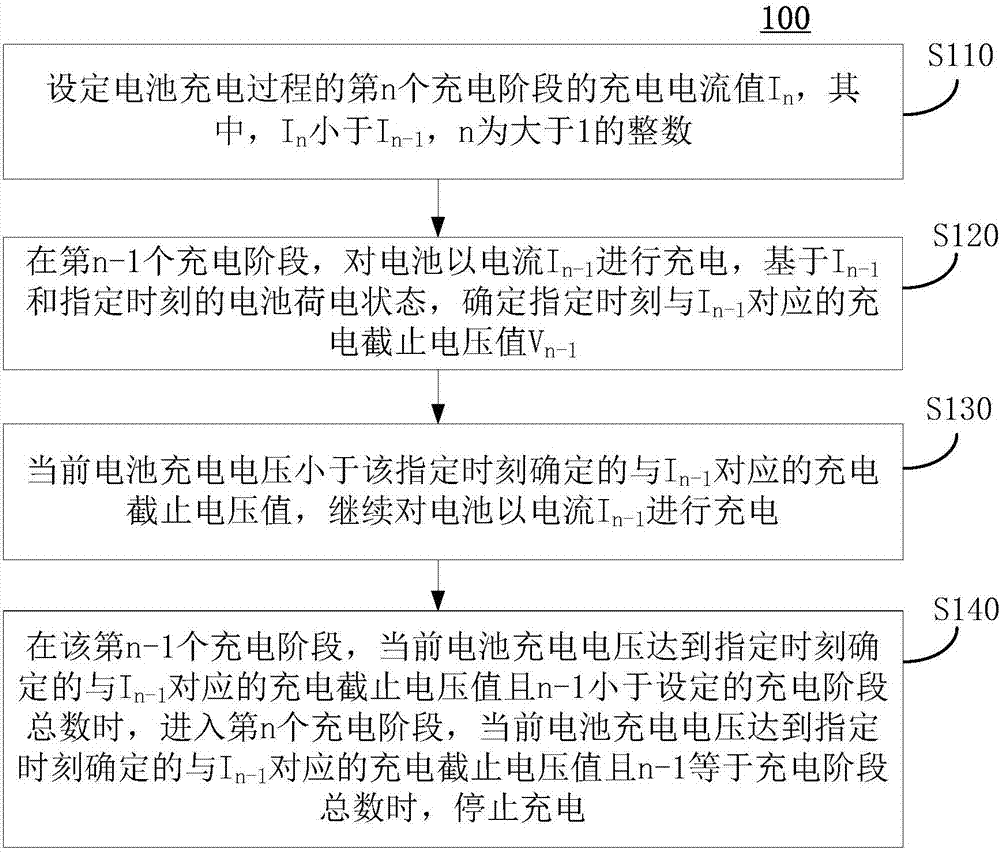

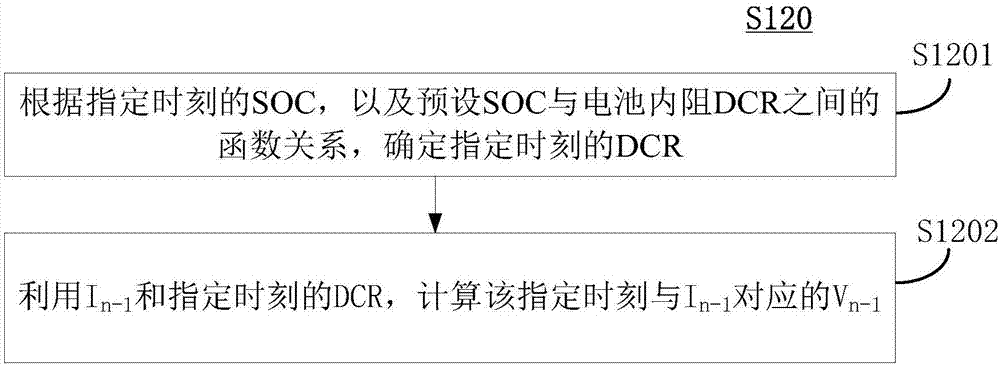

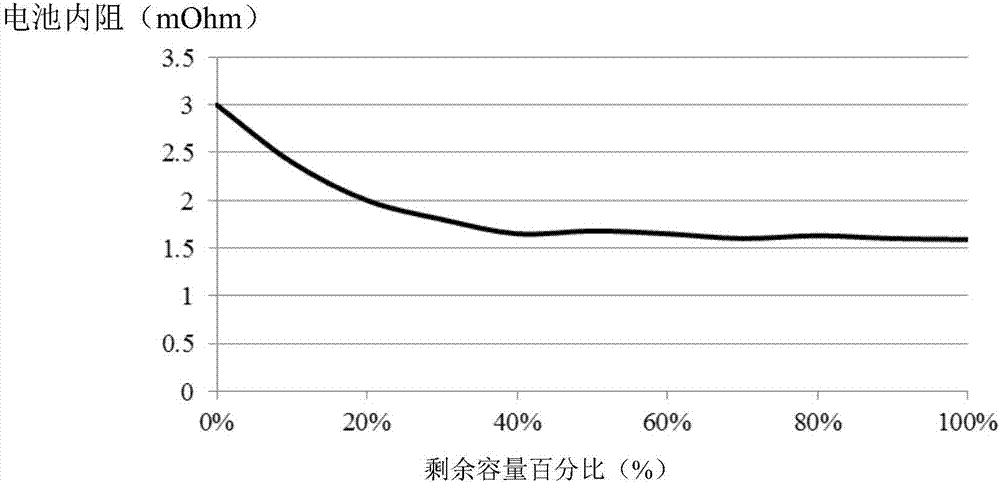

Charging method, device and equipment for battery

ActiveCN107359376AIncrease the speed of chargingImprove charging efficiencyBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentBattery charge

The invention discloses a charging method, device and equipment for a battery. The charging method comprises the following steps: setting the charging current value In of the nth charging stage in the battery charging process; in the (n-1)th charging stage, charging the battery by using current In-1, and based on In-1 and the state of charge SOC of the battery at an appointed moment, determining the charging cut-off voltage value Vn-1 corresponding to In-1 at the appointed moment; when the charging voltage of the battery at present is smaller than the charging cut-off voltage value corresponding to In-1 at the appointed moment, continuously charging the battery by using current In-1; in the (n-1)th charging stage, when the charging voltage of the battery at present reaches the charging cut-off voltage value corresponding to In-1 at the appointed moment and n-1 is smaller than a set charging stage sum, entering the nth charging stage, and when the charging voltage of the battery at present reaches the charging cut-off voltage value corresponding to In-1 at the appointed moment and n-1 is equal to the charging stage sum, stopping charging. According to the charging method for the battery provided by the embodiment of the invention, the charging quantity and charging efficiency can be improved.

