Patents

Literature

129 results about "Woven fabric composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing electrospun nanofiber gas filtering material in mass manner

InactiveCN105133187AIncrease productionGood breathability and moisture permeabilitySemi-permeable membranesFilament/thread formingFiberElectrospun nanofiber

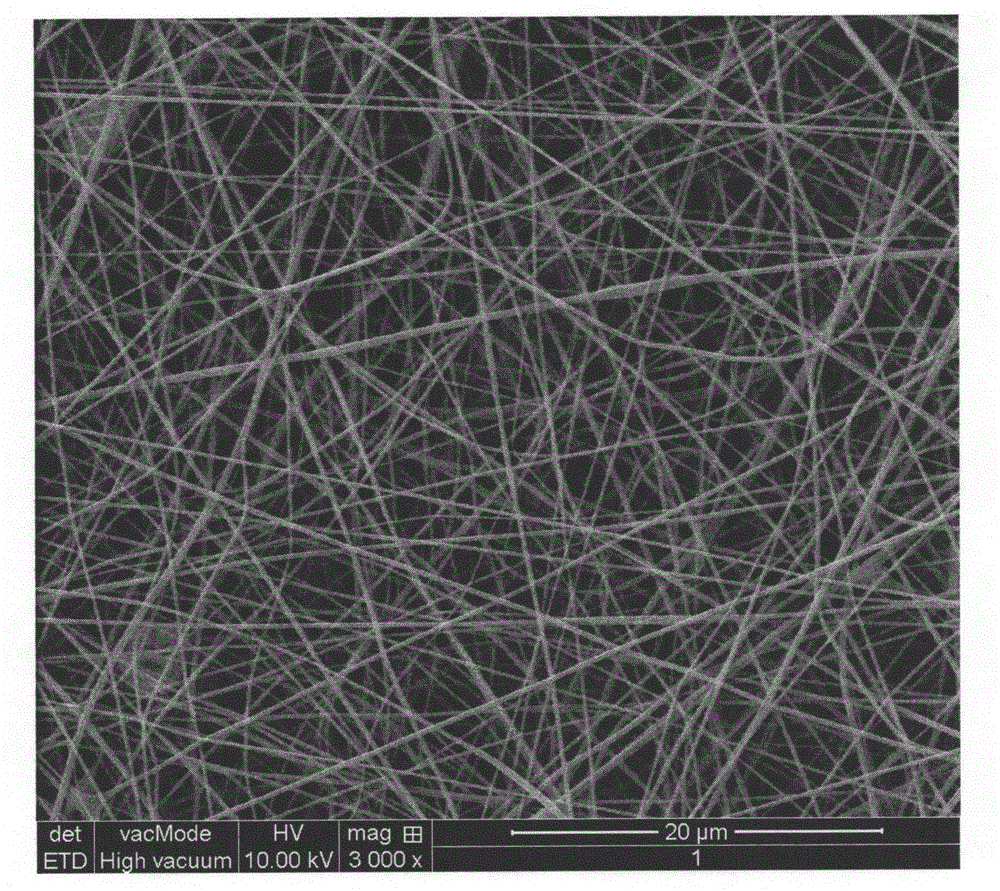

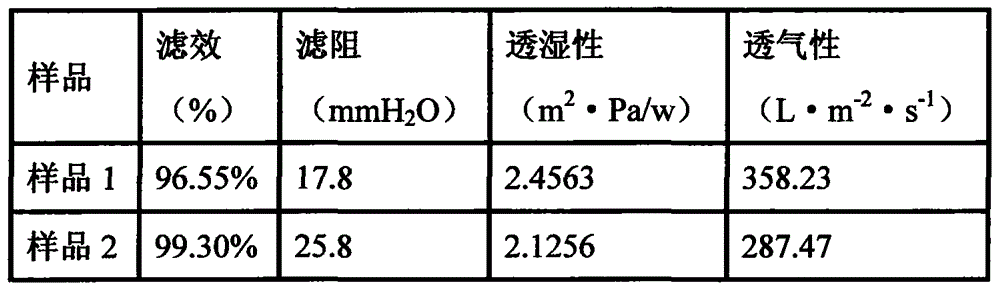

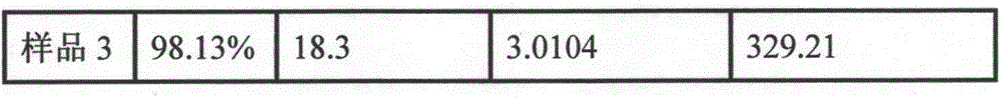

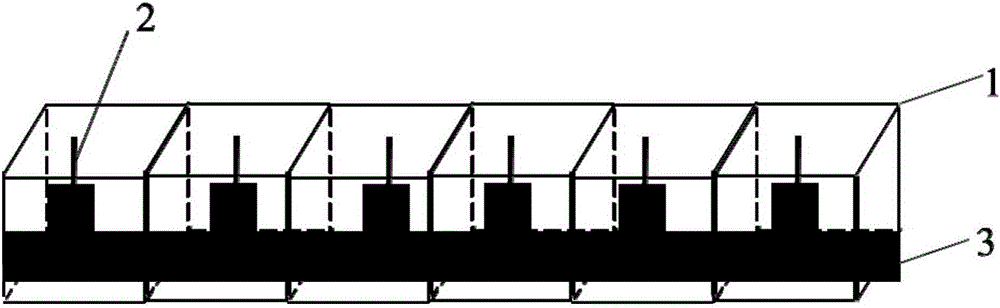

The invention discloses a method for manufacturing an electrospun nanofiber gas filtering material in a mass manner by using an umbrella-shaped electrostatic spinning sprayer. The method comprises: dissolving a high-molecular polymer in a solvent, mixing to obtain an even solution; using the spinning solution in electrostatic spinning to obtain a nanofiber membrane; combining the nanofiber membrane with a non-woven fabric, manufacturing non-woven fabric / nanofilm / non-woven fabric composite film; performing ultrasonic bonding on the non-woven fabric / nanofilm / non-woven fabric composite film, to manufacture a filtering material. The manufacturing method is convenient and fast, and can realize small-batch production. Filtering efficiency of the obtained filtering material reaches up to 99.55%, filtering resistance is 150-200 Pa, gas permeability reaches 355L.m<-2>.s<-1>, and moisture-penetrability reaches 9.6 m<2>.Pa / w, that is, the material has good gas permeability and moisture penetrability, and the method has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV +1

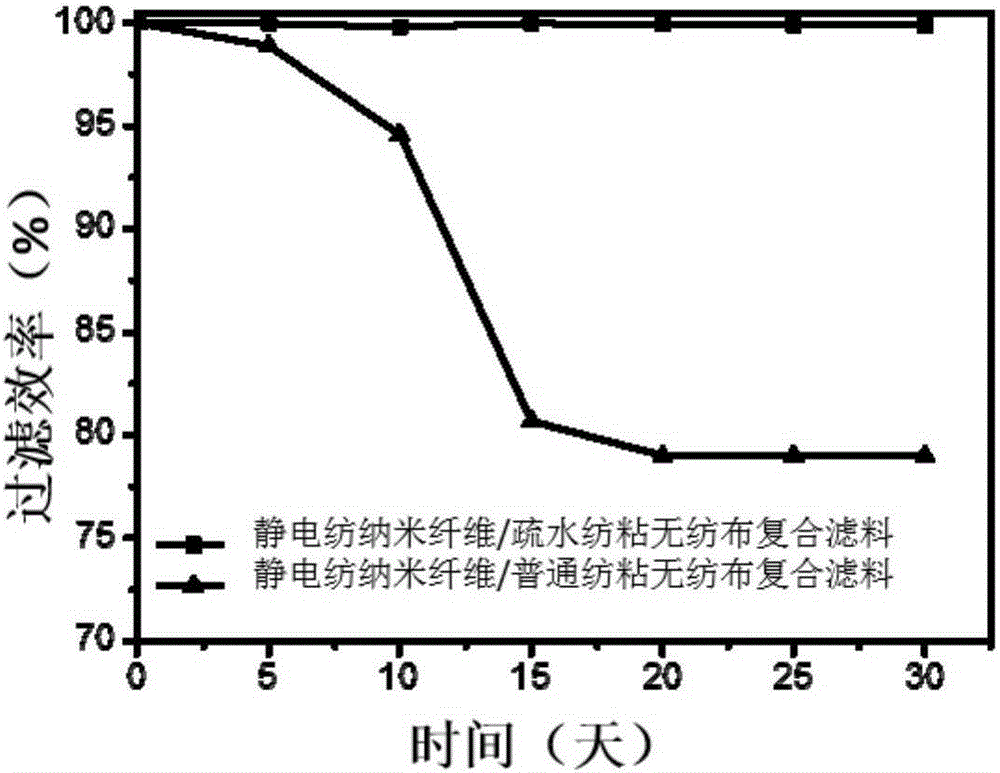

Electrostatic spinning method and nanometer fiber/anti-sticking non-woven fabric composite filter material prepared through electrostatic spinning method

ActiveCN105200539AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationWoven fabric compositeElectrospinning

The invention relates to an electrostatic spinning method and a nanometer fiber / anti-sticking non-woven fabric composite filter material prepared through the electrostatic spinning method. Multi-needle electrostatic spinning is adopted in the electrostatic spinning method, and needles of multi-needle electrostatic spinning are insulated from one another. The prepared nanometer fiber / anti-sticking non-woven fabric composite filter material is formed by overlapping and compositing materials for overlapping from bottom to top according to the low-to-high sequence of filtering efficiency of a filtering material, the face, with electrostatic spinning fiber, of each layer of material for overlapping faces upwards, the uppermost layer of material for overlapping is covered with anti-sticking non-woven fabric, and therefore it is ensured that the top layer and the bottommost layer are both anti-sticking non-woven fabric layers; of every two adjacent layers of materials for overlapping, the filtering efficiency value for particles with grain size of 0.02 micron to 10 microns of the upper layer is 1.03-1.3 times that of the lower layer, the number of overlapping layers of the materials for overlapping ranges from 2 to 6, the anti-sticking non-woven fabric and the interlayer structure with electret effect nanometer fibers arrayed at intervals are formed, and the nanometer fiber / anti-sticking non-woven fabric composite filter material is formed; the filtering efficiency of the nanometer fiber / anti-sticking non-woven fabric composite filter material for particles with grain size of 0.02 micron to 10 microns reaches 99.999% or higher, and the pressure resistance is kept between 10 Pa and 30 Pa.

Owner:DONGHUA UNIV

Environment-friendly type micro-foaming polypropylene sheet and preparation thereof

ActiveCN101353460AReduce investmentSimple preparation processFlat articlesFoaming agentWoven fabric composite

The invention discloses an environment-protecting micro-foaming polypropylene sheet and a preparation method thereof, belonging to the field of polymer materials. The environment-protecting micro-foaming polypropylene sheet is made of materials with the following weight percentage: 30 to 70 percent of disproportionate polypropylene, 10 to 40 percent of random copolymerized polypropylene, 5 to 10 percent of high density polyethylene, 5 to 10 percent of superfine nucleating agent, 0 to 9 percent of inorganic filler, 1 to 3 percent of carboxy compatilizer, 0.5 to 2.0 percent of citric acid foaming agent. The sheet has the advantages of light weight, environment protecting, temperature than higher120 DEG C resistance, odor eliminating in long time use and press molding suitability. The sheet can be widely used in automobile interior ornament material fields such as ceiling, trunks, planks, carpets and thermal insulation boards; the non-woven fabric composite layer mainly exerts the function of decoration.

