CC-CV charging method for improved power lithium ion battery

A lithium-ion battery, CC-CV technology, applied in the field of lithium-ion batteries, can solve the problems of prolonging the constant voltage charging time, the impact of charging efficiency, and the small space for controlling the terminal voltage of the battery, so as to improve charging safety and charging efficiency. To avoid capacity loss and increase in polarization, the effect of lowering the charging voltage

Active Publication Date: 2010-08-25

HUIZHOU EPOWER ELECTRONICS +1

View PDF3 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This traditional CC-CV charging method has the following disadvantages: (1) Since the polarization phenomenon of the battery is very obvious in the initial stage of battery charging, the polarization voltage increases rapidly during the charging process

Therefore, in the traditional constant voltage charging stage, the constant voltage charging is mostly carried out at the higher polarization voltage point, and the terminal voltage remains high to complete the charging, which greatly affects the battery life.

Moreover, at this stage, the rate of change of the polarization voltage is high, and the control space of the terminal voltage of the battery is small. In addition, due to the hysteresis of the battery polarization phenomenon, it is difficult to control the terminal voltage of the battery below the upper limit voltage for long-term charging. Therefore, the current of the battery drops. The process is very fast, which directly affects the battery charging capacity and prolongs the constant voltage charging time

(4) The influence of charging temperature and battery capacity is not considered

In the traditional CC-CV charging method, the ambient temperature changes, but the charging current is fixed, which has a great impact on the charging efficiency; when the battery capacity declines, the charging current corresponding to the same rate will also change. If the original rated capacity corresponds to The current of the battery is charged, and the polarization and heating of the battery are serious.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