Owner:CONTEMPORARY AMPEREX TECH CO

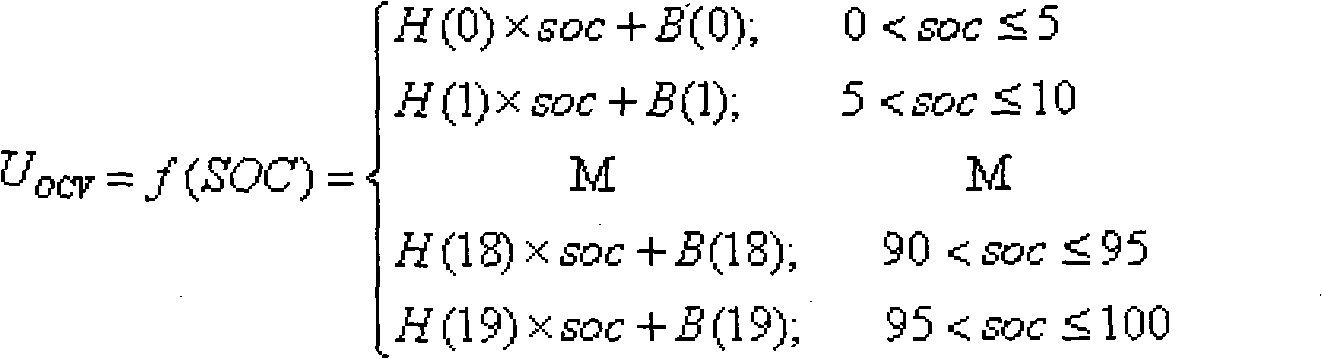

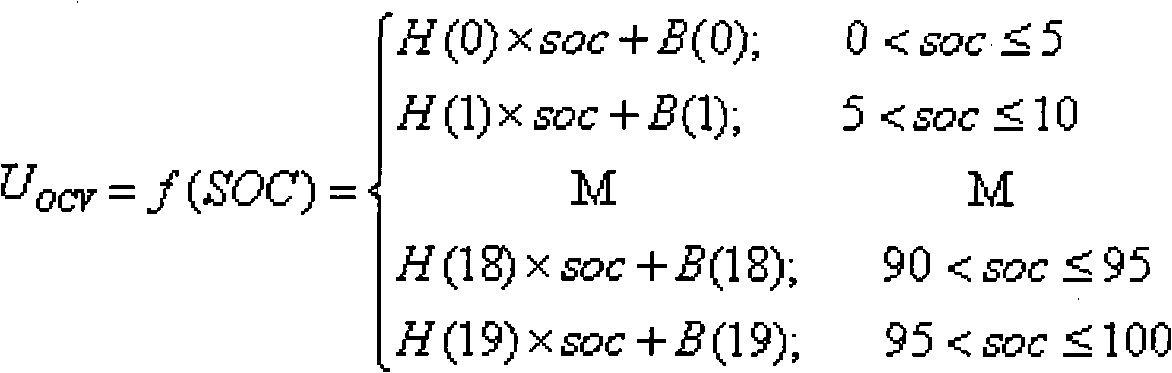

Charging method for lithium ion battery management system

ActiveCN110611133AImprove charging efficiencyImprove charging safetySecondary cells charging/dischargingElectricityState of charge

The invention discloses a charging method for a lithium ion battery management system. The method comprises a five-stage current continuous charging step. The state of charge of a battery is judged before charging, and then, different charging steps are selected according to the state of charge of the battery. When the state of charge of the battery changes, the charging steps of the battery are adjusted in time for charging until the battery is fully charged. The state of charge of the battery can be judged by measuring the voltage of the battery and comparing the measured voltage with presetvoltages in different charging states. According to the charging method for a lithium ion battery management system, a five-stage current continuous charging scheme is adopted, so that anode lithiumprecipitation of lithium ion batteries at low temperature is improved, the safety of batteries during lithium ion charging is enhanced, and the quantity of electricity charged into lithium ion batteries is increased.