Owner:丹阳市华东工程塑料有限公司

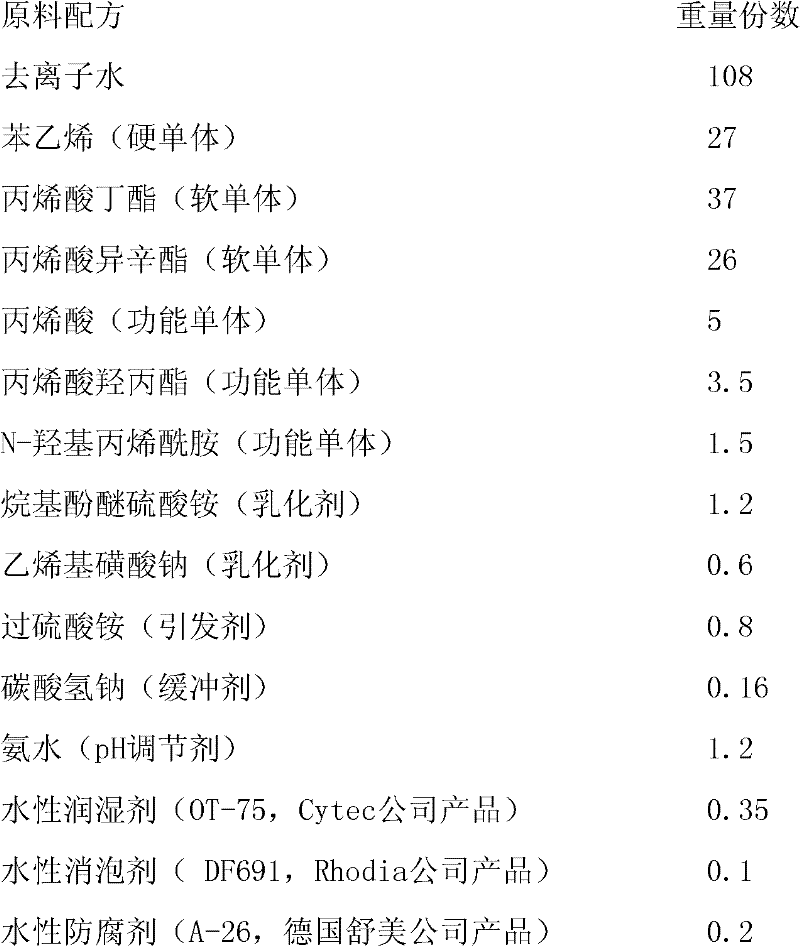

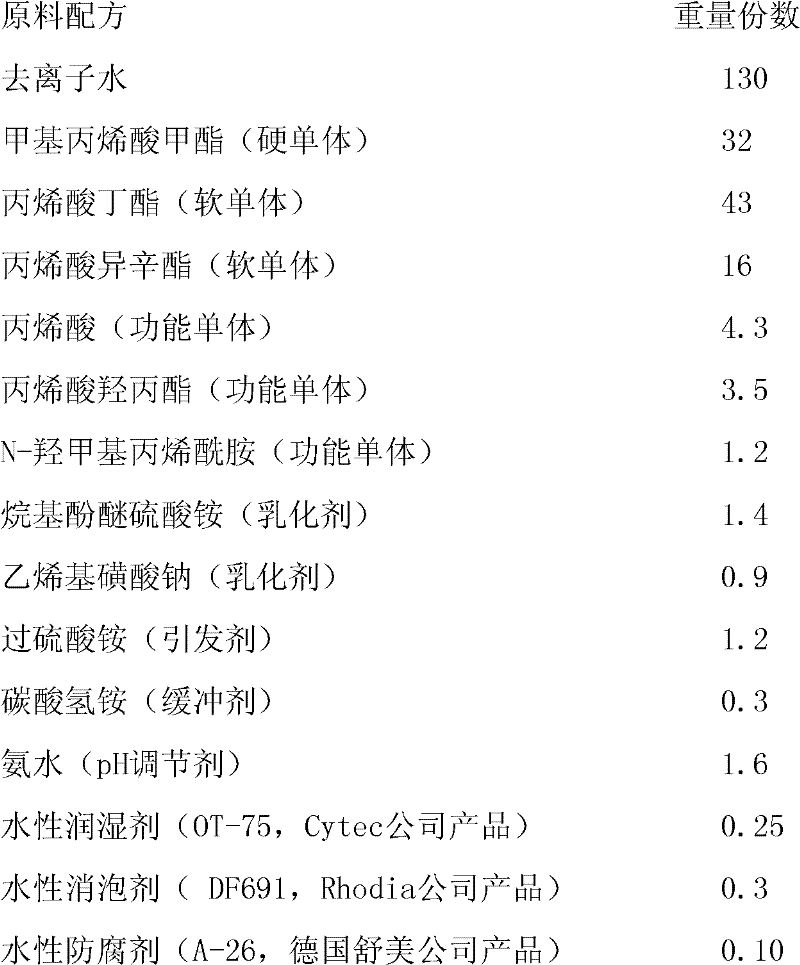

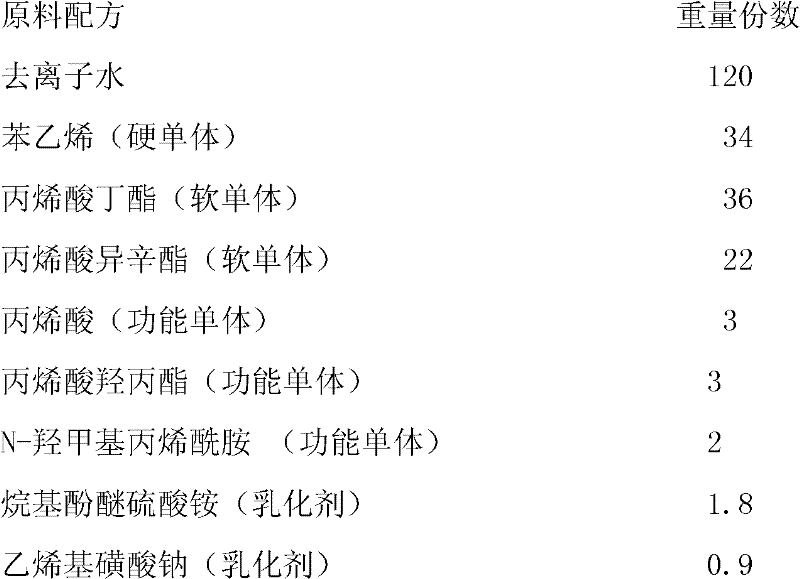

Aqueous adhesive for non-woven fabric composite membrane and preparation method of aqueous adhesive

InactiveCN102443367AImprove stabilityGood adhesionEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

The invention discloses an aqueous adhesive for a non-woven fabric composite membrane and a preparation method of the aqueous adhesive, belonging to the field of manufacturing of adhesives. The adhesive comprises the following components of: deionized water, monomers, a composite emulsifier, an initiator, a buffering agent, a pH regulator and an aqueous addition agent, and the solid content of the adhesive is 40-50%. The monomers in the components of the adhesive comprise a hard monomer, soft monomers and functional monomers, wherein the hard monomer is styrene or methyl methacrylate, the soft monomers are butyl acrylate and iso-octyl acrylate, and the functional monomers are composed of crylic acid, hydroxy-propyl acrylate and N-methylol acrylamide. The monomers comprise the following components in percentage by mass: 20-40% of styrene or methyl methacrylate, 10-30% of iso-octyl acrylate, 30-50% of butyl acrylate, 1-5% of crylic acid, 1-5% of hydroxy-propyl acrylate and 1-5% of N-methylol acrylamide. The aqueous adhesive has the advantages of effectively improving wetting and flatting properties on the surface of a plastic film, ensuring that the plastic film has a better wettingproperty with the non-woven fabric, and enhancing the peeling strength.

