Formula and preparation method of high energy storage lead-acid battery lead paste

A lead-acid battery and high energy storage technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of over-discharge performance and poor charge acceptance, and achieve improved initial capacity, high cycle life, and high initial capacity. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0019] A high-energy storage lead-acid storage battery lead paste formula, including a positive electrode paste formula and a negative electrode paste formula,

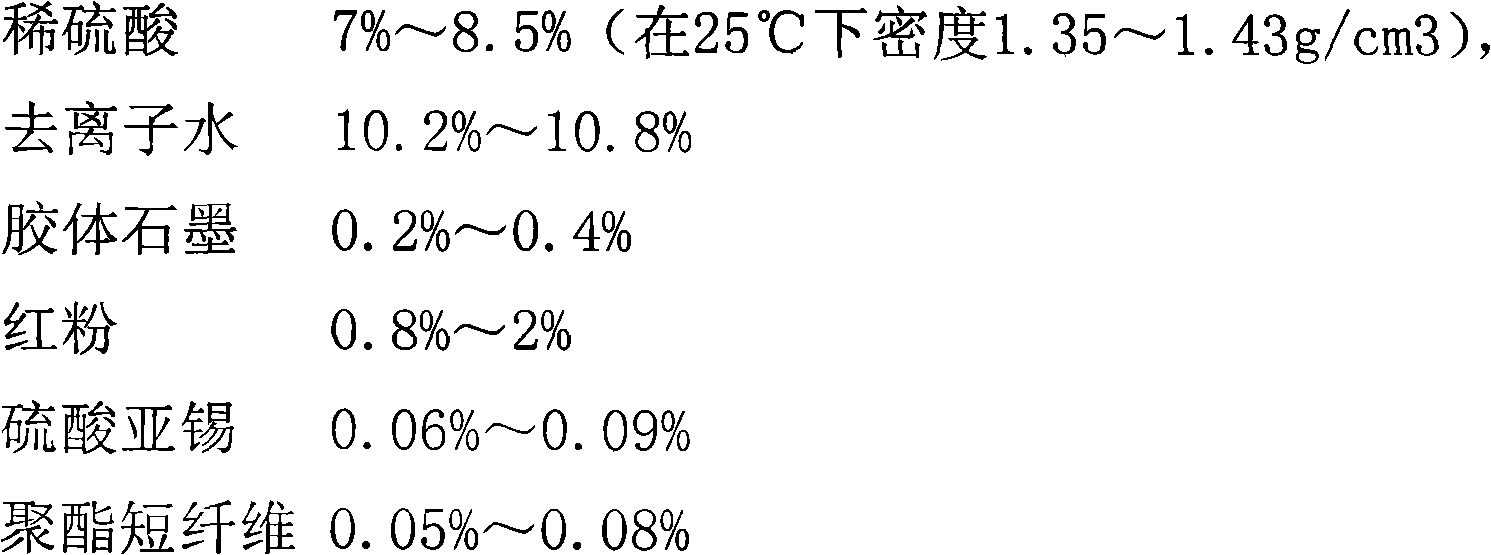

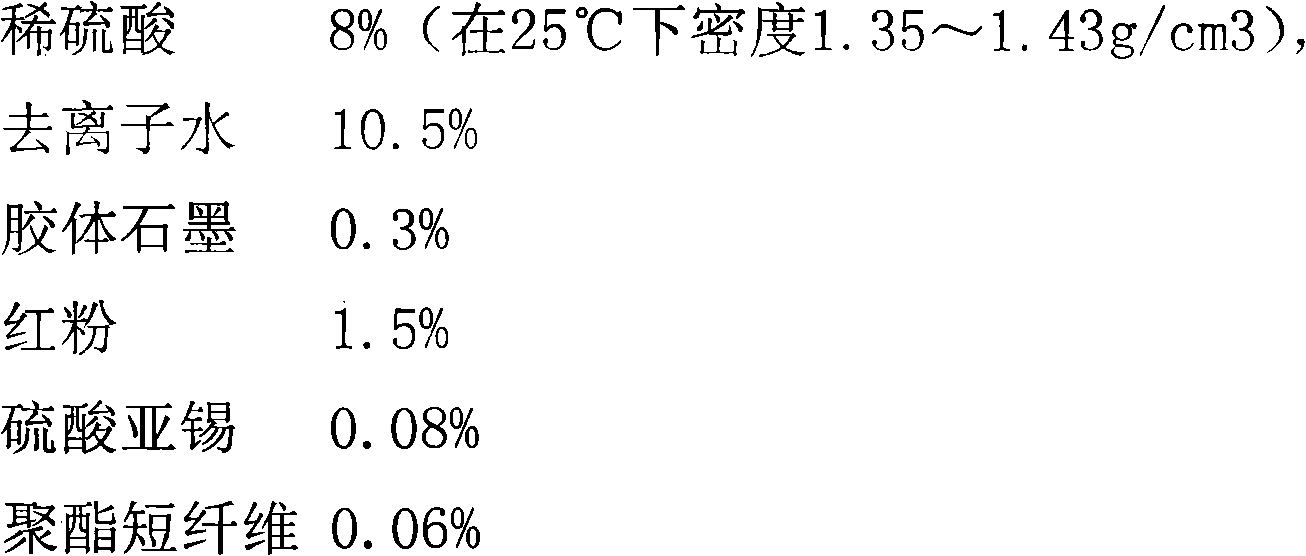

[0020] The positive lead paste formula is composed of the following raw materials by weight percentage:

[0021]

[0022] The rest is lead powder;

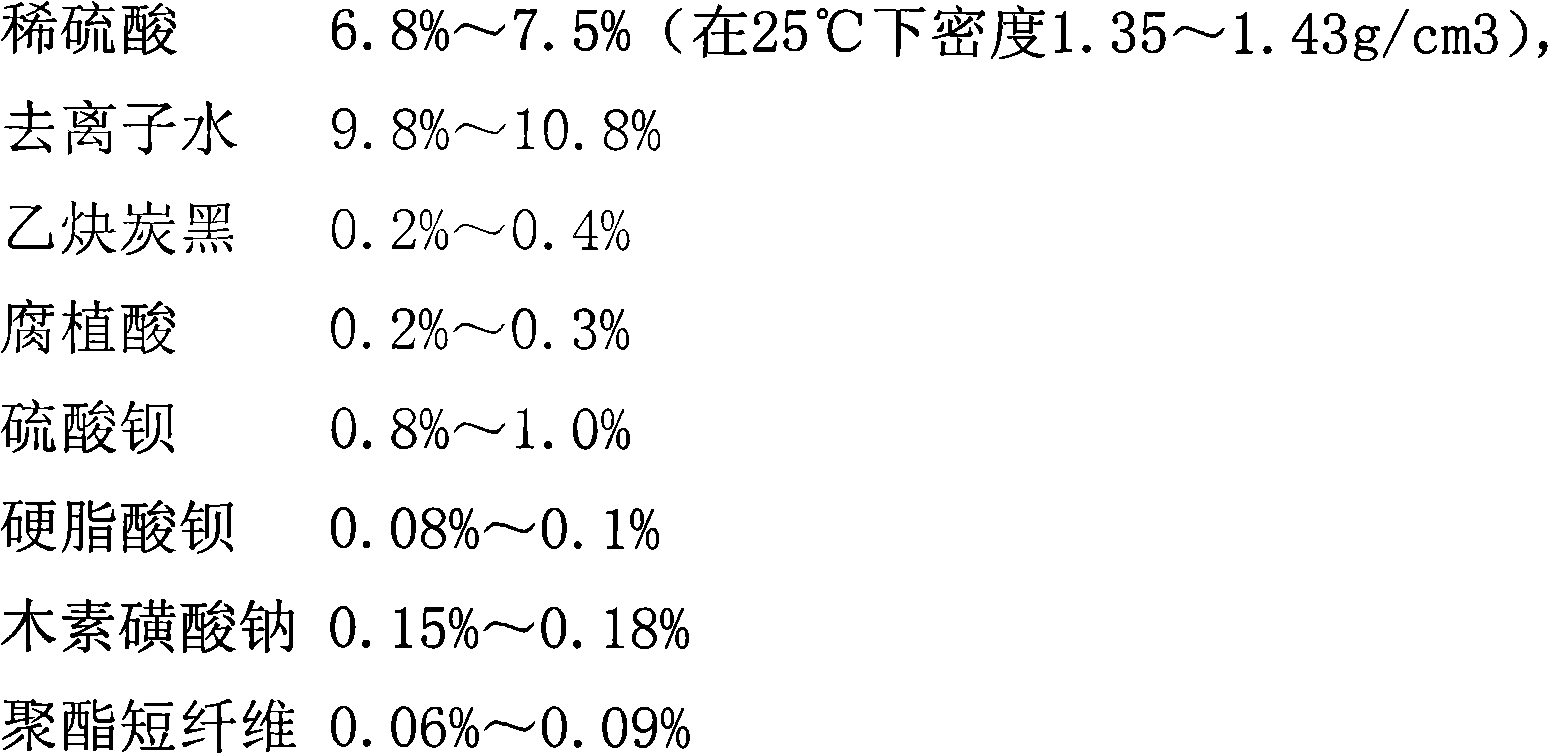

[0023] The negative plate lead paste formula is composed of the following raw materials by weight percentage:

[0024]

[0025]

[0026] The rest is lead powder.

[0027] The degree of oxidation of lead powder is 72% to 78%.

[0028] The method for preparing the above-mentioned high energy storage lead-acid battery lead paste is to add the red powder, colloidal graphite, polyester staple fiber and stannous sulfate in the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com