Preparation method for modified polyethylene glycol terephthalate non-woven fabric composite membrane

A technology of ethylene glycol phthalate and non-woven fabrics, which is applied in the field of preparation of separation materials and composite membrane materials, can solve the problems of low reduction rate of water contact angle and low reduction rate of bovine serum albumin equilibrium adsorption, and achieves Reduce water contact angle, improve pore connectivity, and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

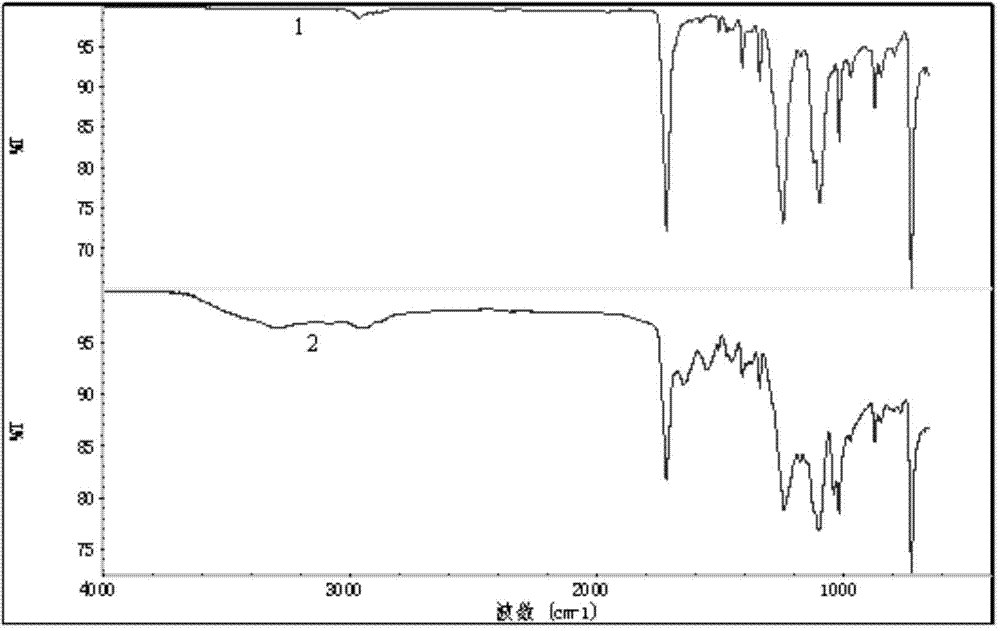

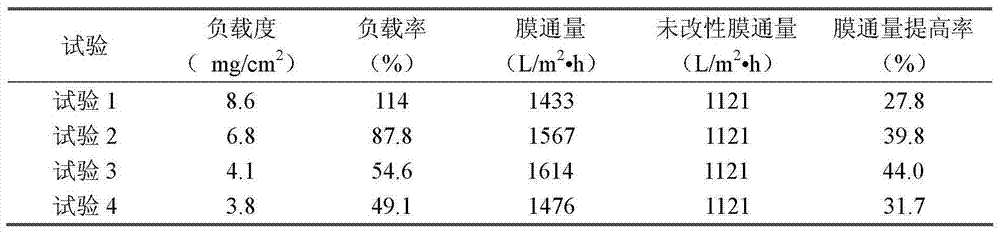

[0017] Specific embodiment one: the preparation method of a kind of modified polyethylene terephthalate non-woven composite film of the present embodiment is carried out according to the following steps:

[0018] 1. Preparation of casting solution: use 2-acrylamide-2-methylpropanesulfonic acid as the hydrophilic monomer, add cross-linking agent N,N'-methylenebisacrylamide and photoinitiator α-ketopentyl Diacid to prepare casting solution; wherein, the mass ratio of 2-acrylamide-2-methylpropanesulfonic acid, N,N'-methylenebisacrylamide and α-ketoglutaric acid is 5-20:1 :1;

[0019] 2. Soak the non-woven fabric in a polyethylene glycol 600 solution with a mass percentage of 1.2% to 3.6% for 2 to 5 hours, take it out and soak it in the casting solution prepared in step 1 for 30 to 60 minutes, and then place it in Irradiate under a 1kW ultraviolet lamp to prepare a modified composite film;

[0020] 3. Place the modified composite membrane prepared in step 1 in a drying oven at 1...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, 2-acrylamide-2-methylpropanesulfonic acid, N,N'-methylenebisacrylamide and α-ketoglutadiene The mass ratio of acid is 20:1:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 2, the irradiation time is 30-70 minutes, and the irradiation distance is 10-25 cm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com