Owner:NANTONG GAOMENG NEW MATERIAL

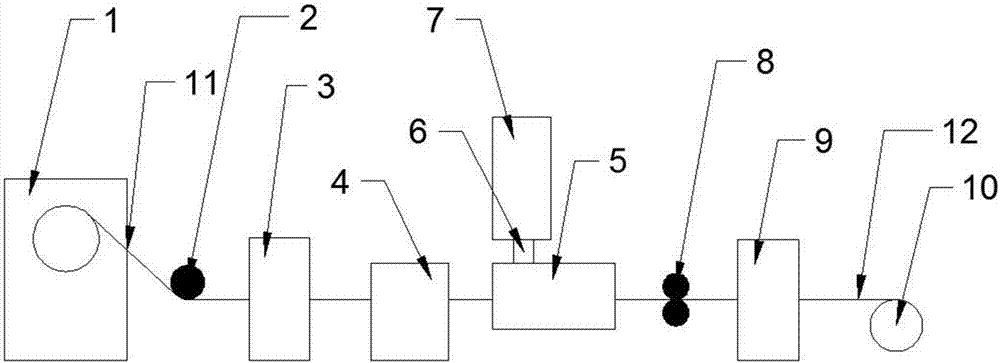

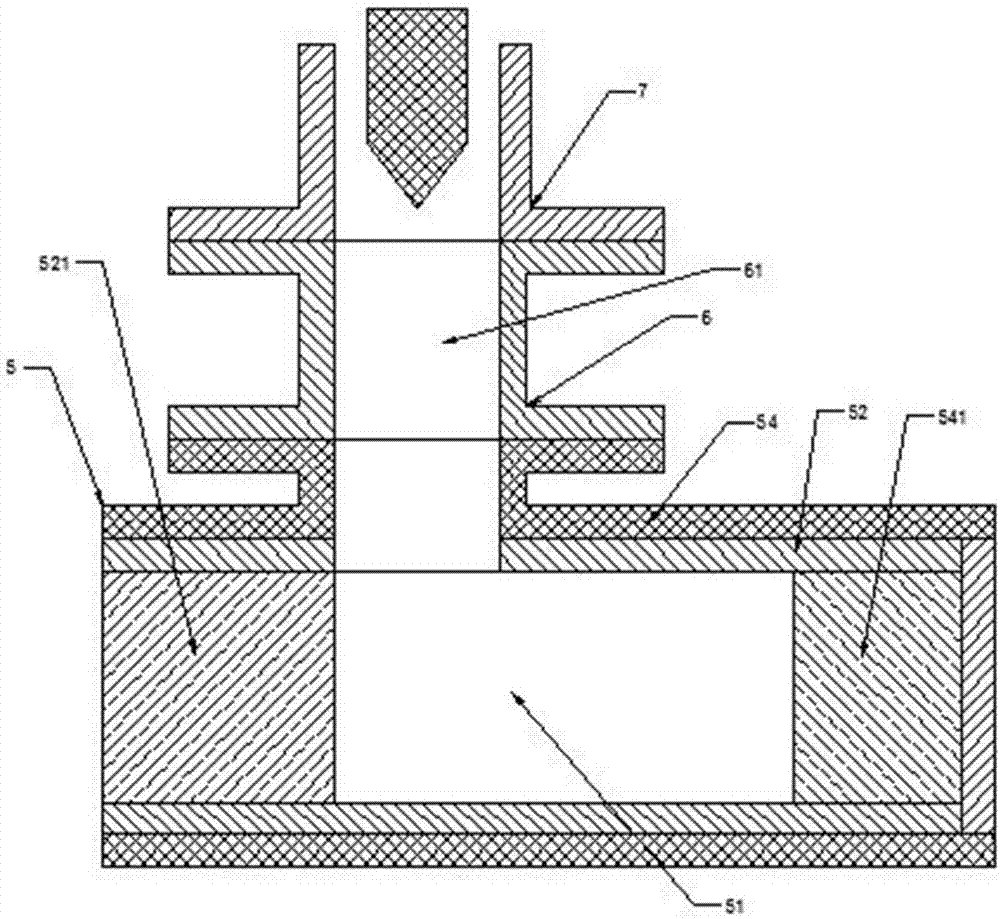

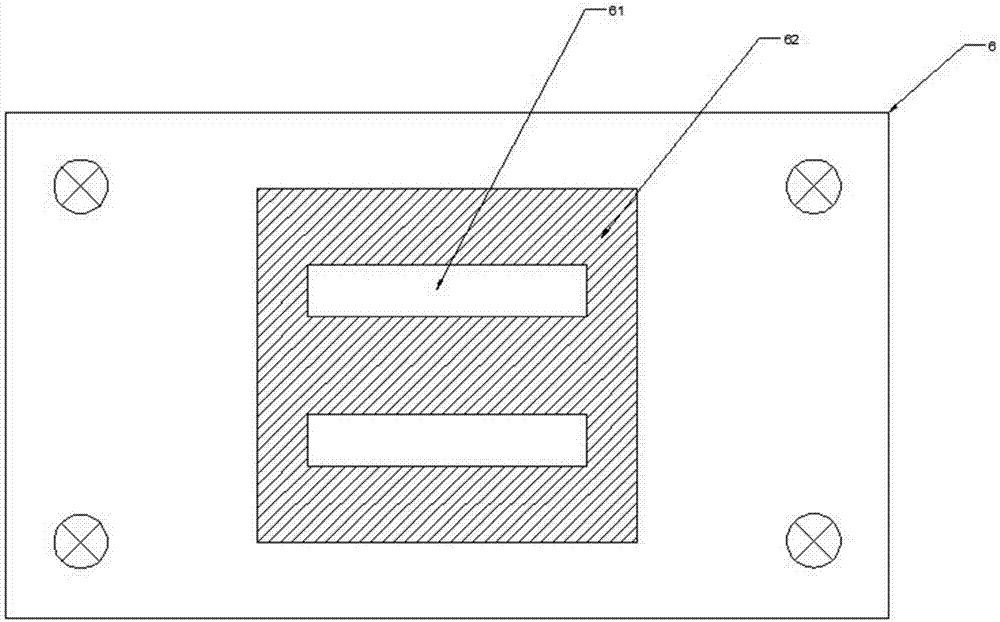

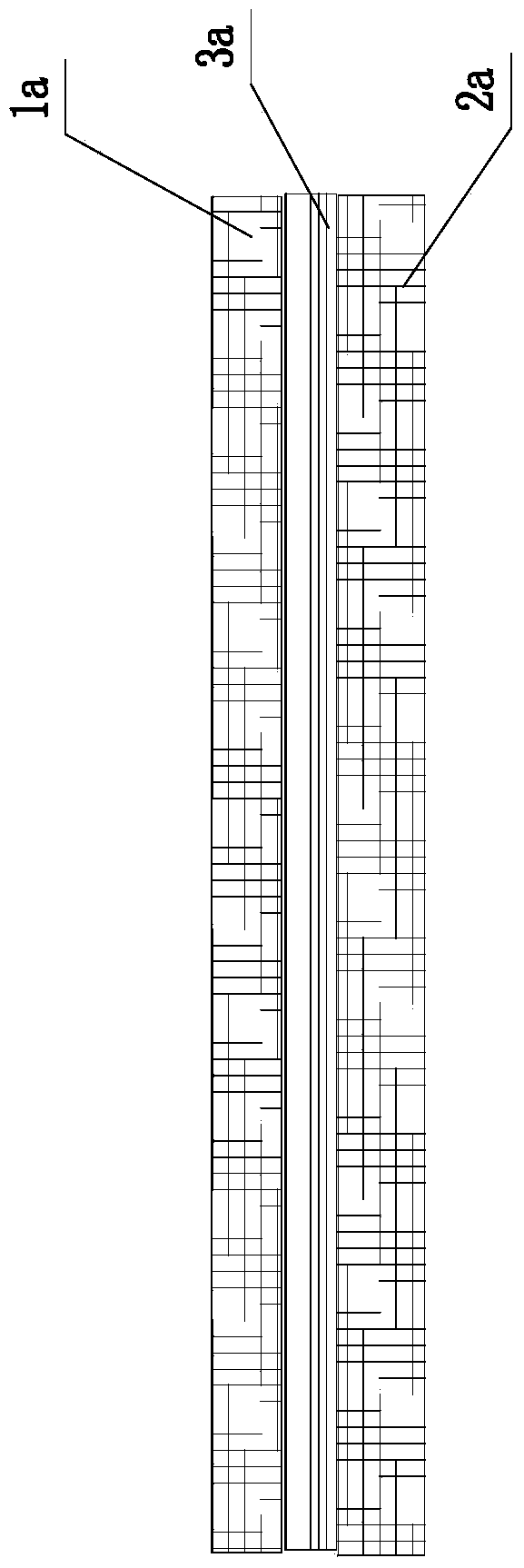

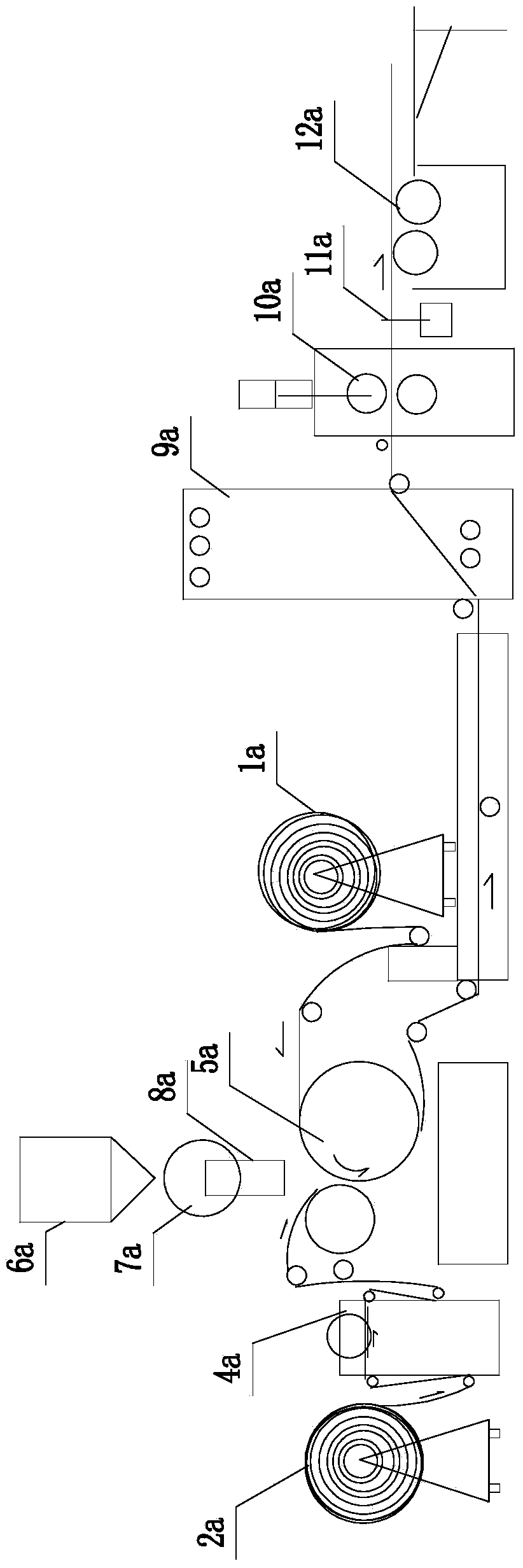

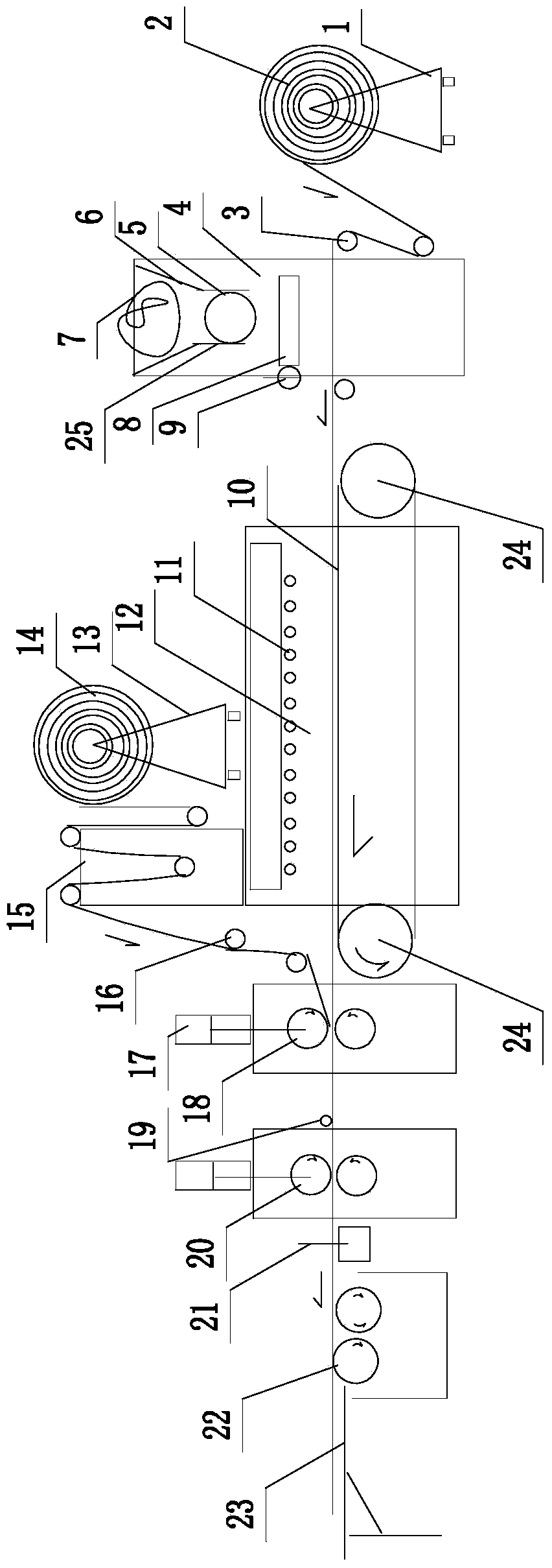

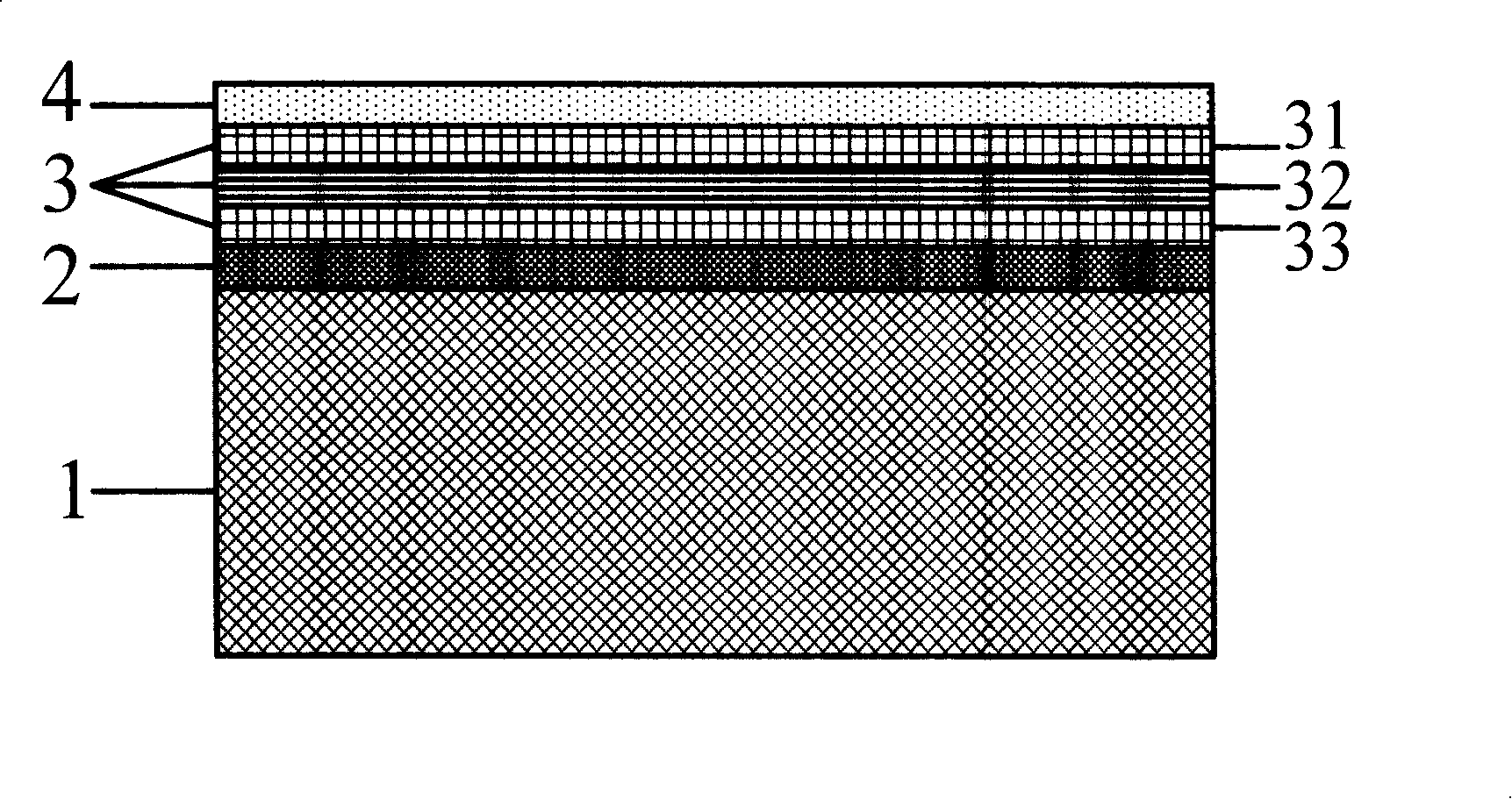

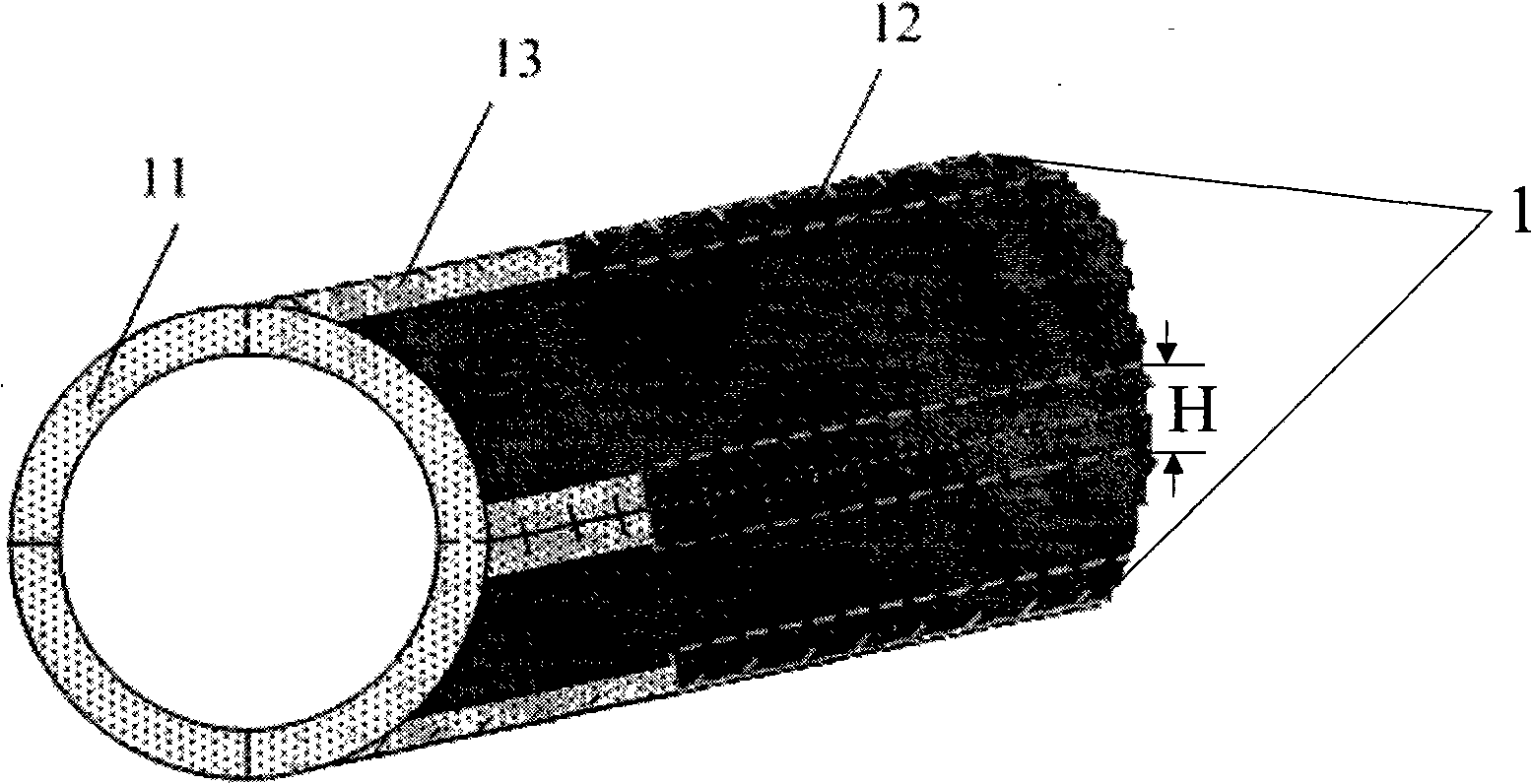

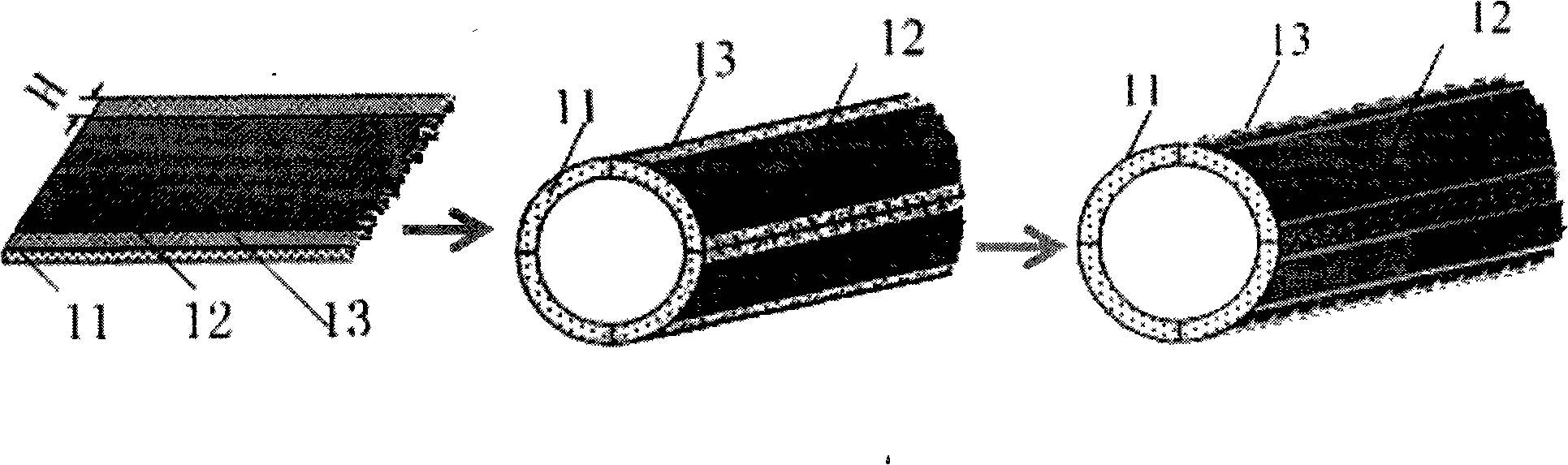

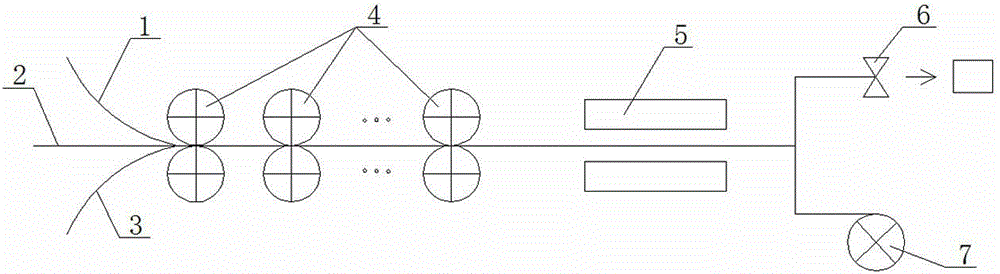

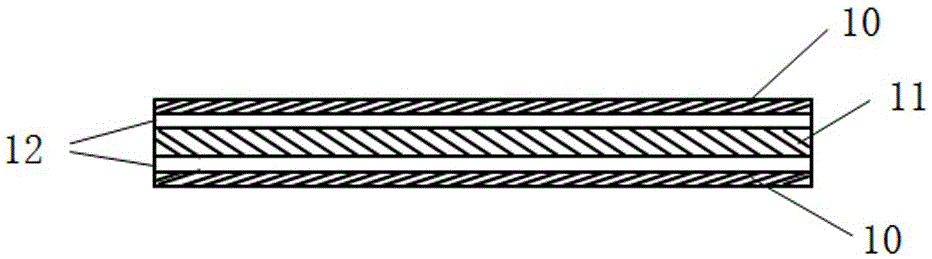

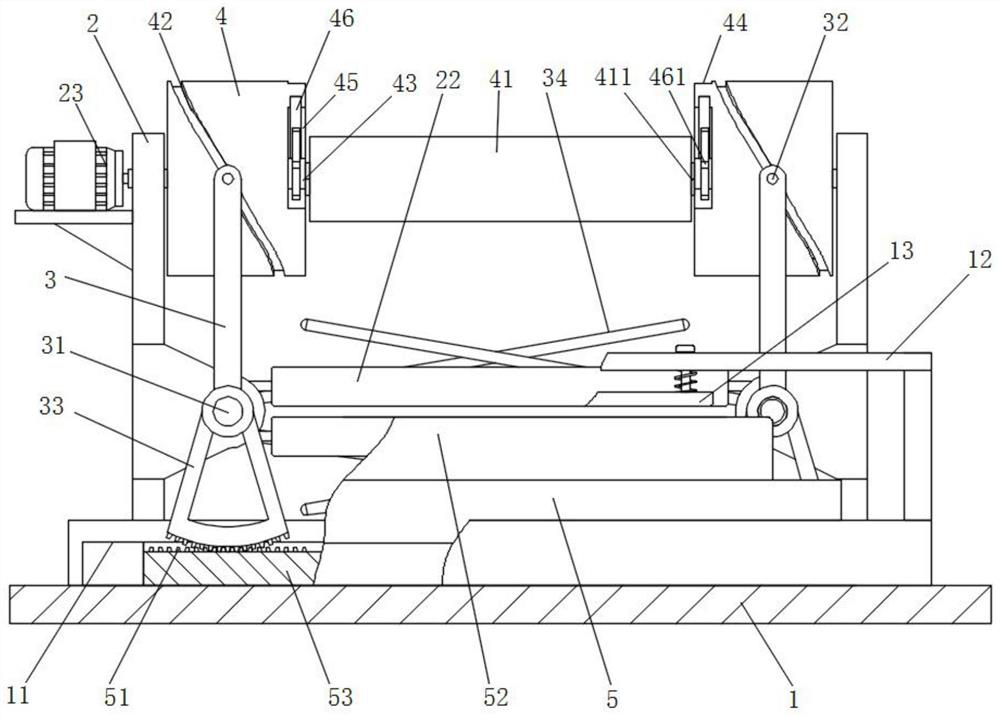

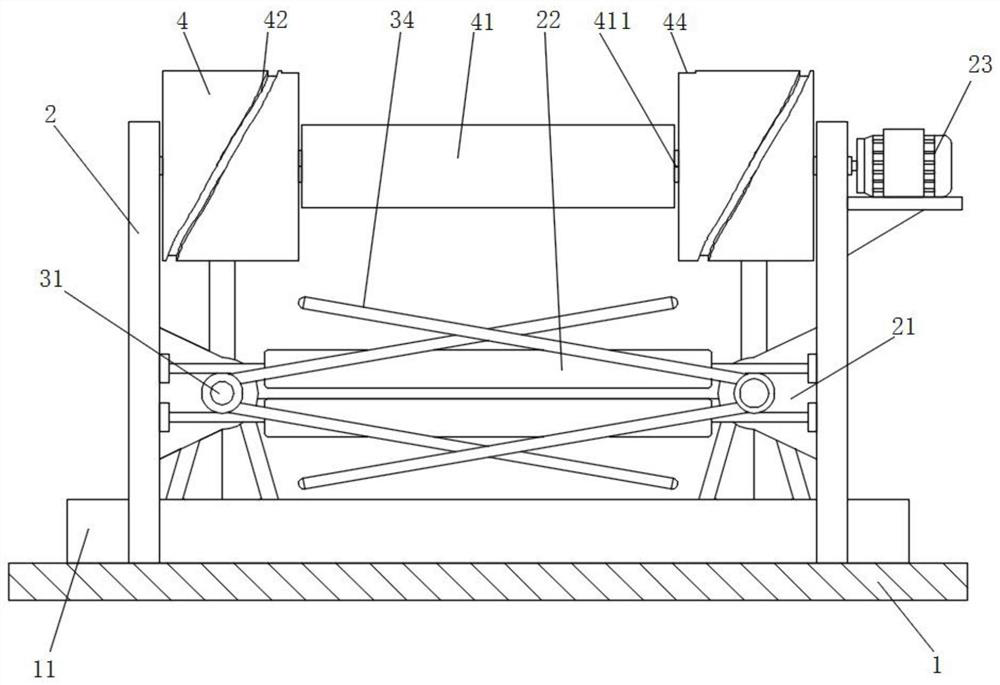

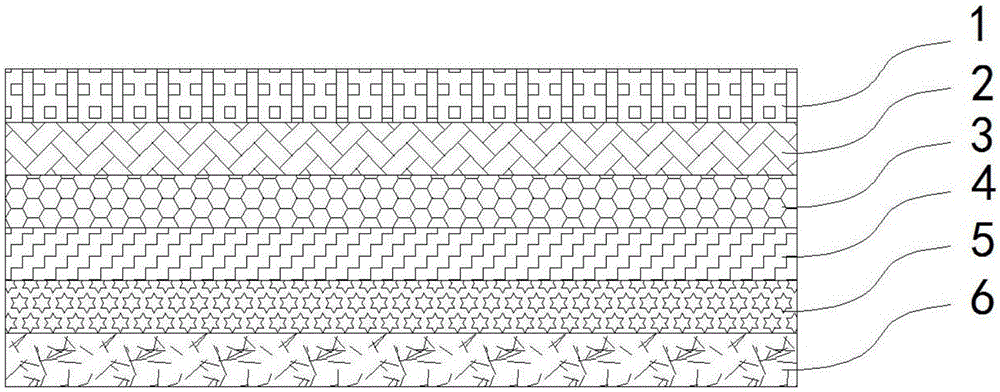

Preparation method and device for continuous-filament woven fabric reinforced thermoplastic composite

InactiveCN108000904AImprove mechanical propertiesGood dimensional stabilityYarnWoven fabric composite

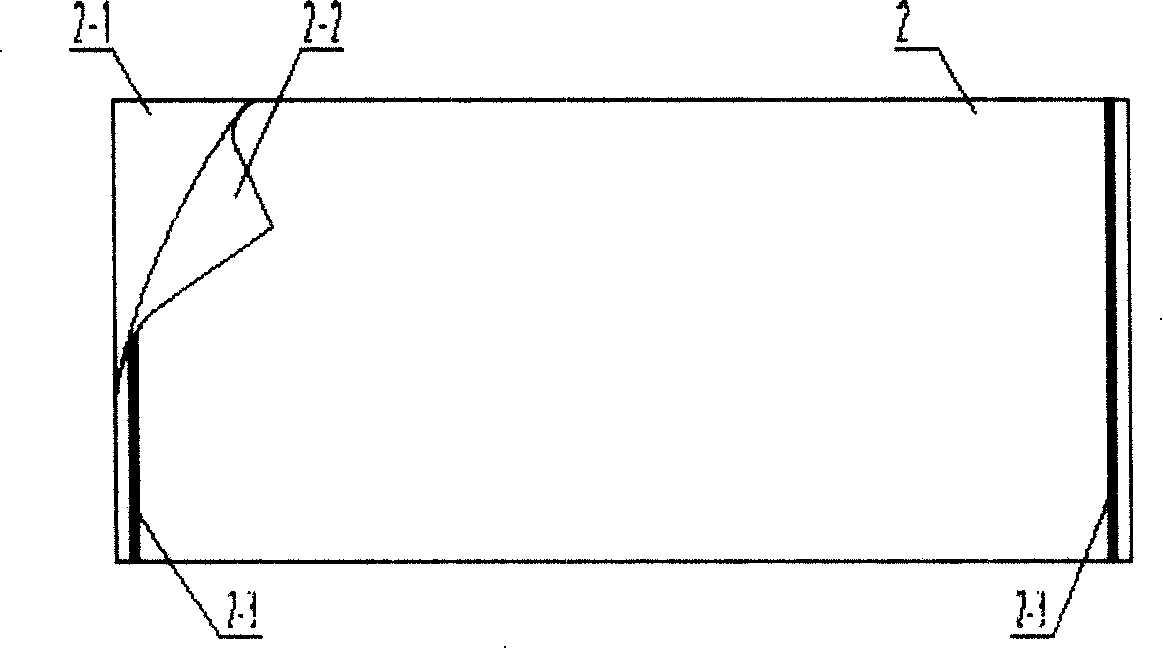

The invention discloses a preparation method and device for a continuous-filament woven fabric reinforced thermoplastic composite. The device mainly comprises an unwinding device (1), a pretensioningdevice (2), a fabric pretreatment device (3), a preheating device (4), a dipping mold (5), a connector (6), a screw machine (7), a forming device (8), a cooling pulling device (9), a winding device (10), continuous-filament woven fabrics (11) and dipped continuous-filament woven fabrics (12). The filament woven fabrics or fiber yarns subjected to dispersion treatment are subjected to pulling, surface treatment, drying, sufficient dipping with resin in the dipping mold and winding after being cooled and formed, and required products are obtained. The one-step forming technology is achieved, equipment investment is reduced, the production efficiency is improved, and the product quality is stable. The connector (6) and the dipping mold (5) are arranged flexibly, and one-step forming of two-layer or even multilayer filament woven fabric composites can be achieved.

Owner:SICHUAN UNIV

Supersoft wet-method spunlaced composite non-woven fabric for infant and production method

InactiveCN107475893ASoft touchAvoid deformationNon-woven fabricsWoven fabric compositeCellulose fiber

The invention relates to a supersoft wet-method spunlaced composite non-woven fabric for infant and a production method. A supersoft barrier melt-blown fiber layer and a short-cellulose fiber layer are combined through a wet-method spunlaced composite technology, the lower layer is the melt-blown fiber layer and has the advantages of being soft in hand feel, good in barrier property, not prone to deformation and the like, the upper layer is the short-cellulose fiber layer with the pulp short fiber as the main part, the upper layer and the lower layer are planted and entangled in melt-blown fiber through a high-pressure spunlacing effect, and the non-woven fabric composite which has an embossment pattern and has the advantages of being good in water absorption property, supersoft and free of flock falling, having the barrier property on one side and the like is obtained by means of a hot rolling technology through hot air type through-drying. The product prepared through the non-woven fabric composite has the advantages of being rapid in water absorption, supersoft in hand feel in a wet state, not prone to deformation, capable of keeping the decorous feeling and the melt-blown side effective barrier property, free of any additives and the like, is incomparable by ordinary spunlaced non-woven fabric products and sanitary paper and is good in application prospects.

Owner:DALIAN RUIGUANG NONWOVEN GROUP

Processing technology of non-woven fabric composite material for automotive interior

InactiveCN103640308AReduce material costsReduce battery consumptionSynthetic resin layered productsLaminationVibration amplitudeWoven fabric composite

The invention relates to a processing technology of a non-woven fabric composite material for automotive interior. The method is characterized by comprising the following steps: (1) evenly spraying polyethylene powder particles on a non-woven fabric bottom layer through a powder spraying device, wherein machine speed for the non-woven fabric bottom layer is 1.8-2.5m / min, vibration amplitude of a vibrating screen is 2-5mm, and the number of meshes of the vibrating screen is 10-20 meshes; (2) placing the non-woven fabric bottom layer with polyethylene powder particles in a drying room, setting temperature in the drying room to be 150-190 DEG C, wherein inside of the drying room is divided into three heating regions according to the temperature from the fabric feeding direction to the fabric discharging direction, the temperature of the three regions rises gradually, and the distance between an electric heating quartz tube at upper part of the drying room and the non-woven fabric bottom layer is 60-80mm; and (3) compositing the non-woven fabric bottom layer output from a fabric discharge port of the drying room and a non-woven fabric surface layer together on a cooling compression roller to obtain the composite non-woven fabric; and after outputting the composite non-woven fabric by a conveying roller, cutting and winding the composite non-woven fabric to obtain the non-woven fabric composite material for automotive interior. With the processing technology, cost can be reduced, and energy consumption can be lowered.

Owner:怡星(无锡)汽车内饰件有限公司

Sponge and elastic non-woven fabric composite self-adhering fascia and production method thereof

