Multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof

An air filter material and sub-micron technology, applied in electrospinning, filtration separation, fiber treatment, etc., can solve the problems of cumbersome preparation process, single structure, and low production output, and achieve uniform thickness, improved precision, and large porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

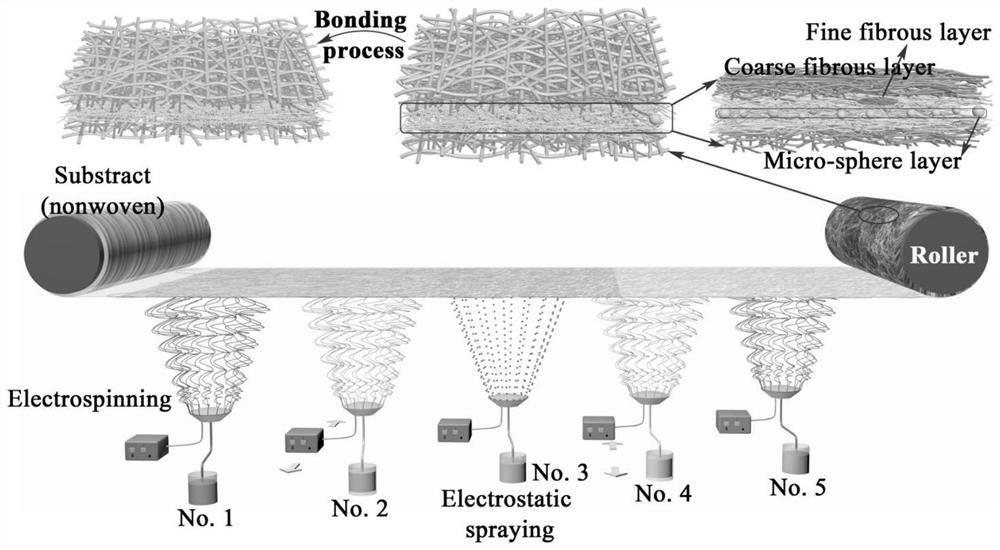

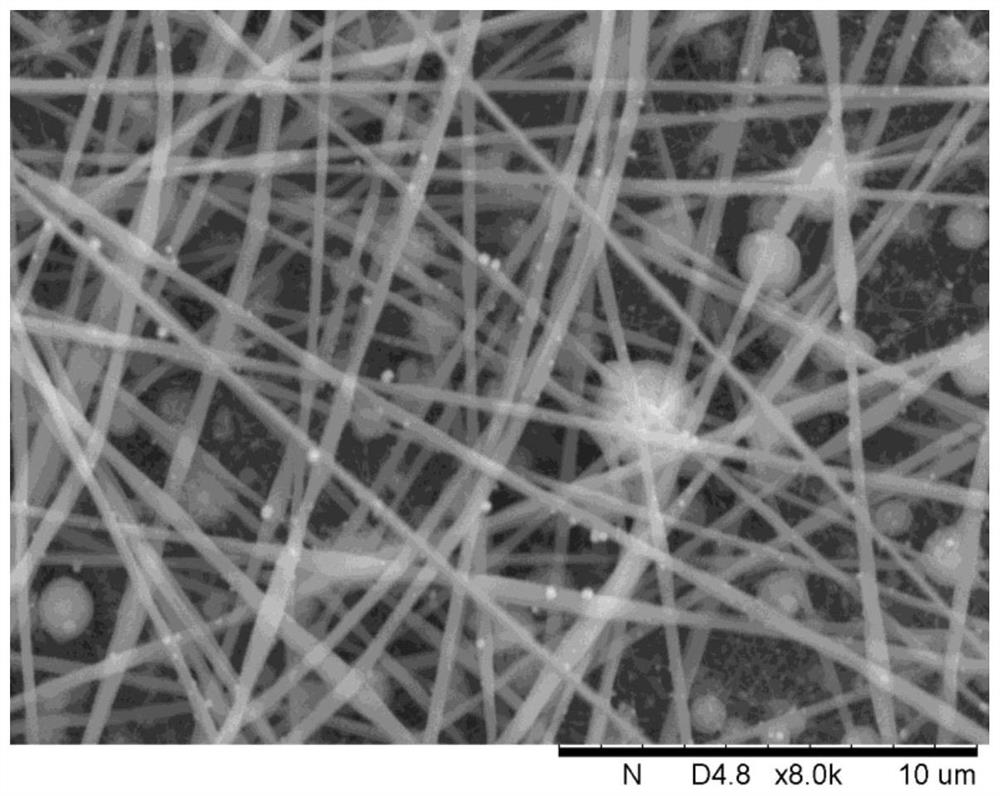

Embodiment 1

[0038] This embodiment provides a multi-combination functional electrospun submicron fiber air filter material, which is a "sandwich" structure in which spunbond nonwovens, submicron fiber composite membranes, and spunbond nonwovens are arranged in sequence, and the submicron The fiber membrane is a composite membrane of gradient structure electrospun submicron fiber membrane and electrostatic spraying micron balls. / Fine electrospun submicron fiber layer is used as the upper and lower layers; the electrostatic spray microsphere layer is a small ball with a diameter of micron as the middle layer, forming a three-dimensional structure. Among them, the fiber diameters of the electrospun submicron fiber thick / fine layers are 100-200nm (fine fiber layer), 300-400nm (coarse fiber layer), the ball diameter of the microsphere layer is 0.7-1.2 μm, and the gram of the gradient composite membrane Weight ~2g m -2 . The spunbonded nonwoven fabric used has a fiber diameter of 15 μm and a...

Embodiment 2

[0048] This embodiment provides a multi-combination functional electrospun submicron fiber air filter material, according to embodiment 1, the fiber diameter of each layer of electrospun submicron fiber thick / fine is 150-270nm (fine fiber layer), 350-480nm (coarse fiber layer), the ball diameter of the microsphere layer is 1.0-2.0μm, and the grammage of the gradient composite membrane is ~3g m -2 , all the other are identical with embodiment 1.

[0049] The batch preparation method of above-mentioned filter material, concrete steps are:

[0050] Step 1: Place the polyacrylonitrile powder in a vacuum drying oven and dry it under vacuum at 60°C for 6 hours;

[0051] Step 2: Dissolve the dried polyacrylonitrile powder in N,N-dimethylformamide solvent, heat and electric stir in a water bath for 4 hours, the temperature is 70°C, and the mass fractions are respectively 5wt%, 12wt%, and 16wt%. High and low concentration solutions of polyacrylonitrile.

[0052] The third step: add ...

Embodiment 3

[0057] The present embodiment provides a multi-combination functional electrospun submicron fiber air filter material, according to embodiment 1, the fiber diameter of each layer of electrospun submicron fiber thick / fine is 250-320nm (fine fiber layer), 380-550nm (coarse fiber layer), the ball diameter of the microsphere layer is 1.5-2.5 μm, and the gram weight of the gradient composite membrane is ~4g m -2 , all the other are identical with embodiment 1.

[0058] The batch preparation method of above-mentioned filter material, concrete steps are:

[0059] Step 1: Place the polyacrylonitrile powder in a vacuum drying oven, and dry it under vacuum at 60° C. for 6 hours.

[0060] Step 2: Dissolve the dried polyacrylonitrile powder in N,N-dimethylformamide solvent, heat and electric stir in a water bath for 4 hours, the temperature is 70°C, and the mass fractions are 7wt%, 14wt%, and 18wt% respectively High and low concentration solutions of polyacrylonitrile.

[0061] The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com