Charging method for lithium ion battery management system

A technology of lithium ion battery and management system, applied in the charging field of battery management system, can solve problems such as unrealizable, achieve the effect of improving efficiency, charging efficiency, and improving anode lithium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

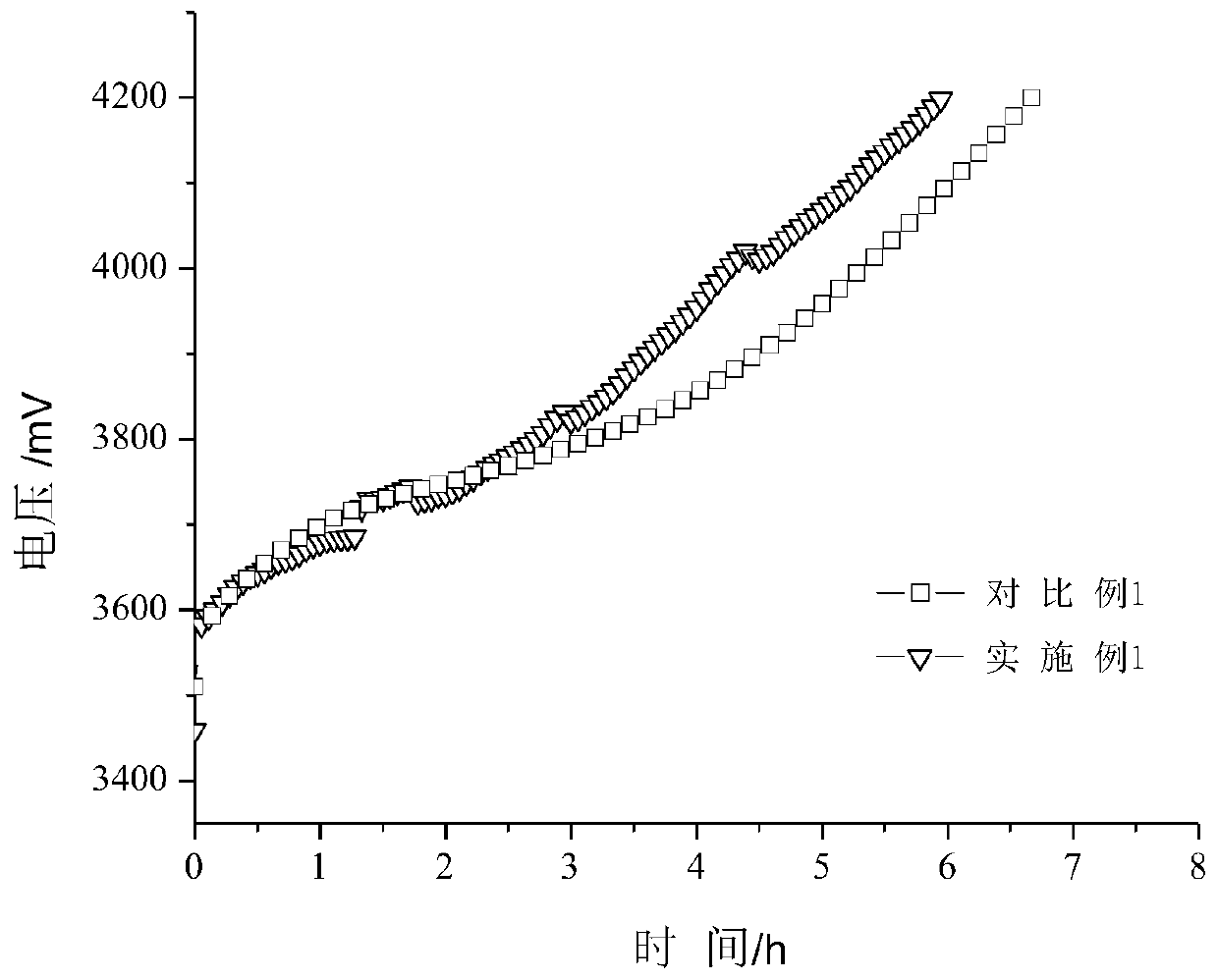

Embodiment 1

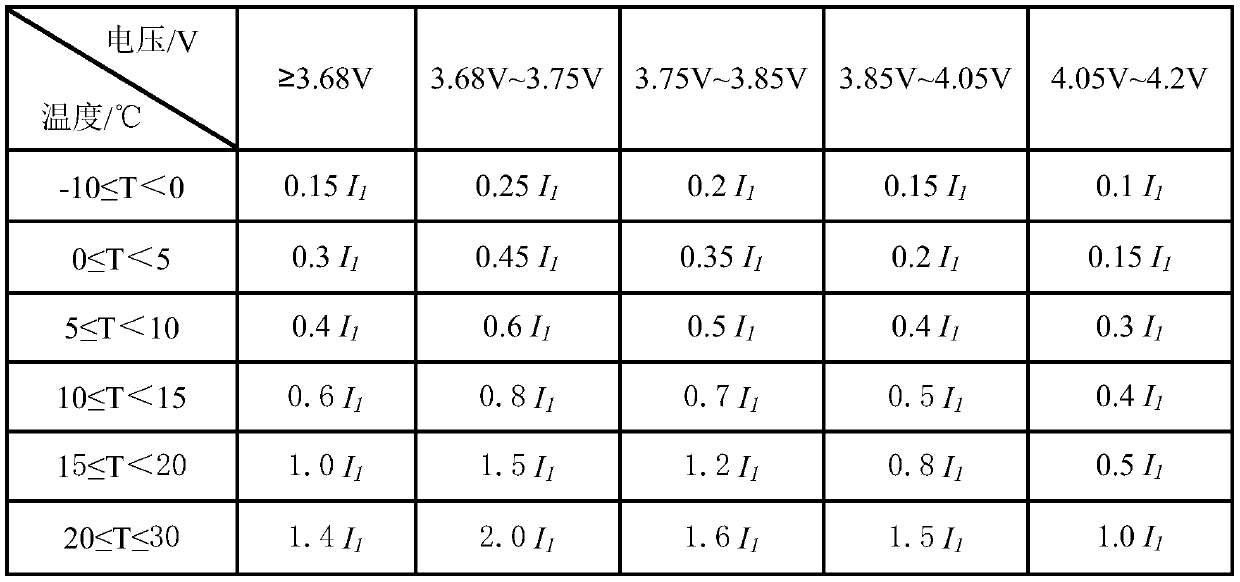

[0069] The state of charge is 0%, and its corresponding voltage is V 0 (V 0 <3.68V), the lithium-ion battery whose battery surface temperature is -10°C is charged in a constant temperature environment of -10°C according to the charging method of the lithium-ion battery management system of the present invention, and the specific steps are as follows:

[0070] 1) With a current of 0.15I 1 Charge the battery with a constant current, the charging capacity is 20% of the rated capacity of the battery, and the voltage of the battery is 3.68V at this time;

[0071] 2) With a current of 0.25I 1 Charge the battery with a constant current, the charging capacity is 10% of the rated capacity of the battery, and the voltage of the battery is 3.75V at this time;

[0072] 3) Use current 0.2I 1 Charge the battery with a constant current, the charging capacity is 25% of the rated capacity of the battery, and the voltage of the battery is 3.85V at this time;

[0073] 4) With a current of 0...