InactiveCN101219235AClosely arrangedImprove breathabilityAbsorbent padsBandagesWoven fabric compositeNonwoven fabric

The invention provides a sponge and elastic nonwoven compounded self-adhesive bandage and a preparation method thereof. Polyurethane sponge and elastic nonwoven are compounded to form the self-adhesive bandage by a composite adhesive and the surface of the elastic nonwoven is coated with a self adhesive. The preparation method is that: the polyurethane sponge, the elastic nonwoven and the composite adhesive are obtained; the surface of the polyurethane sponge is sprayed with the composite adhesive in the forms of fine particles by a spray gun; the elastic nonwoven is compounded onto the polyurethane sponge; and then the surface of the elastic nonwoven is sprayed with the self adhesive; finally the compound is put into an oven to be dried, roll cut and the sponge and elastic nonwoven compositing self-adhesive bandage is obtained. The sponge and elastic nonwoven compositing self-adhesive bandage of the invention has distinctive features of softness, natural air permeability, water repellency, comfort, etc., and no stimulation to skin; the bandage has autoadhesion and can be conveniently separated; furthermore, the bandage can not only be used separately but also in combination with common bandages.

Owner:SUZHOU MEDSPORT PROD

Para-aramid nano fiber/polyphenylene sulfide non-woven fabric composite filter material and preparation method for same

ActiveCN105297283AExtended service lifeImprove filtration efficiencyDispersed particle filtrationFiltration separationWoven fabric compositeNanofiber

The invention relates to composite filter material and a preparation method for the same and in particularly relates to para-aramid nano fiber / polyphenylene sulfide non-woven fabric composite filter material and a preparation method for the same. For deficiencies of the prior art and products and a problem of low filtration efficiency for micro particles by common polyphenylene sulfide non-woven fabric composite filter material, the para-aramid nano fiber, polyphenylene sulfide acupuncture, spunlaced or spun-bonded non-woven fabric are composite via a spraying-coating or impregnation method to acquire graded composite filter material. Compared with the present polyphenylene sulfide acupuncture, spunlaced or spun-bonded non-woven fabric filter material, the composite filter material surface layer or the interior contains firmly-combined para-aramind nano fibers, so the filter material can remain great ventilating rate and high-temperature resistance performance; micro particle filtration rate can be obviously improved; and the filter material can be simply prepared and conserves energy.

Owner:辽宁洁花环保科技装备有限公司

Laser edge banding machine for plastic film, nonwoven cloth composite filter paper

InactiveCN101209582ANo side leakageStrong penetrating powerFiltration separationDomestic articlesWoven fabric compositeEngineering

The invention relates to a filter core manufacture field. The invention discloses a laser edge bonding machine used for plastic films and non-woven fabrics composite filter paper. The invention comprises a laser device, a composite filter paper transmission device, a bracket system, a smoke pumping device and a loading / unloading device. The laser device and the composite filter paper transmission device are supported by the bracket system; the laser device is arranged above the composite filter paper transmission device; the smoke pumping device is arranged above the composite filter paper transmission device and below the laser device; the loading / unloading device is arranged on the side surface of the bracket system. The edge bonding heating of the invention has the advantages of high efficiency, high processing speed and simple structure.

Owner:武汉楚天激光(集团)股份有限公司

Spunlace non-woven fabric composite filter material and manufacturing method thereof

ActiveCN101804274AEasy to fold and shapeEasy to glueSynthetic resin layered productsLaminationWoven fabric compositeComposite filter

The invention discloses a spunlace non-woven fabric composite filter material and a manufacturing method thereof. The manufacturing method of the composite filter material comprises the following steps that: spunlace non-woven fabric which is obtained after the starching treatment is unwound, the surface of the spunlace non-woven fabric is coated, the coat is of oil-based polyurethane with the solid content of 30 to 75 percent, polyfluortetraethylene film is smoothed by a hot ironing roller after being unwound, the spunlace non-woven fabric and the polyfluortetraethylene film are compounded through the compression of pressing rolls, the pressure of the pressing roll is 3 to 10 kg, at the same time the composite material is heated and dried, the drying temperature is 70 to 170 DEG C, and the composite material is rolled to form the finished product after the compounding. Finally the filter material which is formed by compounding the spunlace non-woven fabric and the polyfluortetraethylene film is obtained, the base weight of the composite product is 102 to 258 g / m2, the filter resistant force is 40 to 280 Pa, the filter efficiency is 85 to 99.995 percent, and the stiffness is 1500 to 4500 mg. The filter material has low filter resistant force and high filter efficiency, is easy to fold and for, and can be made into different filters with different shapes.

