Optimized charging method of vehicle-mounted energy storage lithium ion battery for rail transit

A lithium-ion battery and rail transit technology, which is applied in the field of optimized charging of on-board energy storage lithium-ion batteries for rail transit, can solve the problems of battery active material loss, battery thermal runaway, battery safety reduction, etc., to improve battery life and Charging safety, charging time balance, and the effect of increasing charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

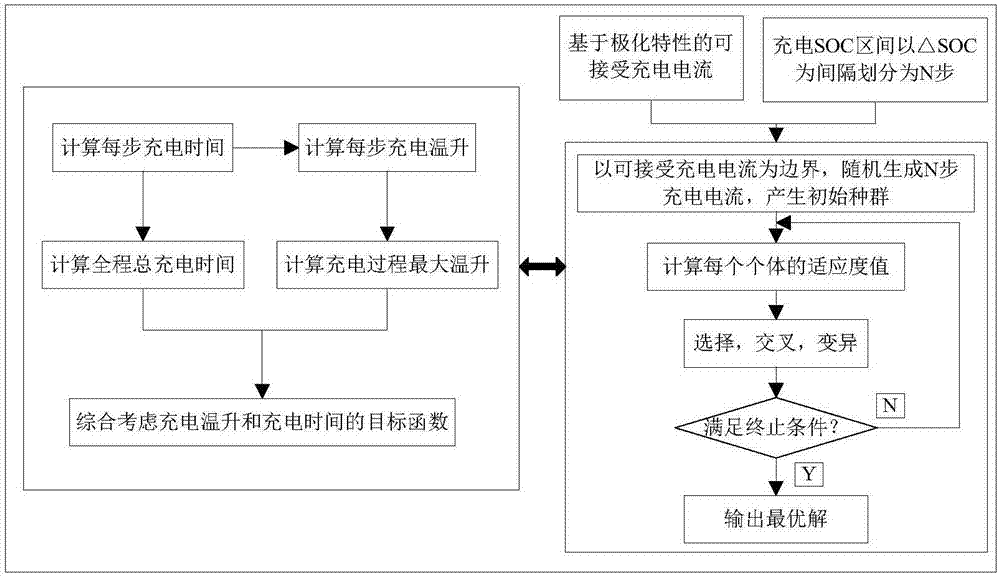

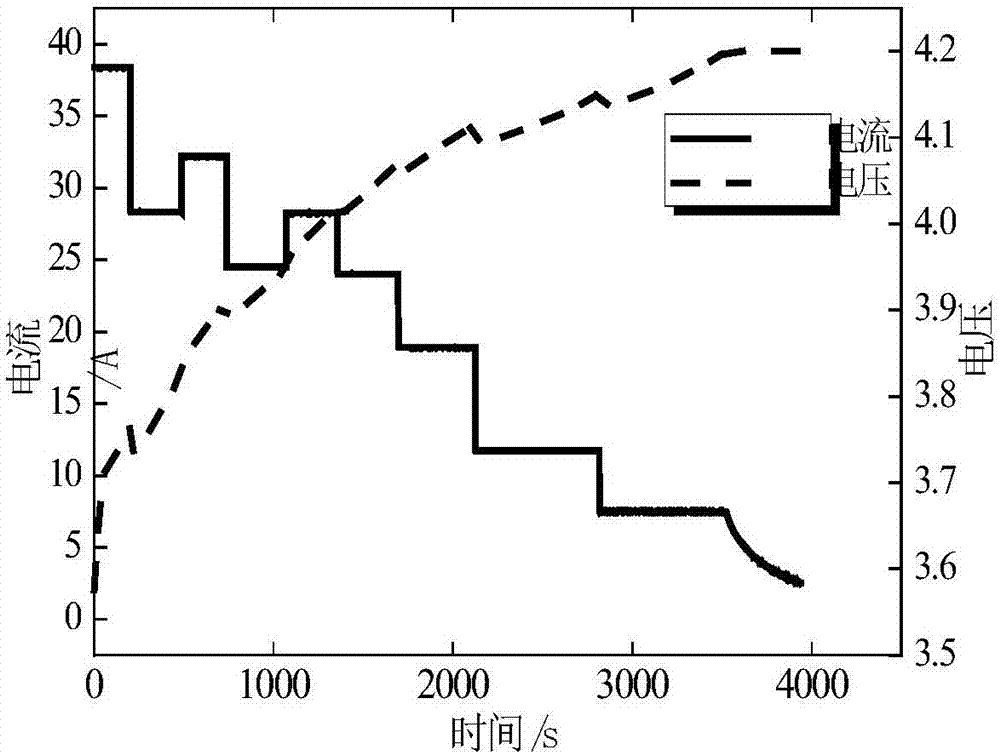

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

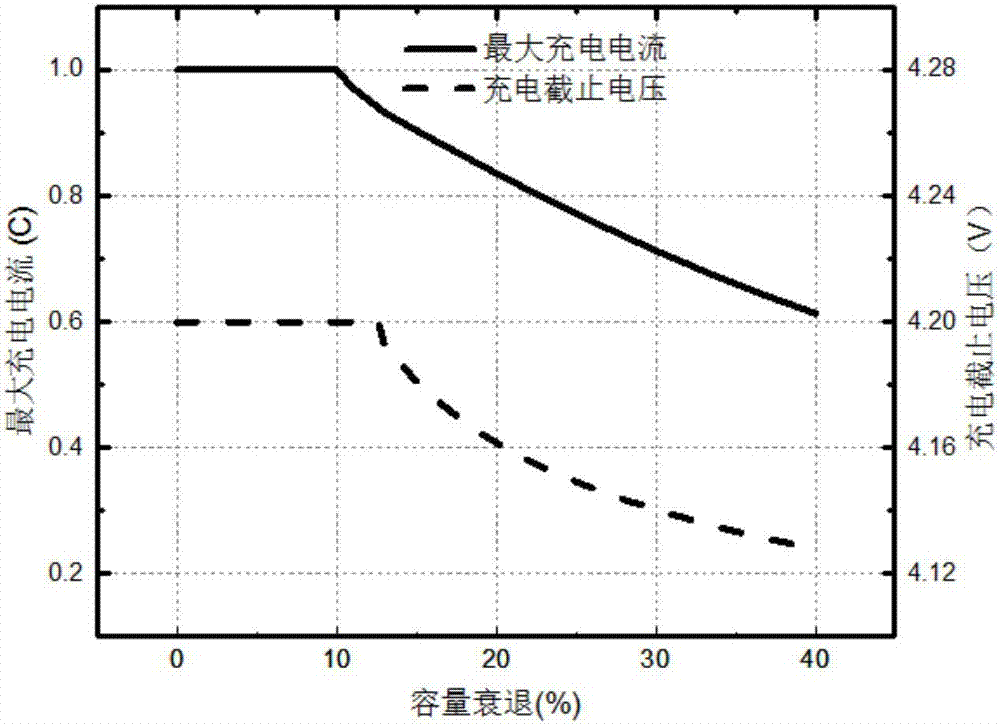

[0048] S1. Calculate the maximum charging current in the full life cycle of the lithium-ion battery based on the battery degradation mechanism, and use the maximum charging current as the boundary condition for optimal charging current selection.

[0049] When there is no accelerated loss of material in the battery, the charging rate is the critical charging rate. After the accelerated loss occurs in the battery, the capacity decline rate in the cycle charging after the accelerated loss is equal to the decay rate at the moment when the accelerated loss occurs in the battery, and then use the formula ( 1) Calculate the charging current of the battery at different aging stages after the accelerated loss. During the charging process of the battery, the charging current cannot exceed the maximum value of the calculated charging current. The maximum value of this c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com