Ultrafiltration embossed melt-blown non-woven fabric and preparation method thereof

A technology of melt-blown non-woven fabrics and ultra-filtration, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., and can solve the problems of mechanical properties such as the strength of melt-blown non-woven fabrics, poor heat resistance, and melt-blown problems. Poor filtration and adsorption performance of non-woven fabrics, poor spinnability of melt-blown non-woven fabrics, etc., to achieve good spinnability, improved anti-ultraviolet aging performance, and excellent filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

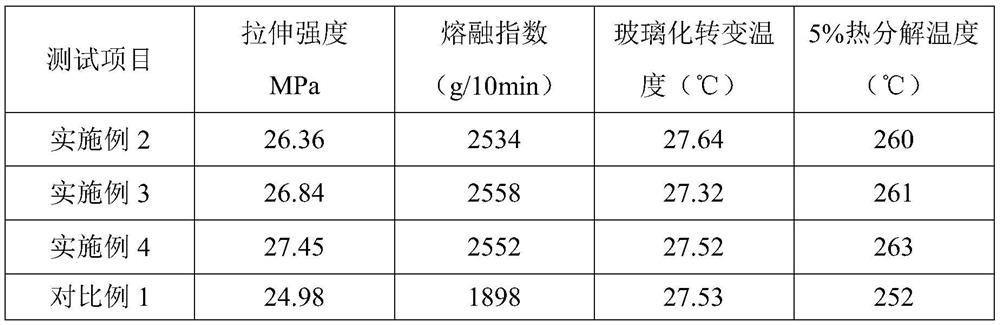

Examples

Embodiment 1

[0052] An ultra-filtration embossed melt-blown non-woven fabric, which is made of a melt-blown non-woven composite slice material;

[0053] The melt-blown non-woven composite chip material is made of raw materials comprising the following parts by weight:

[0054] 65-80 slices of polypropylene melt-blown non-woven fabric,

[0055] 24-36 parts of poly(dimethylsiloxane)-graft-polyacrylate,

[0056] 5-8 parts of maleic anhydride styrene dual monomer grafted polypropylene,

[0057] 4.5-6 parts of nano-titanium dioxide,

[0058] 3-5 parts of mesoporous silica,

[0059] 2.4 to 3 parts of stearyl amide,

[0060] Zinc stearate 1.5 to 2 parts.

[0061] In this embodiment, the melt-blown non-woven composite sheet material is preferably, but not limited to, made of raw materials including the following parts by weight:

[0062] 72.5 pieces of polypropylene melt-blown non-woven fabric slices,

[0063] Poly(dimethylsiloxane)-graft-polyacrylate 30 parts,

[0064] Maleic anhydride st...

Embodiment 2

[0081] An ultra-filtration embossed melt-blown non-woven fabric, which is made of a melt-blown non-woven composite slice material;

[0082] The melt-blown non-woven composite chip material is made of raw materials comprising the following parts by weight:

[0083] 65 slices of polypropylene melt-blown non-woven fabric,

[0084] Poly(dimethylsiloxane)-graft-polyacrylate 24 parts,

[0085] 5 parts of maleic anhydride styrene dual monomer grafted polypropylene,

[0086] Nano titanium dioxide 4.5 parts,

[0087] Mesoporous silica 3 parts,

[0088] 2.4 parts of stearamide,

[0089] Zinc stearate 1.5 parts.

[0090] In this embodiment, the average particle diameter of the mesoporous silica is 90nm, and the specific surface area is greater than 500m 2 / g, the pore diameter (NLDFT method) is 3-4nm, and the pore volume is greater than 0.5cm 3 / g.

[0091] In this embodiment, the meltblown nonwoven composite slice material further includes the following raw materials in parts by...

Embodiment 3

[0102] An ultra-filtration embossed melt-blown non-woven fabric, which is made of a melt-blown non-woven composite slice material;

[0103] The melt-blown non-woven composite chip material is made of raw materials comprising the following parts by weight:

[0104] 80 slices of polypropylene melt-blown non-woven fabric,

[0105] Poly(dimethylsiloxane)-graft-polyacrylate 36 parts,

[0106] 8 parts of maleic anhydride styrene dual monomer grafted polypropylene,

[0107] Nano titanium dioxide 6 parts,

[0108] Mesoporous silica 5 parts,

[0109] Stearylamide 3 parts,

[0110] Zinc stearate 2 parts.

[0111] In this embodiment, the average particle diameter of the mesoporous silica is 100nm, and the specific surface area is greater than 500m 2 / g, the pore diameter (NLDFT method) is 3-4nm, and the pore volume is greater than 0.5cm 3 / g.

[0112] In this embodiment, the melt-blown nonwoven composite slice material also includes the following raw materials in parts by weight:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com