Processing technology of non-woven fabric composite material for automotive interior

A technology for composite materials and automotive interiors, which is applied in the field of processing technology of non-woven composite materials for automotive interiors. It can solve the problems of lack of air permeability and hardness, increase sound absorption, reduce noise, and reduce equipment footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

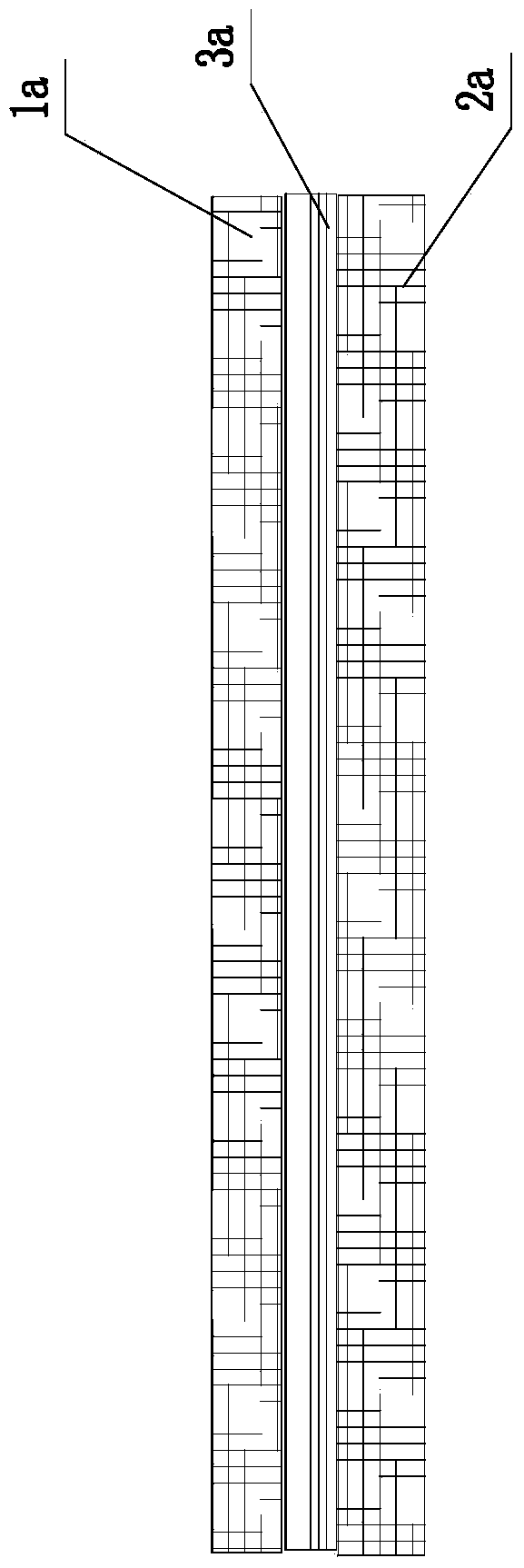

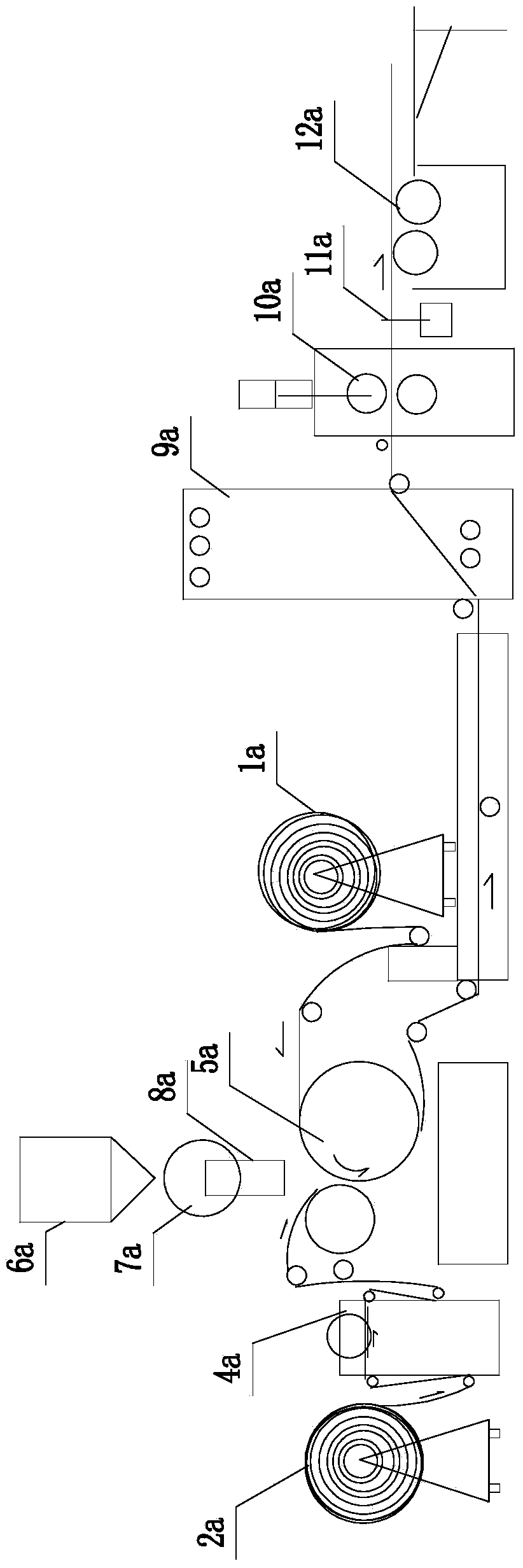

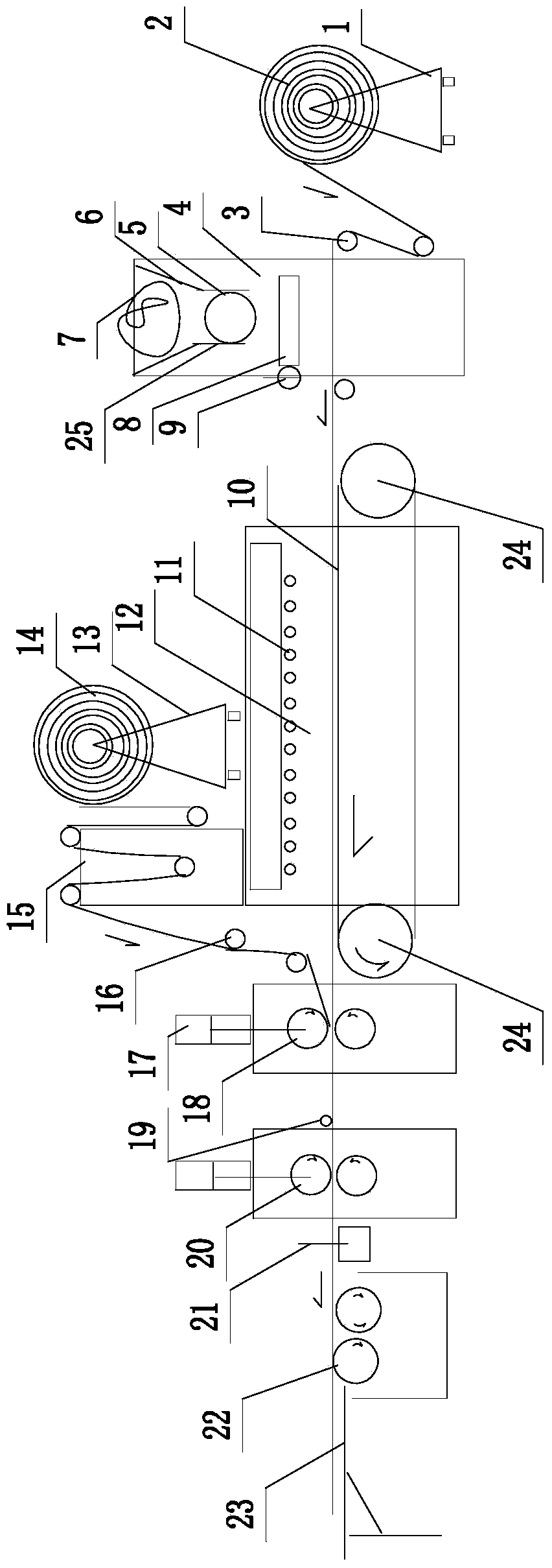

[0025] Embodiment one: a kind of processing technology of non-woven fabric composite material for automobile interior decoration, comprises the following steps:

[0026] (1) Pass the bottom layer of non-woven fabric through the powder spreading device, and evenly sprinkle polyethylene powder particles on the bottom layer of non-woven fabric. The speed of the bottom layer of non-woven fabric is 1.8m / min, and the vibration amplitude of the vibrating screen is 2mm. The number of mesh holes is 10 mesh, and the particle size of polyethylene powder particles is 40 mesh; the bottom layer of the non-woven fabric is made of polyester fiber, polypropylene, waste cotton, non-woven carpet waste, etc. Formed by conventional non-woven fabric production processes such as netting and needle punching, the grammage is 700g / ㎡, and the bottom layer of the non-woven fabric contains polypropylene to ensure the final shape and delivery, and it is mixed with other low-cost materials to facilitate wast...

Embodiment 2

[0029] Embodiment two: a kind of processing technology of non-woven fabric composite material for automobile interior decoration, comprises the following steps:

[0030] (1) Pass the bottom layer of non-woven fabric through the powder spreading device, and evenly sprinkle polyethylene powder particles on the bottom layer of non-woven fabric. The speed of the bottom layer of non-woven fabric is 2.5m / min, and the vibration amplitude of the vibrating screen is 5mm. The number of mesh holes is 20 mesh, and the particle size of polyethylene powder particles is 40 mesh; Formed by conventional non-woven fabric production processes such as netting and acupuncture, the grammage is 1000g / ㎡, the bottom layer of the non-woven fabric contains polypropylene to ensure the shape and delivery, and other low-cost materials are mixed to facilitate waste utilization and reduce product costs; grams It is heavy and has the functions of sound absorption, noise reduction and shock absorption;

[0031]...

Embodiment 3

[0033] Embodiment three: a kind of processing technology of non-woven fabric composite material for automobile interior decoration, comprises the following steps:

[0034] (1) Pass the bottom layer of non-woven fabric through the powder spreading device, and evenly sprinkle polyethylene powder particles on the bottom layer of non-woven fabric. The speed of the bottom layer of non-woven fabric is 2.0m / min, and the vibration amplitude of the vibrating screen is 4mm. The number of mesh holes is 15 mesh, and the particle size of polyethylene powder particles is 40 mesh; Formed by conventional non-woven fabric production processes such as netting and needle punching, the grammage is 800g / ㎡, and the bottom layer of the non-woven fabric contains polypropylene to ensure the final shape and delivery, and it is mixed with other low-cost materials to facilitate waste utilization and reduce product costs; It is heavy and has the functions of sound absorption, noise reduction and shock abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com