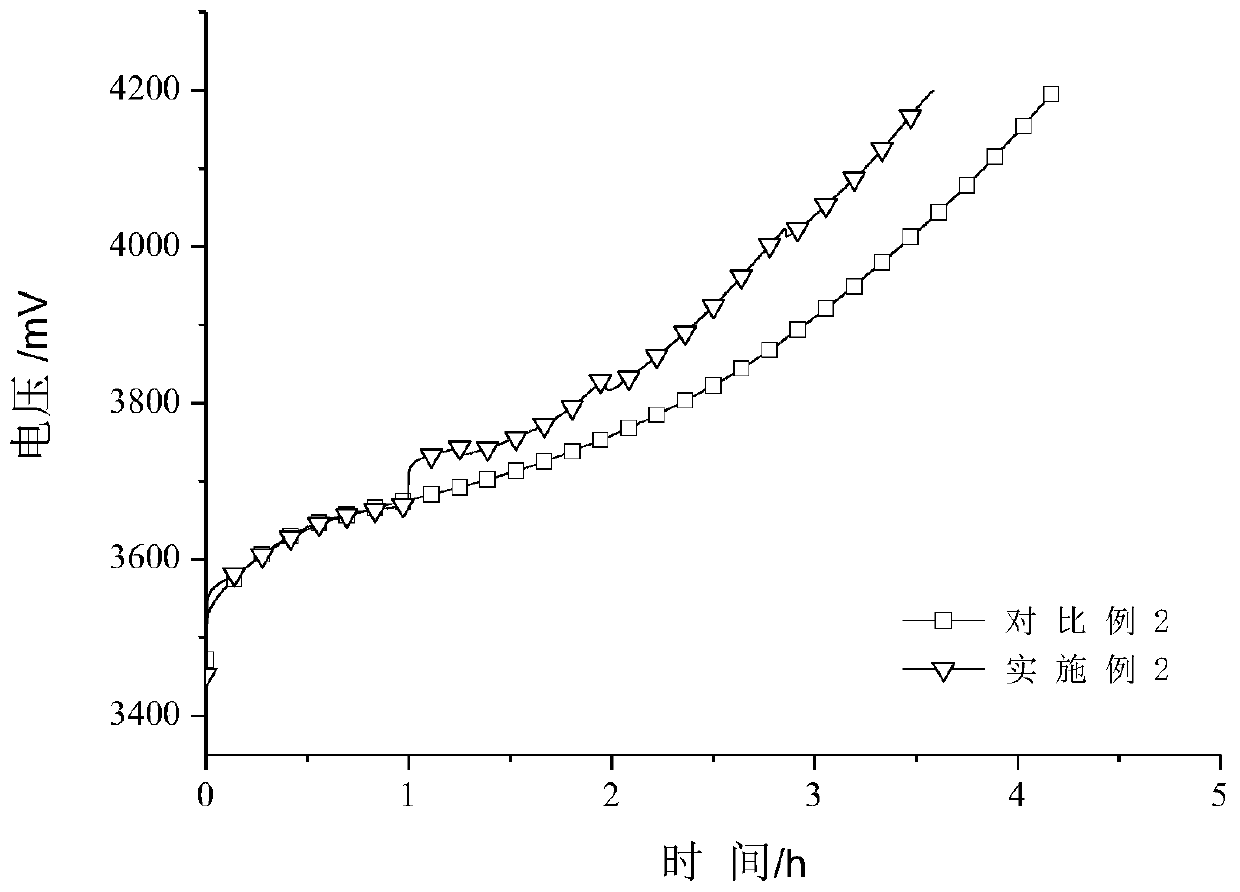

Embodiment 2

[0083] The state of charge is 0%, and its corresponding voltage is V 0 (V 0 <3.68V), the lithium-ion battery whose battery surface temperature is 0°C is charged in a constant temperature environment of 0°C according to the charging method of the lithium-ion battery management system of the present invention, and the specific steps are as follows:

[0084] 1) With a current of 0.3I 1 Charge the battery with a constant current, and the charging capacity is 20% of the rated capacity of the battery. At this time, the voltage of the battery is 3.68V.

[0085] 2) With a current of 0.45I 1 Charge the battery with a constant current, and the charging capacity is 10% of the rated capacity of the battery. At this time, the voltage of the battery is 3.75V.

[0086] 3) With a current of 0.35I 1 Charge the battery with a constant current, and the charging capacity is 25% of the rated capacity of the battery. At this time, the voltage of the battery is 3.85V.

[0087] 4) With a current...

Embodiment 3

[0096] The state of charge is 0%, and its corresponding voltage is V 0 (V 0 <3.68V), the battery surface temperature is 5 ℃ of lithium-ion batteries, under the constant temperature environment of 5 ℃, according to the charging method of lithium-ion batteries of the present invention, the battery is charged with multi-stage current and constant current, and the specific steps are as follows:

[0097] 1) With a current of 0.4I 1 Charge the battery with a constant current, and the charging capacity is 20% of the rated capacity of the battery. At this time, the voltage of the battery is 3.68V.

[0098] 2) With a current of 0.6I 1 Charge the battery with a constant current, and the charging capacity is 10% of the rated capacity of the battery. At this time, the voltage of the battery is 3.75V.

[0099] 3) With a current of 0.5I 1 Charge the battery with a constant current, and the charging capacity is 25% of the rated capacity of the battery. At this time, the voltage of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com