Owner:HENAN LI POWER SUPPLY

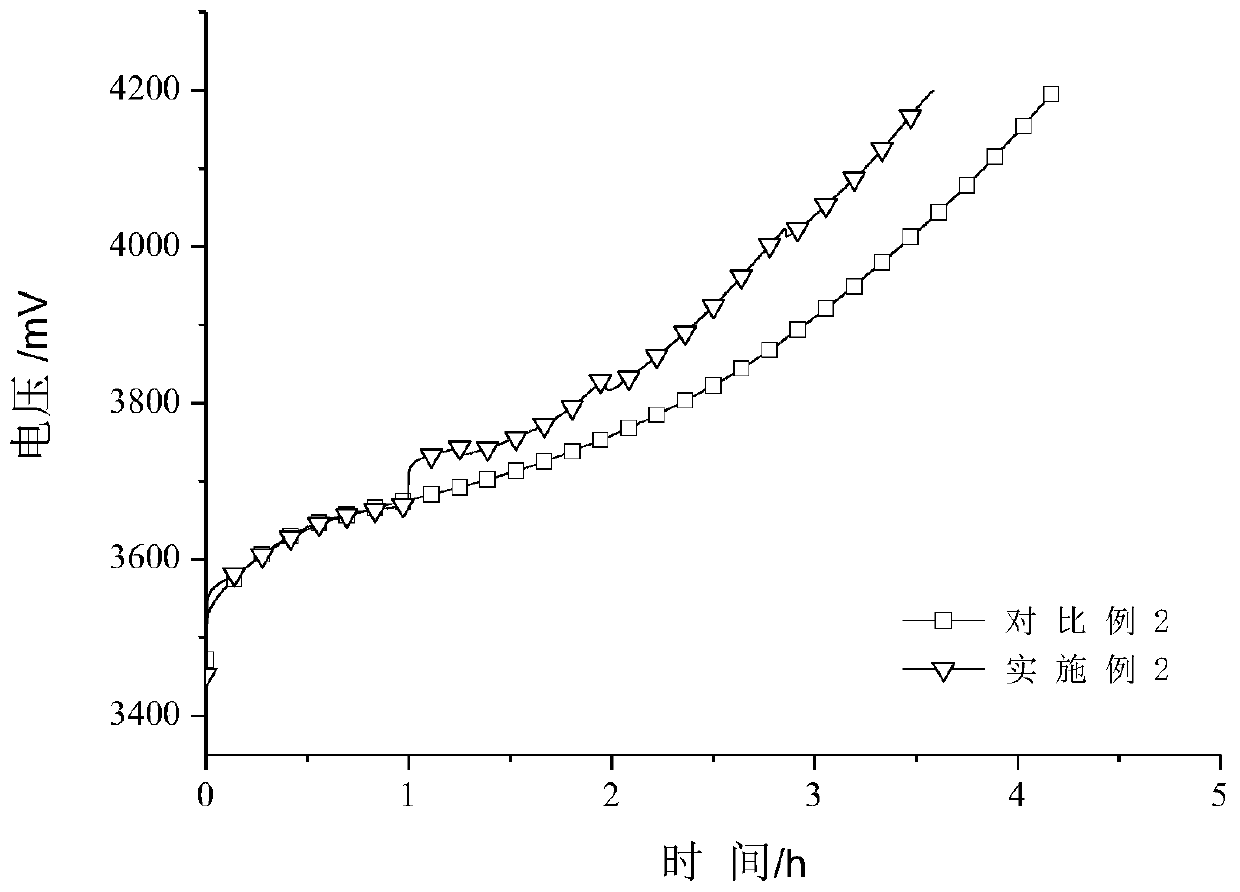

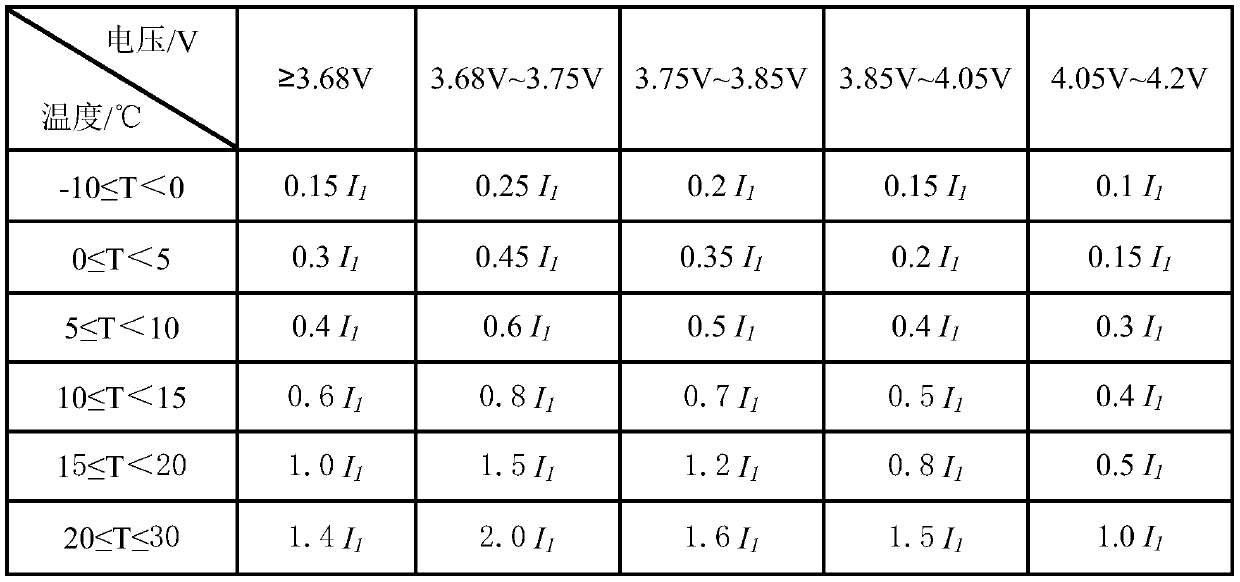

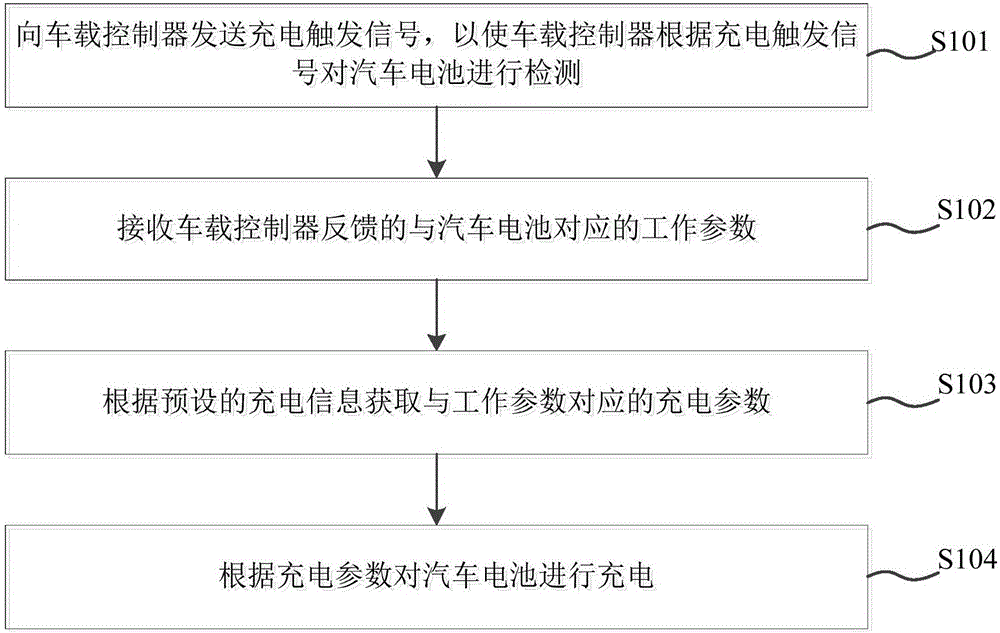

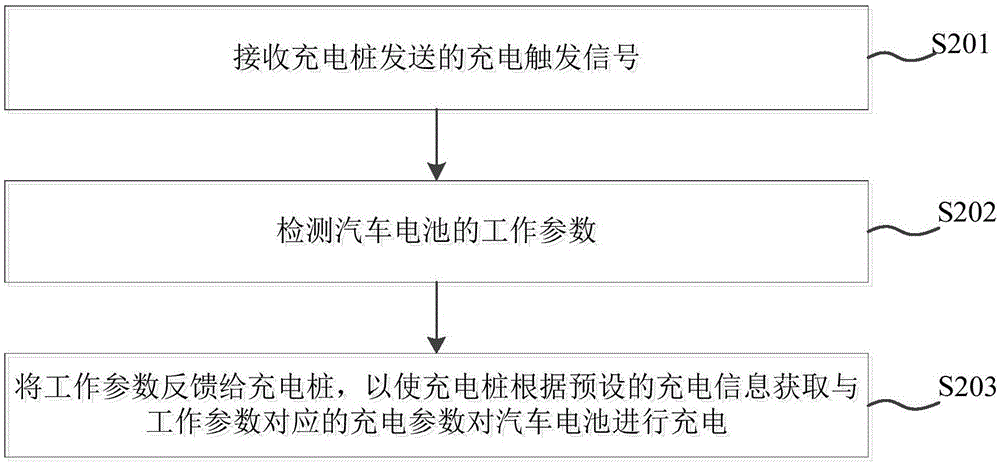

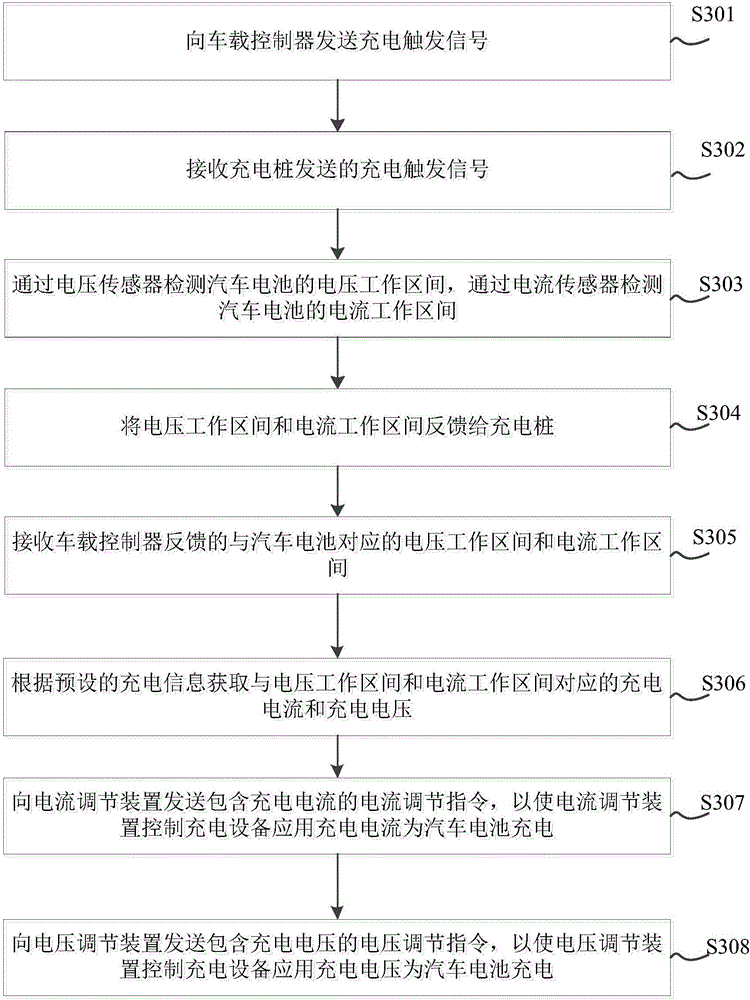

Automobile charging method, charging pile and vehicle-mounted controller

InactiveCN106252762AImprove charging efficiencyImprove charging safetyCharging stationsSecondary cells charging/dischargingAutomotive batteryEngineering

The invention proposes an automobile charging method, a charging pile and a vehicle-mounted controller. The method comprises the following steps of sending a charging trigger signal to the vehicle-mounted controller so that the vehicle-mounted controller detects an automobile battery according to the charging trigger signal; receiving a working parameter, corresponding to the automobile battery, fed back by the vehicle-mounted controller; acquiring a charging parameter corresponding to the working parameter according to preset charging information; and charging the automobile battery according to the charging parameter. Through the method according to the embodiment of the invention, automatic matching charging can be achieved according to battery characteristic, and the charging efficiency and the safety are improved.

