Efficient direct contact type water-air heat exchanging device

A contact and thermal device technology, applied in direct contact heat exchangers, heat exchanger types, water shower coolers, etc., can solve the problem of low heat exchange efficiency, limited contact area, and short contact time between air and water. and other problems to achieve the effect of strengthening heat exchange, improving air quality and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

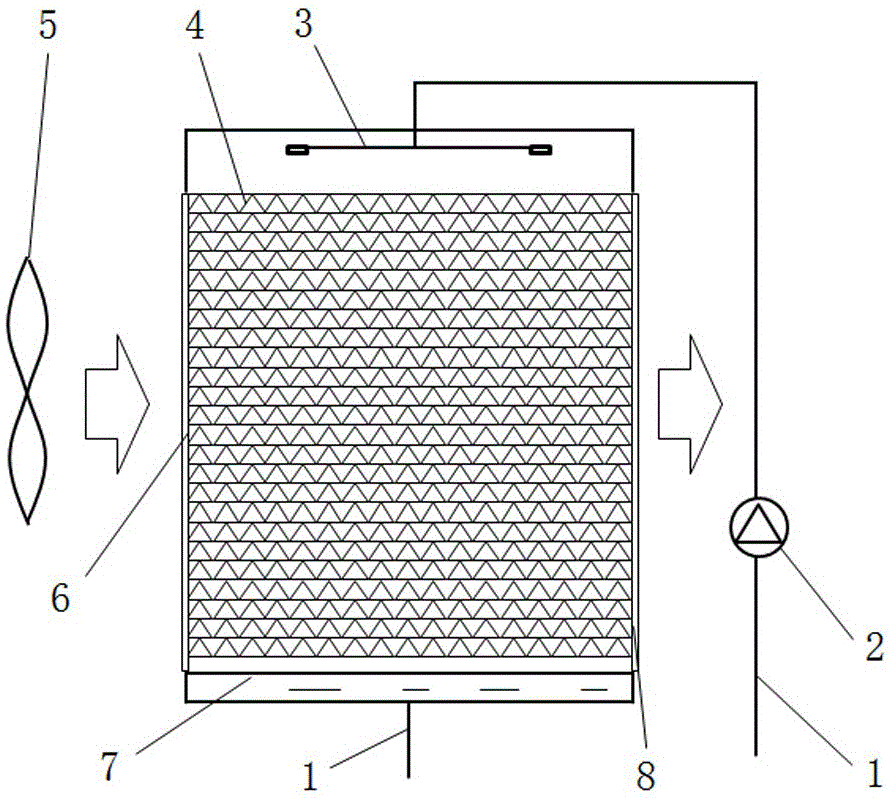

[0019] Embodiment 1 according to the present invention will be described in further detail below in conjunction with the accompanying drawings: see Figure 1~Figure 3 .

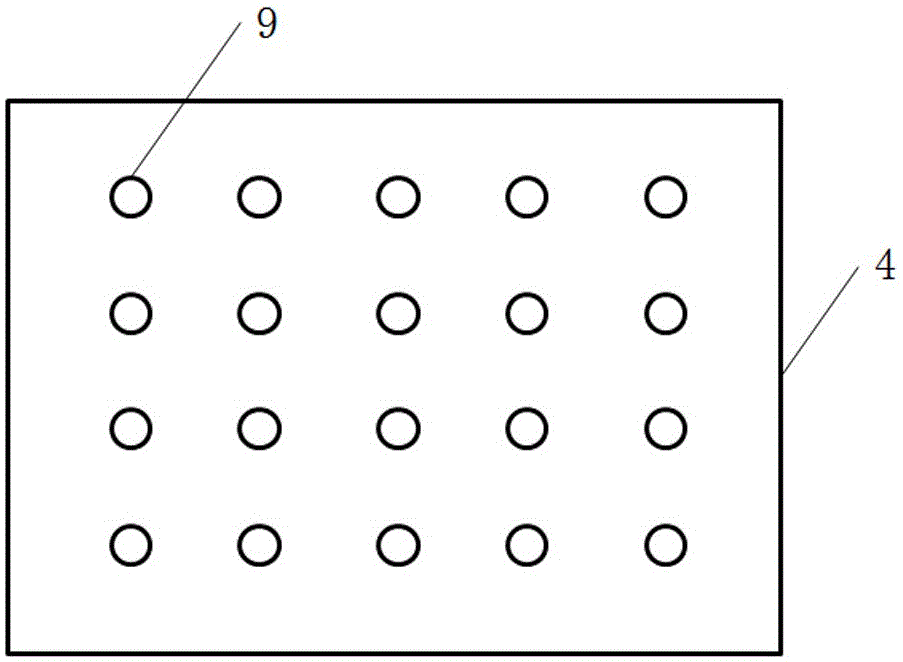

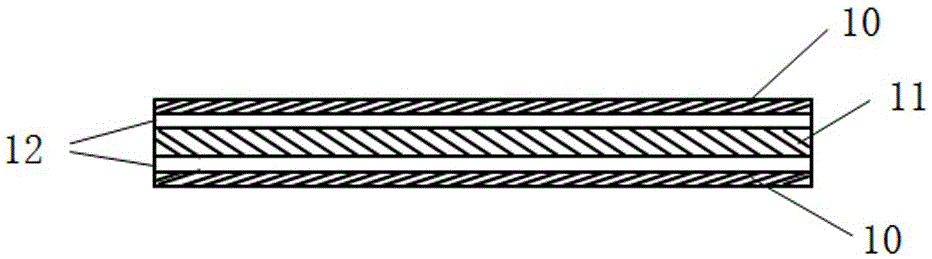

[0020] A kind of efficient direct contact water-air heat exchange device according to Embodiment 1 of the present invention, such as figure 1 As shown, it mainly includes: water pipe 1, circulating water pump 2, water distributor 3, non-woven composite filler 4, fan 5, air inlet grill 6, water collecting tray 7 and outlet grill 8. The water distributor 3 is located above the non-woven composite filler 4, the water collecting tray 7 is located below the non-woven composite filler 4, and the inlet grille 6 and the outlet grille 8 are arranged on the left and right sides of the non-woven composite filler 4. On both sides, the fans 5 are arranged adjacent to the air intake grille 6 .

[0021] The circulating water pump 2 transports high-temperature water to the water distributor 3 through the water pipe 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com