Sponge and elastic non-woven fabric composite self-adhering fascia and production method thereof

A production method and technology of non-woven fabrics, applied in bandages, medical science, absorbent pads, etc., can solve the problems of increasing user pain, affecting wound recovery, increasing wound infection, etc., and achieve superior softness, good recovery, and hand feeling non-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, the preparation of self-adhesive adhesive: take 100 parts of natural latex, 10 parts of white oil, 1 part of butyl acrylate, 0.1 part of potassium sorbate, 30.5 parts of fatty alcohol polyoxyethylene ether; white oil and fatty alcohol polyoxyethylene ether -3 Heat to 55°C to prepare emulsified oil; dissolve potassium sorbate in appropriate amount of water, then pour emulsified oil into emulsified liquid, and let it stand for 3 hours; heat natural latex to 45°C, add emulsified liquid, Stir for 20 minutes; cool the formed mixture to 35°C, add an appropriate amount of water and butyl acrylate, and stir for 10 minutes; filter the formed mixture to remove impurities and leave it for 10 hours to obtain a self-adhesive adhesive, which is set aside.

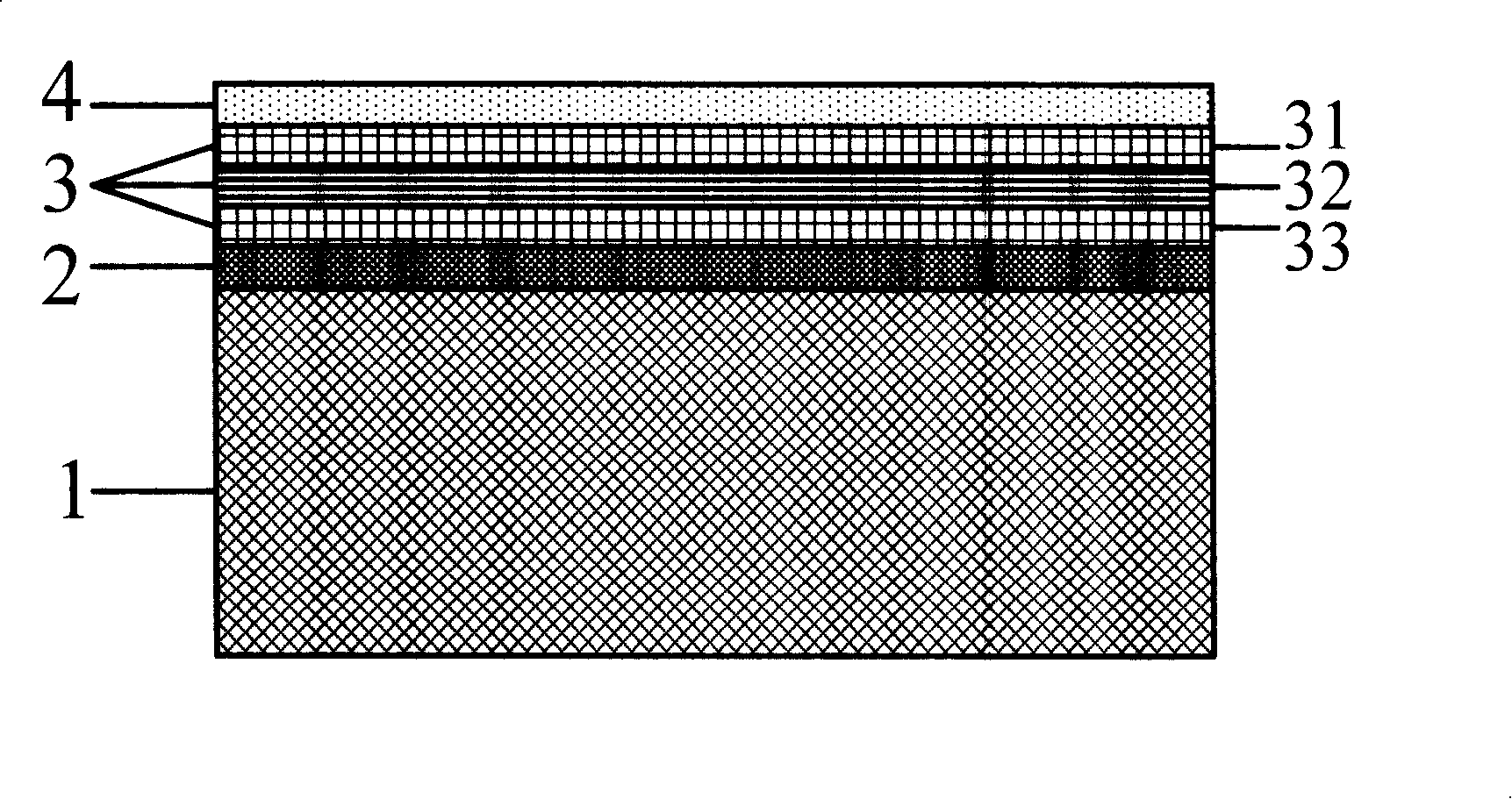

[0040] Take polyurethane sponge, elastic non-woven fabric and rubber-based adhesive, the density of polyurethane sponge is 30kg / m 3 , the thickness is 4.5mm; the thickness of the elastic non-woven fabric is 0.4mm. Use a sp...

Embodiment 2

[0042] First, the preparation of self-adhesive adhesive: take 100 parts of natural latex, 30 parts of white oil, 5 parts of butyl acrylate, 0.5 parts of potassium sorbate, 32.5 parts of fatty alcohol polyoxyethylene ether; white oil and fatty alcohol polyoxyethylene ether -3 Heat to 60°C to prepare emulsified oil; dissolve potassium sorbate in appropriate amount of water, then pour emulsified oil into emulsified liquid, and let it stand for 5 hours; heat natural latex to 50°C, add emulsified liquid, Stir for 30 minutes; cool the formed mixture to 25°C, add an appropriate amount of water and butyl acrylate, and stir for 35 minutes; filter the formed mixture to remove impurities and leave it for 20 hours to obtain a self-adhesive adhesive for use.

[0043]Take polyurethane sponge, elastic non-woven fabric and acrylic adhesive, the density of polyurethane sponge is 40kg / m 3 , the thickness is 3mm; the thickness of the elastic non-woven fabric is 0.3mm. The polyurethane sponge is...

Embodiment 3

[0045] First, the preparation of self-adhesive adhesive: take 100 parts of natural latex, 50 parts of white oil, 10 parts of butyl acrylate, 1 part of potassium sorbate, 35 parts of fatty alcohol polyoxyethylene ether; white oil and fatty alcohol polyoxyethylene ether -3 Heat to 65°C to prepare emulsified oil; dissolve potassium sorbate in appropriate amount of water, then pour emulsified oil into emulsified liquid, and let it stand for 6 hours; heat natural latex to 55°C, add emulsified liquid, Stir for 50 minutes; cool the formed mixture to 10°C, add an appropriate amount of water and butyl acrylate, and stir for more than 60 minutes; filter the formed mixture to remove impurities and leave it for 30 hours to obtain a self-adhesive adhesive, which is set aside.

[0046] Get polyurethane sponge, elastic non-woven fabric and polysiloxane-based adhesive, the density of polyurethane sponge is 50kg / m 3 , the thickness is 0.7mm; the thickness of the elastic non-woven fabric is 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com