Owner:BEIJING ELECTRIC VEHICLE

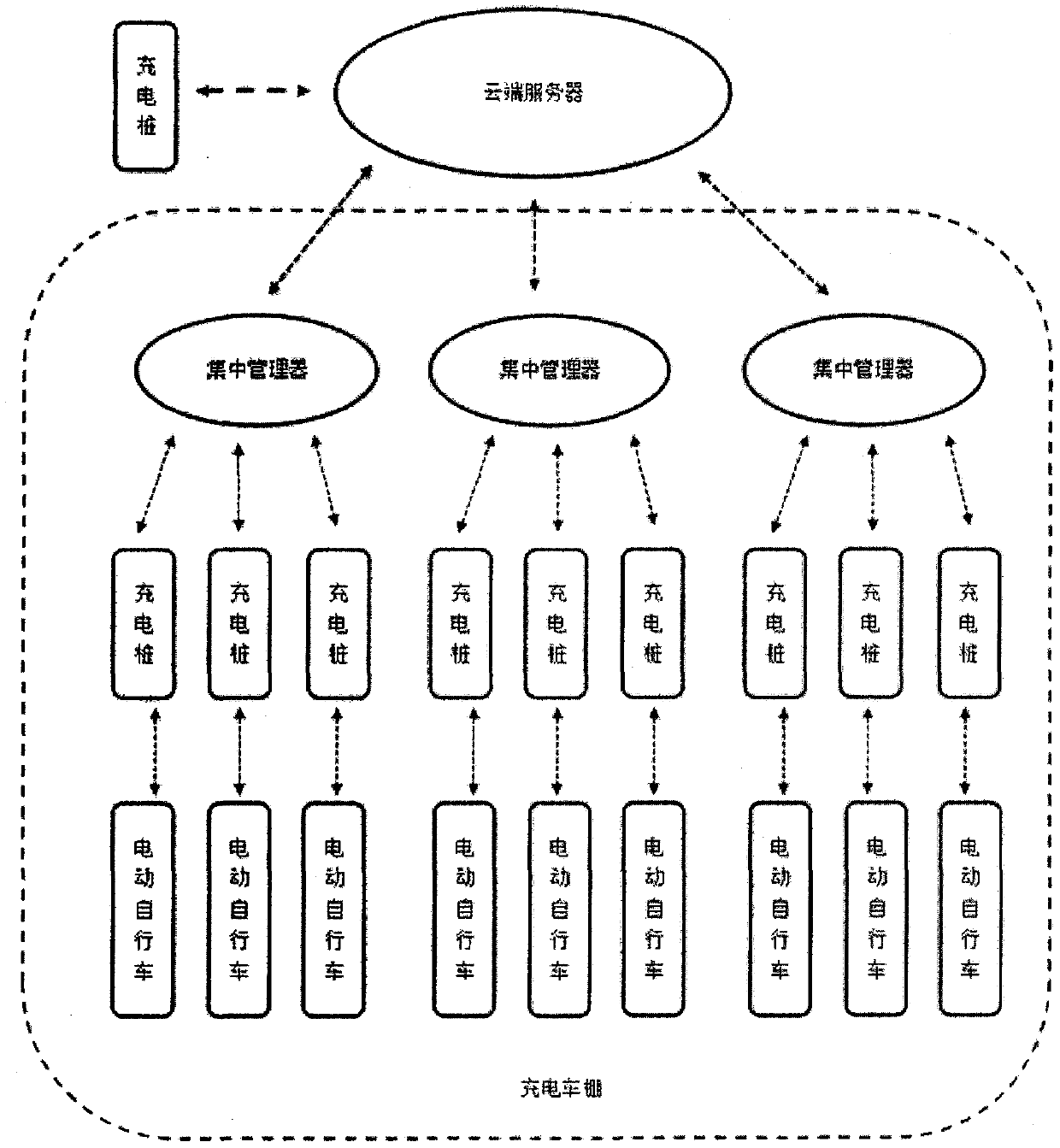

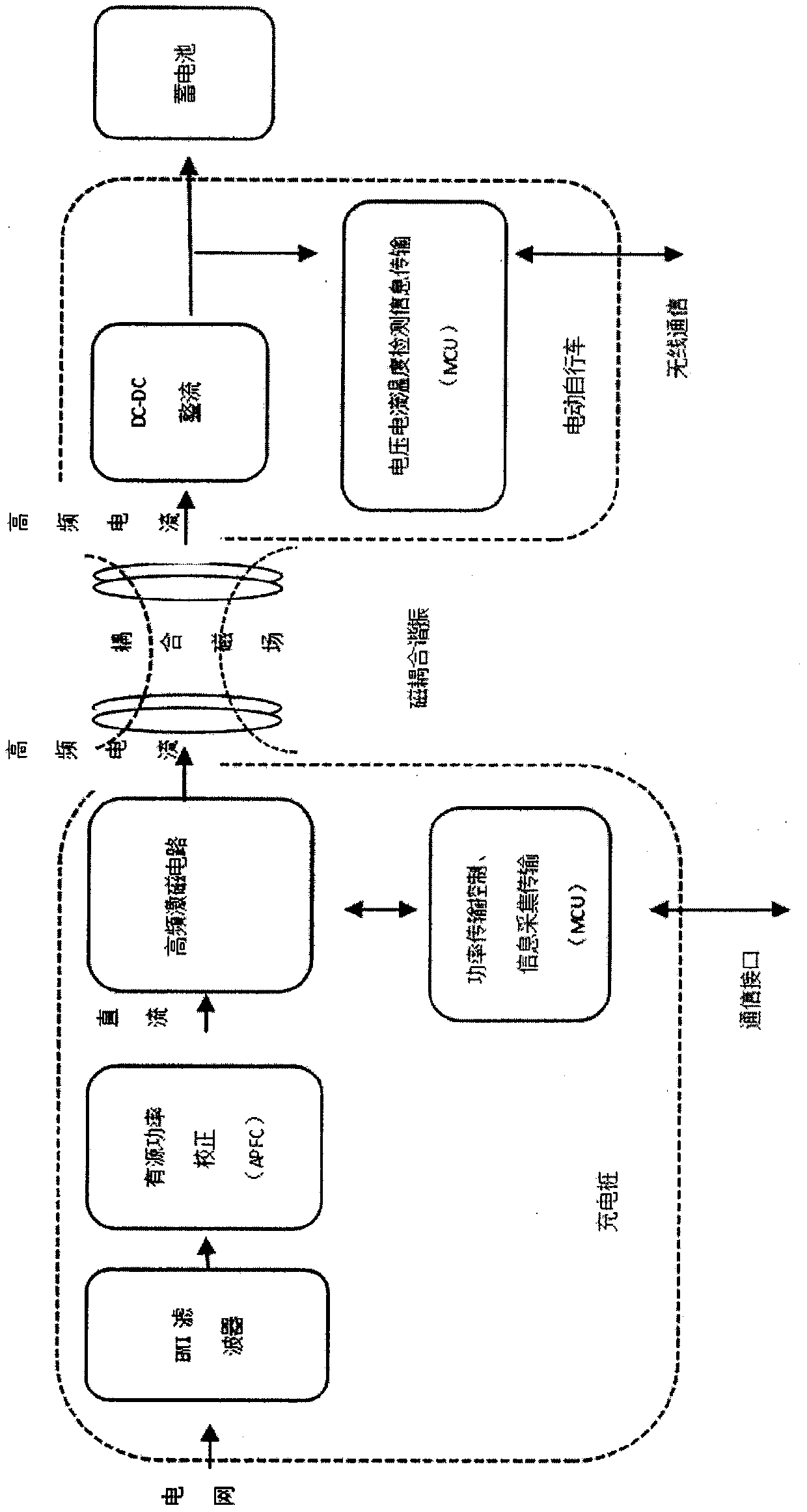

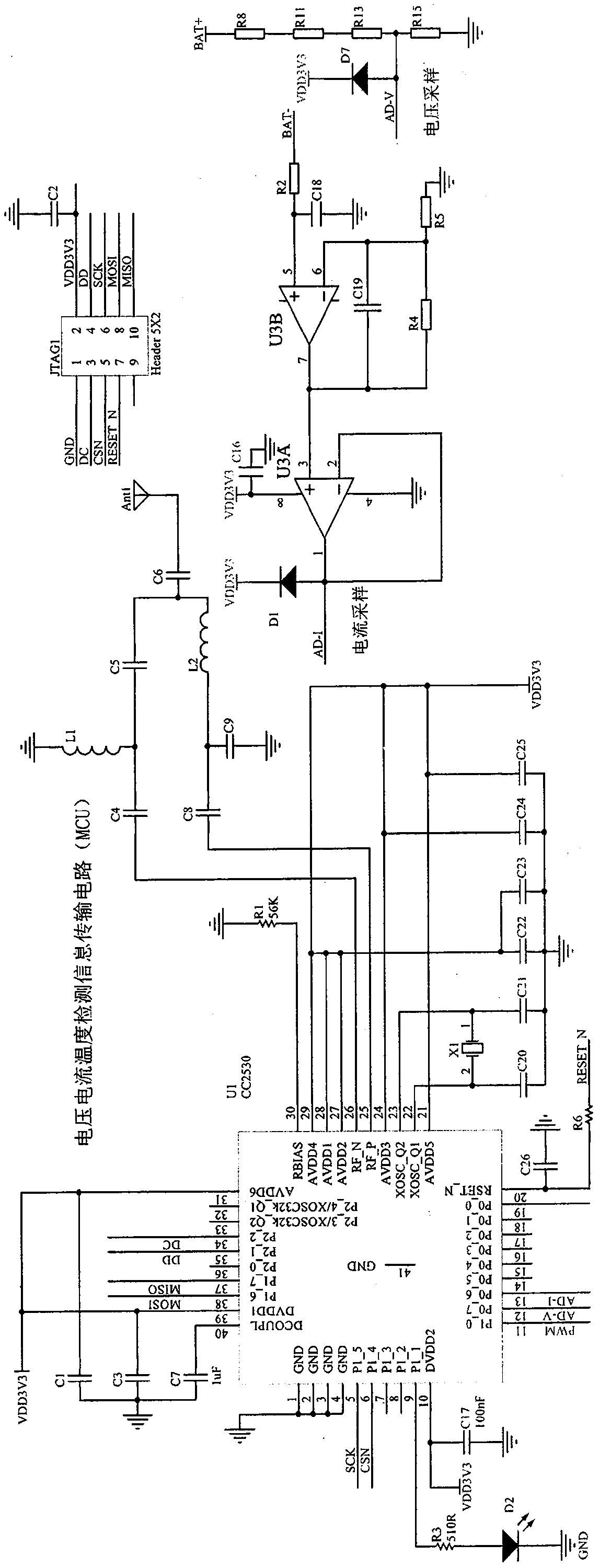

Electric bicycle wireless charging system

InactiveCN110014890AMeet charging needsElectric shock preventionCharging stationsElectric vehicle charging technologyElectricityElectrical battery

The invention discloses an electric bicycle wireless charging system, and relates to the technical field of electric bicycle wireless charging. The electric bicycle wireless charging system comprisesa cloud server, charging carports and charging piles. The charging carports are centrally managed through the cloud server by an internet mode, and the charging carports each comprise a plurality of charging piles and a centralized manager. The centralized managers receive charging process data of each charging pile wirelessly in real time, and the charging piles are fixedly disposed on the groundin the charging carports. Electric bicycle charging coils are induction secondary coils connected with electric bicycle batteries, and no wire connection between charging devices and the electric bicycle batteries is needed. Electric leakage and spark touch caused by the aging of wires and plugging and unplugging of sockets in a traditional charging mode are avoided, potential safety hazards suchas electric shock and fire are avoided, the charging safety is improved, when charging, electric bicycles only need to be parked within a certain range of power receiving for charging, and the use isconvenient.

