Wireless charging circuit, system and method and electronic equipment

A wireless charging and circuit technology, applied in battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve the problems of low charging safety and low charging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

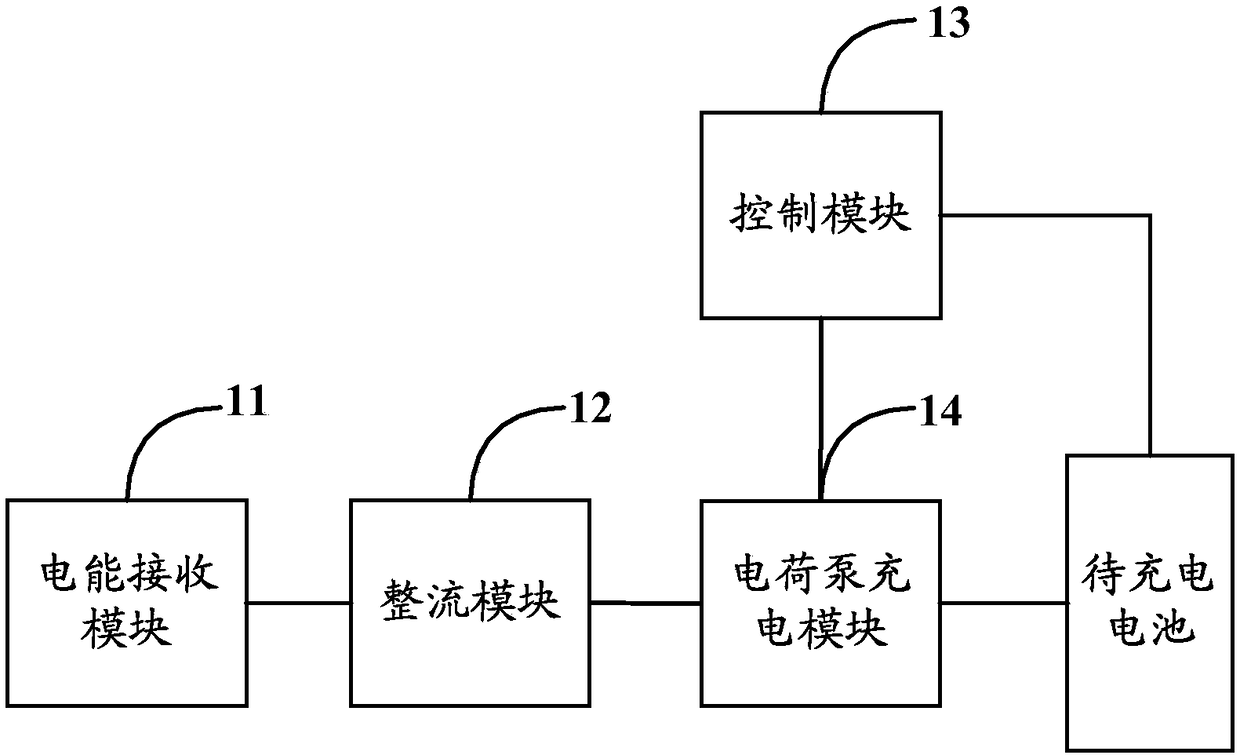

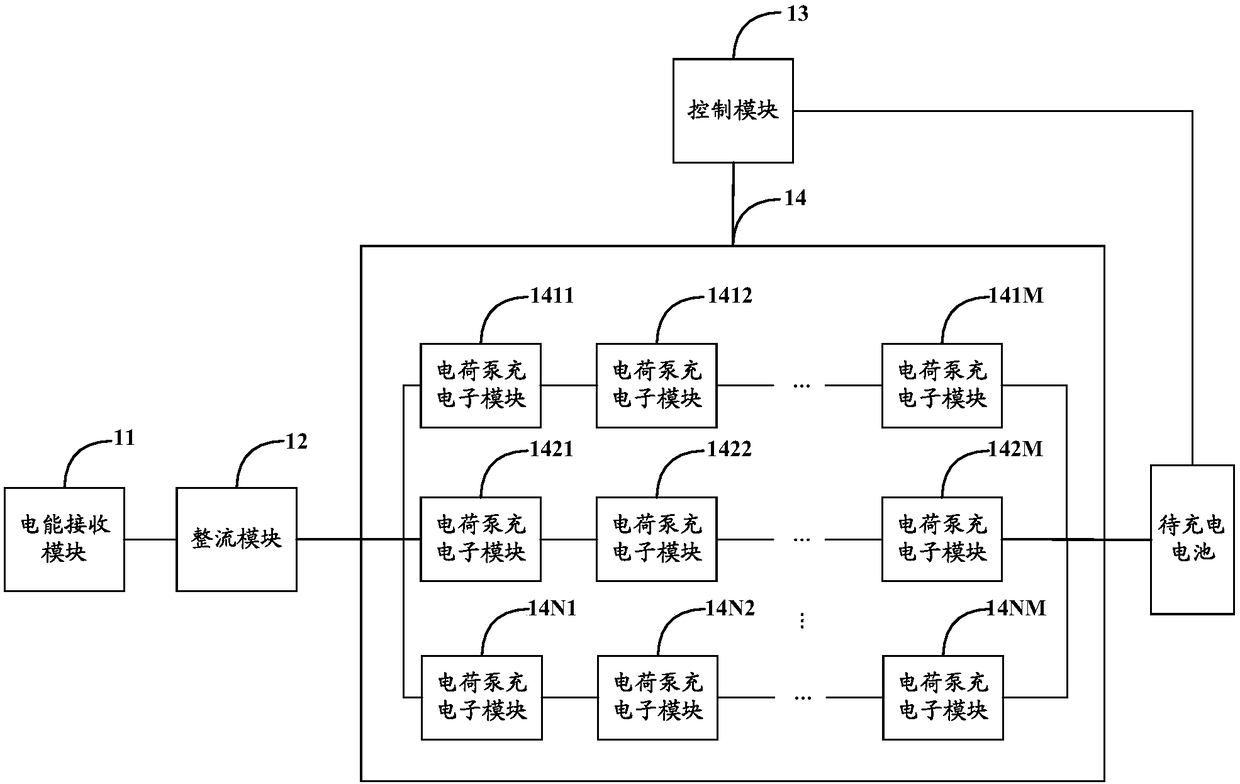

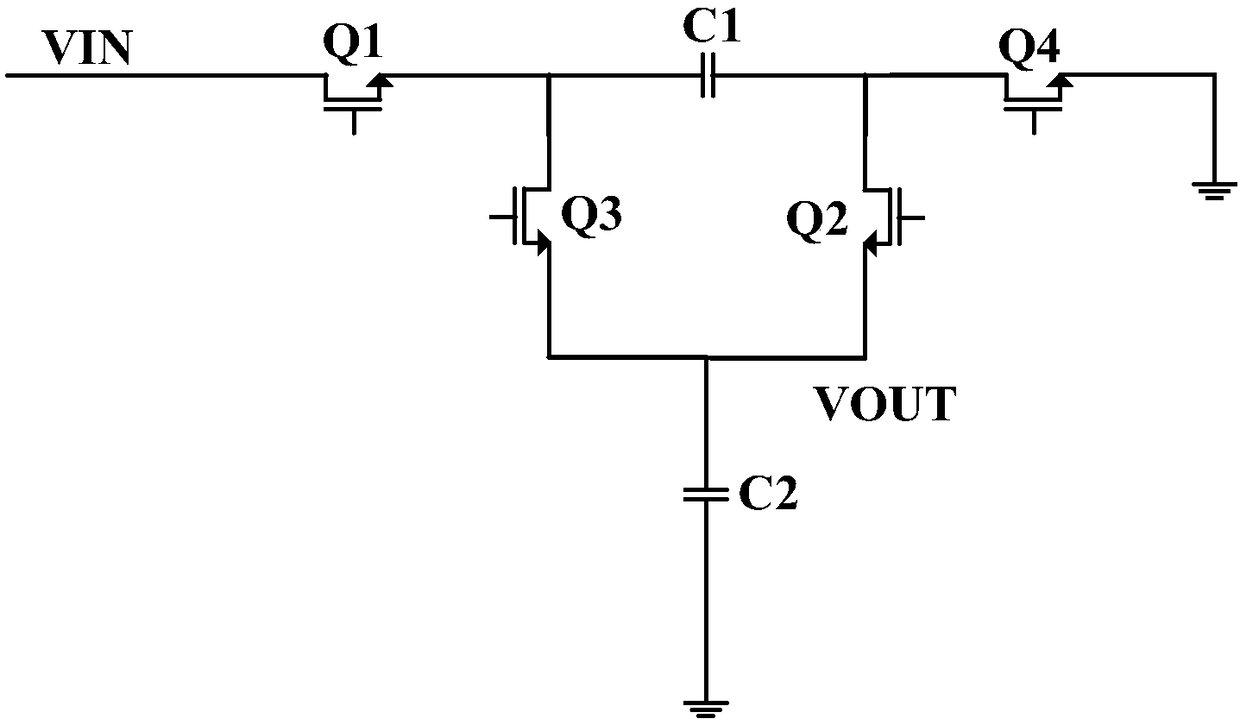

[0062] In order to solve the problems of low charging efficiency and low charging safety in existing wireless charging circuits, an embodiment of the present invention provides a wireless charging circuit. Wherein, the wireless charging circuit can usually be set in a corresponding terminal device, such as a mobile phone, a tablet computer, a smart watch, a camera, etc., for when the terminal device establishes a coupling connection with a corresponding wireless adapter, The electric energy received from the wireless adapter is transmitted to the battery to be charged of the terminal device. Of course, the wireless charging circuit can also be used independently, which will not be described in detail. like figure 1 As shown in , it is a schematic circuit structure diagram of the first wireless charging circuit described in Embodiment 1 of the present invention. Specifically, such as figure 1 As shown, the first type of wireless charging circuit may include a power receiving ...

Embodiment 2

[0160] Based on the same inventive concept as the first embodiment of the present invention, the second embodiment of the present invention provides a wireless charging method, which can be applied to the wireless charging circuit described in the previous embodiment. For the same content, please refer to the first embodiment of the present invention. The relevant content of the present invention will not be described too much in the embodiment of the present invention. like Figure 12 As shown, it is a schematic flowchart of the wireless charging method described in Embodiment 2 of the present invention. Specifically, by Figure 12 It can be seen that the wireless charging method may include the following steps:

[0161] Step 1201: Receive the AC power transmitted by the power transmission module of the wireless adapter;

[0162] Step 1202: Convert the alternating current into direct current;

[0163] Step 1203: Collect the charging voltage of the battery to be charged, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com