Owner:杭州路先非织造股份有限公司

Non-sticky high-friction-coefficient high polymer material, non-woven fabric composite material and application of non-woven fabric composite material

ActiveCN104844939AOther chemical processesSynthetic resin layered productsForeign matterPolymer science

The invention relates to a non-sticky high-friction-coefficient high polymer material, a non-woven fabric composite material and application of the non-woven fabric composite material. The non-sticky high-friction-coefficient high polymer material is characterized in that (a) isotatic polypropylene macromolecules and / or isotatic polypropylene derivatives are contained; (b) the flow speed parameters of isotatic polypropylene macromolecules and / or isotatic polypropylene derivatives are 5-15. According to the high polymer material, the disadvantages of traditional medical sizing shoe covers that the wear resistance and the skid resistance are poor, rubber easily falls off and is adhered with foreign matters, procedures are complex, and the cost is high can be solved, and the traditional medical rubber shoe covers are mutually adhered due to poor high temperature resistance; an anti-skid part further has the characteristics of high temperature resistance and no stickiness. The non-sticky high-friction-coefficient high polymer material, a membrane prepared from the non-sticky high-friction-coefficient high polymer material and the composite material can be applied to the fields of families, agriculture, industry, medicines and the like and can be used as operative towels, operative tablecloth, beautifying towels, automotive anti-skid mats, toilet bowl mats, stacking packaging bags, storage rack exhibition table boards, and the like.

Owner:SUZHOU ADDISON NONWOVEN PROD CO LTD

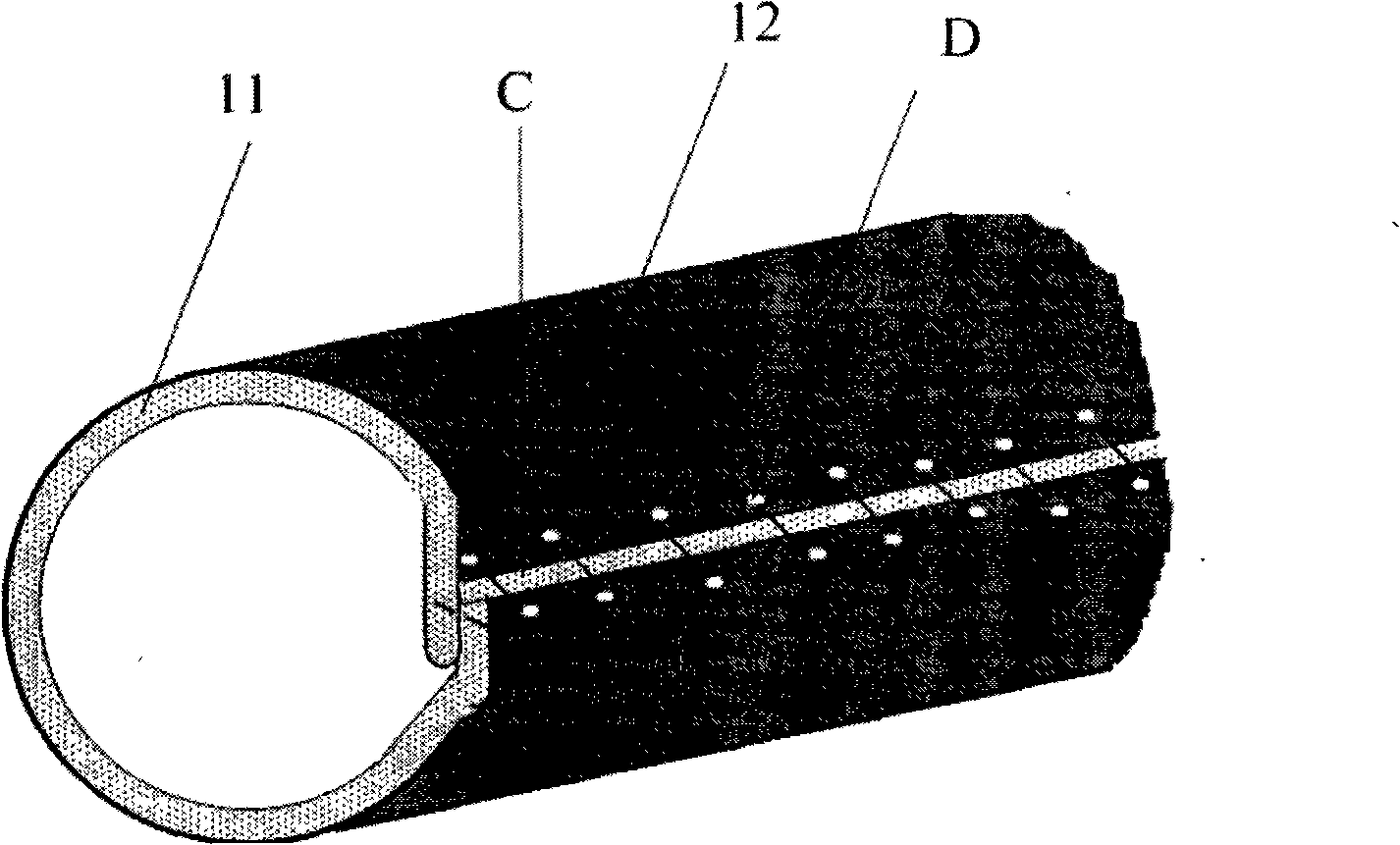

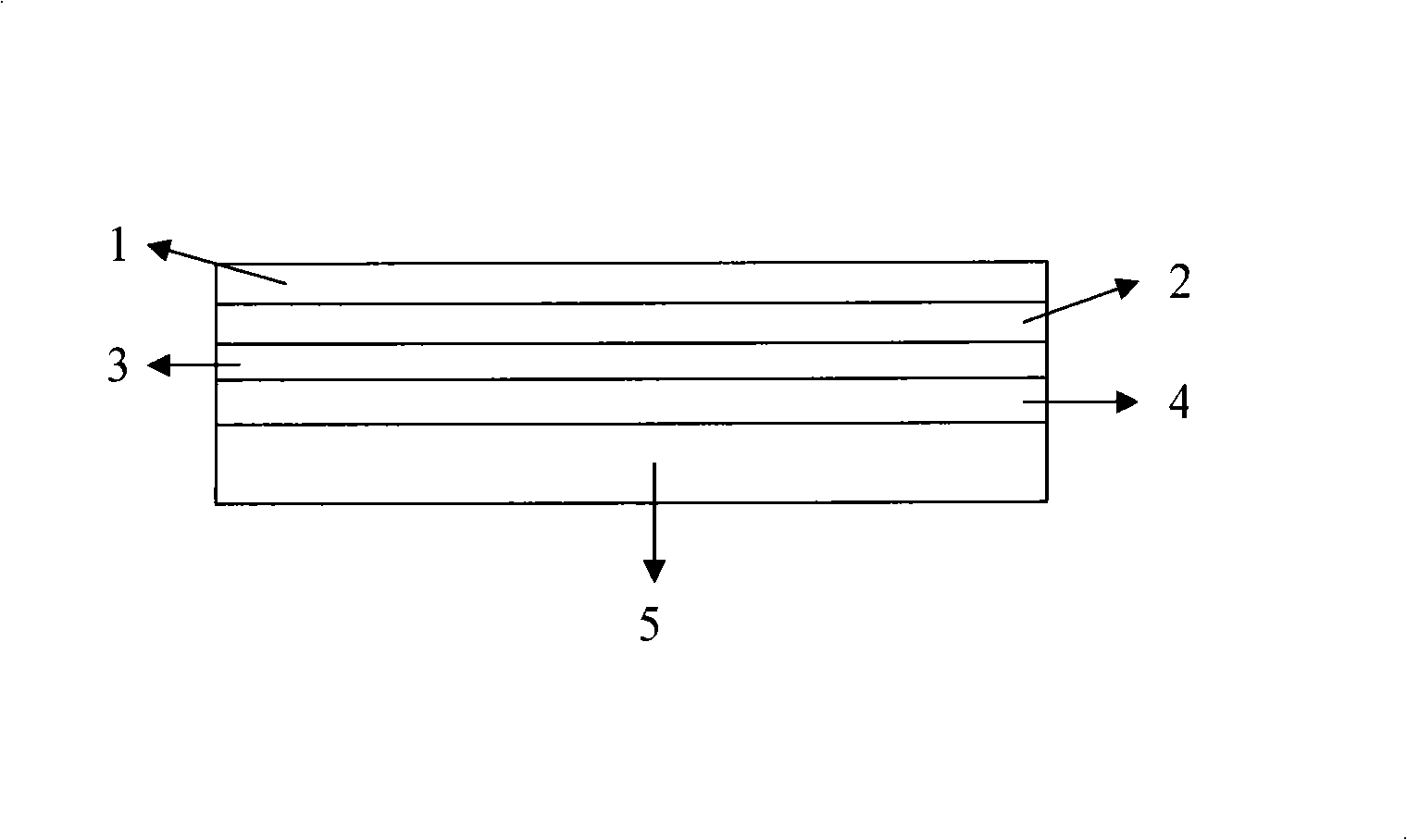

Carbon fiber composite artificial bone and preparation method thereof

ActiveCN110841114AStrong penetrating powerHigh carbon fiber contentTissue regenerationProsthesisWoven fabric compositeArtificial bone

The invention provides a carbon fiber composite artificial bone and a preparation method thereof. The section of the artificial bone in a direction perpendicular to the length of the artificial bone is in a U shape, continuous carbon fiber woven fabric composite material layers and carbon fiber non-woven fabric composite material layers are stacked to form the artificial bone, and spaces among thecarbon fibers of the continuous carbon fiber woven fabric composite material layers and the carbon fiber non-woven fabric composite material layers are filled with carbon substrates. The carbon fibercomposite artificial bone has the advantages that the composite material is light in weight, good in biocompatibility, chemical stability and fatigue performance and high in designability, the mechanical property of the composite material is similar to that of a human bone, fake shadows are avoided and the like, hydroxylapatite is stably adhered onto gaps in the surface and the surface, so that biological activity of the composite material is improved, bone growth is facilitated, and bone proliferation is induced.

