Non-sticky high-friction-coefficient high polymer material, non-woven fabric composite material and application of non-woven fabric composite material

A high friction coefficient, polymer material technology, applied in the field of non-woven composite materials, non-stick high friction coefficient polymer materials, can solve the problems of slippage, poor wear resistance, and the inability to form a uniform single phase by thermal compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

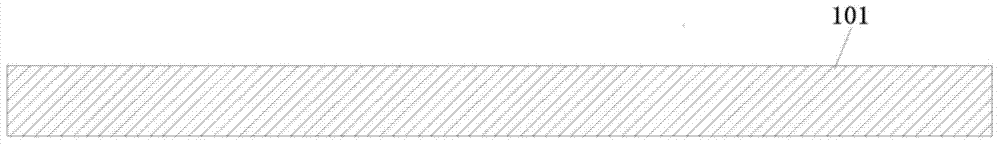

[0032] refer to figure 1 It is a non-adhesive high friction coefficient single-layer film material disclosed by the present invention, 101 is a film containing isotactic polypropylene macromolecule and derivatives, composed of: isotactic copolymer polypropylene elastomer with a weight ratio of 60%, 38% Polyethylene, 2% antistatic agent; thickness 30um. The flow rate parameter of the isotactic copolymerized polypropylene elastomer in this example is 6.0. According to ASTM D1894, the measured COF is 1.25, compared with existing materials in the market and other examples as shown in Table 1.

[0033] The present embodiment adopts cast extrusion process, see Figure 9 , the operation steps are as follows:

[0034] (1) take raw materials in weighing area 103 by proportioning,

[0035] (2) Inhale the weighed raw material in the high-speed mixer 104,

[0036] (3) Inhale the mixed raw materials in the extruder hopper 105,

[0037] (4) The raw materials are melted and mixed throu...

Embodiment 2

[0040] Adopt embodiment 1 formula, adopt blown film extrusion process, see Figure 10 , the operation steps are as follows:

[0041] (1) take raw materials in weighing area 103 by proportioning,

[0042] (2) Inhale the weighed raw material in the high-speed mixer 104,

[0043] (3) Inhale the mixed raw materials in the extruder hopper 105,

[0044] (4) The raw materials are melted and mixed in the extruder 106 and passed through the annular die 107. The temperature of the die is controlled at 150-250° C., and extruded

[0045] Tubular thin bubble 108, the cylindrical thin bubble is cooled by cooling roller 109, and the tubular film 111 is obtained, and the tubular film is drawn

[0046] The flattening roller 112 is rewound by the rewinding device 113, and the tubular film can be single-cut, double-cut or cut when rewinding simultaneously.

[0047] Do not dissect.

Embodiment 3

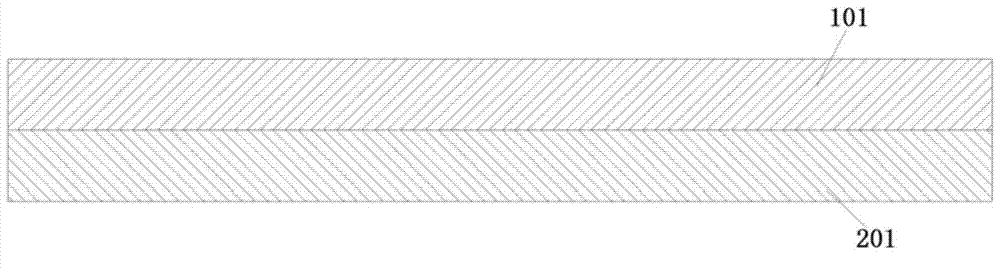

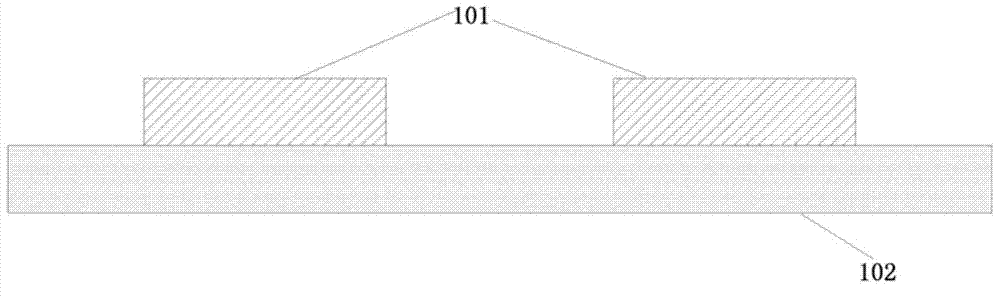

[0049] refer to figure 2 It is a non-adhesive high friction coefficient double-layer film material disclosed by the present invention, and the film thickness is 30um. 101 is a film containing isotactic polypropylene macromolecule and its derivatives, composed of: isotactic copolymer polypropylene elastomer with a weight ratio of 60%, 38% polyethylene, 2% antistatic agent; the thickness is 30um. The flow rate parameter of isotactic copolymerized polypropylene elastomer in this example is 6.0. 201 is polyethylene film. Tested separately according to ASTM D1894 Figure 2-10 1 surface and Figure 2-2 Measured on the surface of layer 01, the COFs are 1.25 and 0.30, respectively. It is compared with existing products in the market and other embodiments as shown in Table 1.

[0050] In this embodiment, a double-layer casting machine is adopted, and the casting and extrusion process is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com