Method for manufacturing electrospun nanofiber gas filtering material in mass manner

A nanofiber and filter material technology, applied in chemical instruments and methods, filtration separation, fiber treatment, etc., can solve the problem of low filtration resistance, no data on filtration efficiency and resistance, no data on product filtration efficiency and resistance, etc. problems, achieve low filter resistance, improve strength, and reduce gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

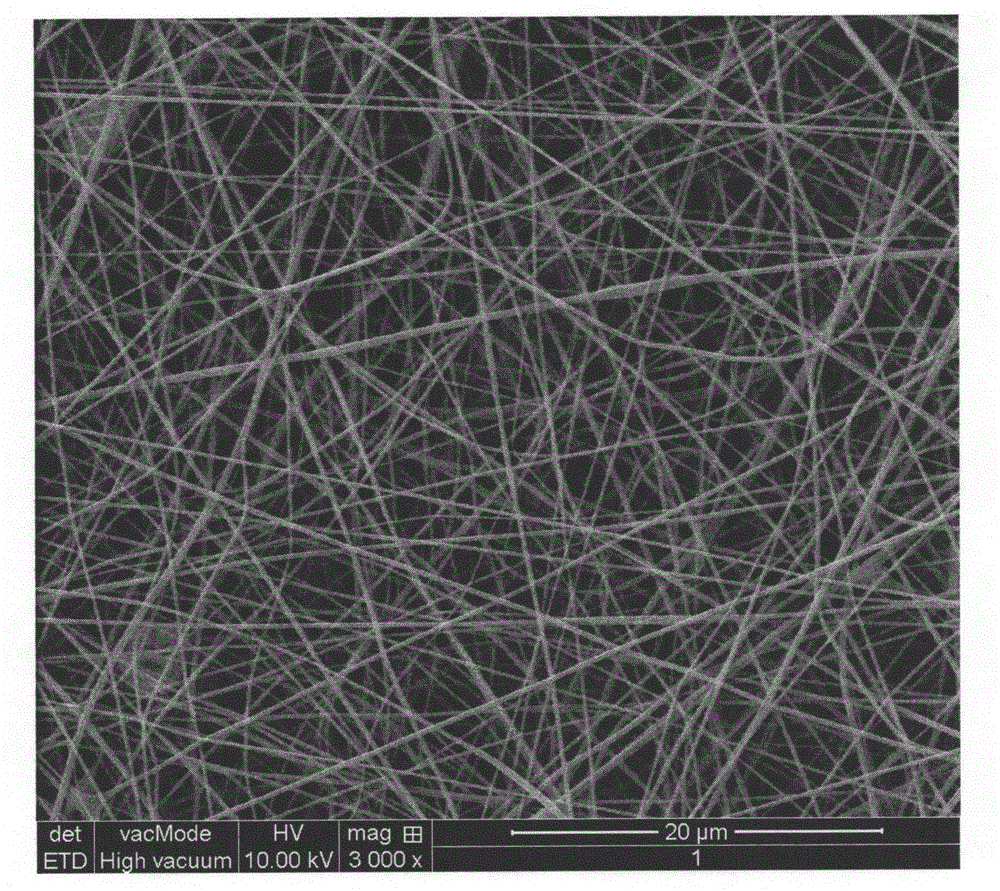

[0039] Dissolve 5g of polyacrylonitrile in 45g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g) spinning solution. The patent application number is CN201310032194.9 electrospinning nozzle for electrospinning, the parameters are: voltage 60KV, receiving distance 15cm, drum speed 30r / min, spinning time 10min, ambient temperature 25°C, ambient relative humidity 55%.

[0040] Using the drum as the receiving device, a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability is prepared, and a nonwoven / electrospun nanofiber membrane / nonwoven composite membrane is prepared by ultrasonic bonding, which is prepared by cutting. filter material.

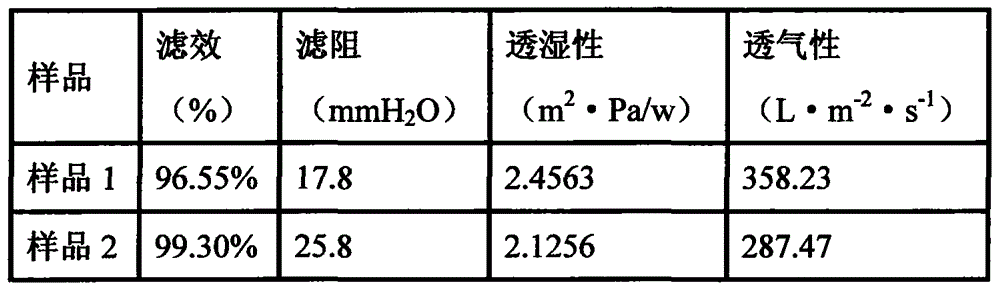

[0041] The filter materials prepared by the above method were made into 3 samples, and their filtration efficiency, filter resistance, air permeability and nonwoven / electrospun nanofiber membrane...

Embodiment 2

[0046] Dissolve 7g of polyacrylonitrile in 43g of N,N-dimethylformamide, stir for 8h until completely dissolved to obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g) spinning solution. The patent application number is CN201310032194.9 electrospinning nozzle for electrospinning, the parameters are: voltage 68KV, receiving distance 20cm, drum speed 30r / min, spinning time 15min, ambient temperature 27°C, ambient relative humidity 45%.

[0047] Using the drum as the receiving device, a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability is prepared, and a nonwoven / electrospun nanofiber membrane / nonwoven composite membrane is prepared by ultrasonic bonding, which is prepared by cutting. filter material.

[0048] The filter material prepared by the above method is made into 3 samples, and their filtration efficiency, filter resistance, air permeability and nonwoven / electrospun nanofiber membrane / nonw...

Embodiment 3

[0052] Dissolve 5g of polyvinylidene fluoride in 45g of N,N-dimethylformamide, stir for 8h until completely dissolved, and obtain polyacrylonitrile / N,N-dimethylformamide with a concentration of 10% (g / g). Amide spinning solution. The patent application number is CN201310032194.9 electrospinning nozzle for electrospinning, the parameters are: voltage 65KV, receiving distance 15cm, drum speed 60r / min, spinning time 20min, ambient temperature 25°C, ambient relative humidity 40%.

[0053] Using the drum as the receiving device, a nanofiber membrane with high filtration efficiency, low filtration resistance and good air permeability is prepared, and a nonwoven / electrospun nanofiber membrane / nonwoven composite membrane is prepared by ultrasonic bonding, which is prepared by cutting. filter material.

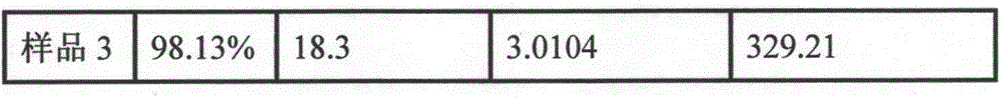

[0054] The filter material prepared by the above method is made into 3 samples, and their filtration efficiency, filter resistance, air permeability and nonwoven / electrospun nanofibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com