Owner:HUNAN TANKANG BIOTECH CO LTD

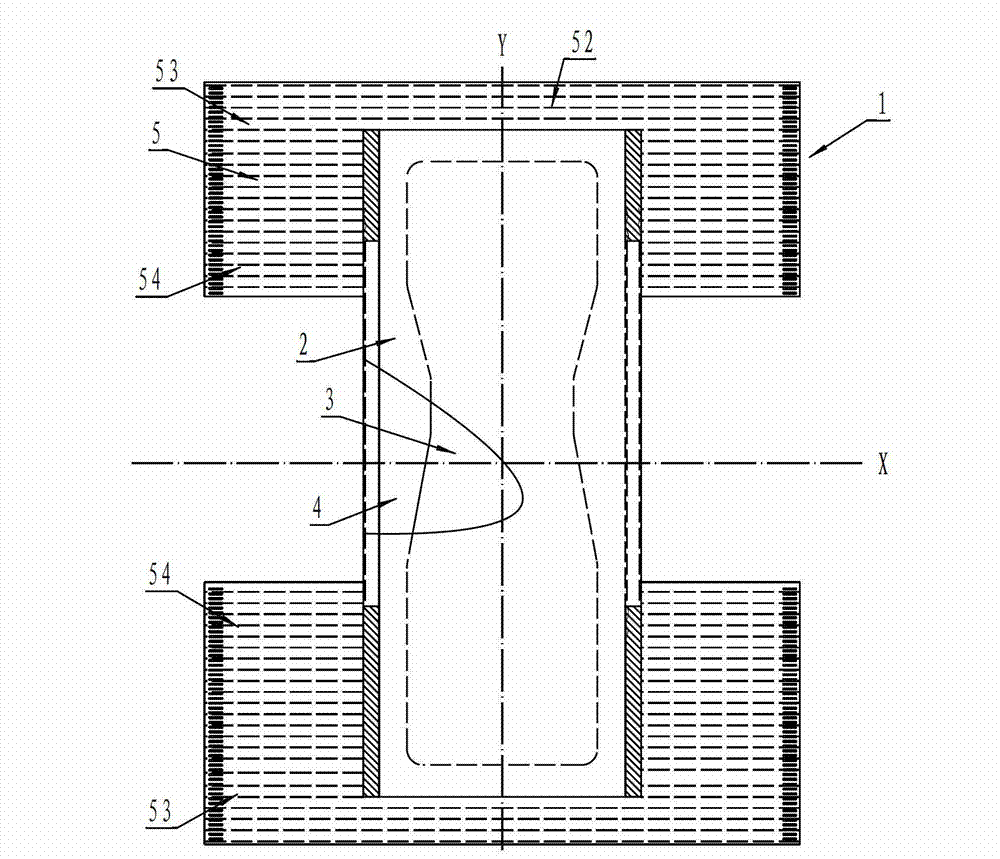

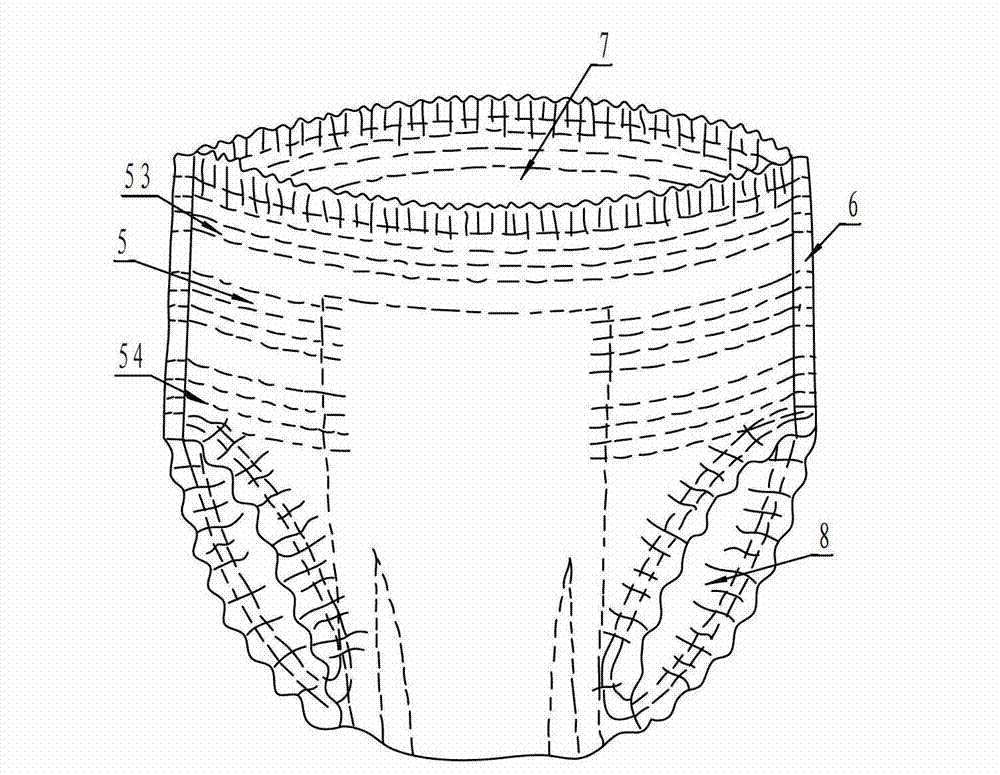

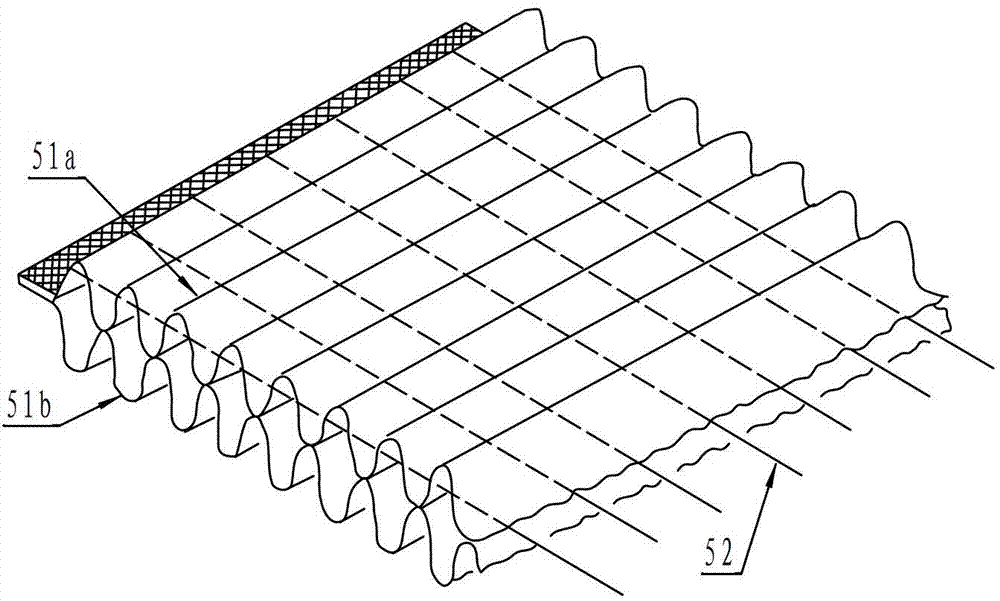

Disposable absorption article

The invention discloses a disposable absorption article. The disposable absorption article is provided with a liquid-permeability surface layer, a non-liquid-permeability bottom layer and an absorption core which is positioned between the liquid-permeability surface layer and the non-liquid-permeability bottom layer, the front waistline and the rear waistline of the disposable absorption article are formed by two layers of non-woven fabric composite elastic components, the elastic components stretch along a waistline direction and are distributed at intervals in a direction vertical to the waistline direction, two side edge parts of a front waistline area and a rear waistline area are mutually jointed to form two side surface sealing parts, a waist opening and a pair of leg openings, two ends of each elastic component in areas of the front waistline and the rear waistline close to the waist opening are fixedly jointed between two layers of non-woven fabrics through adhesives, at least one part of middle parts of at least one part of the elastic components is jointed between the two layers of the non-woven fabrics, and thus the middle joint part of the elastic components is formed. The waist areas of the disposable absorption article disclosed by the invention can be gently attached to the waistline of a user, tying marks or red marks cannot be left, and the dressing comfort and the fitting performance can be increased.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Tubular nonwoven compound material and manufacturing method thereof

InactiveCN101280872ASimple processIncrease productivityPipe elementsWoven fabric compositeEngineering

The invention relates to a tube shaped composite material non-woven fabric and method of producing the same, the composite material is made by tubular opposite joint of non-woven fabric base fabric and coating layer on it in width direction, the composite material is used for non-digging repair of damaged pipeline burred in city, the invention is characterized in that the base fabric of the composite material is made by opposite joint stitch of 2 or more than 2 same no-woven fabric base fabric in width direction, and is stitched into tubular non-woven fabric base fabric, and integral thickness of the coating layer on the same is uniformly consistent. The production method includes techniques: 1 designing split joint block number of the non-woven fabric base fabric; 2 remaining joining edge on both sides of each non-woven fabric base fabric in width direction, and homogeneously coating resin on other place; 3 using joining edge to oppositely joint the non-woven fabric base fabric with designed block number into tubular shape; 4 executing complement resin process at joining place and uniforming the thickness of resin at joining place of plane opposite joint and coated resin at other place, thereby obtaining the tube shaped non-woven fabric composite material.

Owner:TIANJIN POLYTECHNIC UNIV

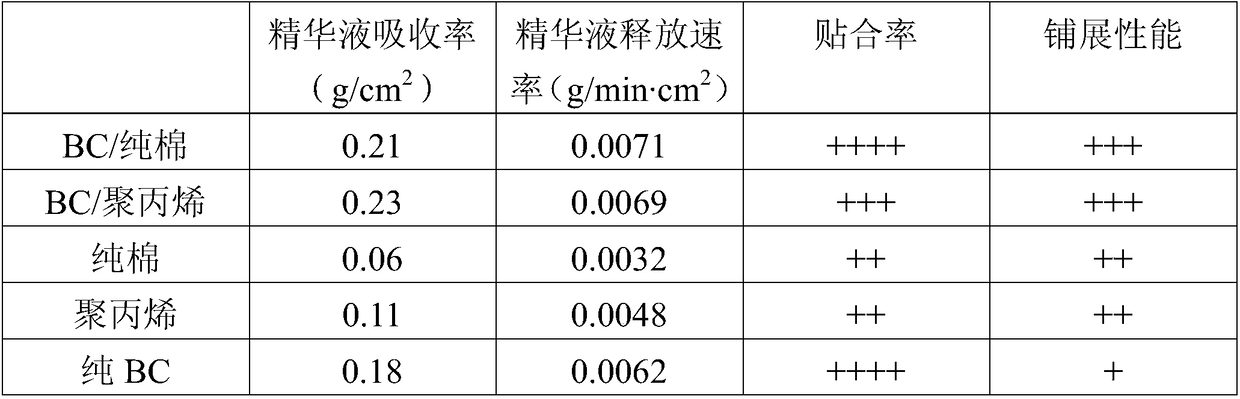

Medical bacterial cellulose/non-woven fabric composite hydrogel facial mask and preparation method thereof

ActiveCN108478468AFacilitated DiffusionImprove adsorption capacityCosmetic preparationsToilet preparationsFiberWoven fabric composite

The invention discloses a preparation method of a medical bacterial cellulose / non-woven fabric composite hydrogel facial mask. The preparation method is characterized in that non-woven fabric facial mask paper is immersed in fermentation liquid of bacterial celluloses and is subjected to static culture at a suitable temperature, and the bacterial celluloses are grown into fibers of the non-woven fabric facial mask paper in the fermentation process to form an interlaced interpenetrating network, so that the bacterial celluloses are closely compounded with the non-woven fabric facial mask paper.The invention further provides the medical bacterial celluloses / non-woven fabric composite hydrogel facial mask prepared by the method. The medical bacterial cellulose / non-woven fabric composite hydrogel facial mask disclosed by the invention is easy to spread and high in moisture content, has efficient adsorption / diffusion dual effects and can effectively absorb skincare essence. During the use,the composite hydrogel facial mask can efficiently release skincare components and keep good wettability.

Owner:SOUTH CHINA UNIV OF TECH

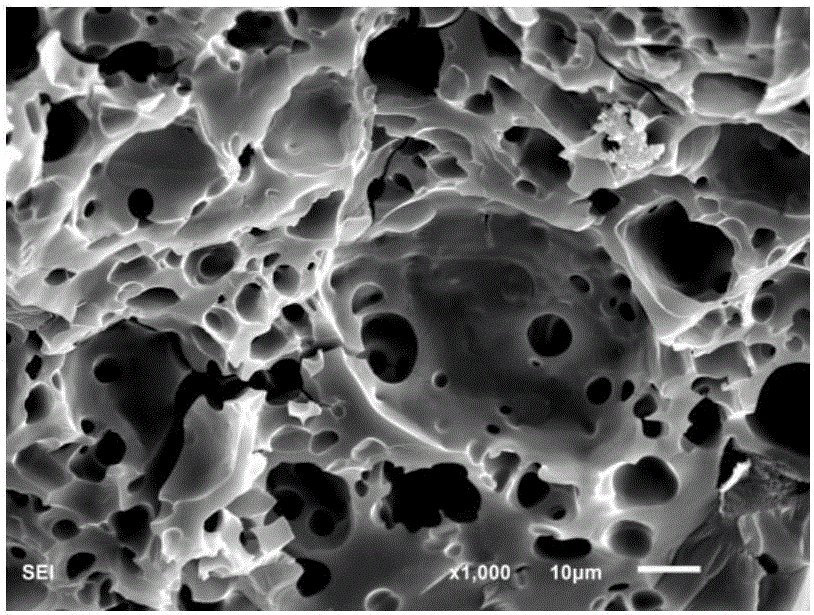

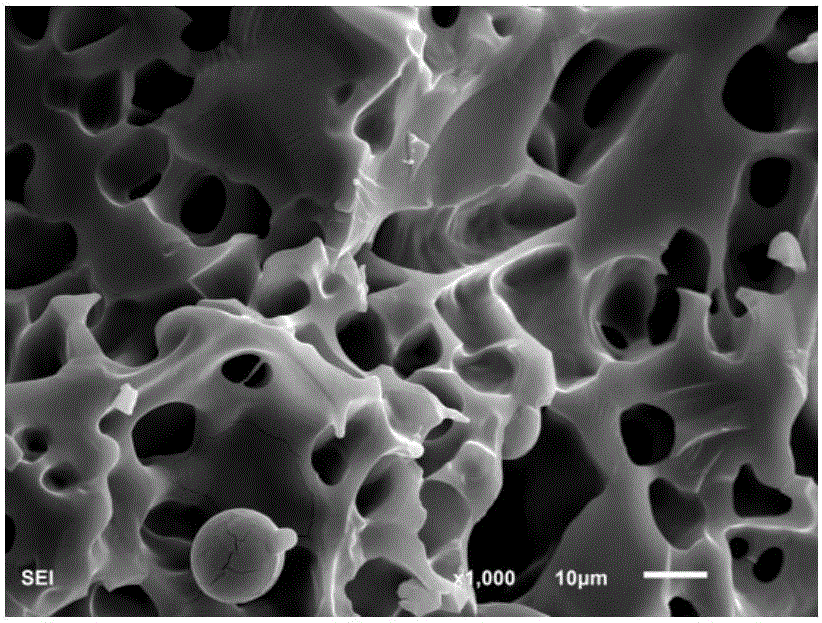

Ultrafiltration embossed melt-blown non-woven fabric and preparation method thereof

InactiveCN112111853AImprove filtering effectModerate weightConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer scienceMesoporous silica

The invention discloses ultrafiltration embossed melt-blown non-woven fabric and a preparation method thereof. The ultrafiltration embossed melt-blown non-woven fabric is prepared from a melt-blown non-woven fabric composite slice material; and the melt-blown non-woven fabric composite slice material is prepared from the following raw materials in parts by weight: 65-80 parts of polypropylene melt-blown non-woven fabric slices, 24-36 parts of poly(dimethylsiloxane)-grafted-polyacrylate, 5-8 parts of maleic anhydride styrene dimonomer grafted polypropylene, 4.5-6 parts of nano titanium dioxide,3-5 parts of mesoporous silicon dioxide, 2.4-3 parts of stearyl phthalamide and 1.5-2 parts of zinc stearate. The ultrafiltration embossed melt-blown non-woven fabric is prepared from the melt-blownnon-woven fabric composite slice material, and the melt-blown non-woven fabric composite slice material can be normally produced through an existing melt-blown non-woven fabric machine; and the produced ultrafiltration embossed melt-blown non-woven fabric is excellent in filtering performance, moderate in gram weight, high in tensile strength and good in softness.

Owner:FUJIAN GUAN HONG IND

Paint-free self-bonding thin lumber and process for manufacturing the same

InactiveCN101318339AEasy compoundAvoid pollutionWood veneer joiningWood layered productsWoven fabric compositeLacquer

The invention relates to a self-adhesive veneer material used for the surface treatment in indoor decoration construction and furniture production and a manufacturing method thereof; wherein, the paint-exempt self-adhesive veneer material which comprises sliced veneer materials is pasted on base materials; the self-adhesive veneer material is characterized in that the material also comprises a non-woven fabric composite pasted on the back of the veneer material, a hot-melt adhesive layer roll coated under the non-woven fabric and a paint coating layer which is arranged on the surface of the veneer material. The self-adhesive veneer material can combine the veneer on the base materials by using an electric iron (heating directly based on the thermal transport property of the material) or an electromagnetic heating tool (heating indirectly by a magnetic conductor) after finishing model installation and laying, and has the advantages of being convenient and easy to be repaired and changed; the processes of glue spreading, gun-nail fixing and painting are removed; nail holes and the surface paint malady caused by construction environment do not appear on the veneer. Meanwhile, the self-adhesive veneer material of the invention improves the construction environment greatly, reduces the influence of cross job, accelerates the construction progress, leads to a real industrialization in decoration, and avoids the pollution caused by indoor decoration effectively.

Owner:陈跃明

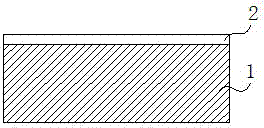

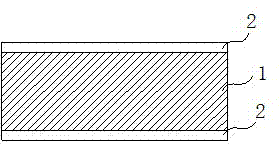

Metal non-woven fabric composite board and processing method thereof

InactiveCN102744933ALight in massWon't come offLaminationLamination apparatusWoven fabric compositeSurface layer

The invention provides a metal non-woven fabric composite board and a processing method thereof. The metal non-woven fabric composite board comprises a metal material layer on the surface layer, a non-woven fabric layer at the bottom layer and a binding material layer in the middle, wherein the metal material layer and the non-woven fabric layer are bonded together in a high temperature compounding or cold compounding manner by virtue of the binding material layer. The binding material layer comprises a macromolecule coating and an adhesive, wherein the metal material layer and the non-woven fabric layer are bonded together through high temperature rolling by virtue of the macromolecule coating, and the metal material layer and the non-woven fabric layer are bonded together through rolling by virtue of the adhesive. The metal non-woven fabric composite board has the advantages of light weight, heat resistance and low manufacturing cost, and construction is simple and bonding is firm when the metal non-woven fabric composite board is applied to the external wall of a building.

