Novel safety management method and device for power battery pack of electric vehicle

A technology for power battery packs and electric vehicles, which is used in batteries, secondary batteries, and secondary battery repair/maintenance. , The effect of preventing overcharge or overdischarge and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

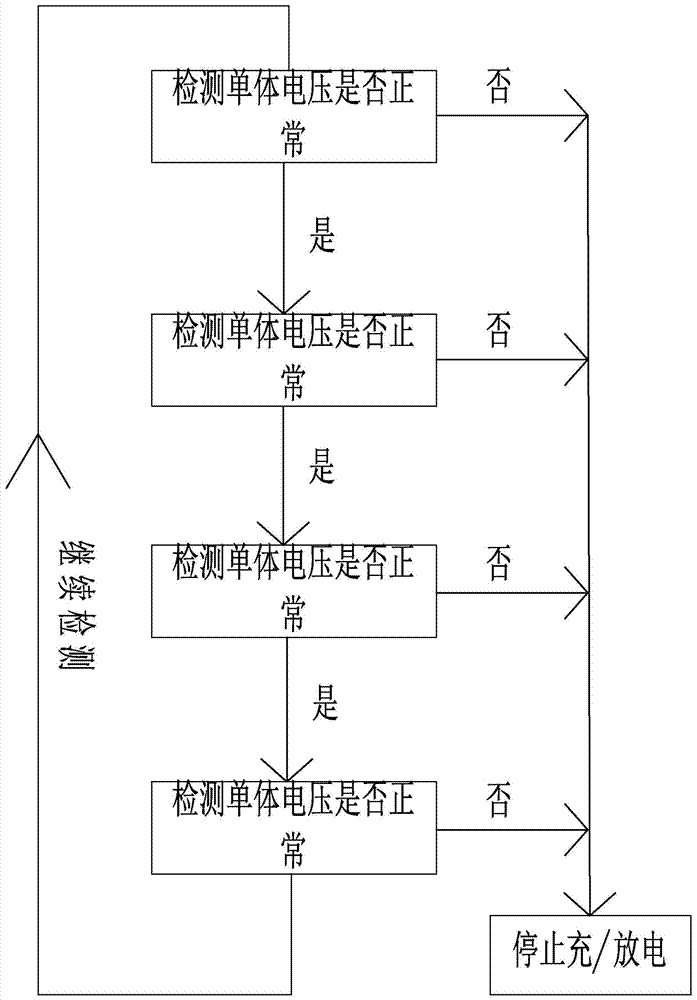

[0037] The safety management method for the power battery pack of the novel electric vehicle includes detecting the cell pressure and the cell pressure of each power battery cell of the power battery pack through the air pressure detection module, the temperature detection module, the voltage detection module, and the charge / discharge current detection module. The four parameters of cell temperature, cell voltage and power battery pack charge / discharge power are collected by the data acquisition system and transmitted to the charge / discharge management system. The charge / discharge management system calculates the four measured parameters , Analyze, and then control the charge / discharge status of the power battery pack, such as image 3 , The specific control steps are:

[0038] In the first step, the charge / discharge management system compares the internal cell pressure of each power battery cell with its pre-set safety value. As long as one of the power battery cells is reached,...

Embodiment 2

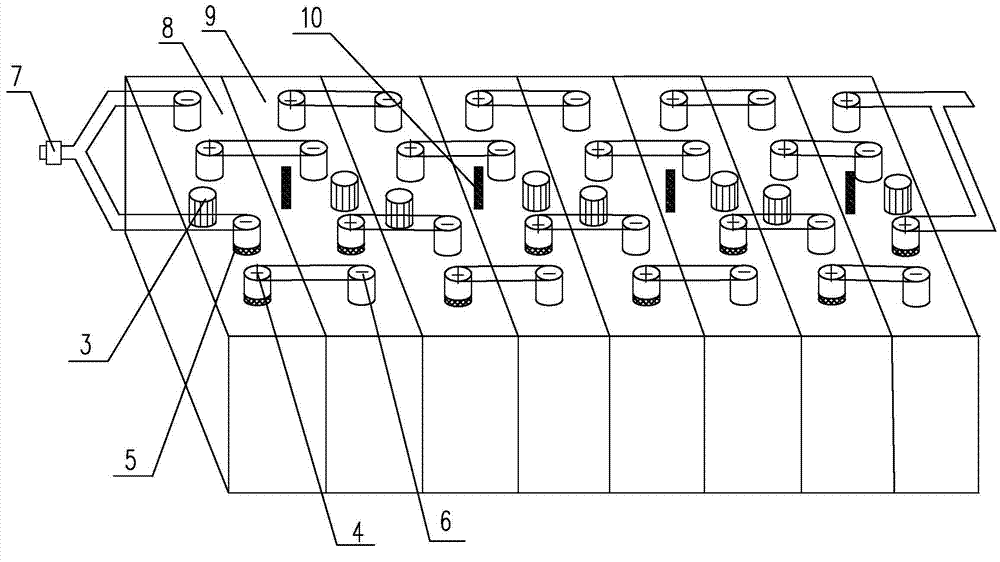

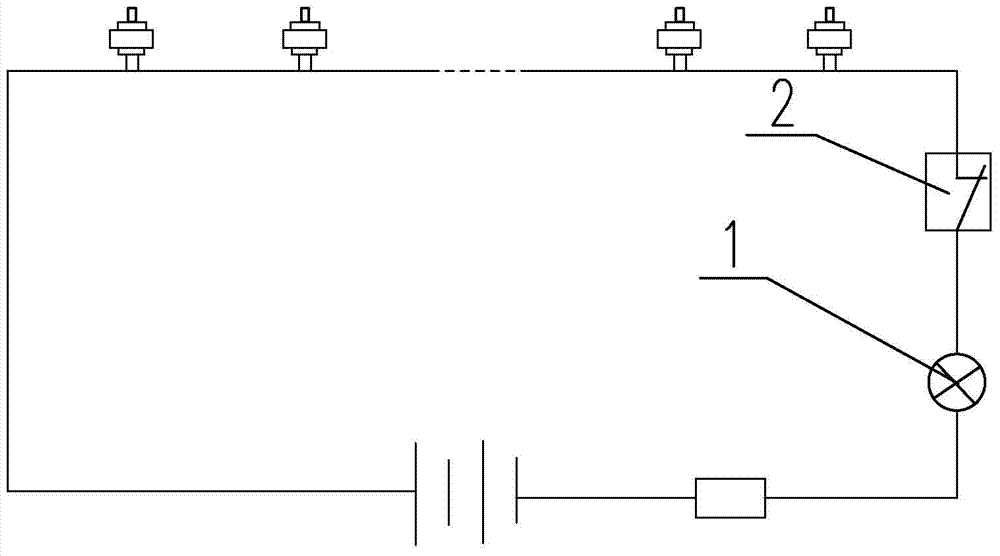

[0053] Such as figure 1 , 2 As shown, the new electric vehicle power battery pack safety management system of this embodiment includes a power battery pack. The power battery pack is composed of a plurality of power battery cells connected in series, and is characterized in that the power battery pack output line is provided with Hall sensor 7, each power battery cell is equipped with a normally closed air pressure switch sensor 3, a temperature sensor 10, and a voltage sensor 5. The data acquisition system and each normally closed air pressure switch sensor 3, temperature sensor 10, and voltage sensor 5 It is connected to the Hall sensor 7 respectively, and the charging / discharging management system is connected to the data acquisition system.

[0054] The four parameters of the cell pressure, cell temperature, cell voltage and charge / discharge current of the power battery pack are detected in real time through the normally closed air pressure switch sensor 3, temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com