Owner:西安恒常电磁科技有限责任公司

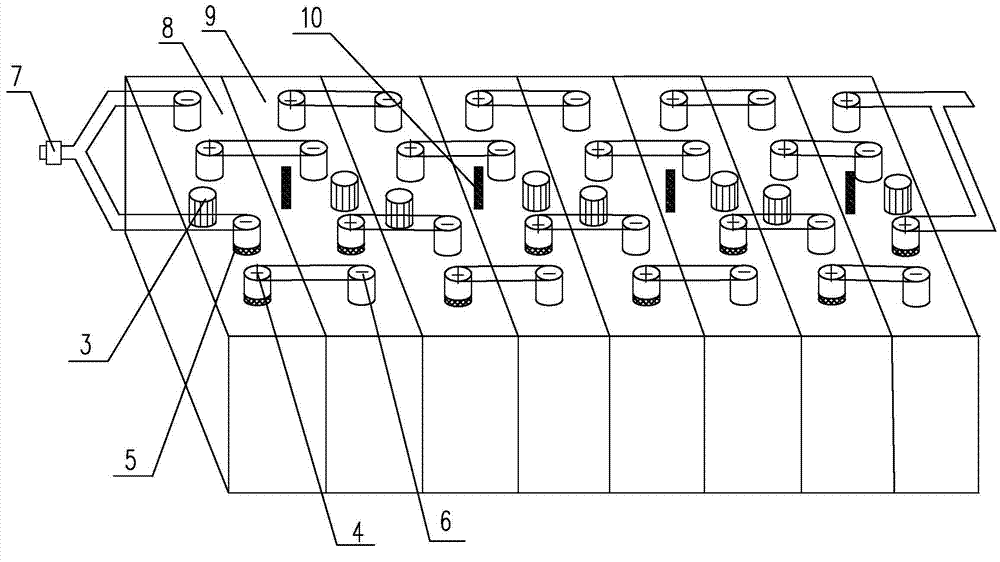

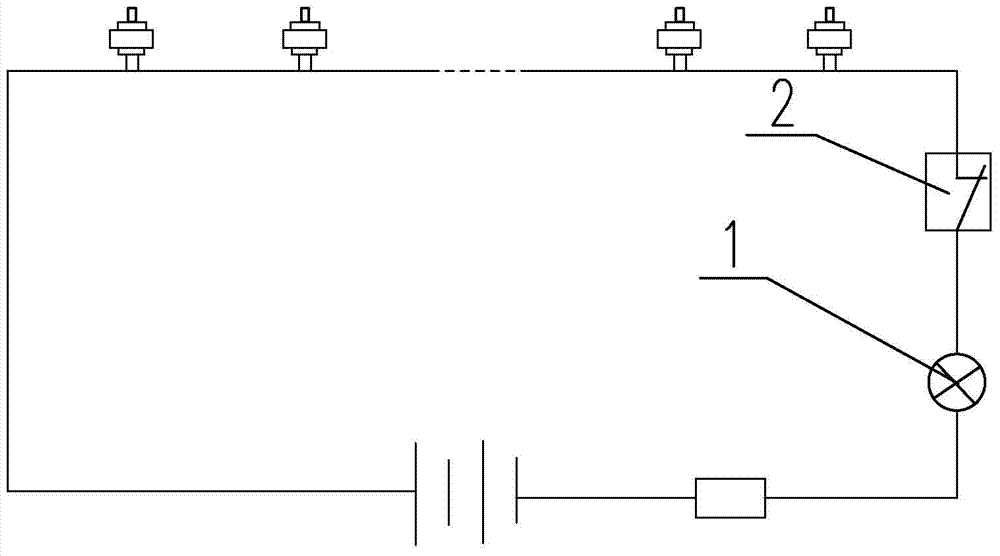

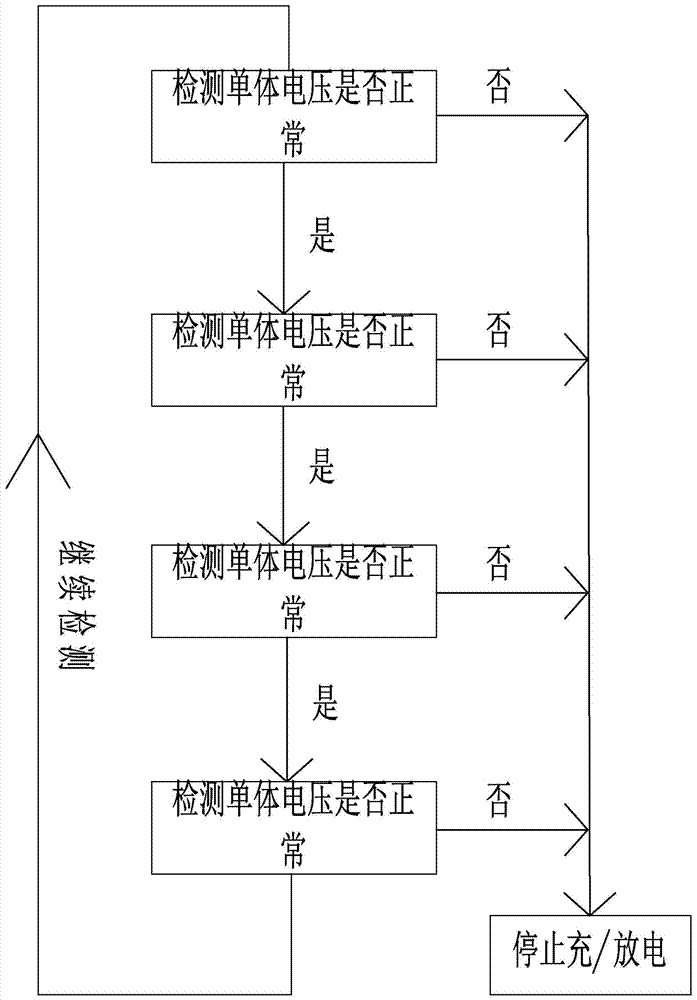

Novel safety management method and device for power battery pack of electric vehicle

InactiveCN103490108AImprove charging safetyLong cycle lifeSecondary cells servicing/maintenanceBatteriesPower batteryElectrical battery

The invention discloses a novel safety management method and a novel safety management device for a power battery pack of an electric vehicle. A data acquisition system and a charging / discharging management system are used for sequentially detecting, analyzing and calculating four parameters of single air pressure, single temperature, single voltage and power battery pack charging / discharging current of the power battery pack to further control the charging / discharging state of the power battery pack, wherein the single air pressure, the single temperature, the single voltage and the power battery pack charging / discharging current of the power battery pack are detected through a normally closed air pressure switching sensor, a temperature sensor, a voltage sensor and a Hall sensor respectively. According to the method and the device, the charging / discharging of the power battery pack is instantly stopped when one of the four parameters reaches a charging / discharging stopping condition in a process of detecting the four parameters, and the four parameters are continuously detected if all is normal, so that all single power batteries are effectively prevented from being over-charged or over-discharged, the service life of the power battery pack is prolonged, and the safety of the power battery pack is improved.

