Lead acid battery charge protection and optimization technology

A lead-acid battery, charging protection technology, applied in secondary battery charging/discharging, battery circuit device, secondary battery repair/maintenance, etc., can solve problems such as unsatisfactory three-stage charging, battery or charger damage, etc. Achieve the effects of increasing charging safety, prolonging service life, and preventing charging thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

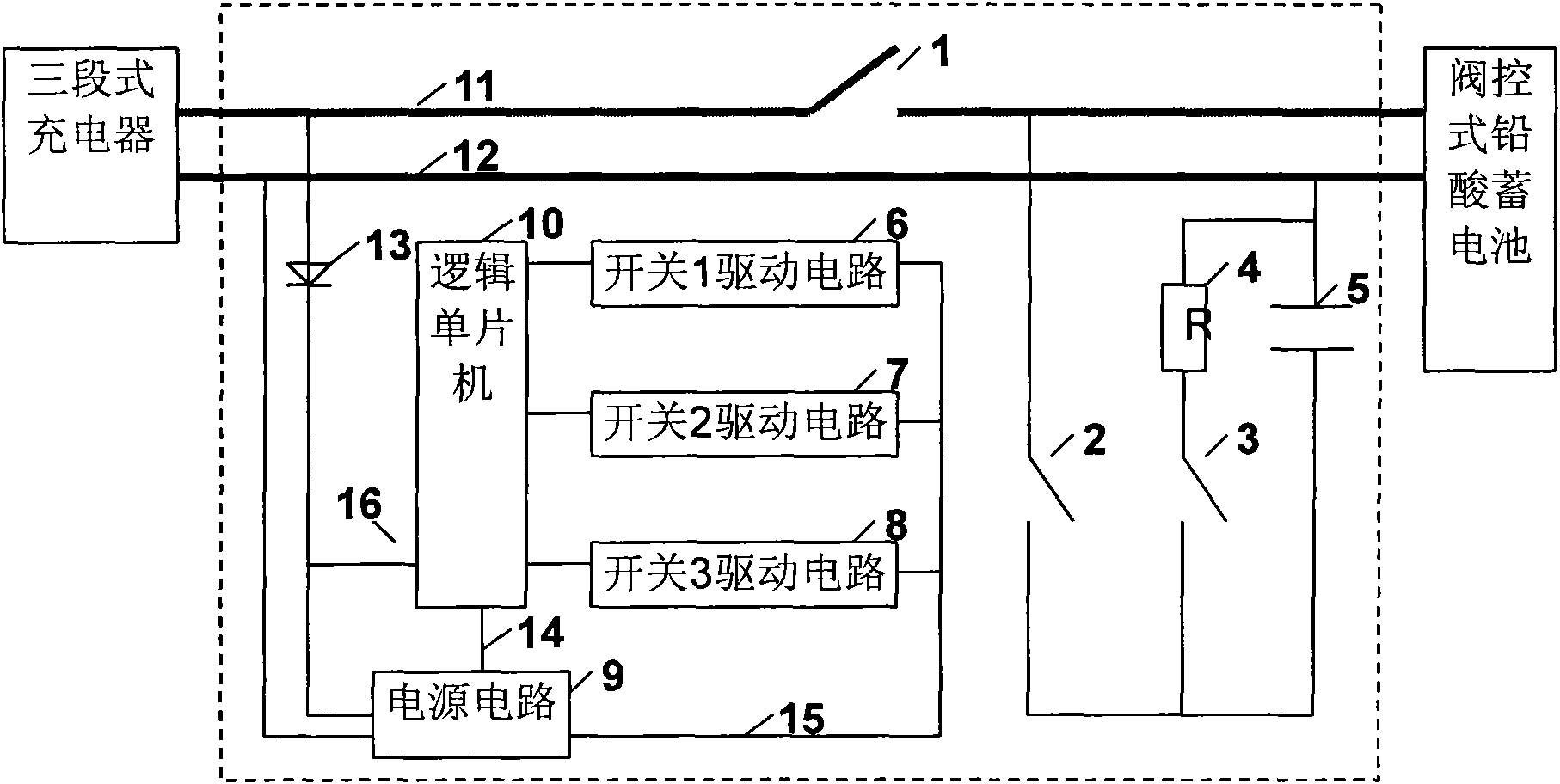

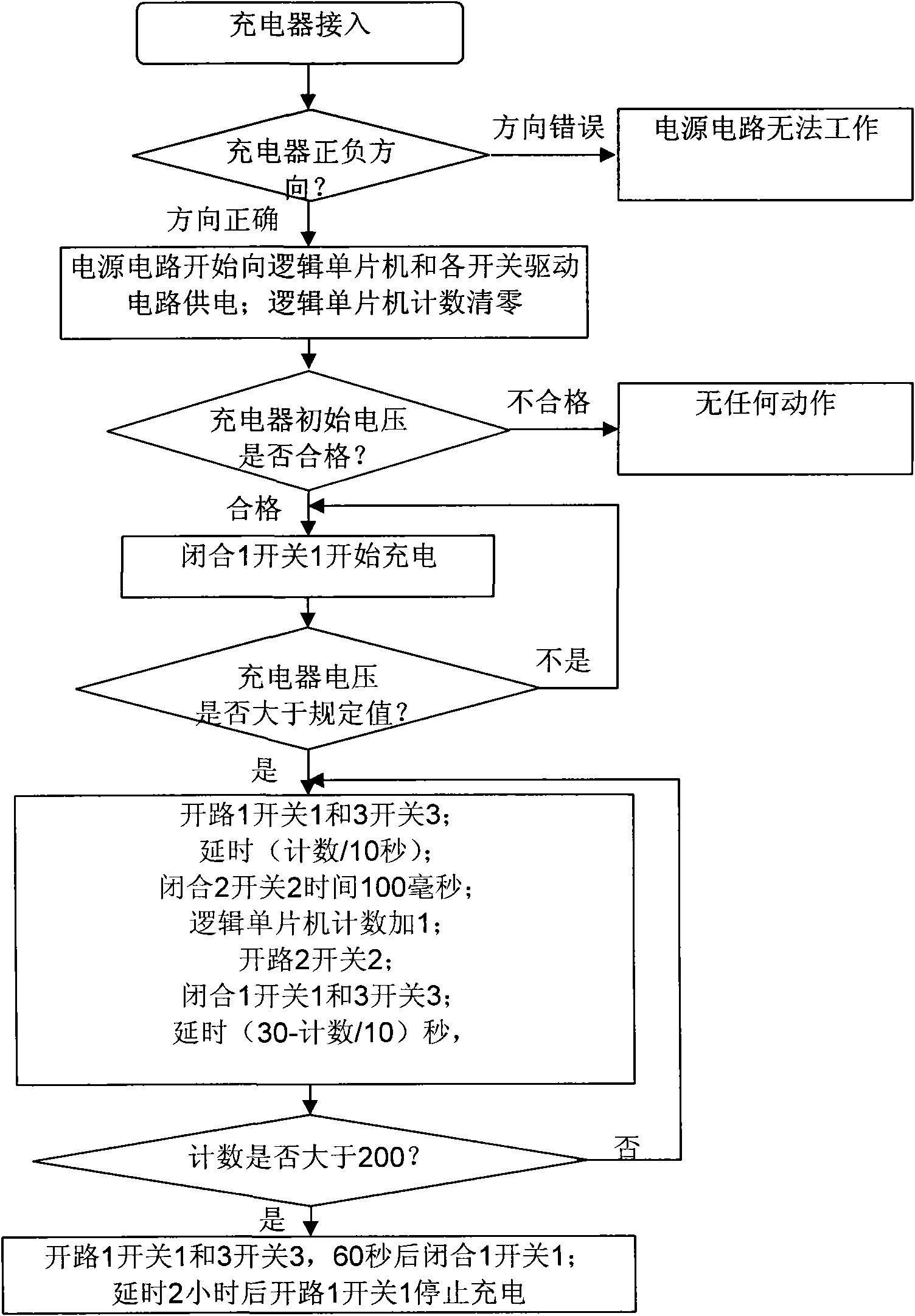

[0022] The three-stage charger recharges the valve-regulated lead-acid battery through the circuit or device constituted by the invention.

[0023] first step, with figure 1 1 switch 1, 2 switch 2, and 3 switch 3 are in the normally open state, and the three-stage charger is connected through 11 main power positive wire and 12 main power negative wire. On the contrary, 13 diodes prevent the current between the charger and the 9 power supply circuit, the 9 power supply circuit cannot be powered on and work, the device or circuit of the present invention does not produce any action, the open state of the 1 switch 1 makes charging impossible, the charger and the 9 power supply circuit cannot be charged. The valve-regulated lead-acid batteries do not form a closed circuit, and the short-circuit fault is eliminated, which protects the charger from damage. When the positive and negative polarity direction of the charger is consistent with the requirements of the lead-acid battery, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com