Tubular nonwoven compound material and manufacturing method thereof

A non-woven fabric and composite material technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of difficult stitching, decreased lining effect of pipe 2, low stitching efficiency, etc., and achieves sealing and mechanical properties. Good performance, easy industrial application, easy mechanical construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

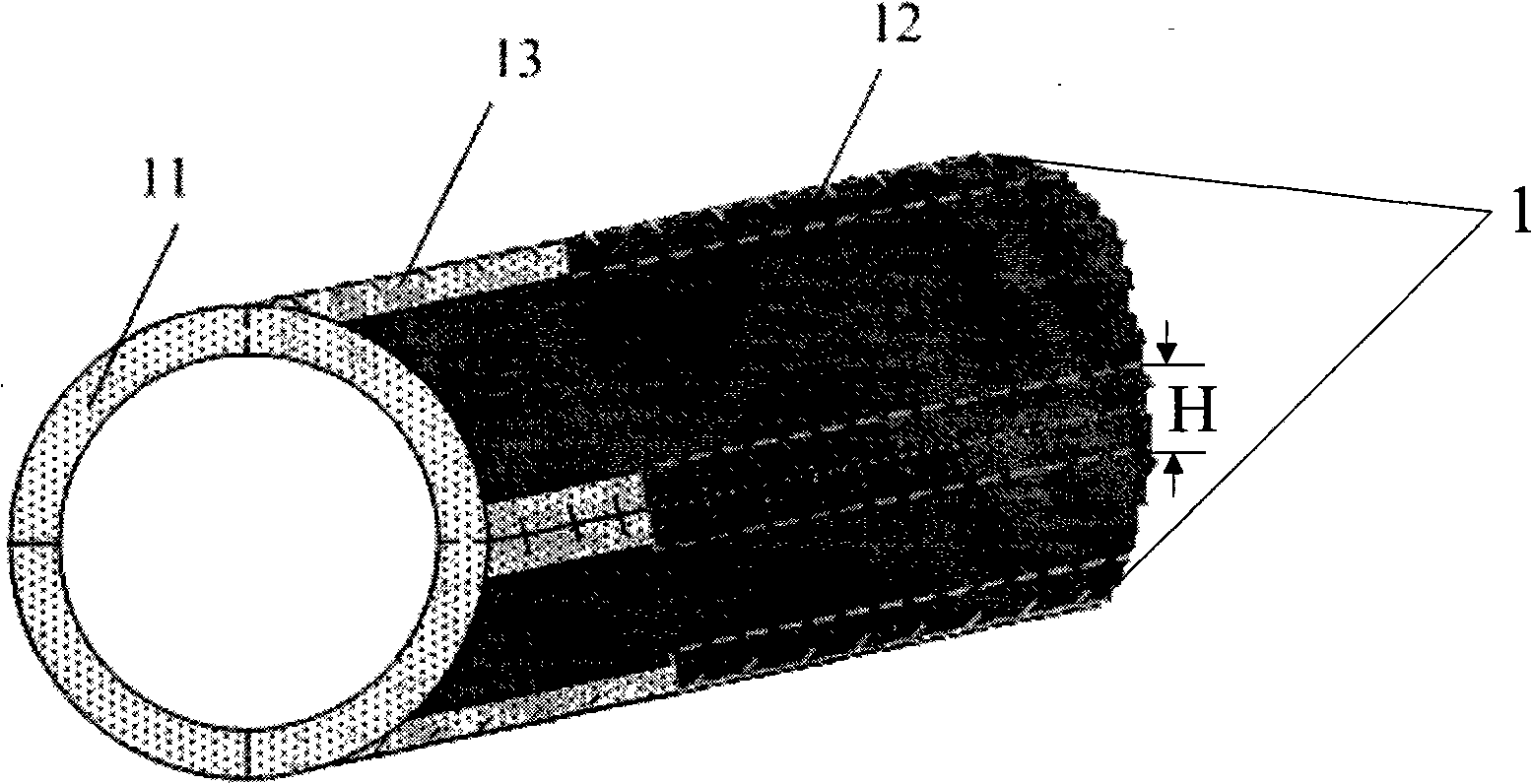

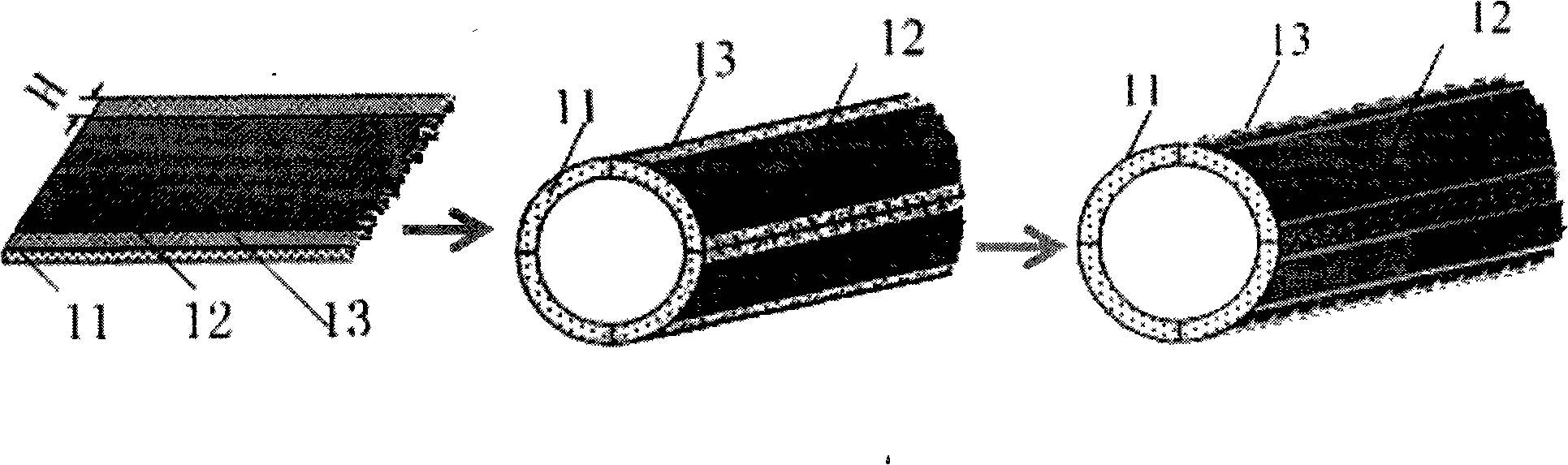

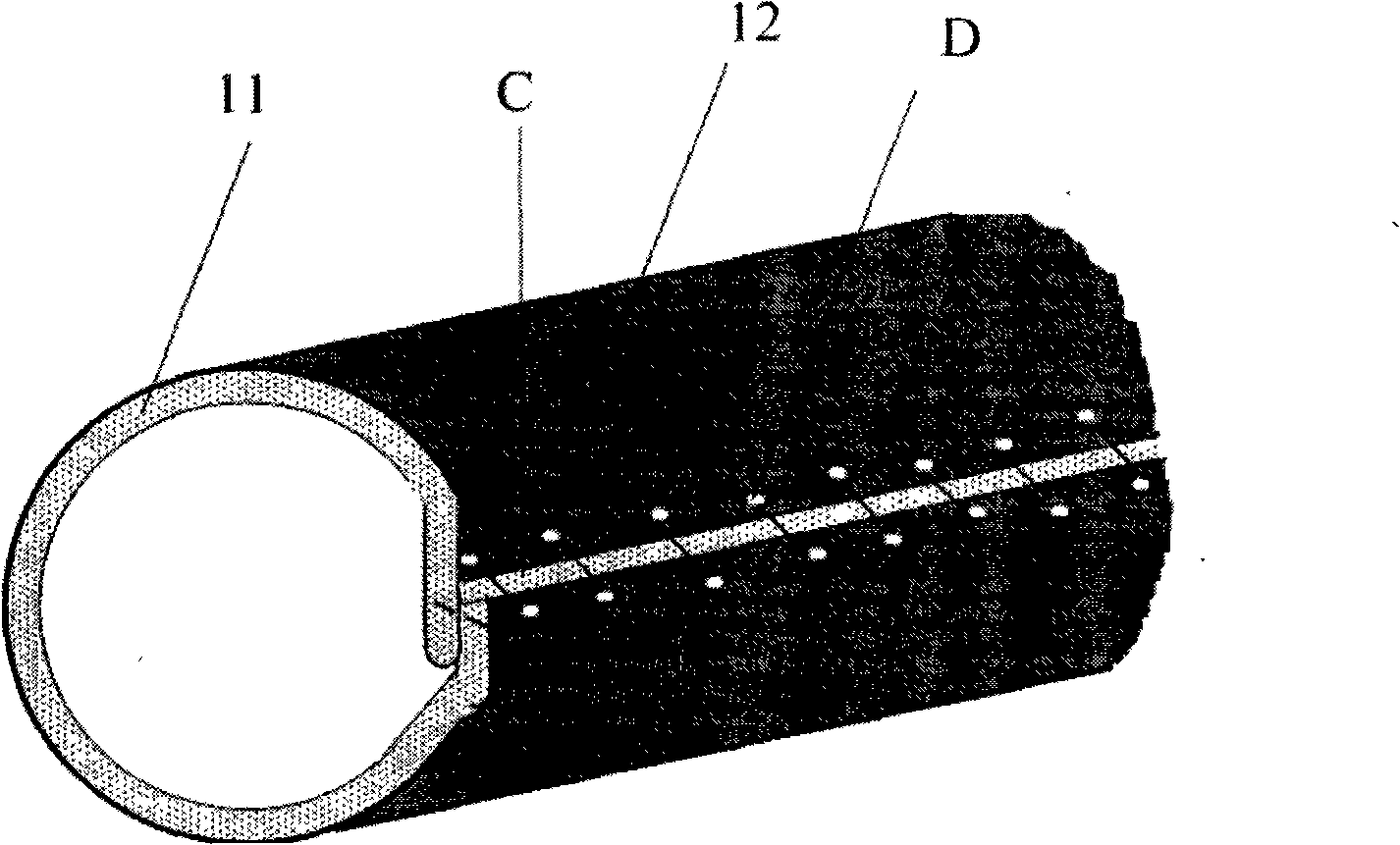

[0032] A tubular nonwoven composite material with a diameter of 800 mm was fabricated. The splicing block number of design this composite material base cloth is 4 (being 4 joints), and the width of every piece of nonwoven fabric base cloth is 628mm (referring to figure 1 , 2 ). The raw material of the non-woven fabric base fabric is long-staple polyester fiber, with an average length of 100mm and a fineness of 67dtex. The reinforced fabric of the base fabric is polyester filament plain woven fabric, the warp and weft fineness are 100tex and 200tex respectively, and the warp and weft density are 30 threads / 10cm. The resin of the coating (film) layer is polyurethane, the molding pressure is 0.8Mpa, the molding time is 3 seconds, and the thickness of the coating layer is designed to be 0.3mm. When coating, the two sides of the base cloth are left with a seam edge, and the width is 30mm. The plane butt seaming of the base fabric adopts the three-thread overlock method and uti...

Embodiment 2

[0035] After the plane butt seam described in Example 1 is completed, use a prefabricated resin strip with a width of 60 mm and a thickness of 0.3 mm, at the plane seam of the seam side of the base fabric, with a temperature of 180 ° C and a molding pressure of 0.8 Mpa. The composite material of the present invention can be obtained after direct thermocompression bonding and even coating layer. The rest are the same as embodiment 1.

[0036] The obtained composite material has a uniform appearance, a consistent thickness, no splicing marks, and a good overall effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com