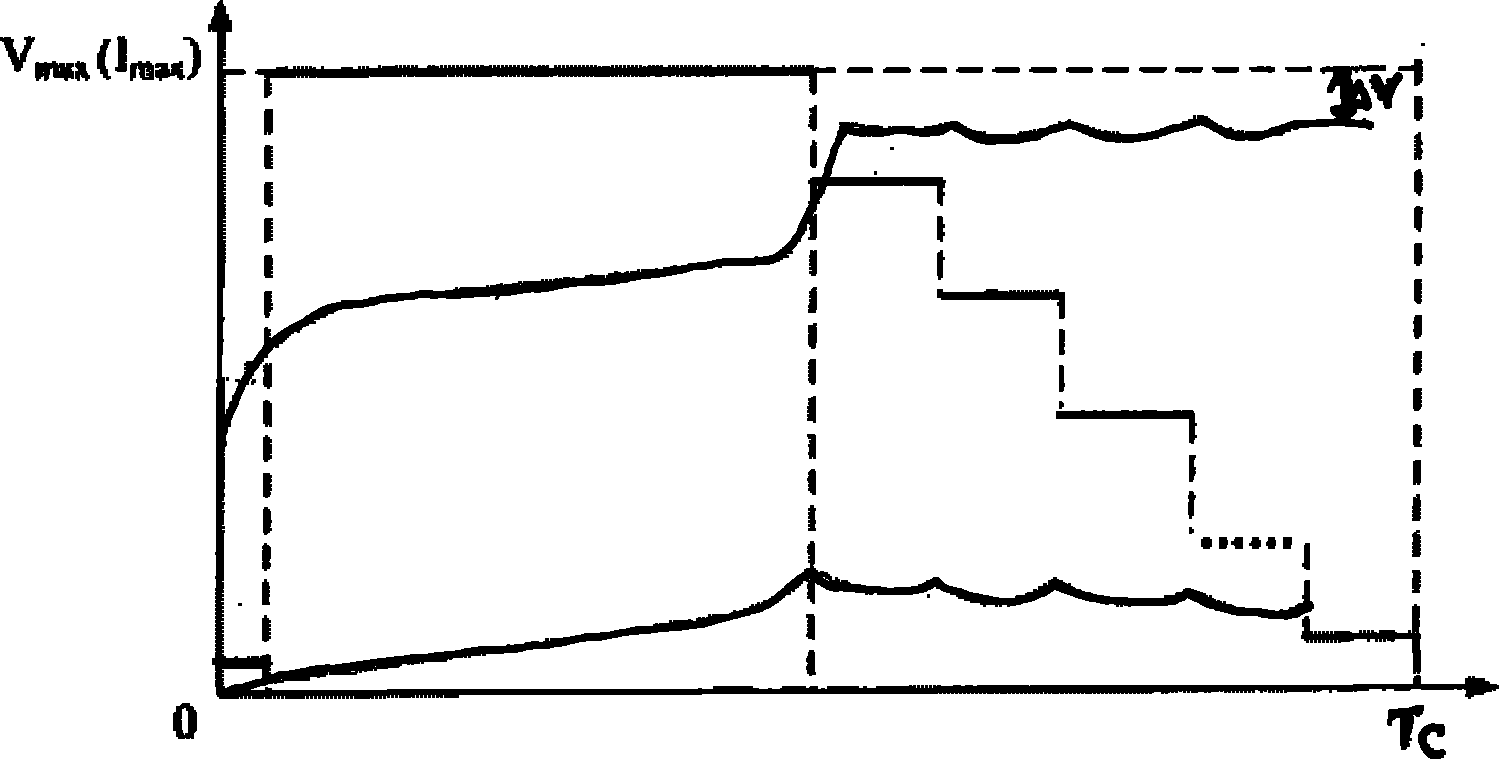

Login to View More Abstract

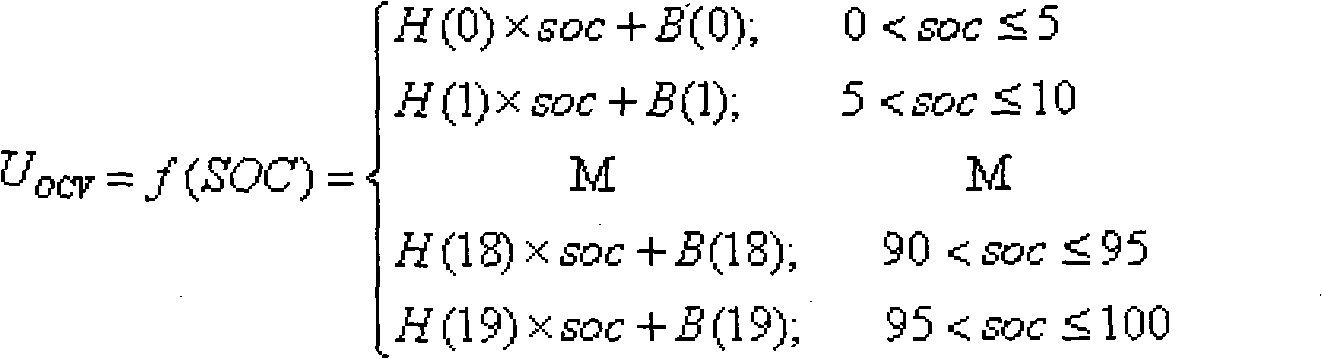

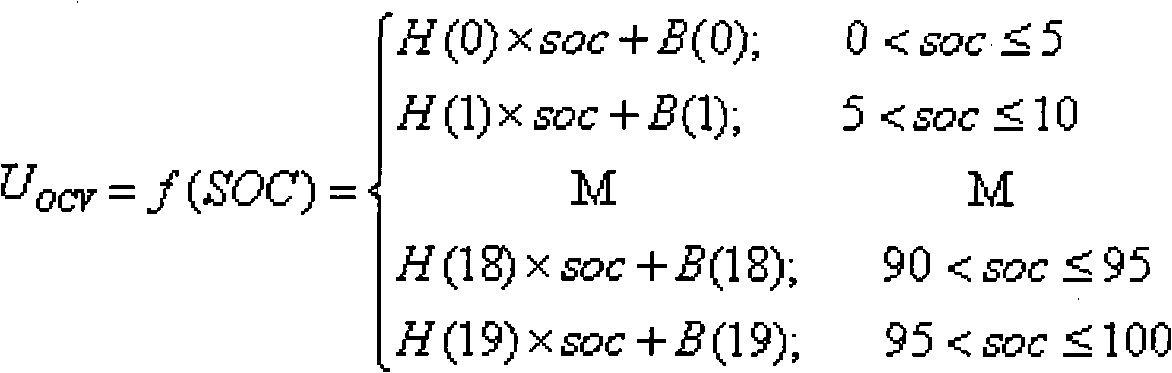

The invention relates to the technical field of the lithium ion batteries, in particular to a CC-CV charging method for an improved power lithium ion battery. The charging method comprises the following steps of: firstly, pre-charging the lithium ion battery by adopting 0.1C-0.3C current; enhancing the charging current to the constant charging stage when the charging capacity reaches 5% of the total capacity of the battery; and entering the constant voltage charging stage when the polarization voltage of the battery is abrupt. When the battery is at an environmental temperature of 20-45 DEG C, the charging current formula adopted in the constant current stage is ICC=KC*CA, wherein KC represents the charging and discharging multiplying power efficient at constant temperature of the battery, CA represents the actual capacity of the batter, and Kc is usually 0.5-1. In the method, the external characteristic parameters of the battery are fully taken into consideration, and the charging efficiency and service life of the battery are taken into account.

Description

Improved power lithium-ion battery CC-CV charging method technical field The invention relates to the technical field of lithium ion batteries, in particular to a charging method for lithium ion batteries. Background technique At present, power lithium-ion batteries generally adopt the traditional constant current first and then constant voltage (CC-CV) charging method. In this method, the constant current stage uses a fixed low-rate current (generally 0.3C) to charge the battery, and when it reaches the upper limit of the charging voltage (generally 4.2V), it is converted to a constant voltage and current-limiting method. Keep the charging voltage constant and gradually reduce the charging current until the charging current drops to a small enough value (generally 0.05C) to complete the charging process. This traditional CC-CV charging method has the following disadvantages: (1) Since the polarization phenomenon of the battery is very obvious in the initial stage of batt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/44

CPCY02E60/12Y02E60/10

Inventor 冯大明刘飞阮旭松张维戈王占国文锋温家鹏

Owner HUIZHOU EPOWER ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com