Metal non-woven fabric composite board and processing method thereof

A technology for metal non-woven fabrics and composite panels, applied in the field of building panels, can solve problems such as insecurity, high cost, and troublesome construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

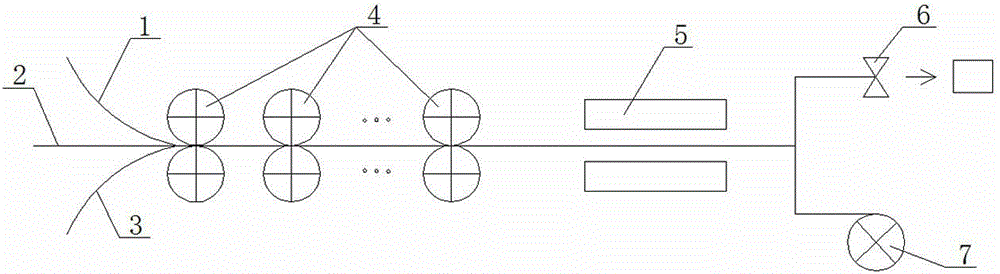

[0029] The metal non-woven fabric composite sheet of the present invention includes a metal material layer 1 on the surface, a non-woven fabric layer 3 on the bottom layer and a polymer film 2 in the middle, and the metal material layer 1 and the non-woven fabric layer 3 pass through the polymer film 2. Bonded together under high temperature rolling. The metal material layer 1 is a thin metal plate, specifically a stainless steel plate. The thickness of the metal material layer 1 is 0.2 mm. The thickness of the non-woven fabric layer 3 is 0.2 mm.

[0030] The processing method of the above-mentioned metal non-woven composite sheet comprises the following steps:

[0031] (1) Set a layer of polymer film 2 between the metal material layer 1 and the non-woven fabric layer 3, and use the rolling device 4 to perform high-temperature rolling to melt the polymer film 2 to form a composite sheet; high-temperature roll The pressing temperature is about 160°C.

[0032] (2) Use 5 exha...

Embodiment 2

[0035] The metal non-woven fabric composite sheet of the present invention includes a metal material layer 1 on the surface, a non-woven fabric layer 3 on the bottom layer and a polymer film 2 in the middle, and the metal material layer 1 and the non-woven fabric layer 3 pass through the polymer film 2. Bonded together under high temperature rolling. The metal material layer 1 is a metal surface processed plate, specifically a color steel plate. The thickness of the metal material layer 1 is 0.8mm. The thickness of the non-woven fabric layer 3 is 1mm.

[0036] The processing method of the above-mentioned metal non-woven composite sheet comprises the following steps:

[0037] (1) A layer of polymer film 2 is arranged between the metal material layer 1 and the non-woven fabric layer 3, and the rolling device 4 is used to carry out five high-temperature rolling presses with gradually lowering temperatures to melt the polymer film 2, Composite sheets are formed; the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com