Owner:徐建永

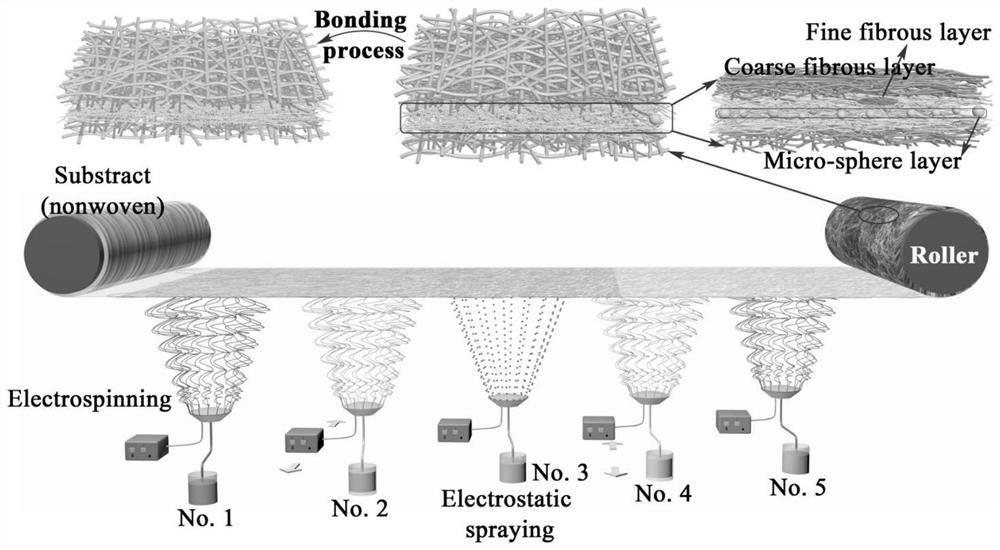

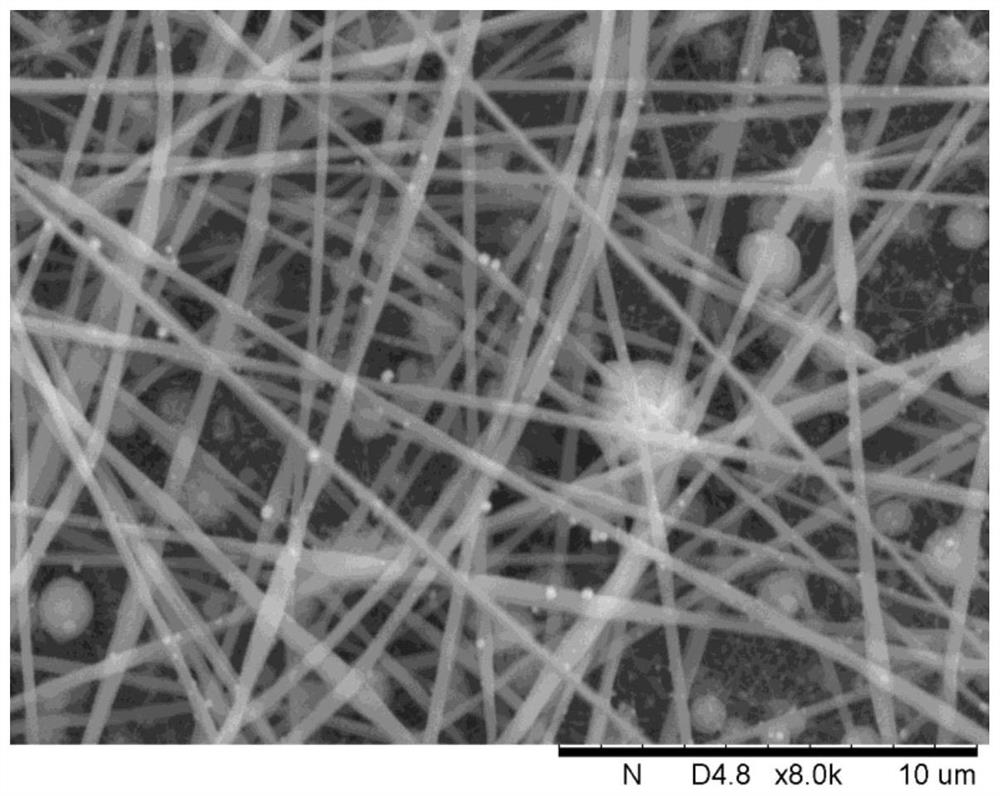

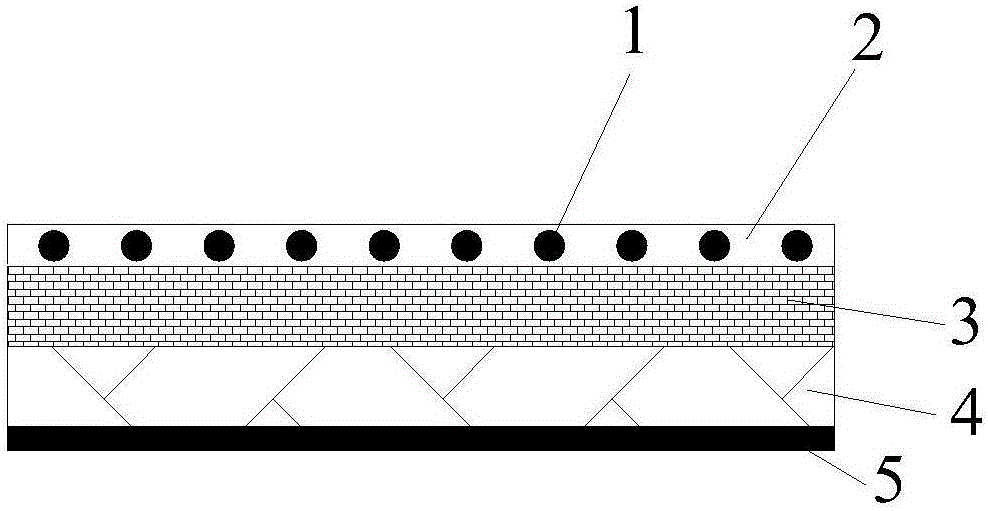

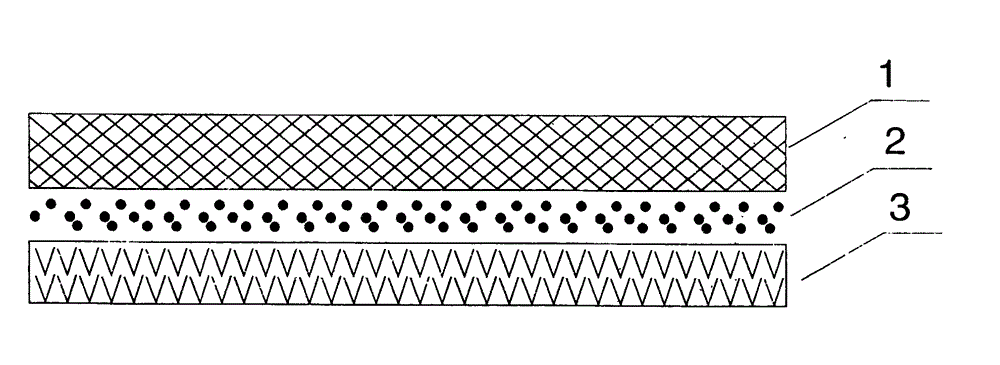

Multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof

ActiveCN112755651AImprove uniformitySmall apertureHuman health protectionElectro-spinningFiberPolymer science

The invention relates to a multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof. The material is of a sandwich structure formed by sequentially arranging a spun-bonded non-woven fabric, a sub-micron fiber / microsphere composite film and a spun-bonded non-woven fabric. The preparation method comprises the following steps: preparing a low-concentration electrostatic spinning solution with additional functionality, preparing a high-concentration electrostatic spinning solution with additional functionality, preparing an electrostatic spraying polymer solution with additional functionality, preparing a sub-micron fiber composite membrane / non-woven fabric composite material, and preparing the sub-micron fiber air filtering material. The preparation method has simple and controllable process parameters, and the prepared filter material has good structural controllability.

Owner:DONGHUA UNIV

Medical dressing with capacity of intelligently releasing antibacterial agent and preparation method of medical dressing

ActiveCN105999361AImprove barrier propertiesGood moisture permeabilityNon-adhesive dressingsAbsorbent padsWoven fabric compositeMedicine

The invention discloses a medical dressing with the capacity of intelligently releasing an antibacterial agent and a preparation method of the medical dressing, and belongs to the field of medical dressing materials. The medical dressing is made of a non-woven fabric, and the obverse side of the non-woven fabric is coated with a waterproof and moisture-permeable layer which is made of a polyurethane nanofiber membrane; the surface of the waterproof and moisture-permeable layer is coated with a hydrogel layer which is made of hydrogel, and the antibacterial agent is loaded in the hydrogel; the reverse side of the non-woven fabric is also coated with a waterproof layer. The invention further provides the preparation method. The preparation method comprises the steps that firstly, the non-woven fabric composited with the polyurethane nanofiber membrane is prepared, and the reverse side of the non-woven fabric is coated with a polyvinylidene fluoride solution to obtain a polyvinylidene fluoride waterproof layer; secondly, the hydrogel loaded with the antibacterial agent is applied to the surface of the polyurethane nanofiber membrane, standing is conducted, and then the medical dressing with the capacity of intelligently releasing the antibacterial agent is obtained. The preparation method is simple, and the medical dressing prepared through the method not only is good in waterproof and moisture-permeable effect, but also can intelligently release the antibacterial agent to reduce bacterial drug resistance.

Owner:WUHAN TEXTILE UNIV

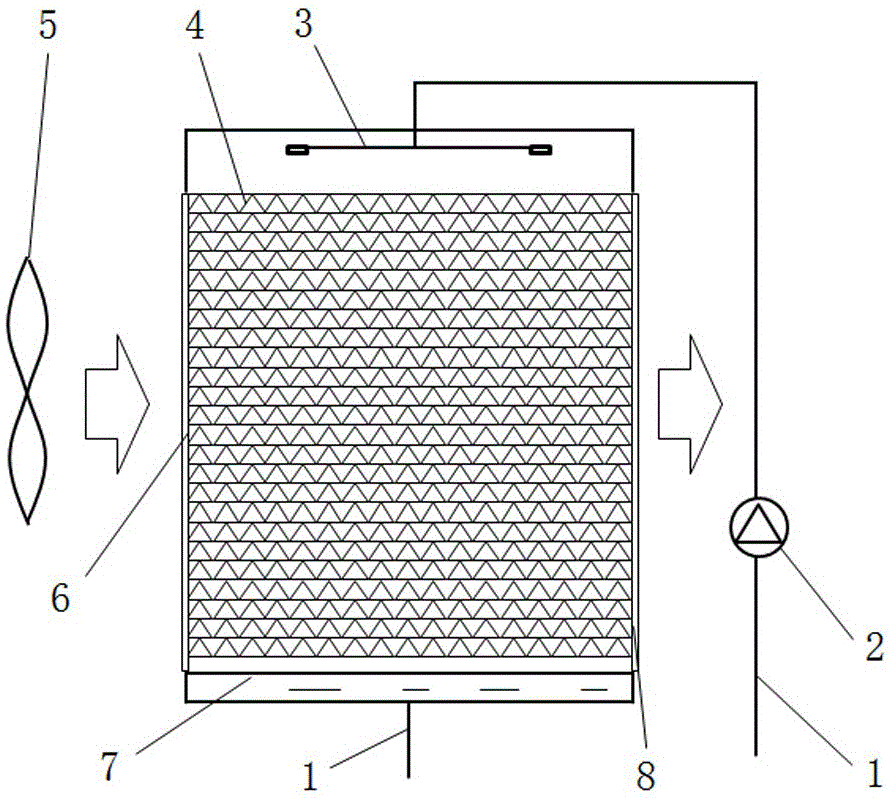

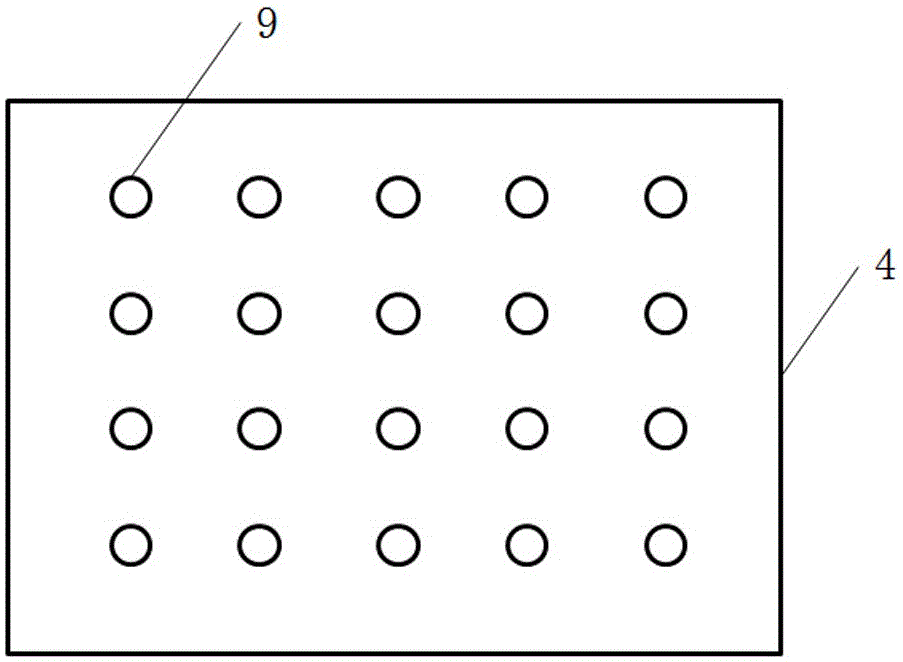

Efficient direct contact type water-air heat exchanging device

InactiveCN105783545AImprove heat transfer effectImprove heat transfer efficiencyTrickle coolersHigh humidityWoven fabric composite

The invention discloses an efficient direct contact type water-air heat exchanging device. The efficient direct contact type water-air heat exchanging device comprises a water pipe, a circulating water pump, a water distributor, non-woven fabric composite filler, a draught fan, an air-inlet grille, a water collecting disk and an air-outlet grille. The water pipe communicates with the circulating water pump and the water distributor. The circulating water pump conveys high-temperature water to the water distributor through the water pipe. The water distributor evenly sprays the high-temperature water to the surface of the non-woven fabric composite filler. The non-woven fabric composite filler is of a multi-layer composite structure, each layer of the non-woven fabric composite filler is provided with a plurality of drain holes, water flows from top to bottom and conducts direct contact type heat exchange with air blown by the draught fan from the air-inlet grille, high-temperature and high-humidity air flows out through the air-outlet grille, and cooled water flows into the water collecting disk to be circularly used later. According to the efficient direct contact type water-air heat exchanging device, the effect of intensifying heat exchanging is achieved by prolonging the contact time of air and water and increasing the contact area of air and water.

Owner:HANGZHOU DAZHAN ELECTROMECHANICAL TECH CO LTD

High-density large-flowered-backing colorful coconut coal non-woven fabric composite multifunctional wall cloth

InactiveCN103061476AHealth hasWith visual comfortCovering/liningsSynthetic resin layered productsSurface layerWoven fabric composite

The invention discloses high-density large-flowered-backing colorful coconut coal non-woven fabric composite multifunctional wall cloth which comprises a surface layer, a middle layer and a lining layer. The surface layer is high-density large-flowered-backing colorful jacquard fabrics, a binding agent (the middle layer) is pasted on a back face of the surface layer, and then hot pressing is carried out on the lining layer coconut coal Dacron needling non-woven fabrics and the surface layer to form the wall cloth. The wall cloth adopts a structure with three layers, patterns on the surface layer are big, distinct and natural and are different in color and light reflection, and fibers made of alloy germanium can release efficient anion and infrared rays to improve indoor air; the middle layer is an organosilicone binding agent which is non-toxic, tasteless, high-temperature resisting, not easy to age and good in binding performance; and the lining layer is the coconut coal Dacron needling non-woven fabrics which have effects of absorbing indoor harmful gas, moisturizing, humidifying and the like. Through compounding of the three layers, the wall cloth is comfortable in vision, absorbs noise, ventilates, resists to anti-static electricity, protects a wall, resists to abrasion and is free of taste, environment-friendly, healthy and fashionable.

