Preparation method and device for continuous-filament woven fabric reinforced thermoplastic composite

A continuous fiber and fiber fabric technology, applied in the field of design of continuous fiber reinforced thermoplastic composite materials, can solve the problems of long production cycle, poor resin impregnation effect, unstable product quality, etc., achieve convenient operation, improve dimensional stability, good effect of impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto. The modifications and optimization adjustments made by those skilled in the art according to the present invention in practical applications still belong to the protection scope of the present invention.

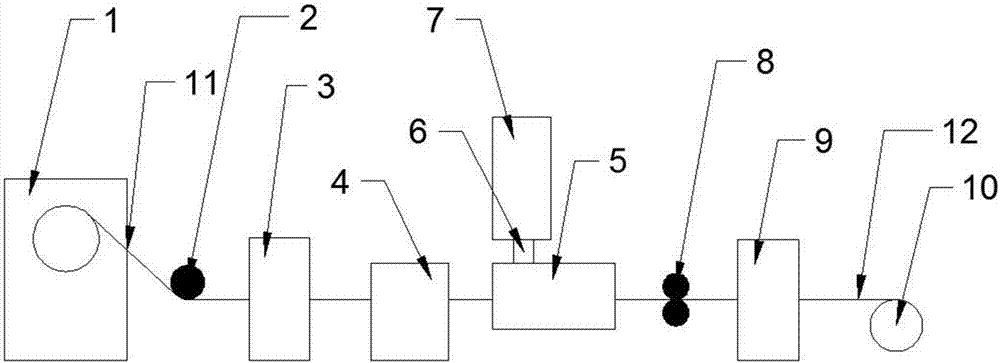

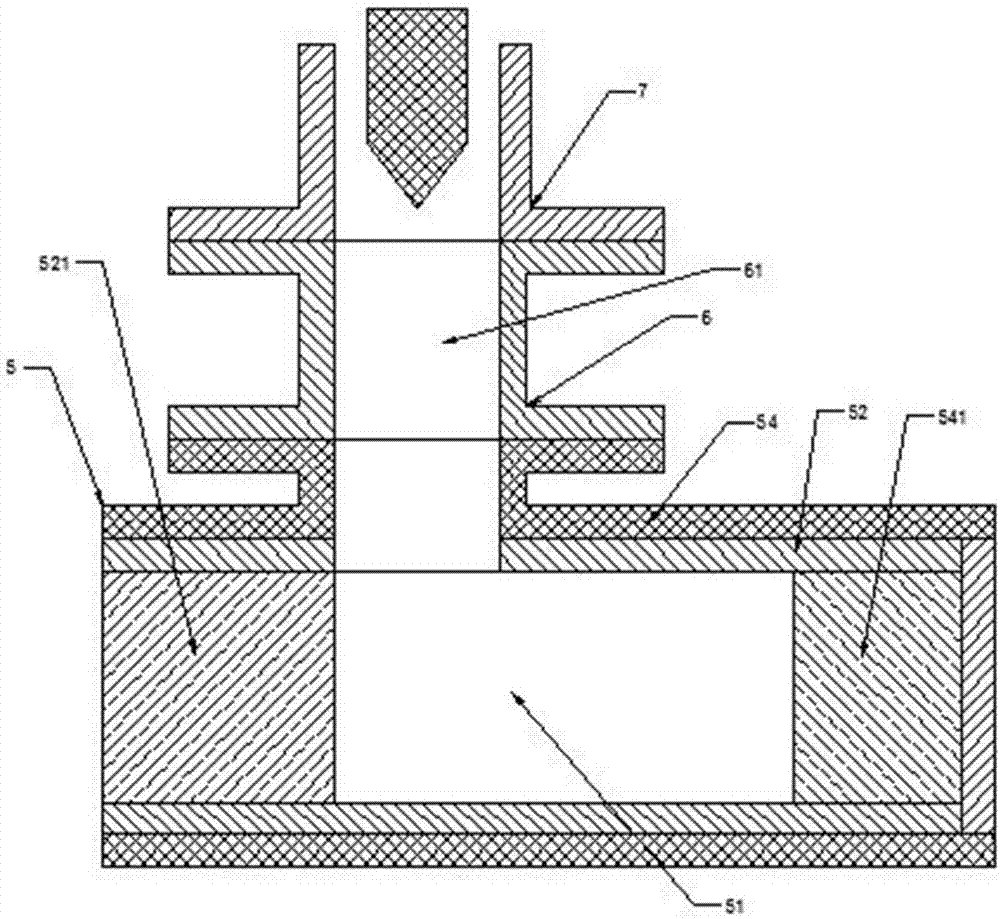

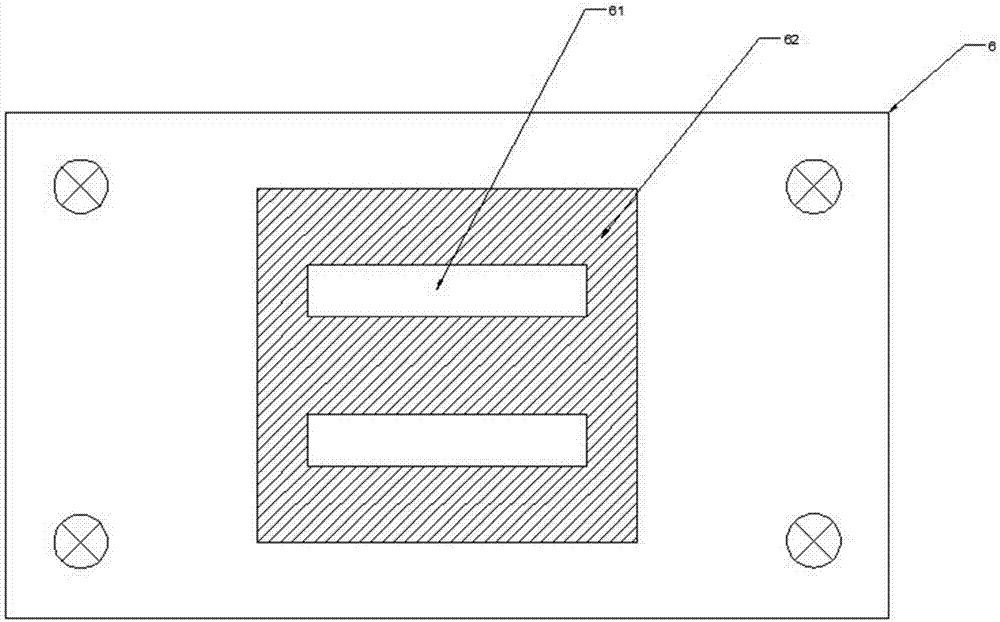

[0053] Such as figure 1 As shown, a method and equipment for preparing a continuous fiber reinforced thermoplastic composite material, the main steps include: the continuous fiber fabric 11 is placed horizontally on the unwinding device 1, and the unwinding speed of the continuous fiber fabric 11 is adjusted by the unwinding roller; The rolled continuous fiber fabric 11 enters the pre-tensioning device 2 to give the continuous fiber fabric 11 a certain tension to keep it moving smoothly and evenly during traction processing; the pretreatment device 3 sprays the coupling agent solution to the continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com