Non-woven fabric composite material for filter mask

A technology of composite materials and non-woven fabrics, applied in filtration and separation, membrane filters, applications, etc., can solve the problems of easy breeding of bacteria on the surface of the mask, poor comfort of the wearer, and wet inner layer of the mask, so as to increase the filtering effect, Increased antibacterial performance, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

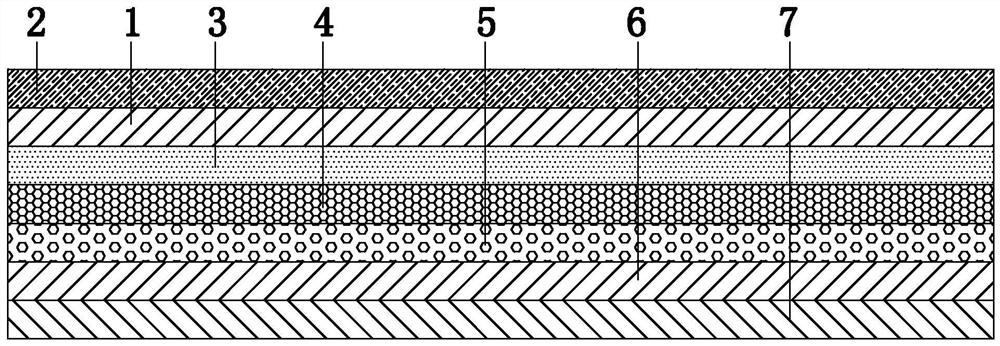

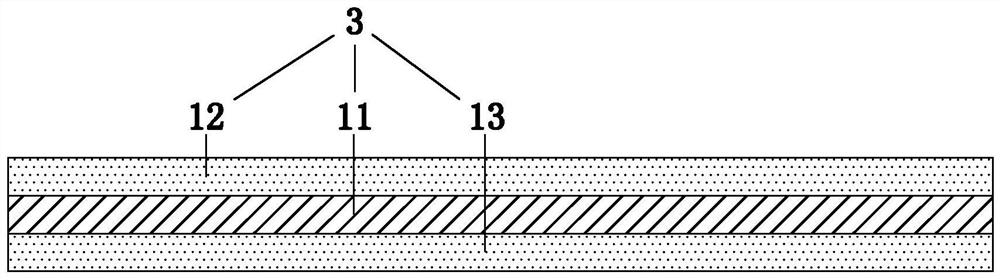

[0025] see Figure 1-4 , according to a non-woven fabric composite material for a filter mask according to an embodiment of the present invention, comprising an outer layer 1, a waterproof breathable layer 2 is fixed on the outer layer 1, an antibacterial layer 3 is fixed under the outer layer 1, The antibacterial layer 3 is fixed with a filter layer 4, the filter layer 4 is fixed with an adsorption layer 5, the adsorption layer 5 is fixed with an inner layer 6, and the inner layer 6 is fixed with a skin-friendly layer. Layer 7, the antibacterial layer 3 includes a built-in silver ion antibacterial fabric layer 11, and the built-in silver ion antibacterial fabric layer 11 is coated with a porous nano-titanium dioxide silver-carried antibacterial agent coating 12, and the porous nano-titanium dioxide silver-carried The upper surface of the antibacterial coating 12 is fixedly connected with the outer layer 1, and the built-in silver ion antibacterial fabric layer 11 is fixedly p...

Embodiment 2

[0028] see figure 1 , for the outer layer 1, the outer layer 1 and the inner layer 6 are made of non-woven fabric; for the waterproof and breathable layer 2, the waterproof and breathable layer 2 is composited with a polymer waterproof and breathable material and cloth Formed, the waterproof and breathable material is a PTFE film; for the skin-friendly layer 7, the skin-friendly layer 7 is made of natural silk non-woven fabric.

[0029] Through the above solution of the present invention, the natural silk non-woven fabric can improve the touch of the skin, make the skin feel more comfortable when used, effectively prevent allergies, and have good air permeability.

Embodiment 3

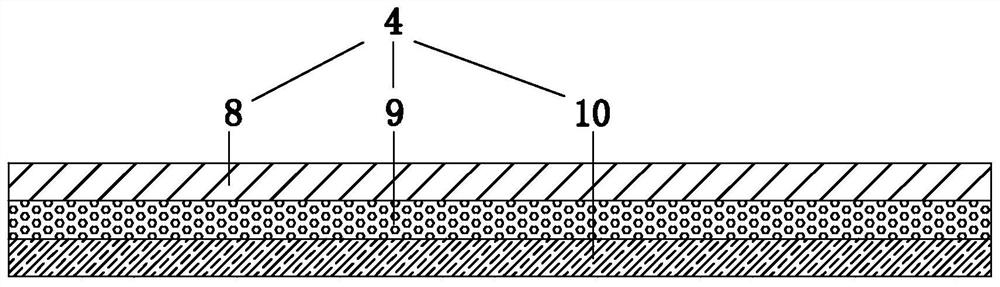

[0031] see image 3 , for filter layer 4, described filter layer 4 comprises fiber filter cotton layer 8, and described fiber filter cotton layer 8 is fixedly provided with polytetrafluoroethylene microporous membrane layer 9, and described polytetrafluoroethylene microporous membrane A melt-blown cloth layer 10 is fixed under the layer 9, the upper surface of the fiber filter cotton layer 8 is fixedly connected with the porous biological polypeptide antibacterial agent coating 13, and the lower surface of the melt-blown cloth layer 10 is connected with the bamboo original The fiber fabric layer 14 is fixedly connected; for the polytetrafluoroethylene microporous membrane layer 9, the thickness of the polytetrafluoroethylene microporous membrane layer 9 is 0.05-0.09 mm, and the pore size is 0.2-0.5 μm.

[0032] Through the above scheme of the present invention, the fiber filter cotton layer 8, the polytetrafluoroethylene microporous film layer 9 and the melt-blown cloth layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com