Owner:SHANDONG UNIV OF TECH

Wireless charging module, wireless charging table and wireless charging method

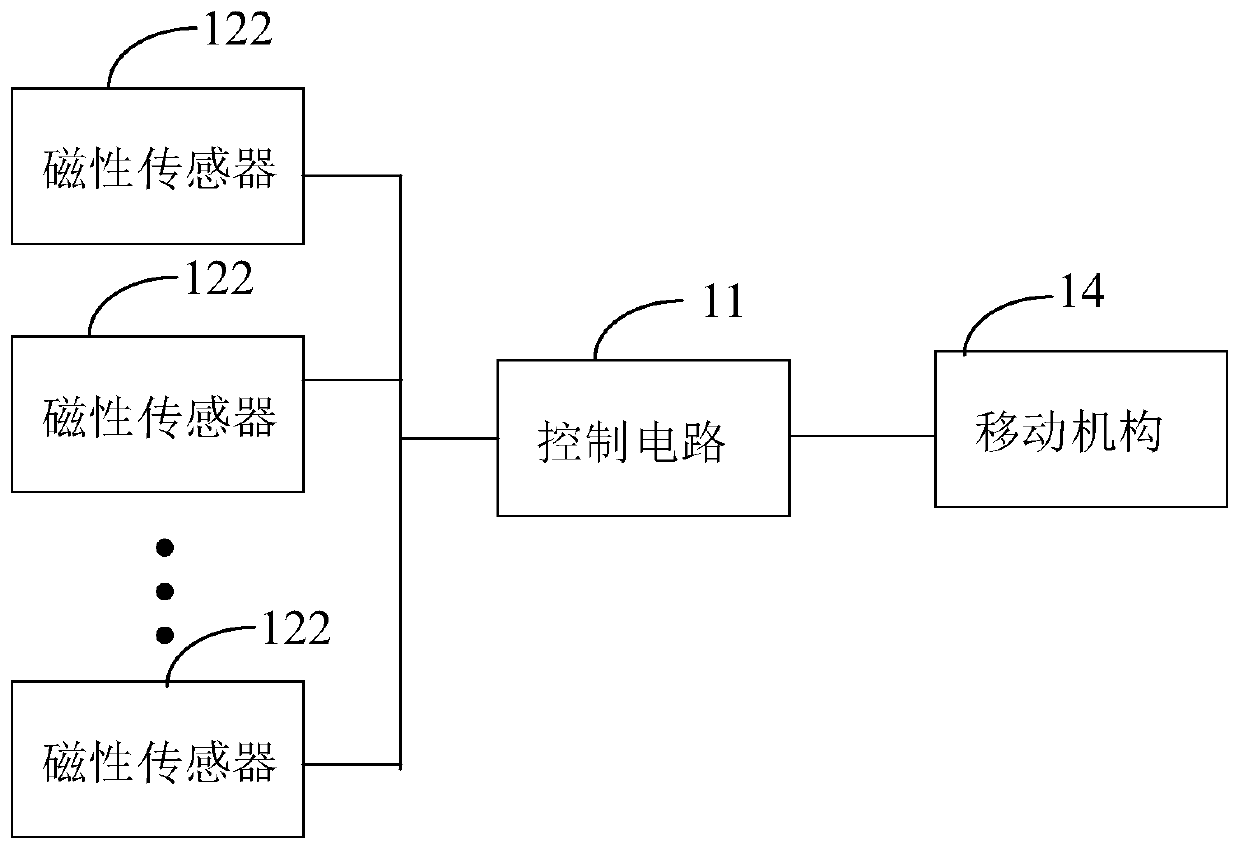

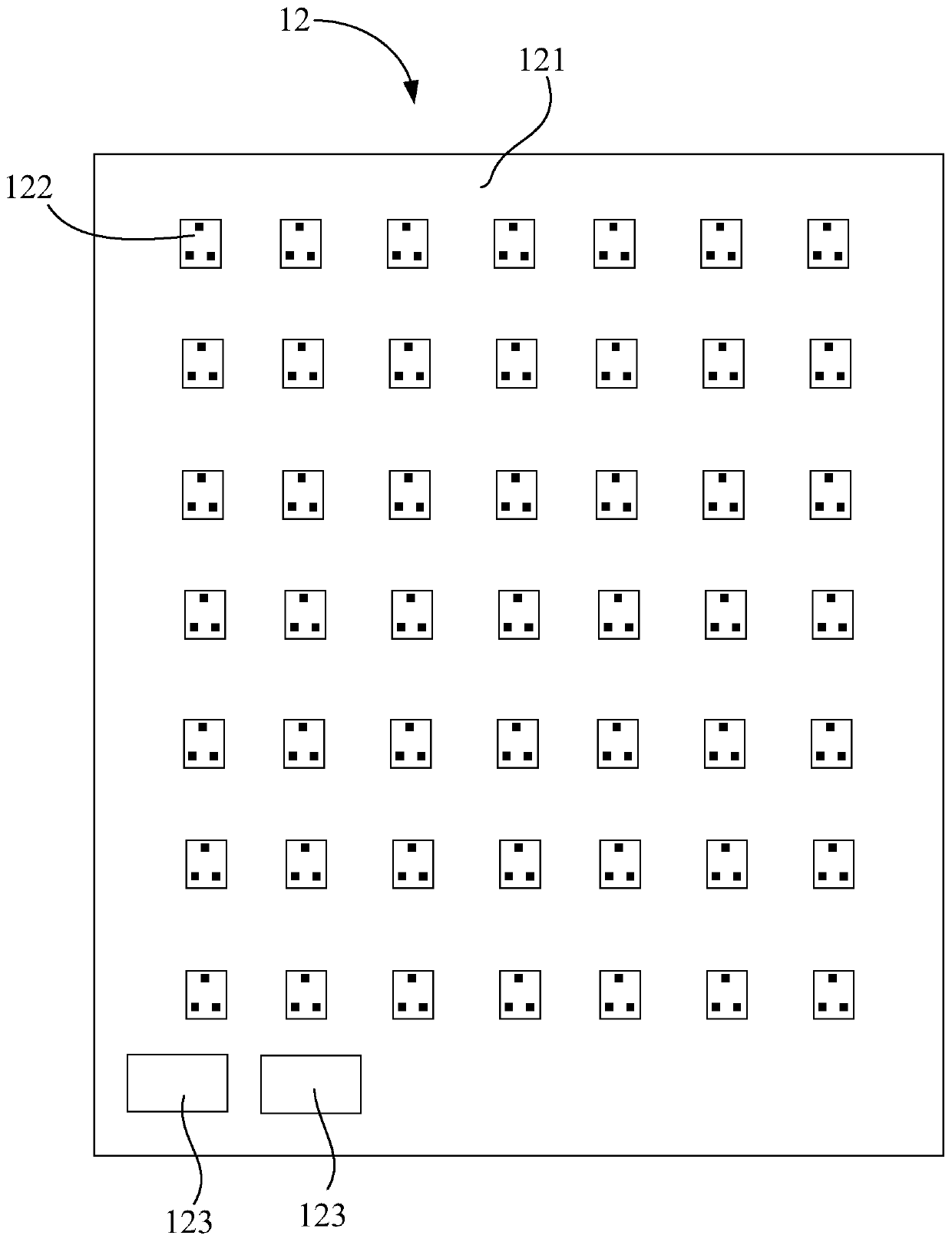

PendingCN110867931AGuaranteed stabilityImprove couplingBatteries circuit arrangementsSecondary cells charging/dischargingControl circuitInductive charging

The invention provides a wireless charging module, a wireless charging table and a wireless charging method. The wireless charging module comprises a control circuit, a detection plate, a wireless charging base and a moving mechanism. The detection plate is arranged corresponding to a desktop; and the detection plate comprises a substrate and a plurality of magnetic sensors. The plurality of magnetic sensors are electrically connected with the control circuit; and the magnetic sensors are used for detecting the position of a device to be charged on a plane. The wireless charging base is used for wirelessly charging the device to be charged. The moving mechanism supports the wireless charging base. The control circuit is used for controlling the moving mechanism to work according to the position, detected by the multiple magnetic sensors, of the device to be charged placed on the plane, so that the moving mechanism drives the wireless charging base to move to the position of the deviceto be charged. According to the scheme, the effectiveness of wireless charging can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com