Owner:SHAOXING SHULILE TEXTILE PROD

Environment-friendly fiber/non-woven fabric composite board for home decoration and preparation method thereof

ActiveCN103112208AGood moisture absorption and air permeabilityHigh hardnessSynthetic resin layered productsEnvironmental resistanceWoven fabric composite

The invention discloses an environment-friendly fiber / non-woven fabric composite board for home decoration and a preparation method thereof. The environment-friendly fiber / non-woven fabric composite board for home decoration is composed of a base board and a non-woven fabric arranged on the surface of the base board, wherein the base board comprises the following components in percentage by weight: 50-80% of jute fiber, 20-50% of low-melting-point fiber and 0-30% of Alpinia zerumbet fiber. According to the environment-friendly fiber / non-woven fabric composite board for home decoration, the base board is prepared by compounding low-melting-point fibers and jute fibers, the non-woven fabric layer is covered on the base board, and no other components are added, thereby ensuring that the product is free of other harmful chemical substances and causing no harm to the body; and meanwhile, the jute fibers bring favorable moisture absorption and air permeability, and have bacterium resistance and mite prevention effects. The environment-friendly board is light in weight and high in hardness, can be used instead of wallpaper, paint and other decorative materials, and can be directly used in places to be decorated, such as walls, roofs and the like. The preparation method of the environment-friendly composite board is simple in procedures, convenient to operate and easy to realize industrialization; and the gram weight of the prepared product can be up to 100-300 g / m<2>, and the thickness is 0.3-5 mm.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

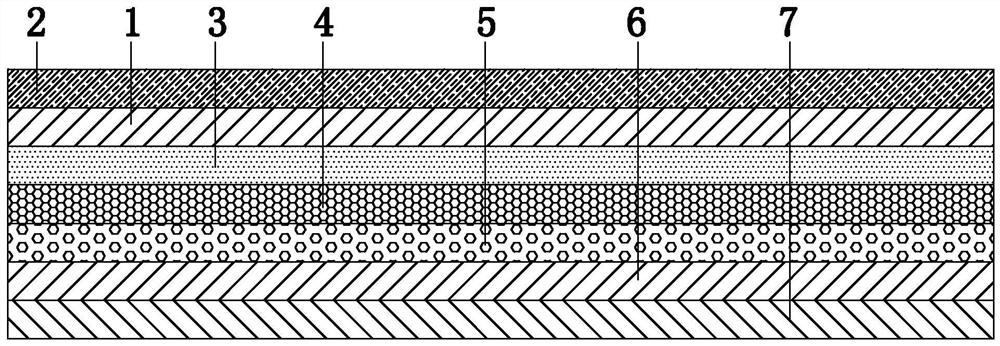

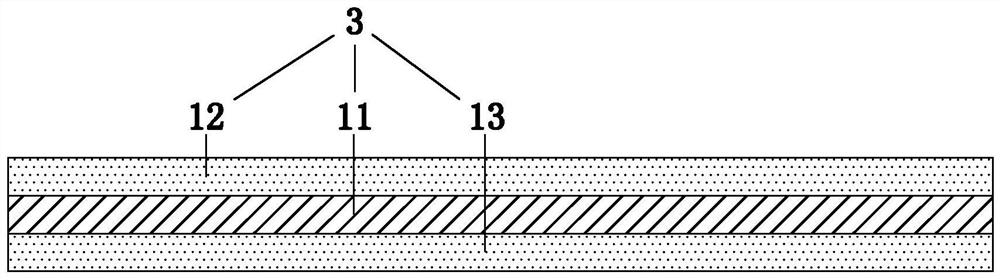

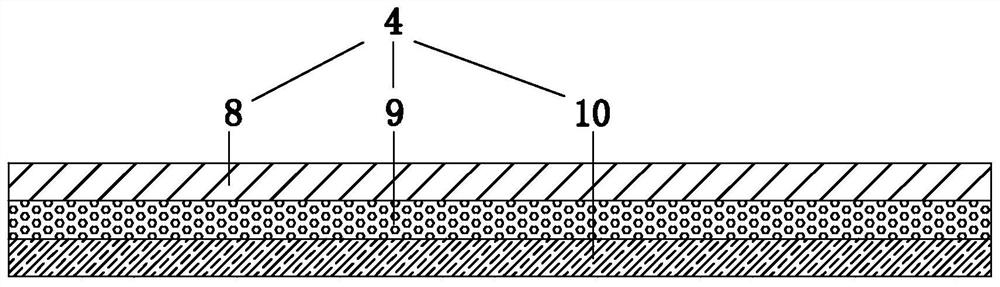

Non-woven fabric composite material for filter mask

PendingCN111775520AImprove antibacterial propertiesEffective waterproof protectionProtective equipmentSynthetic resin layered productsWoven fabric compositeNonwoven fabric

The invention discloses a non-woven fabric composite material for a filter mask. The material comprises an outer layer, a waterproof breathable layer is fixedly arranged on the outer layer; an antibacterial layer is fixedly arranged below the outer layer; wherein a filter layer is fixedly arranged below the antibacterial layer, an adsorption layer is fixedly arranged below the filter layer, an inner layer is fixedly arranged below the adsorption layer, a skin-friendly layer is fixedly arranged below the inner layer, the antibacterial layer comprises a built-in silver ion antibacterial fabric layer, and the built-in silver ion antibacterial fabric layer is coated with a porous nano titanium dioxide silver-loaded antibacterial agent coating. The composite material has the advantages that theantibacterial performance of the mask can be greatly improved, bacterium breeding is effectively prevented, the outer wall of the mask can be waterproof and breathable, inner side materials are effectively subjected to waterproof protection, a good adsorption effect is achieved, water vapor and peculiar smells on the inner side of the mask can be adsorbed, and the inner side of the mask can be kept dry.

Owner:福建省福杯满溢科技有限公司

Spunlace non-woven fabric composite filter material and manufacturing method thereof

ActiveCN101804274BEasy to fold and shapeEasy to glueSynthetic resin layered productsLaminationWoven fabric compositeComposite filter

Owner:杭州路先非织造股份有限公司

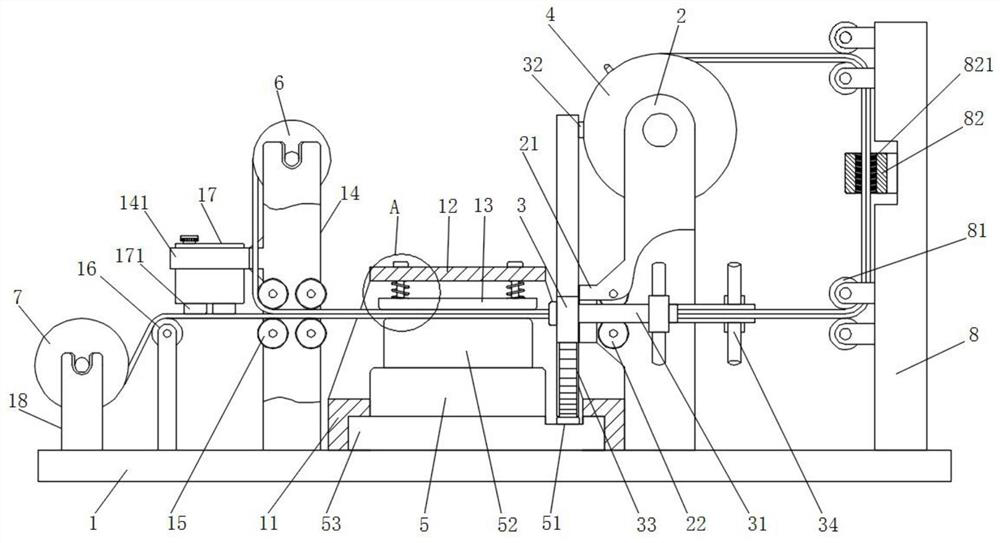

Non-woven fabric composite processing equipment

InactiveCN112848627ARealize the winding functionRealize the ironing functionMechanical cleaningLiquid surface applicatorsWoven fabric compositeElectric machinery

The invention discloses non-woven fabric composite processing equipment. The equipment comprises a base, two first supports are fixedly mounted at the top of the base, rotating drums are rotatably mounted on the inner sides of the top ends of the two first supports, cloth collecting rollers are mounted on the inner sides of the two rotating drums, a driving motor is arranged on the outer side of the top end of one first support, the driving motor and the first support are fixedly installed through a motor frame, the driving motor is in transmission connection with one rotating drum through an output shaft, and third supports are fixedly installed on the two sides of one end of the top of the base. According to the non-woven fabric composite processing equipment, the rotating drums are rotationally driven, the function of winding composite fabric is achieved, the function of ironing the fabric is achieved through continuous movement of an ironing device, meanwhile, the functions of loosening and impurity removing of the composite fabric are achieved through continuous beating by two sets of beating rods, and the composite processing efficiency of non-woven fabric is further improved.

Owner:方嘉诚

Functional material with health care and health preservation, its preparation method and its application

InactiveCN102745939APromote smooth flow of meridiansPromote recovery from illnessDiseaseSocial benefits

The invention relates to a functional material with health care and health preservation, its preparation method and its application. The functional material comprises 20-30% of nano far-infrared balls, 20-30% of nano anion balls; 10-20% of nano ceramic powder, 10-20% of nano silica, 5-10% of active carbon and 20-30% of biogel. The preparation method is characterized in that the functional components with health care and health preservation are prepared under normal temperature, uniformly mixed and stirred, then the components are bonded on an active carbon-non-woven fabrics composite base material by a biogel, and drying under the temperature of 50-80 DEG C for 8-12 hours. The functional material can be used for life articles like door pads, shoe pads, seat cushions, back cushions and mattresses which can perform the health care and health preservation effects. Each acupoint is massaged by body-building and health preserving movement, people can receive the far-infrared, negative ion and magnetic energy deep physiotherapy, thereby the material of the invention can smooth the channels and collaterals of human body, and possesses the functions of overcoming disease and recovering as well as building up body, and has remarkable health care and health preserving efficacy value as well as economical and social benefits.

Owner:陈荷庚

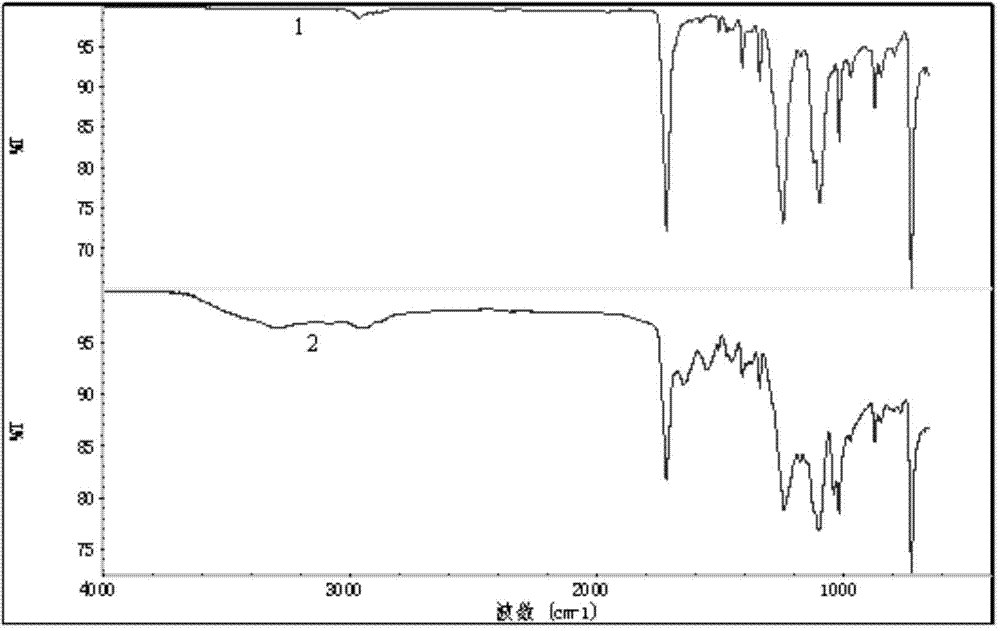

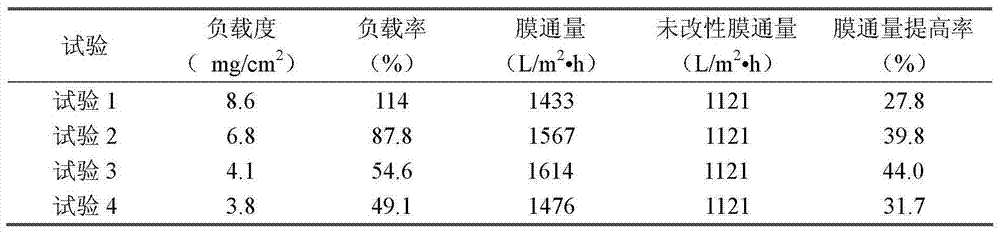

Preparation method for modified polyethylene glycol terephthalate non-woven fabric composite membrane

ActiveCN103495351AImprove hydrophilicityImprove mechanical propertiesSemi-permeable membranesReduction rateAbsorption capacity

The invention discloses a preparation method for a modified polyethylene glycol terephthalate non-woven fabric composite membrane and relates to a preparation method for parting materials and composite membrane materials in order to solve the technical problem that a modified composite membrane prepared according to an existing membrane material modification or membrane surface modification method is low in reduction rate of a water contact angle and in reduction rate of equilibrium solution absorption capacity of bovine serum albumin (BSA). The preparation method includes the steps of: 1), preparation of a casting membrane solution; 2), preparation of the modified composite membrane; 3), preparation of the modified non-woven fabric composite membrane. By the preparation method, the water contact angle of the composite membrane is lowered, the equilibrium solution absorption capacity of the BSA of the composite membrane is decreased, and membrane flux of the composite membrane is increased.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Agricultural protective mask material

InactiveCN106376992APrevent penetrationHealth hazardProtective garmentSpecial outerwear garmentsCarbon fibersFiltration

The invention discloses an agricultural protective mask material which comprises an ultra-thin polypropylene melt-blowing material layer, a hydrophobic spun-bonded non-woven fabric layer, a fiber melt-blowing non-woven fabric composite layer, a hydrophilic spun-bonded non-woven fabric layer, a zirconium dioxide micro-spherical material layer and a carbon fiber / nano-zero-valent iron composite material layer, wherein the ultra-thin polypropylene melt-blowing material layer, the hydrophobic spun-bonded non-woven fabric layer, the zirconium dioxide micro-spherical material layer, the carbon fiber / nano-zero-valent iron composite material layer, the fiber melt-blowing non-woven fabric composite layer and the hydrophilic spun-bonded non-woven fabric layer are laminated sequentially to form the mask material. The agricultural protective mask material has absorptive filtration and pesticide degradation effects, has an isolation protection effect on pesticide application staff, and can protect people from injury when pesticide is inhaled into a mouth.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com